UO2-metal fuel pellet and production method thereof

A metal fuel and manufacturing method technology, applied in the direction of manufacturing reactors, reactor fuel materials, nuclear power generation, etc., can solve problems affecting the ratio of oxygen to uranium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

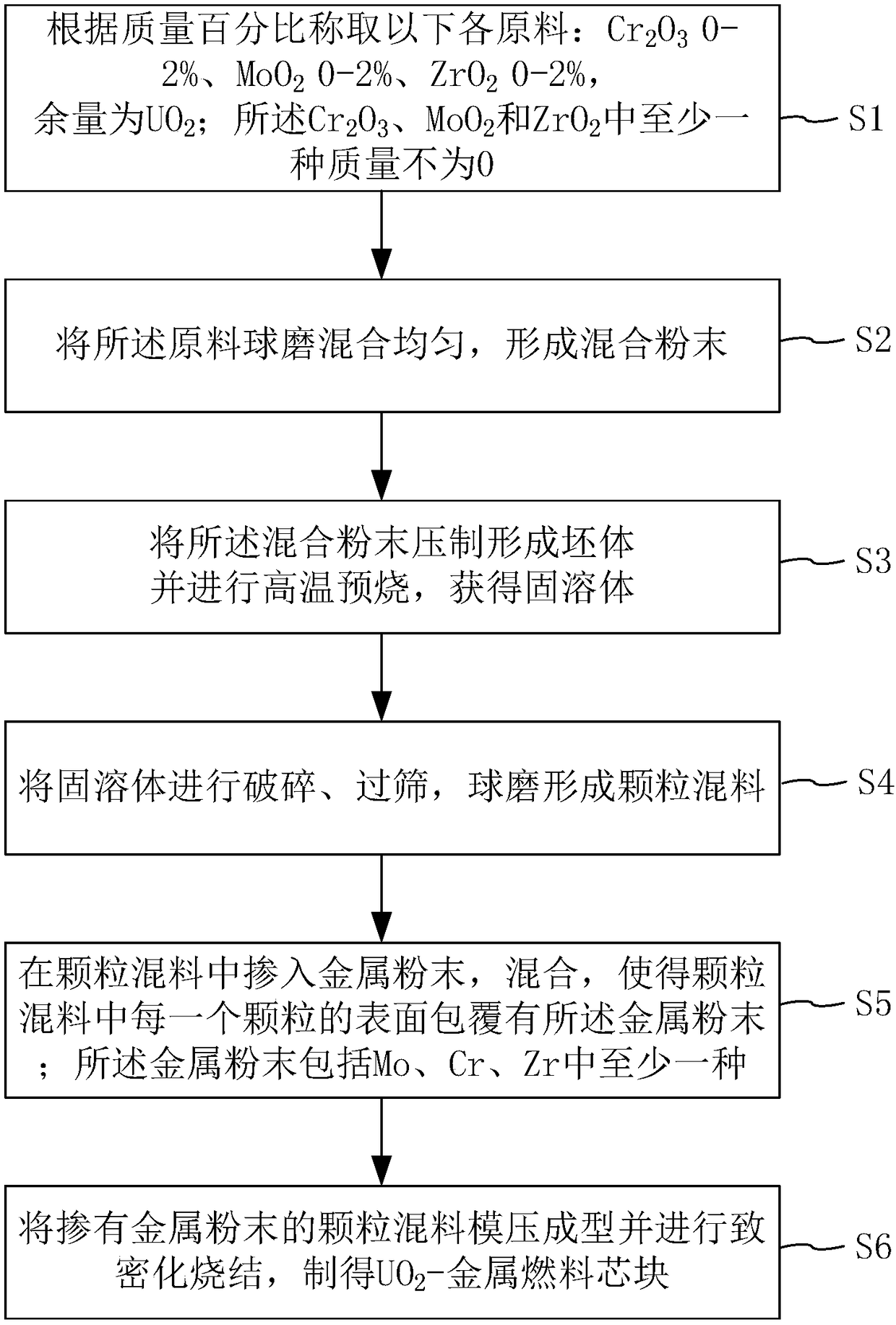

Method used

Image

Examples

Embodiment 1

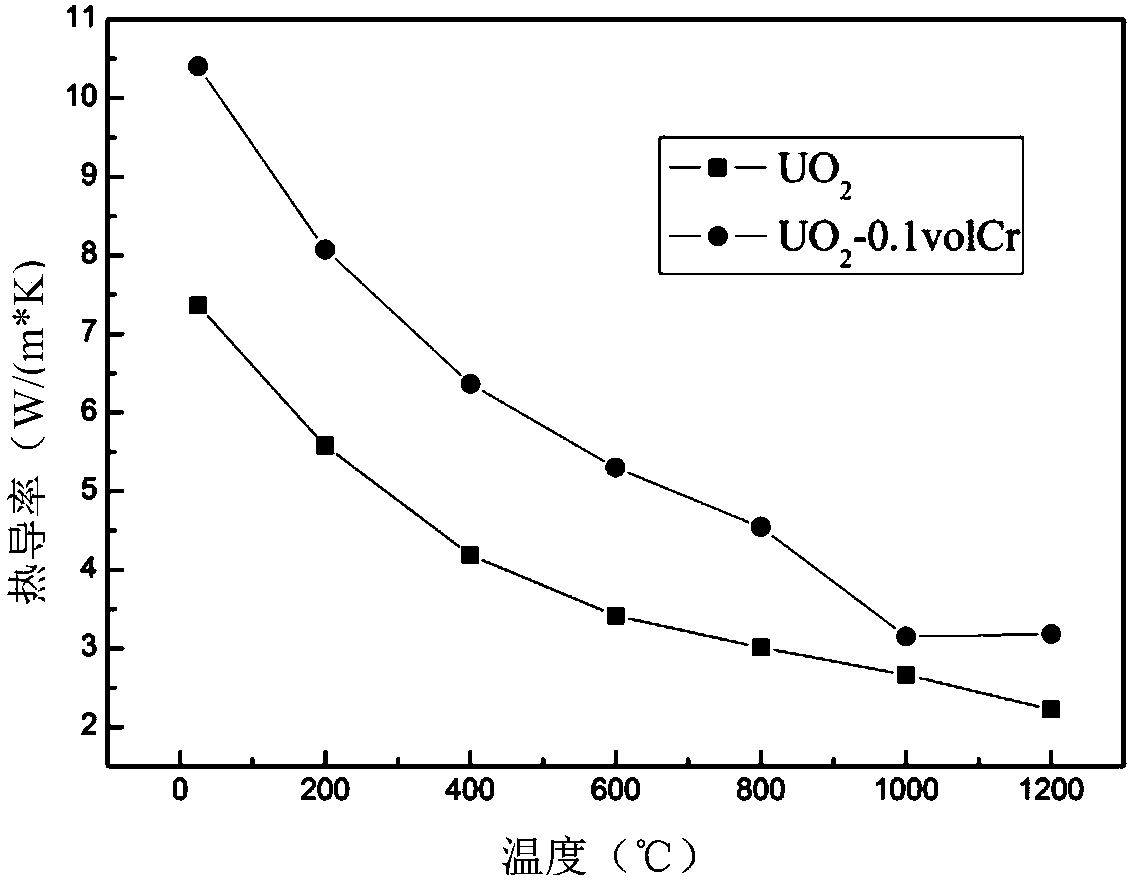

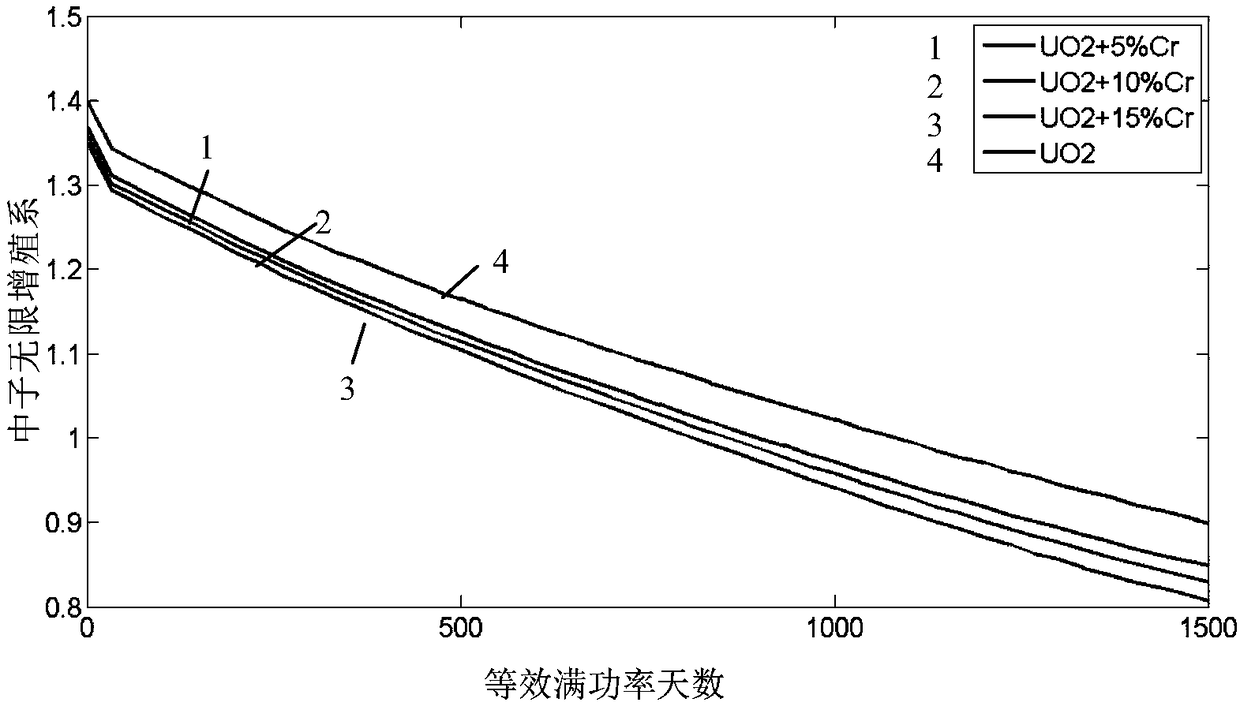

[0051] Weigh Cr with a particle size of 1 μm 2 o 3 Powder 0.5wt.%; the balance is UO with a particle size of 0.5μm 2 powder. Put each powder into a ball mill jar and mix evenly on a roller ball mill or a planetary ball mill. The mixed powder is compacted into a green body at a pressure of 100 MPa, and the formed green body has a radius of φ50 mm and a height of 20 mm. The green body is pre-fired in a high-temperature atmosphere furnace, the sintering temperature is 1500°C, and the holding time is 4h. The solid solution obtained after pre-calcination is crushed and sieved, and then the approximately spherical UO is obtained by self-grinding 2 Particles; at UO 2 Add 10wt.