Energy-saving control system for braking process of electrically-driven mining automobile

An energy-saving control system and automobile braking technology, which is applied in electric braking systems, electric vehicles, control drives, etc., can solve the problem of high engine fuel consumption and achieve the effect of saving energy output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

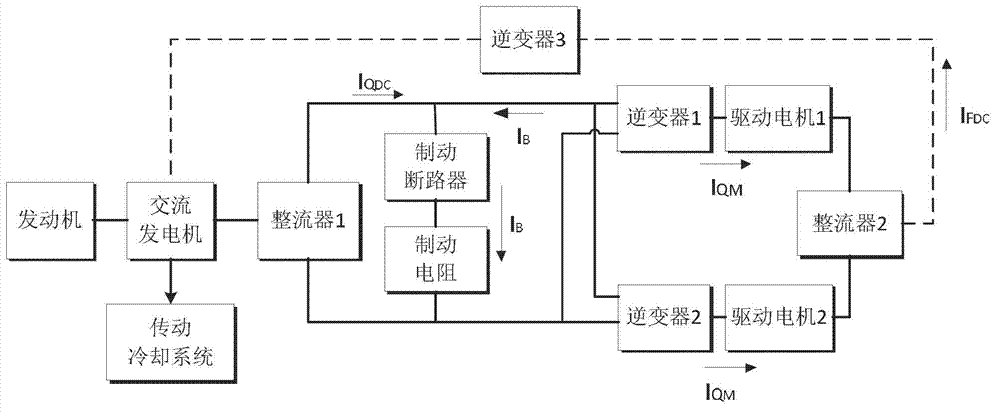

[0012] Such as figure 1 In the shown system diagram, the solid line part is a schematic diagram of a general electric drive mining vehicle drive system, and the technical scheme of the present invention is as follows if the system constitutes figure 1 The dashed path. The energy-saving control system of the braking process of the electric drive mining vehicle in the present invention includes: engine, alternator, rectifier 1, 2, inverter 1, 2, 3, drive motor 1, 2, brake circuit breaker, brake Resistance, transmission cooling system.

[0013] Engine: the power source of the transmission system;

[0014] Alternator: converts the mechanical energy of the engine into electrical energy in the form of alternating current;

[0015] Rectifier 1: converts the alternating current of the alternator to direct current;

[0016] Inverters 1 and 2: convert the DC power into the AC power needed to drive the motors 1 and 2;

[0017] Drive motors 1 and 2: convert electrical energy into mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com