Low-melting-point optical glass forming device

An optical glass and molding device technology, applied in glass molding, glass pressing, glass manufacturing equipment, etc., can solve problems such as difficulty in producing low-melting glass, poor viscosity of glass liquid, easy generation of convective streaks, etc. Path and residence time, narrowing temperature and viscosity differences, the effect of preventing convection streaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

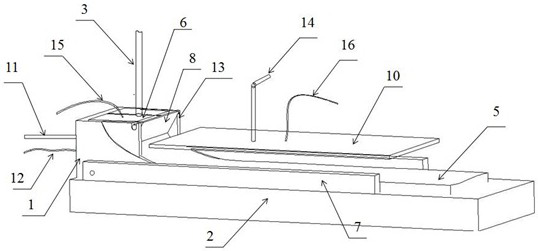

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

[0042] Such as Figure 3-5shown. The low-melting point optical glass molding device of the present invention comprises a mold rear baffle 1, a mold bottom plate 2, a glass leakage pipe 3, a mold space cover 10, a mold side baffle 7, a material retaining plate 8, a rear baffle cover 6, a rear Baffle temperature monitoring thermocouple 12 and baffle plate fixing frame 13. Wherein, the mold back baffle 1 forms a U-shaped groove with the mold side baffle 7 and the mold bottom plate 2, and the working surface of the mold back baffle 1 contacting the glass liquid is an arc surface. The working surface of the mold back baffle is designed to be arc-shaped in the direction of glass running, so that the molten glass can flow directly to the mold back baffle. At the same time, the arc shape of the working surface also prolongs the path for the glass liquid to enter the forming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com