A kind of molybdenum sulfide/ferric oxide composite material and its preparation method and application

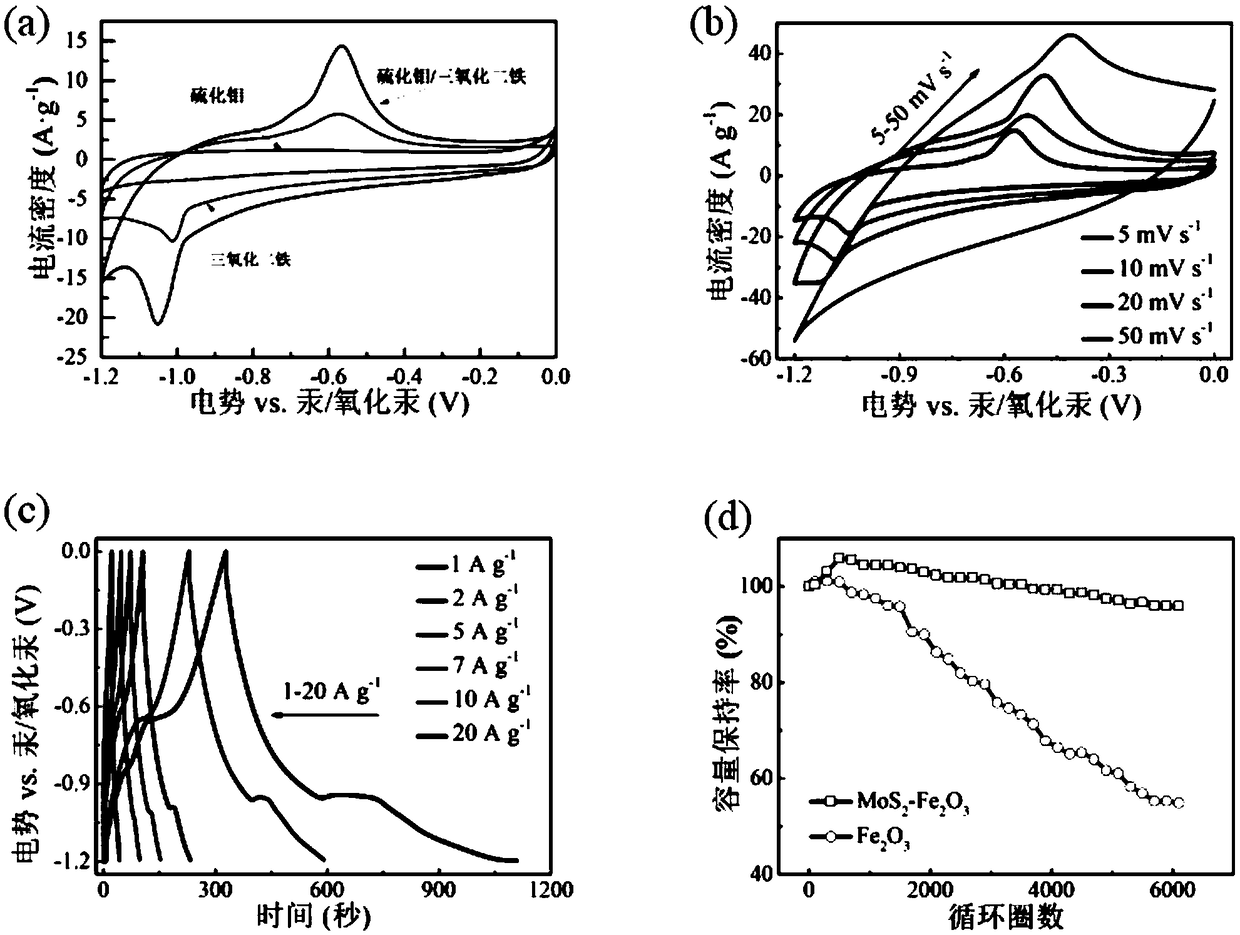

A technology of ferric oxide and composite materials, applied in the directions of molybdenum sulfide, iron oxide, iron oxide/iron hydroxide, etc., can solve problems such as the reduction of surface active sites, improve the rate performance, and the synthesis method is convenient and economical. The effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

