Production method of steel for 82 B steel stranded wires

A production method and steel strand technology, applied in the manufacture of converters, etc., can solve problems such as complex production process, increased difficulty of production organization and production cost, subcutaneous quality and central segregation of slab, poor porosity and shrinkage cavity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

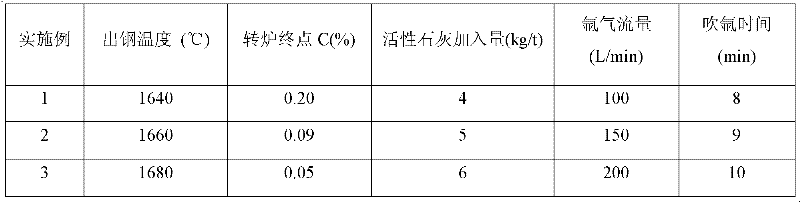

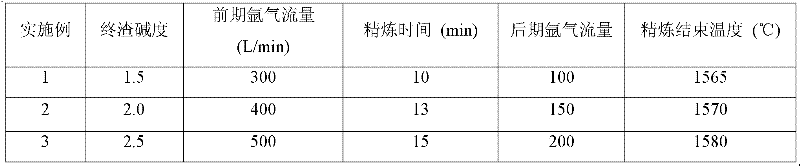

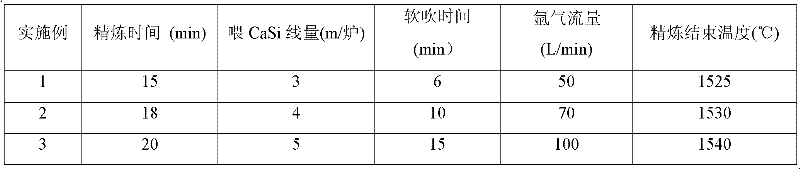

Examples

Embodiment Construction

[0020] The invention adopts the process route of "converter primary refining-LF refining-RH refining-bloom continuous casting" to produce clean steel strand steel 82B steel, wherein, in the bloom continuous casting process, the end of the solidified end adopts dynamic light pressing. The soft reduction technology is a technology that slightly compresses the slab at a certain stage of the continuous casting process; the dynamic soft reduction technology (DSR) is to dynamically track the slab according to the solidification of the slab during the continuous casting production process. The solidification range specified on the billet, and the soft reduction parameter command is issued in real time. DSR can adjust the soft reduction parameters in time according to the liquid core position of the slab during the continuous casting transition process, so as to better achieve the effect of soft reduction.

[0021] Among them, in the above-mentioned bloom continuous casting process, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com