Shrinking process for producing solid, transportable and printable containers and device for carrying out said shrinking process

A technique of wrapping, process, applied in the field of shrinking process for manufacturing strong, transportable and printable packages and equipment for implementing such shrinking process, able to solve the problem of inflation, sliding, not always reaching the package Strength and other issues, to achieve the effect of reducing energy output and rapid shape stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

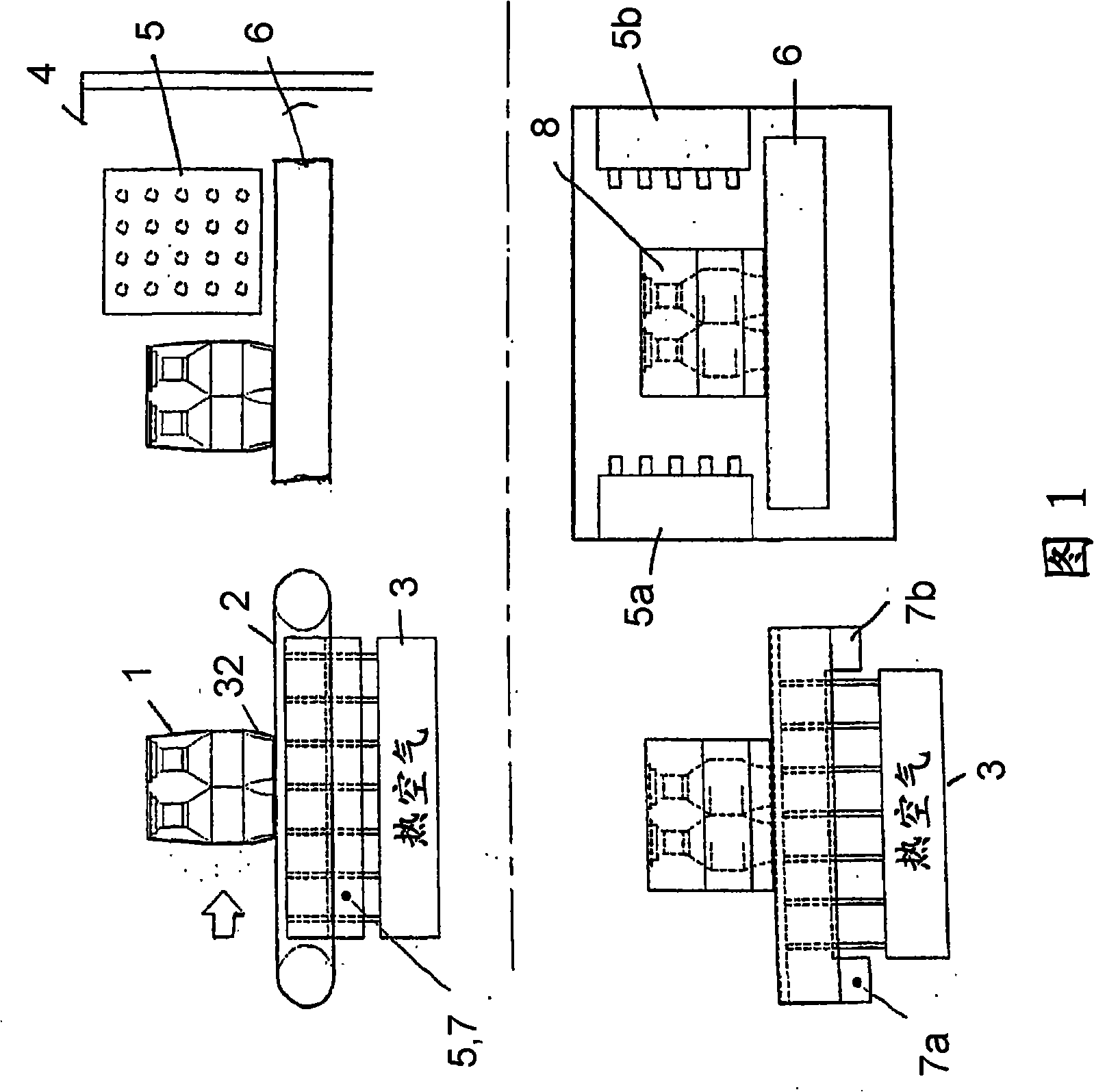

