Semiconductor LED lamp housing

A technology for LED lamps and LED lamp housings, which is applied to semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, lighting devices, etc. Insufficient heat dissipation area, etc., to achieve the effect of light weight, beautiful appearance and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

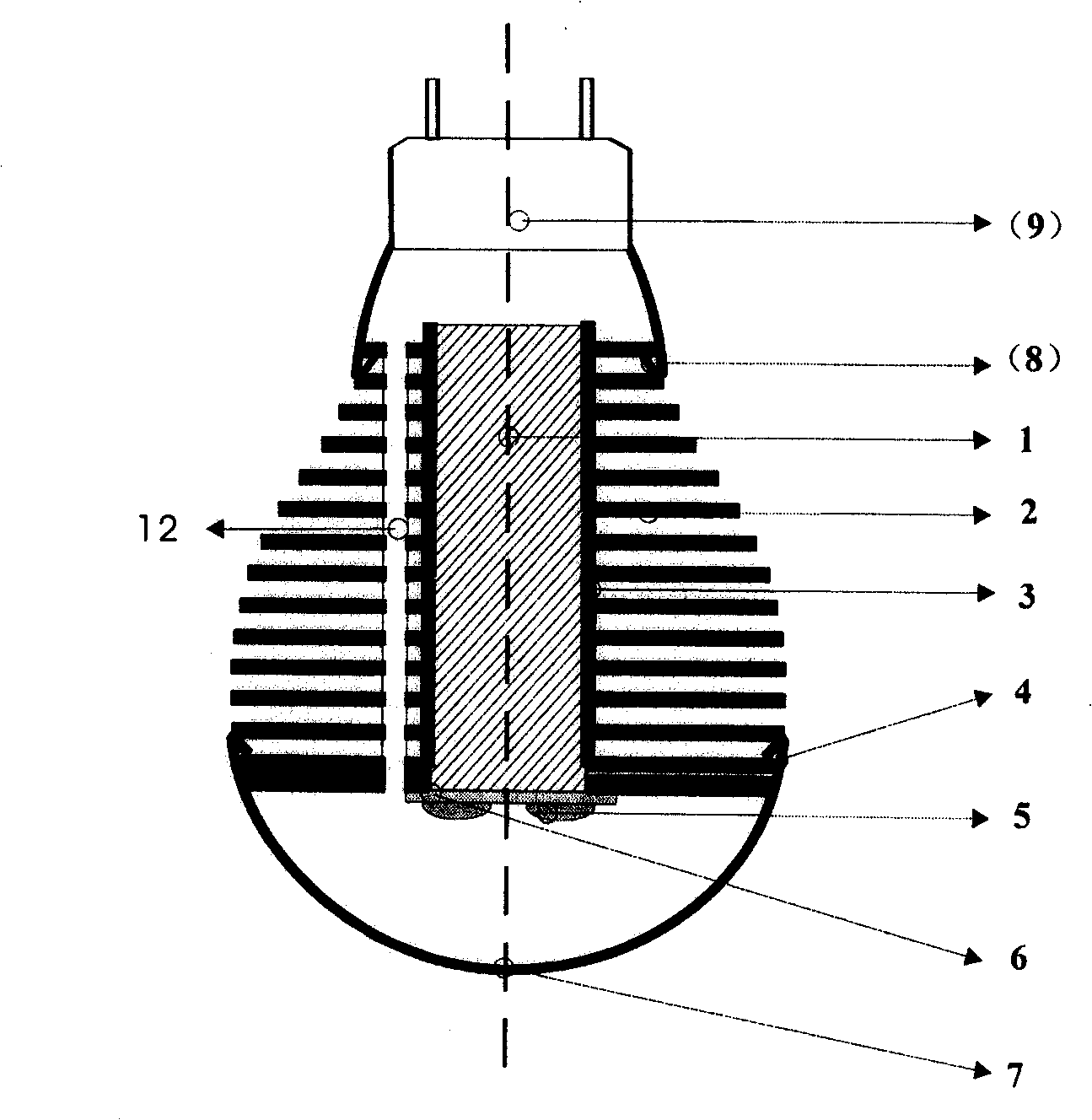

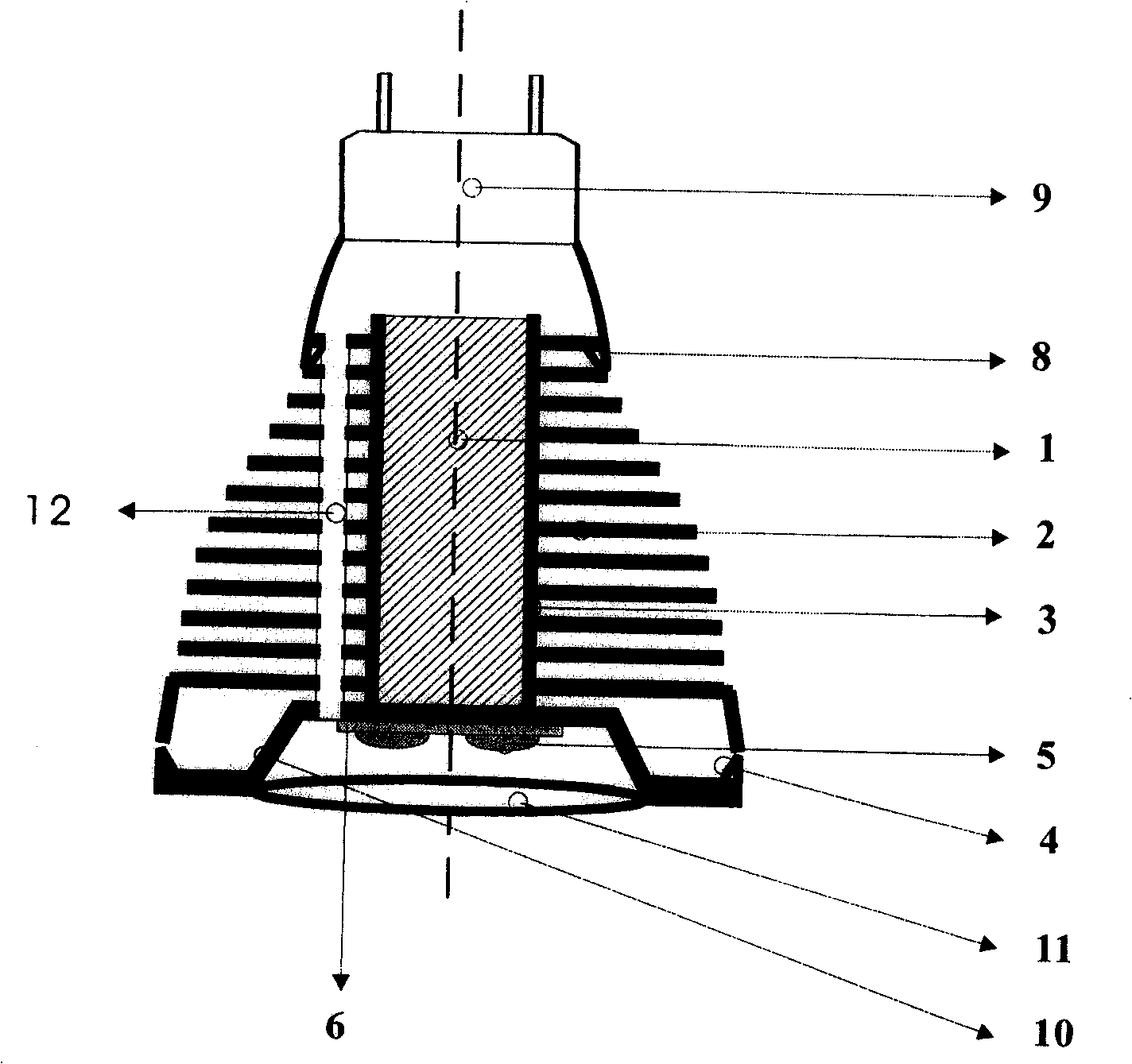

[0009] Referring to the accompanying drawings, the housing of the light-emitting LED lamp includes: a central connecting shaft base (1), thin-plate heat dissipation fins (2) arranged horizontally on the central connecting shaft base (1), and horizontally arranged thin-plate cooling fins (2) overlapped in all parts. The fins (2) are provided with L-shaped flanging fastening holes (3) and wire penetration holes (12), which are used to connect and fix the power supply buckle (8) of the power supply cover (9), and are used to connect and fix the lampshade (7) Or the lampshade buckle (4) of convex mirror lampshade (11).

[0010] plan 1,

[0011] First, process the central connecting shaft base (1) of the lamp housing according to the power of the LED lamp and heat dissipation requirements. The central connecting shaft base (1) can be a heat pipe, a metal blind tube, or a solid cylindrical material. Next, according to the required size of the heat exchange area of the LED lamp, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com