Gradient type concrete water pipe control system and control method

A control system and concrete technology, which is applied to household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of inability to control concrete cooling and fine control, and achieve the effects of reducing cracking risk, cost reduction, and heat insulation temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

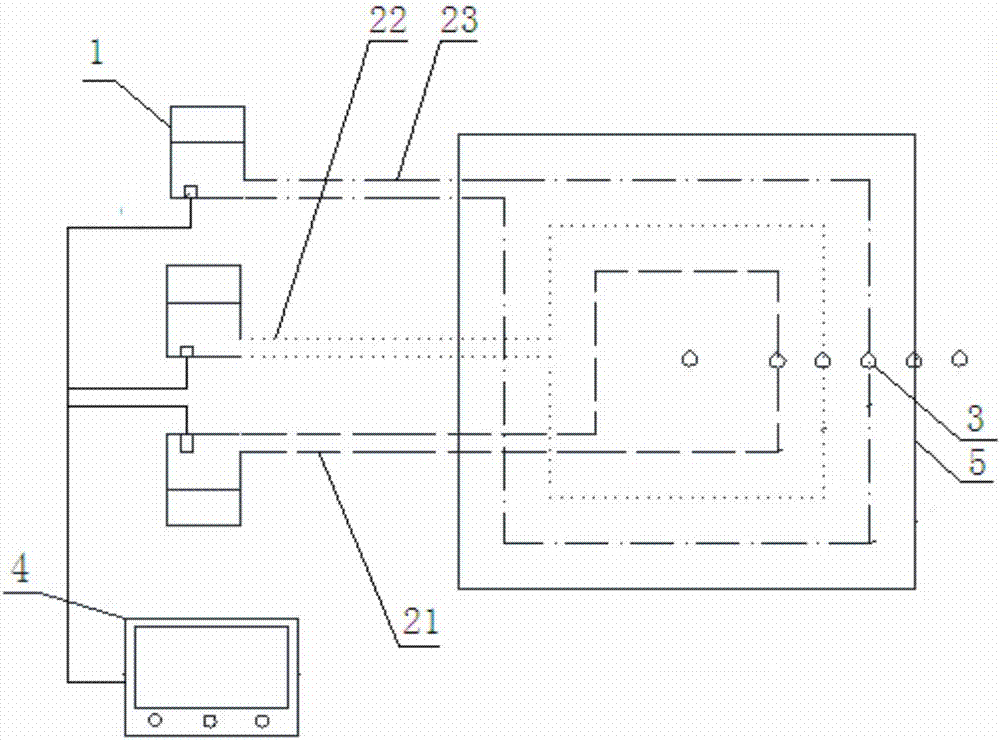

[0034] Embodiment 1: as figure 1 As shown, this embodiment provides a gradient concrete water pipe control system. In this embodiment, the distance range from the surface of the concrete structure to 50-80 cm inward is set as the low-temperature zone, and the temperature in this zone is usually 15°C~ lower than the high-temperature zone. 20°C; the area 100cm~200cm inward from the low temperature area is the medium temperature area, and the temperature in this area is 3°C~6°C lower than the temperature in the high temperature area; the high temperature area is inward from the medium temperature area. In this division, the high temperature area is usually The range is very large, and in the same high-temperature zone, there will also be a temperature difference of about 3°C;