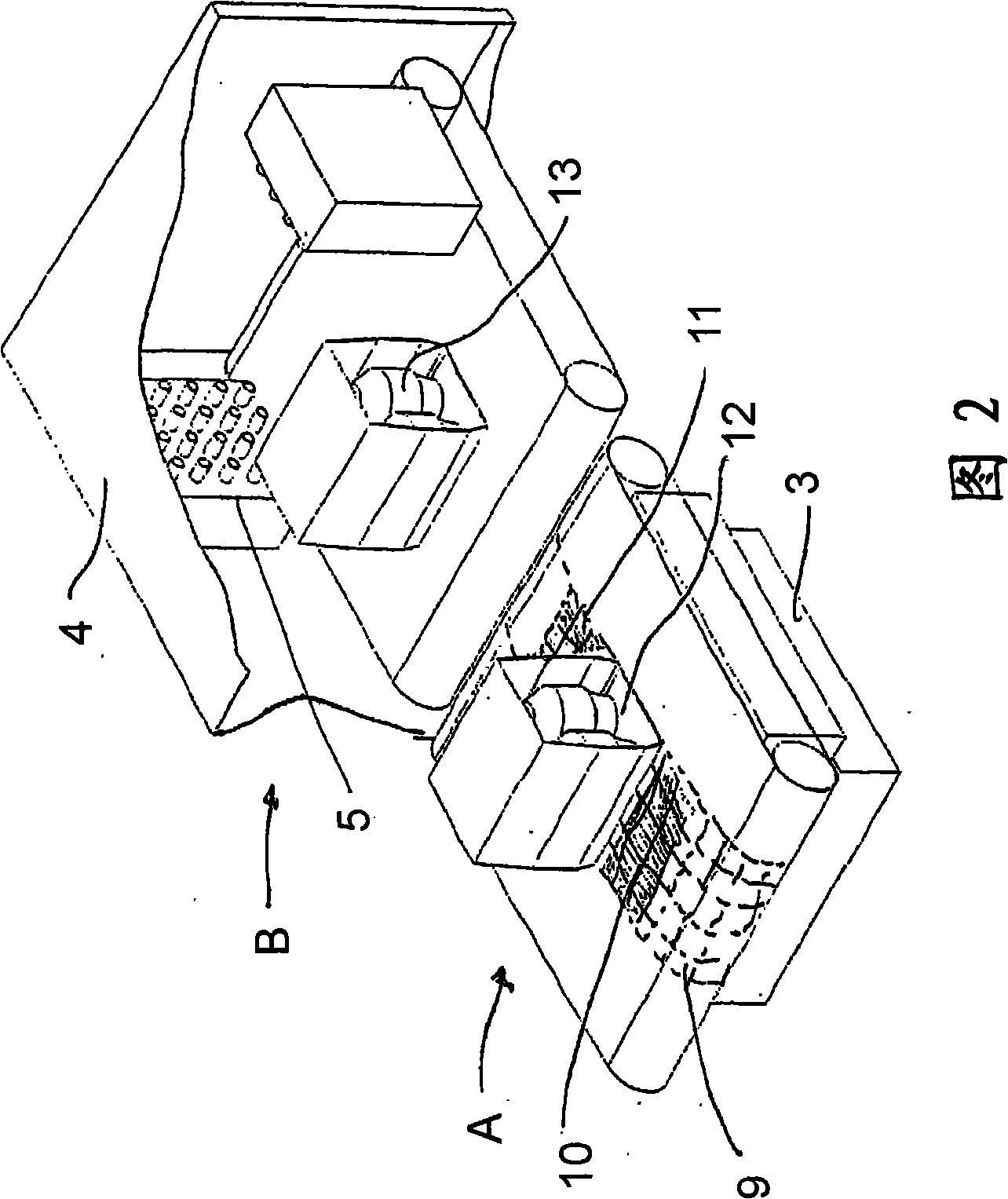

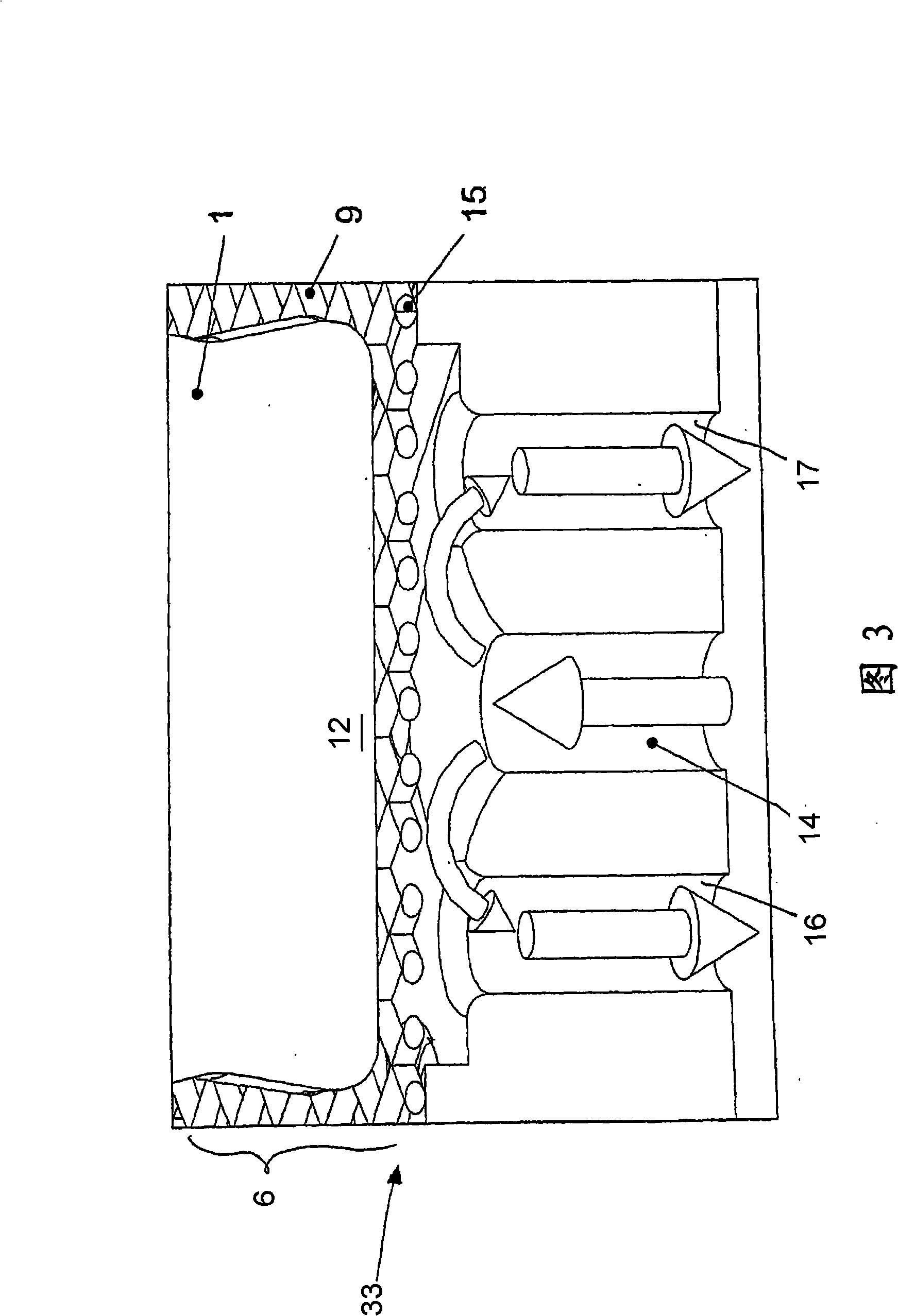

[0020] In the upper part of FIG. 1, a front view of the apparatus for implementing the shrinking process according to the present invention is shown. It can be seen that the air intake and exhaust systems 5 and 7 together with the package 1 are arranged on the conveyor belt 2 above the hot air source 3. The hot air applied in the countercurrent (see the arrow direction in FIG. 3) is used to form a pre-stabilized edge shell 32 in the bottom area of the wrapper.

[0021] In the right part of FIG. 1, the package 1 is shown in a device with a lateral hot air input device 5. The articles (bottles) of the package are conveyed by the conveyor belt 6 along the product travel direction and pass through the shrinking device 4. Once the package 1 with the encapsulating film 8 reaches the front of the hot air input device 5, there is a danger that the air pressure will inflate the film encapsulation and may slip. This is prevented by a pre-formed edge shell in the bottom area of the packa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com