% Cr powder to the pellets and mix. Using compression molding method, the pressing pressure is 300MPa, and the UO 2 The particles are pressed into pellets; under an inert or reducing atmosphere, the pellets are densified by pressureless sintering at a sintering temperature of 1700°C to obtain fuel pellets...

Embodiment 2

[0055] Weigh MoO with a particle size of 1 μm 2 Powder 0.5wt.%; the balance is UO with a particle size of 0.5μm 2 powder. Put each powder into a ball mill jar and mix evenly on a roller ball mill or a planetary ball mill. The mixed powder is compacted into a green body at a pressure of 100 MPa, and the formed green body has a radius of φ50 mm and a height of 20 mm. The green body is pre-fired in a high-temperature atmosphere furnace, the sintering temperature is 1500°C, and the holding time is 4h. The solid solution obtained after pre-calcination is crushed and sieved, and then the approximately spherical UO is obtained by self-grinding 2 Particles; at UO 2 Add 10wt.% Mo powder to the pellets and mix. Using compression molding method, the pressing pressure is 300MPa, the UO mixed with Mo powder 2 The particles are pressed into pellets; under an inert or reducing atmosphere, the pellets are densified by pressureless sintering at a sintering temperature of 1700°C to obtain...

Embodiment 3

[0059] Weigh ZrO with a particle size of 1 μm 2 Powder 0.5wt.%; the balance is UO with a particle size of 0.5μm 2 powder. Put each powder into a ball mill jar and mix evenly on a roller ball mill or a planetary ball mill. The mixed powder is compacted into a green body at a pressure of 100 MPa, and the formed green body has a radius of φ50 mm and a height of 20 mm. The green body is pre-fired in a high-temperature atmosphere furnace, the sintering temperature is 1500°C, and the holding time is 4h. The solid solution obtained after pre-calcination is crushed and sieved, and then the approximately spherical UO is obtained by self-grinding 2 Particles; at UO 2 Add 10wt.% Zr powder to the pellets and mix. Using compression molding method, the pressing pressure is 300MPa, the UO mixed with Zr powder 2 The particles are pressed into pellets; under an inert or reducing atmosphere, the pellets are densified by pressureless sintering at a sintering temperature of 1700°C to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com