Immersion type hollow fiber membrane component and complete equipment thereof

A complete set of equipment and fiber membrane technology, applied in the field of submerged hollow fiber membrane modules and their complete sets of equipment, can solve the problems of large local impact of membrane filaments, complex structure, and complicated installation of membrane components, so as to reduce rigid fatigue damage and realize The filter membrane area solves the effect of occupying a large space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

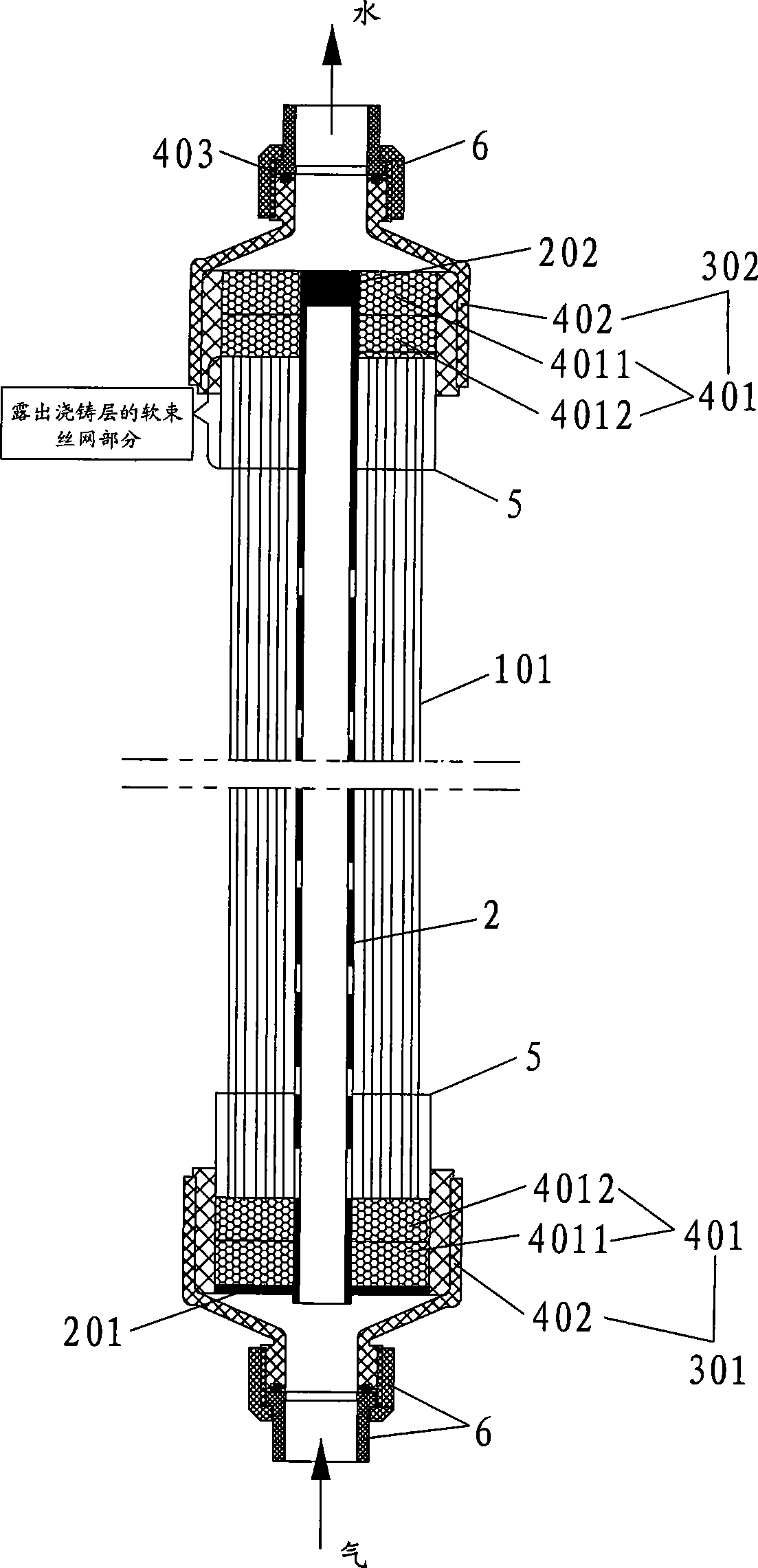

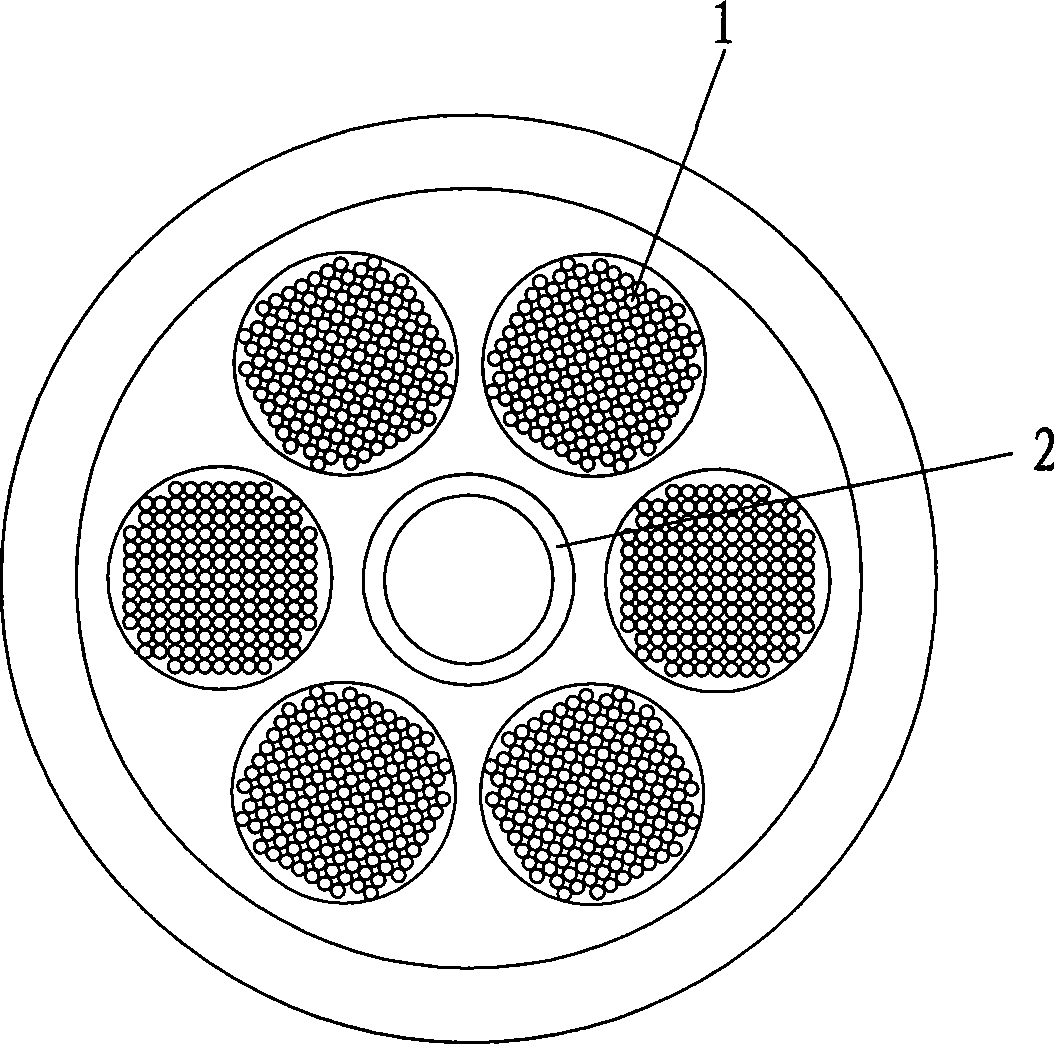

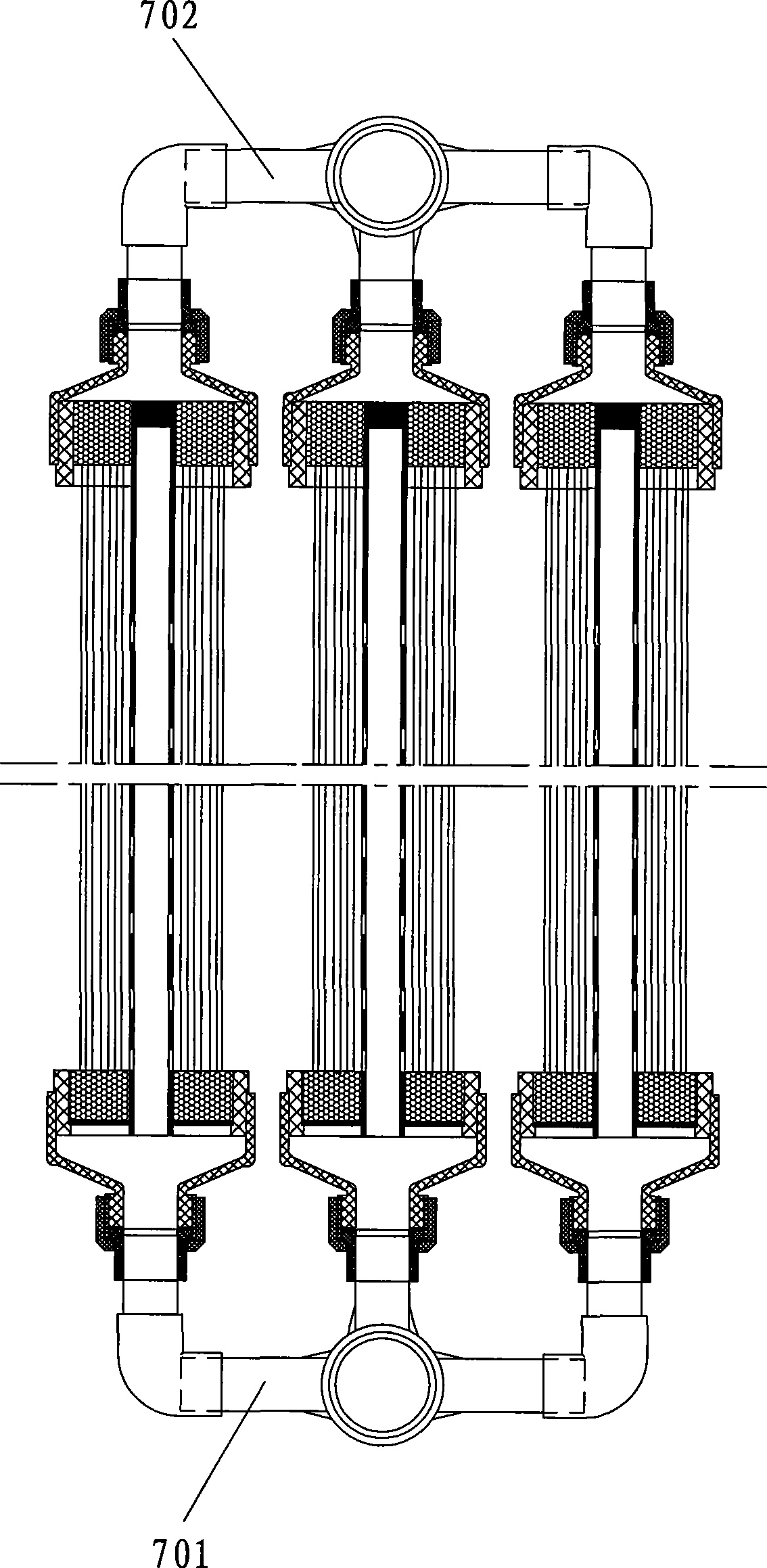

[0035] Example: a structure such as figure 1 , figure 2 As shown, a submerged hollow fiber membrane module, wherein the fiber membrane module is composed of a membrane tow 1, a membrane head and a central support tube 2, said membrane tow 1 is at least four bundles, distributed in the central support Around the tube 2, a membrane head is provided at both ends of the membrane tow 1, one of which is an air inlet head 301, and the other is a water production head 302.

[0036] The membrane head is composed of a casting sleeve 401 and a head outer sleeve 402. The casting sleeve is cast in two layers. At the water outlet, the upper layer near the water outlet is an epoxy resin layer 4011, and the lower layer is a polyurethane layer 4012; The lower layer near the air inlet is epoxy resin layer 4011, and the upper layer is polyurethane layer 4012. The outer wall of the casting casing 401 has external threads, and the part where the head outer casing 402 connects with the casting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com