Multi-spinning-station carbon fiber precursor rolling device

A technology of carbon fiber precursor and winding device, which is applied in the direction of transportation and packaging, delivery of filamentous materials, and thin material processing, etc., which can solve the problems of static electricity, inability to solve the problem of fiber precursor hairiness, and limit the use of carbon fiber. Achieve the effects of reducing the broken wire rate, improving product quality and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

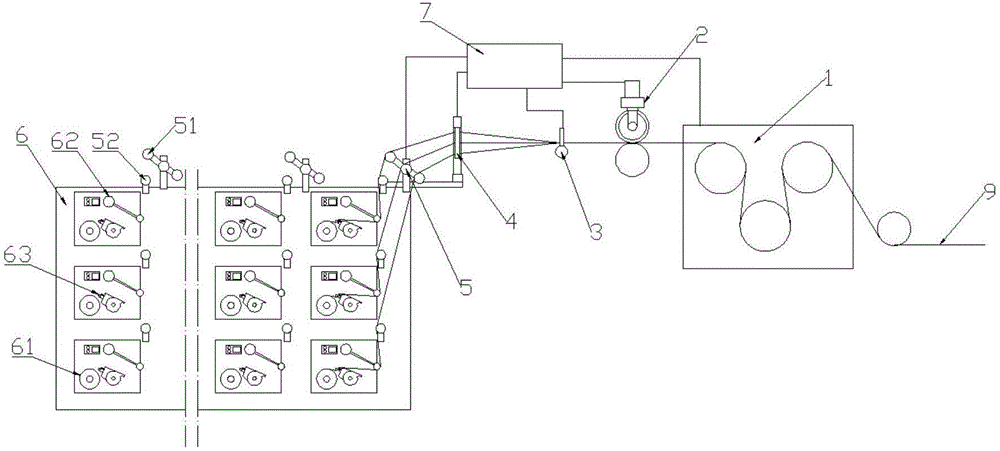

[0031] figure 1 It is a structural schematic diagram of a multi-spinning carbon fiber precursor winding device in a preferred solution of the present invention. From figure 1 It can be seen from the figure that the carbon fiber precursor coiling device is composed of a drafting device 1 , a holding device 2 , a splitting device 3 , a splitting guide device 4 , a spinning device 6 and a static elimination device 7 .

