Production method of high pressure rubber tube wire

A production method and technology of high-pressure rubber hose, which is applied in the field of pressure hose steel wire and its production, and can solve the problems of uneven heating of steel wire, increased wire breakage rate, and poor cleaning performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

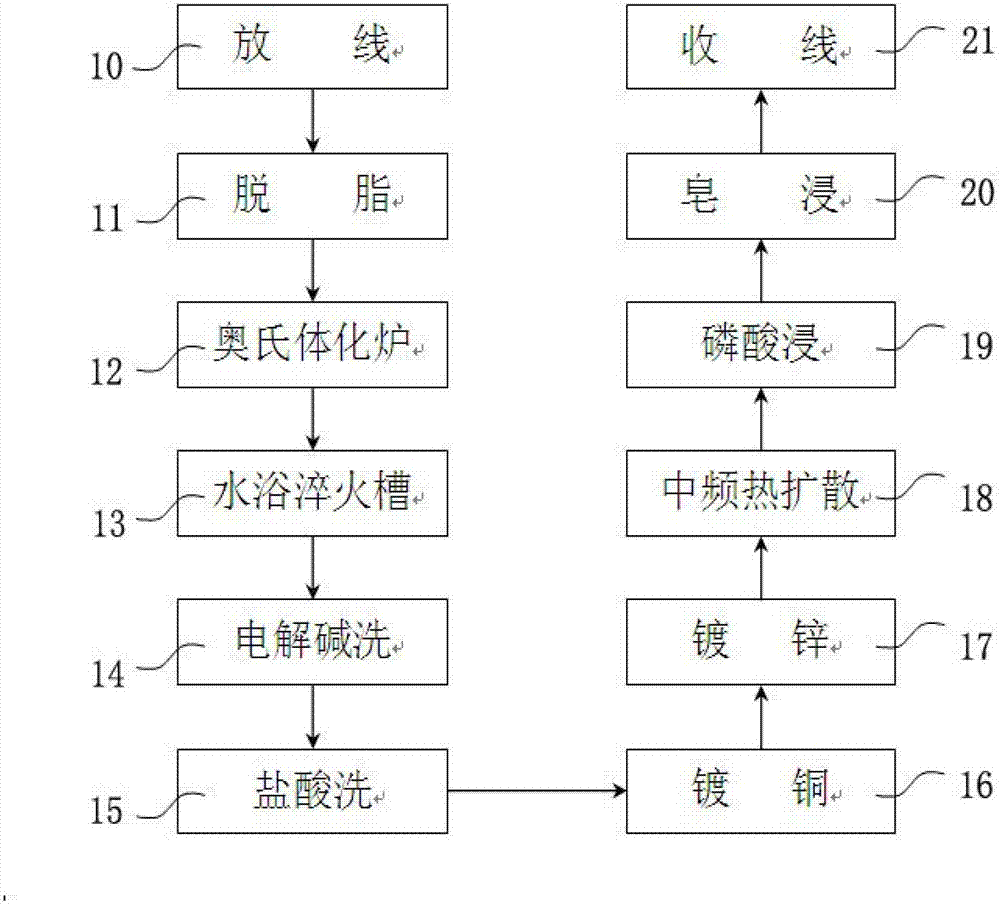

[0037] Such as figure 1 As shown, the present invention provides a kind of high-pressure rubber hose steel wire and production method thereof, comprising the following steps:

[0038] (10) The steel wire of the rubber hose after intermediate drawing is paid off through the pay-off device, and the tension is constant during the pay-off process, so as to avoid the fluctuation of the tension and the large dispersion of the performance of the strip.

[0039] (11) The steel wire of the rubber hose enters the degreasing tank for degreasing, and the borax soap powder remaining on the surface is washed away, so that the steel wire can evenly receive the heat from radiation in the furnace. The degreasing medium is soap powder, and the set temperature of the degreasing tank is ≥85°C. If the temperature is too low, the flow of the degreasing liquid will be affected. Moreover, the coated soap solution can control the heating rate of the steel wire in the furnace, control the oxidation pr...

Embodiment 2

[0062] On the basis of the above examples, if figure 1 Shown, a kind of high-pressure hose steel wire production method, wherein, comprises the following steps:

[0063] Step 10: The drawn rubber hose steel wire passes through the wire-releasing device for wire-releasing;

[0064] Step 11: enter the degreasing tank for degreasing;

[0065]Step 12: entering an austenitizing furnace for structural transformation;

[0066] Step 13: After the internal structure of the steel wire is transformed into austenite, it enters the water bath quenching tank;

[0067] Step 14: The steel wire enters the electrolytic alkaline washing tank;

[0068] Step 15: Hose steel wire enters hydrochloric acid washing;

[0069] Step 16: Enter the copper electroplating process after being washed with high-pressure water;

[0070] Step 17: the steel wire enters the galvanizing process;

[0071] Step 18: After the steel wire is preheated and cleaned with high-temperature hot water, the surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com