[0035] The system includes,

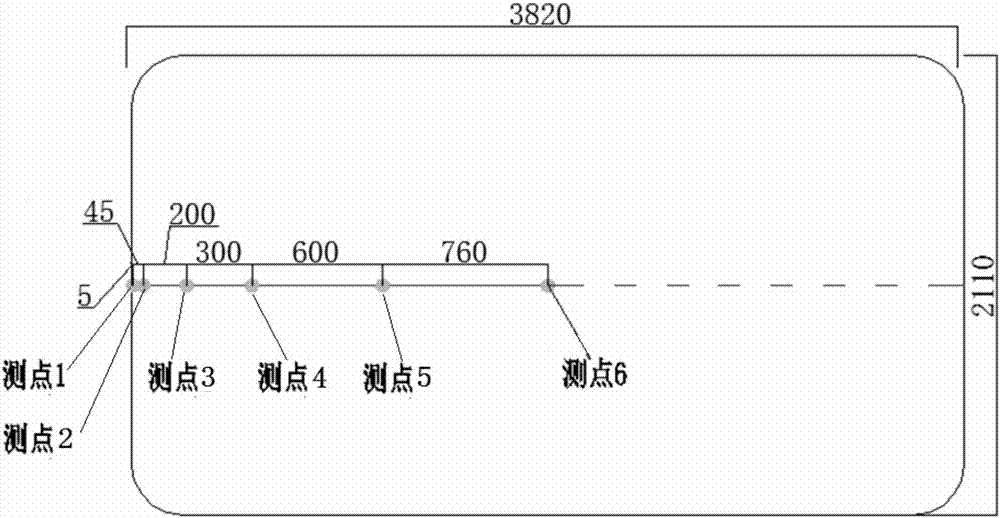

[0036] The temperature sensor 3 is arranged in the concrete structure 5, and is used to detect the temperature of different positions of the concrete; the temperature sensor ...

Embodiment 2

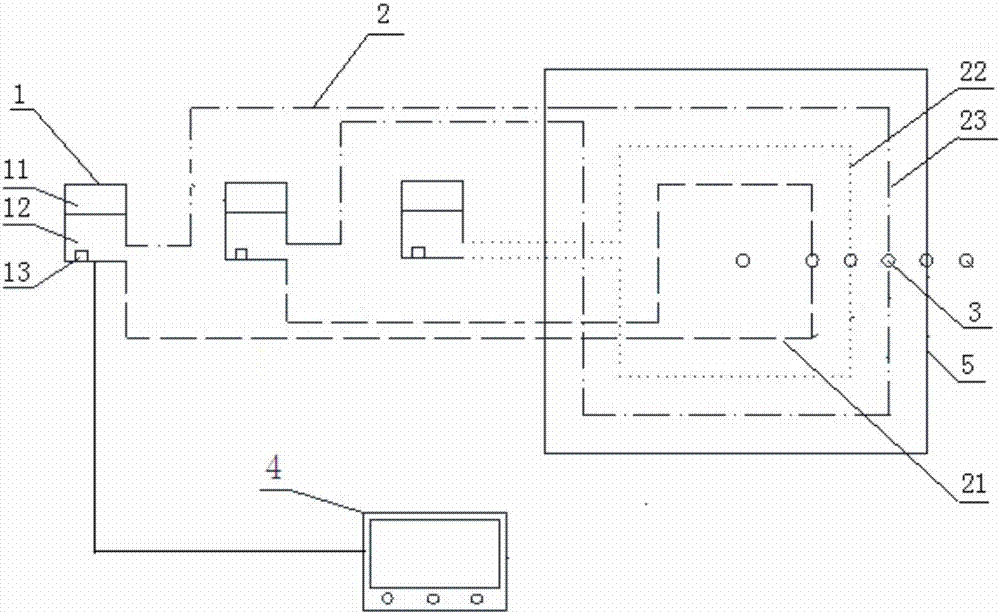

[0045] Embodiment 2: as figure 2 As shown, this embodiment also provides a gradient concrete water pipe control system, but the difference from Embodiment 1 is that in this embodiment, the outlet of the outer water control unit is connected to the water inlet end of the outer water pipe 23; The water return end of the outer water pipe 23 is connected to the inlet of the inner water control unit; the outlet of the inner water control unit is connected to the water inlet end of the inner water pipe 21; the return of the inner water pipe 21 The water end is connected to the inlet of the outer layer water control unit. That is, in this embodiment, the return water of the inner layer water pipe 21 will enter the outer layer water control unit, and because the temperature of the inner layer of concrete is higher, the water temperature of the water flowing back from the inner layer water pipe 21 will be higher than that of the inner layer The water inlet temperature of the water pi...

Embodiment 3

[0046] Embodiment 3: This embodiment also provides a gradient concrete water pipe control system, but the difference from Embodiment 1 is that in this embodiment, the temperature difference in different regions of the concrete during the heating process is first judged based on experience or experimental values. Then set multiple temperature zones according to the division method of a gradient every 5 degrees, and set a circulating water pipe 2 in each temperature zone. Multiple circulating water pipes 2 can be numbered in sequence according to the distance from the surface of the concrete structure, and each circulating water pipe 2 corresponds to a The circulating water control unit 3 and the control unit 4 independently control the water temperature of the circulating water pipe 2 in each temperature zone according to the temperature in the temperature zone. In some embodiments, the temperature zones of the concrete structure can also be divided according to other temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com