Catalyst for catalytic removal of formaldehyde and carbon monoxide and preparation method thereof

A carbon monoxide and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of insufficient Pt dispersion, limited utilization of light efficiency, insufficient specific surface area, etc., and achieve strong visible light. Catalytic performance, the effect of promoting electron-hole separation, and improving oxidative ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

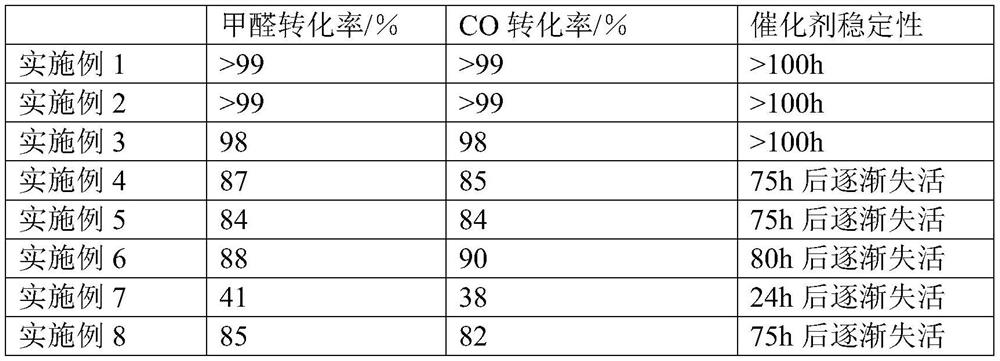

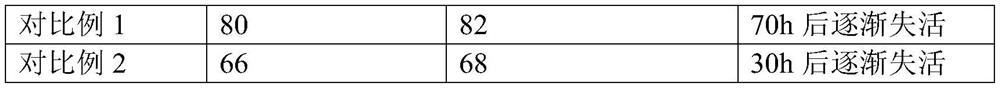

Examples

Embodiment 1

[0033] The catalyst of this embodiment is Pt / Ce-TiO 2 / g-C3N4, that is, Pt loaded Ce-TiO 2 / g-C3N4, Pt as the active component, Ce-TiO 2 / g-C3N4 as carrier, carrier Ce-TiO2 / g-C3N4 is Ce-doped TiO 2 And complex in g-C3N4. Among them, the loading amount of Pt is 0.6wt%, and the balance is the carrier Ce-TiO 2 / g-C3N4; Ce-TiO 2 / g-C3N4: Ce / TiO 2 The mass ratio is 1.5wt%, TiO 2 / g-C3N4 mass ratio is 0.3.

[0034] The preparation method of the catalyst of the present embodiment is as follows:

[0035] (1) Dissolve tetrabutyl titanate in absolute ethanol, stir until dissolved at room temperature, then ultrasonically disperse g-C3N4 (purchased from Sinopharm Chemical Reagent Co., Ltd.) in the above solution, and mix well to obtain solution B ;

[0036] (2) dissolving cerium nitrate, acetic acid and deionized water in ethanol, stirring to obtain solution C;

[0037] (3) Add solution C dropwise to solution B in a stirring state, and keep stirring until a sol is formed, leave...

Embodiment 2

[0042] The catalyst of this embodiment is Pt / Ce-TiO 2 / g-C3N4, that is, Pt loaded Ce-TiO 2 / g-C3N4, carrier Ce-TiO 2 / g-C3N4 is Ce-doped TiO 2 And complex in g-C3N4. Among them, the loading amount of Pt is 0.6wt%, and the balance is the carrier Ce-TiO 2 / g-C3N4; Ce-TiO 2 / g-C3N4: Ce / TiO 2 The mass ratio is 1.5wt%, TiO 2 / g-C3N4 mass ratio is 0.3.

[0043] The preparation method of the catalyst of the present embodiment is as follows:

[0044] (1) Dissolving tetrabutyl titanate in absolute ethanol, stirring at room temperature until dissolved, then ultrasonically dispersing g-C3N4 in the aforementioned solution, and mixing uniformly to obtain solution B;

[0045] (2) dissolving cerium nitrate, acetic acid and deionized water in ethanol, stirring to obtain solution C;

[0046] (3) Add solution C dropwise to solution B in a stirring state, and keep stirring until a sol is formed, leave the resulting sol at room temperature for 24 hours to obtain a gel, and dry the obtain...

Embodiment 3

[0050] The catalyst of this embodiment is Pt / Ce-TiO 2 / g-C3N4, that is, Pt loaded Ce-TiO 2 / g-C3N4, carrier Ce-TiO 2 / g-C3N4 is Ce-doped TiO 2 And complex in g-C3N4. Among them, the loading amount of Pt is 0.6wt%, and the balance is the carrier Ce-TiO 2 / g-C3N4; Ce-TiO 2 / g-C3N4: Ce / TiO 2 The mass ratio is 1.5wt%, TiO 2 / g-C3N4 mass ratio is 0.3.

[0051] The preparation method of the catalyst of the present embodiment is as follows:

[0052] (1) Dissolving tetrabutyl titanate in absolute ethanol, stirring at room temperature until dissolved, then ultrasonically dispersing g-C3N4 in the aforementioned solution, and mixing uniformly to obtain solution B;

[0053] (2) dissolving cerium nitrate, acetic acid and deionized water in ethanol, stirring to obtain solution C;

[0054] (3) Add solution C dropwise to solution B in a stirring state, and keep stirring until a sol is formed, leave the resulting sol at room temperature for 24 hours to obtain a gel, and dry the obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com