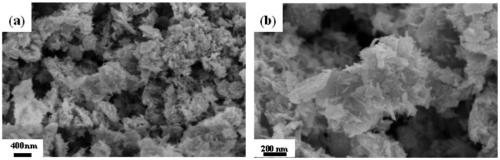

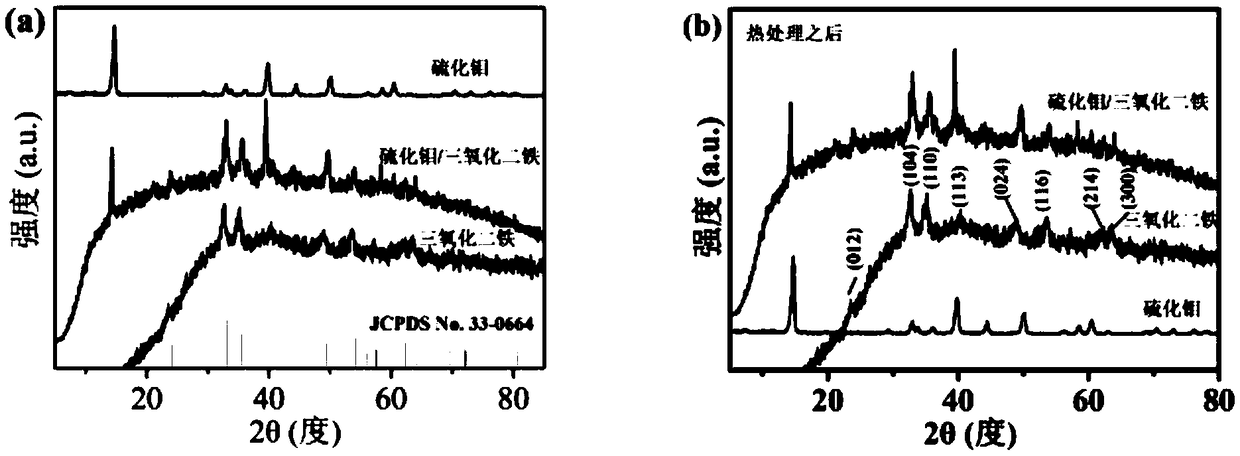

[0035] (1) Add 2g of molybdenum sulfide ore (molybdenite) to 500g of dimethylformamide, use the experimental cell pulverizer to continuously sonicate for 10 hours (the ultrasonic program is 8s at work, 2s at intervals), and take the supernatant Centrifuge to obtain a uniform dispersion, which is a dispersion of molybdenum sulfide nanosheets, with a concentration of 0.2 mg / ml;

[0036] (2) Take the above-mentioned dispersion liquid, suction filter, obtain molybdenum sulfide nanosheet solid, wash with 30mL ethanol and 30mL deionized water alternately three times and then dry and store;

[0037] (3) Disperse 60 mg of the above-mentioned molybdenum sulfide nanosheets in 100 mL of deionized water, and ultrasonically obtain a stable dispersion of molybdenum sulfide nanosheets; wherein, the concentration of the dispersion is 0.6 mg / ml;

[0038] (4) Get 337.5mg ferric chloride hexahydrate and join in above-mentioned dispersion liquid, mechanical stirring makes it disperse evenly;

[...

Embodiment 2

[0055] (1) Add 1g of molybdenum sulfide ore (molybdenite) to 200g of dimethylol ethyl urea, use an experimental ultrasonic cleaner for continuous ultrasonication for 20 hours, take the supernatant and centrifuge to obtain a uniform dispersion, which is vulcanization Molybdenum nanosheet dispersion, the concentration of the dispersion is 0.5mg / ml;

[0056] (2) Take 100 mL of the above-mentioned dispersion liquid, filter with suction to obtain solid molybdenum sulfide nanosheets, alternately wash with 30 mL of ethanol and 30 mL of deionized water three times, and then wash with 150 mL of deionized water.

[0057] (3) Disperse 80 mg of the above-mentioned molybdenum sulfide nanosheets in 100 mL of deionized water, and obtain a stable dispersion of molybdenum sulfide nanosheets by ultrasonication;

[0058] (4) Get 302.9mg ferric nitrate nonahydrate and join in the above-mentioned dispersion liquid, stir mechanically to make it disperse evenly;

[0059] (5) Put the above three dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com