Thermal treatment double-station uninterrupted unwinding device

A pay-off device and double-station technology, which is applied in thin material handling, transportation and packaging, and delivery of filamentous materials, etc., can solve the problems of incoherence and inconvenient pay-off work, and reduce the broken wire rate and reduce the Stretching, less labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution will be described in detail below through a best embodiment, but the protection scope of the present invention is not limited to the embodiment.

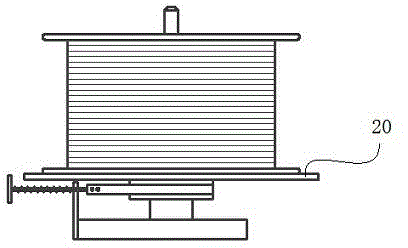

[0021] Such as figure 1 As shown, the existing technology adopts the working state of the pay-off turntable, and the full-line I-shaped wheel is sleeved on the central axis of the pay-off turntable, and the tension belt is arranged at the bottom of the turntable, and the end of the wire is drawn out from below. With the rotation of the wire turntable, the steel wire is pulled out. What mainly utilize is that the rotation of the rotating disk 20 below the spool wheel realizes paying off.

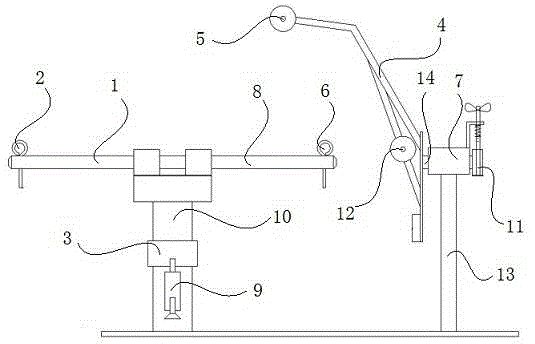

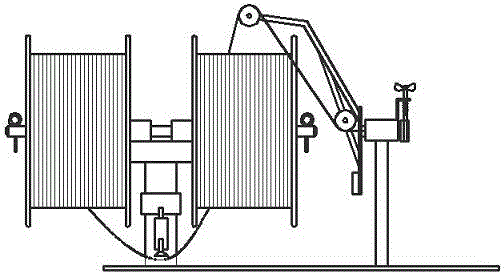

[0022] Such as figure 2 As shown, the heat treatment double-station uninterrupted pay-off device of the present invention includes a station support 10, a coil I-shaped wheel and a wire-winding support. The end of the pay-off shaft A1 is provided with a safety pin A2, the end of the pay-off shaft B8 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com