Gas shielded welding machine power supply

A gas shielded welding machine and power supply technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of complex structure of the control system, increased cost, and failure to reach the output current state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

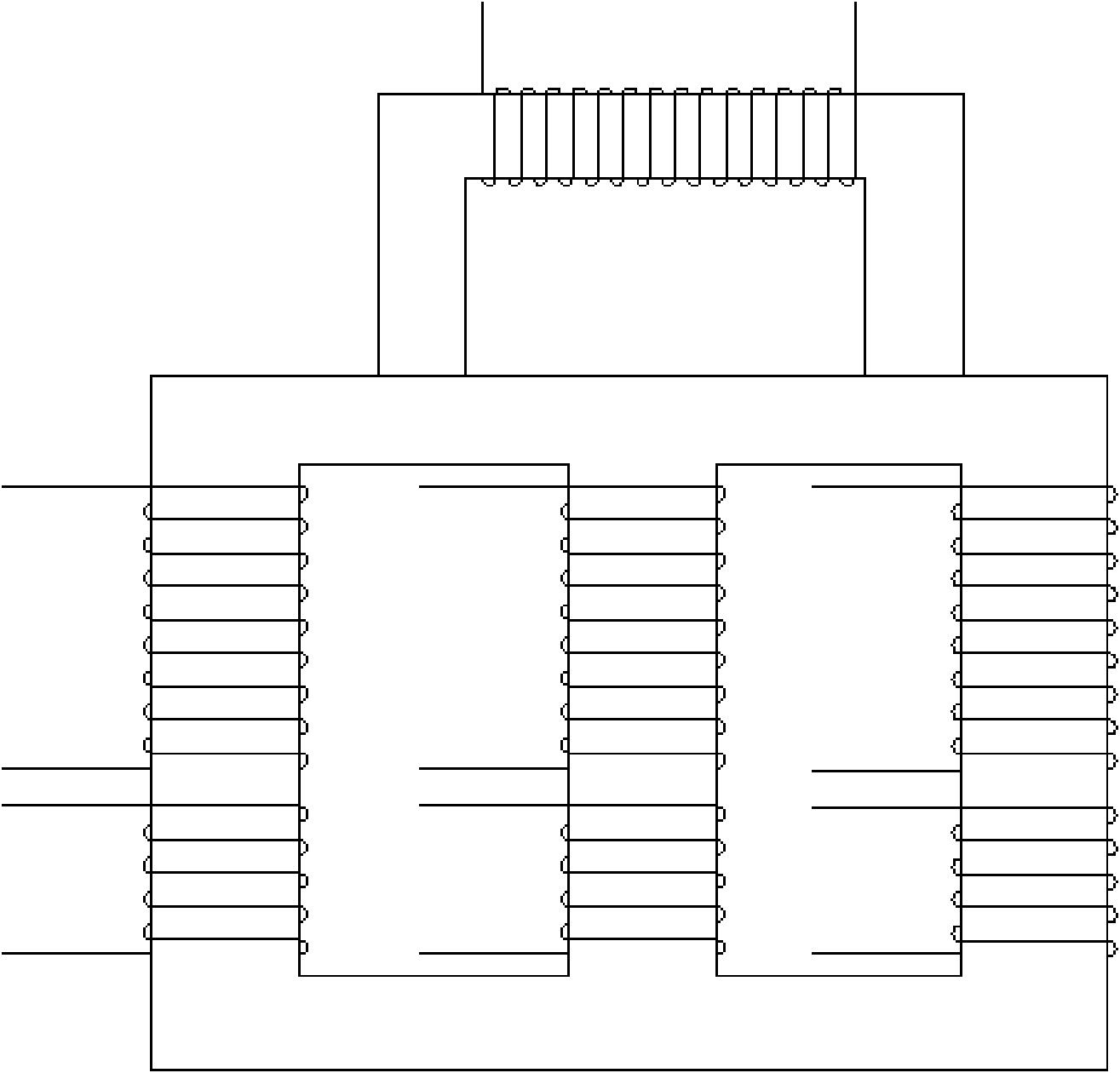

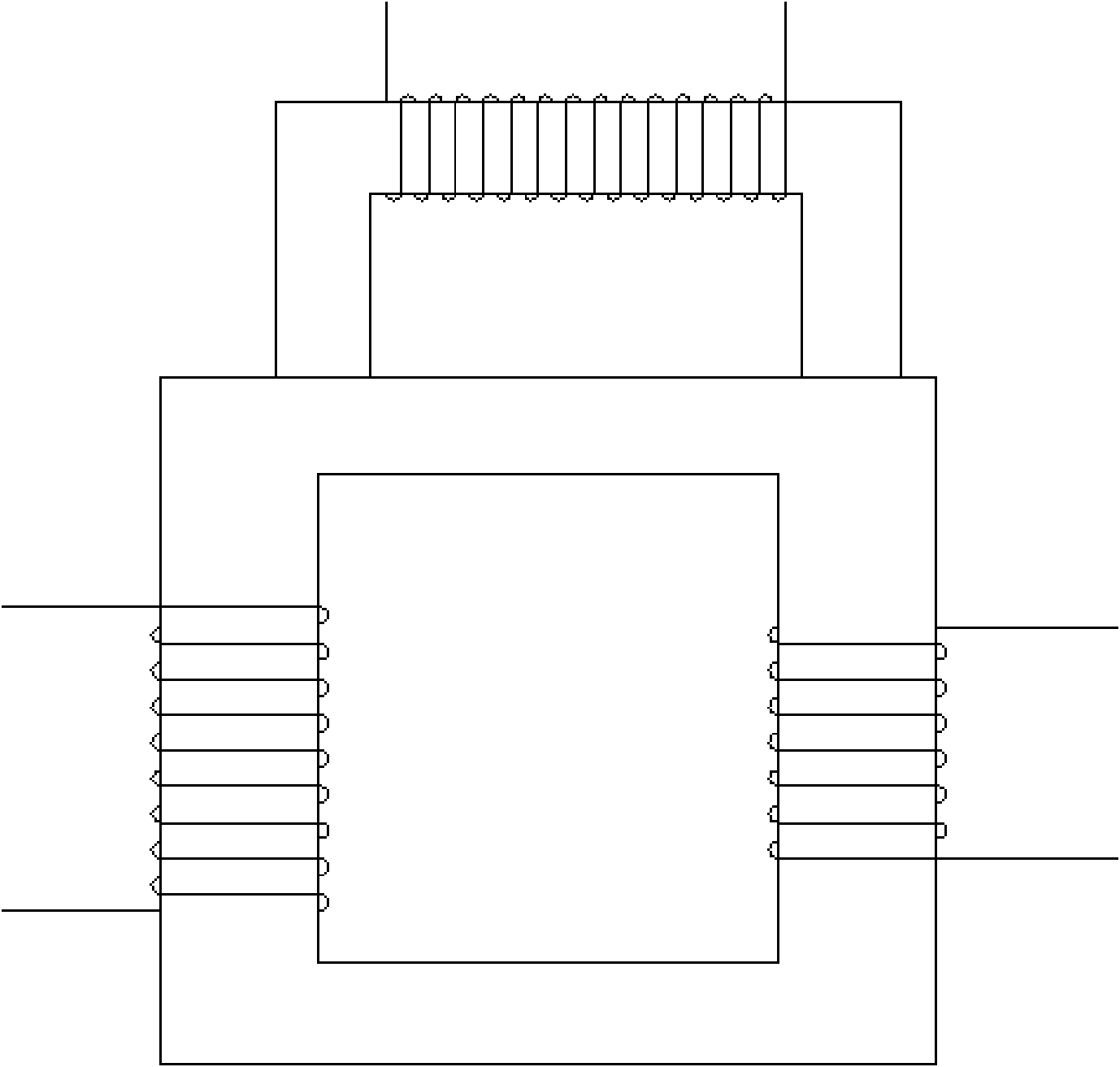

[0013] refer to figure 1 , a gas-shielded welding machine power supply of the present invention, its main transformer is a three-phase main transformer, used for grid isolation and energy conversion, an inductor is connected in series in the main power rectification circuit, and the inductor is installed on the magnetic field line generated when it is energized Within the range where the lines of magnetic force generated when the coils of the main transformer are energized intersect.

[0014] The necessary condition to realize the effect of the present invention is that the magnetic lines of force generated when the inductor is energized can intersect with the magnetic lines of force generated when the coil of the main transformer is energized. Fixed on the main transformer, the magnetic field lines emitted by the inductor when it is energized will not enter the iron core of the main transformer. Even if part of it enters the iron core of the main transformer, its strength can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com