Method for manufacturing viscose-based graphite felt

A production method and technology of graphite felt, which can be used in heating/cooling fabrics, textiles and papermaking, fiber processing, etc., can solve the problems of low tenacity rate, broken wire rate, etc., poor production equipment technology, and loss of insulation layer Effect and other issues, to achieve the effect of low broken wire rate, excellent electrical performance, and avoid being broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

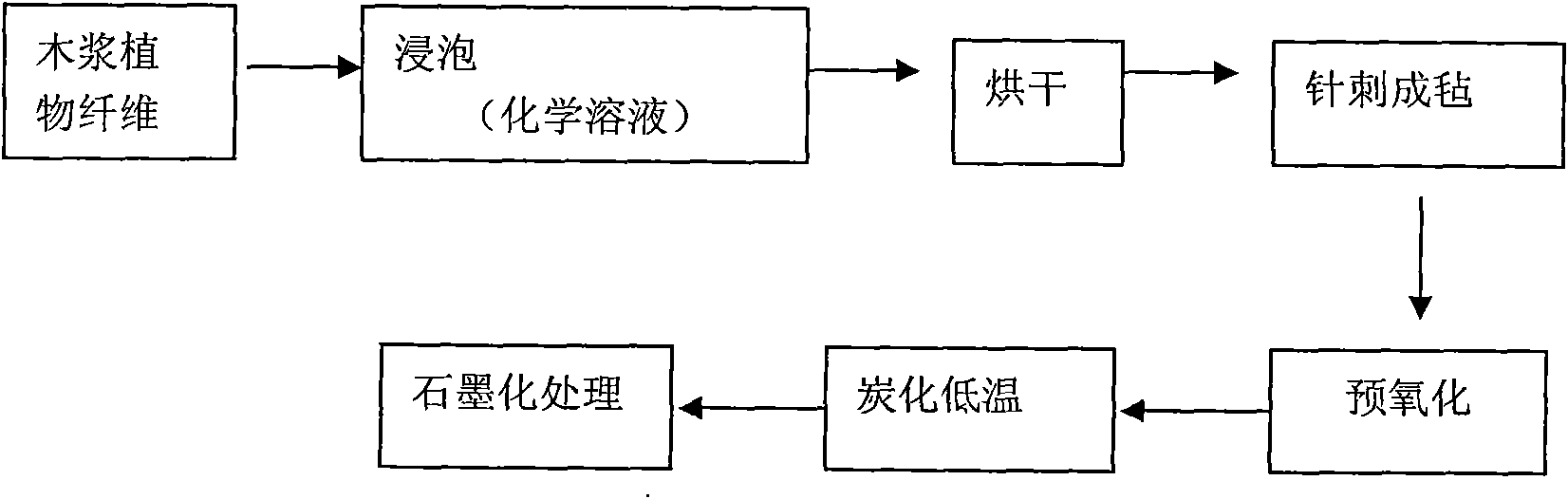

[0019] Below, in conjunction with accompanying drawing, the present invention will be further described:

[0020] A method for making viscose-based graphite felt, the steps of which are

[0021] a. Select wood pulp plant viscose fiber with high tensile strength, low broken wire rate and good toughness as raw material, preheat it from room temperature to 80°C, stir evenly, pour the fiber into diammonium hydrogen phosphate according to the weight of 22 % ratio and in the water phase mixed solution, the ratio of diammonium hydrogen phosphate and water is 22:100 (weight). Take it out after soaking for 1 hour, so that the surface of the wood pulp plant viscose fiber absorbs the solution, so that the fiber tends to be stable; then dry it in an oven at 60°C, take it out, and needle it into a felt body on a needle loom;

[0022] b. The needle felt body imported from abroad is used to make it difficult to break the fiber during the needle punching process, reduce the fiber breakage ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com