A high-speed burner with large speed difference and low NOx

A low-NOx, high-speed burner technology, used in burners, combustion types, combustion equipment, etc., can solve the problem of high emissions, and achieve the effects of reducing NOx production, long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

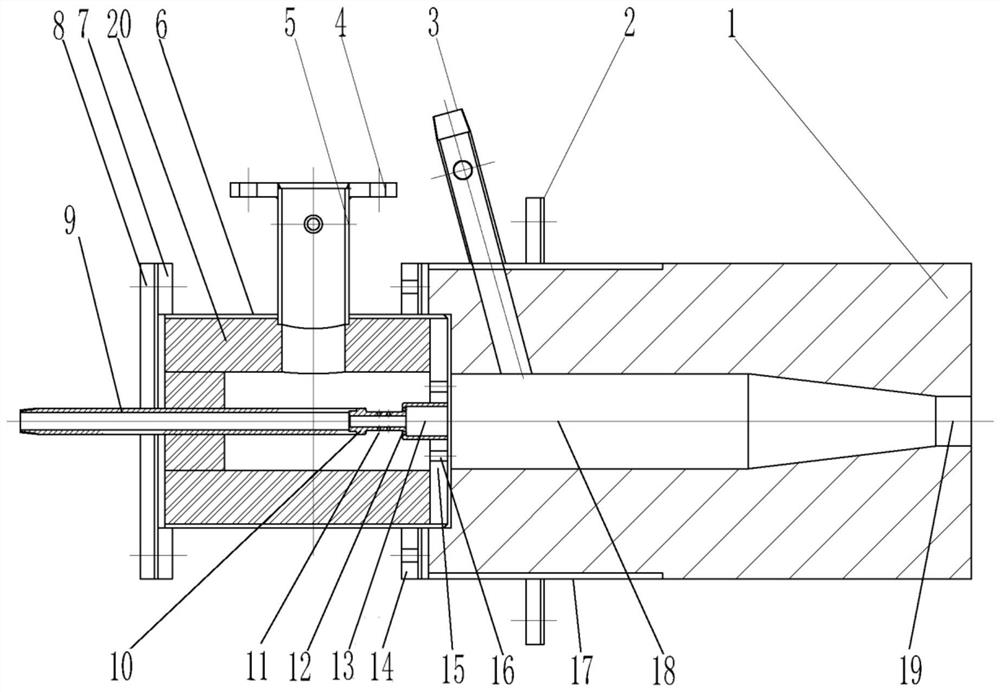

[0016] Embodiment 1: The present invention provides a kind of high-speed burner with large speed difference and low nitrogen oxides, its structure is as follows figure 1 As shown, the high-speed burner of this embodiment is used in a high-temperature tunnel-type heat treatment furnace for oriented silicon steel, and the fuel used is natural gas. The high-speed burner is equipped with burner brick 1, burner installation flange 2, ignition gun tube 3, air intake pipe flange 4, air intake pipe 5, burner shell 6, burner shell flange A7, gas Intake pipe flange 8, gas inlet pipe 9, gas nozzle pipe 10, burner shell flange B14, air distribution plate 15 and burner brick outer cylinder 17; The outer cylinder of the burner brick is connected to the flange B of the burner shell through bolts, the inner cavity of the burner brick is used as a combustion chamber 18 for air and gas, and the front end of the inner cavity of the burner brick forms a burner port 19 by reducing its diameter; T...

Embodiment 2

[0020]Embodiment 2: The present invention provides a high-speed burner with large speed difference and low nitrogen oxides. The high-speed burner in this embodiment is used in a seamless steel pipe heat treatment furnace, and the fuel used is coke oven gas. The structure of the high-speed burner of this embodiment is the same as that of Embodiment 1, the difference is that 3% of the combustion-supporting air enters the pre-combustion chamber through the primary air inlet passage 11, and 25% of the combustion-supporting air enters the combustion-supporting air in the burner housing during use. The combustion-supporting air enters the pre-combustion chamber through the secondary air intake channel 12; the remaining combustion-supporting air enters the combustion chamber 18 through the third air intake channel 16 of the air distribution plate 15; the coke oven gas enters through the primary and secondary air intake channels The combustion-supporting air is incompletely combusted i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com