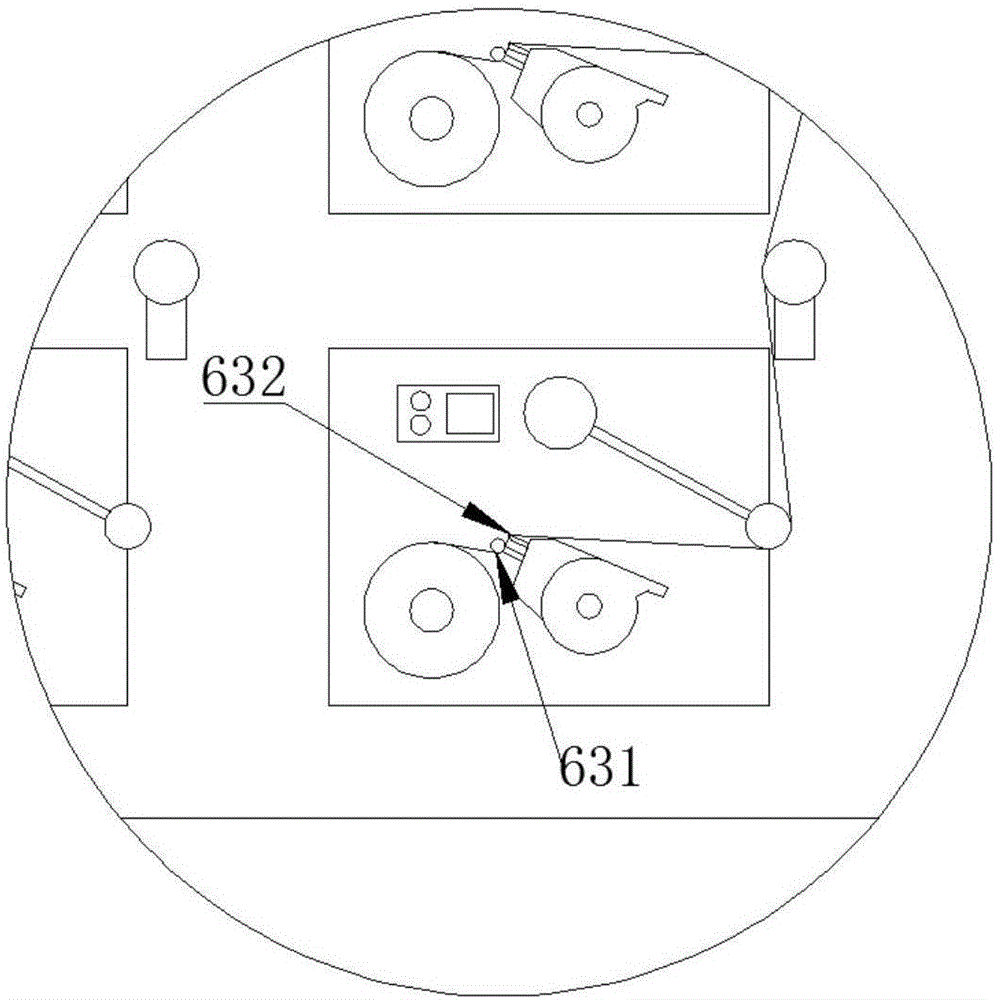

[0032] Wherein, the drafting device 1 includes three gripping rollers, and the fiber tow 9 is guided into the drafting device 1 by the guide rollers, and then passed through the holding device 2 after being gripped and drawn out. The holding device 2 is made up of two pressing rollers up and down. The upper pinch roller is a rubber pinch roller, the lower part is a smooth roll, and the upper pinch roller is connected with a telescopic mechanism (such as a telescopic pneumatic cylinder or a hydraulic cylinder, so as to control the distance between the pinch rolle...

specific Embodiment approach 2

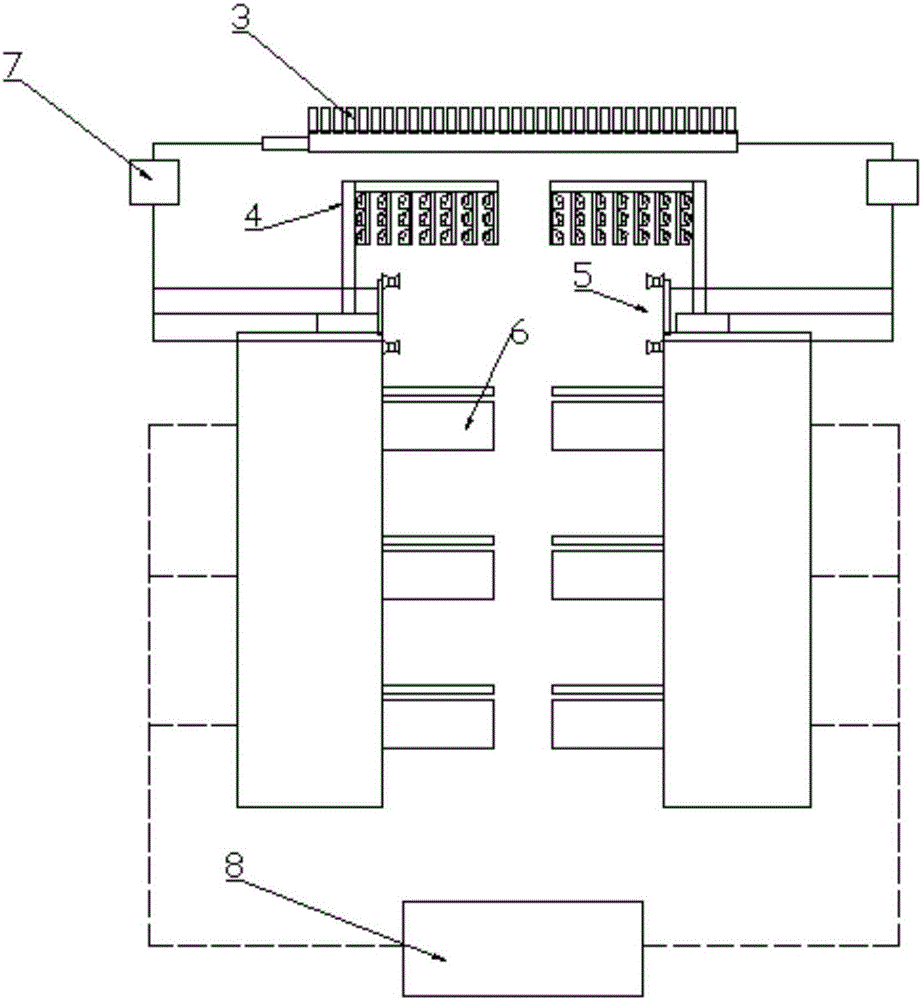

[0039] figure 2 It is a schematic diagram of a side view structure in a preferred solution of the present invention (omitting the drafting and pinch rollers. The difference between this embodiment and the specific embodiment one is that the winding device 6 is divided into two parts, left and right , each part is provided with an outer casing. The upper part of each outer casing is respectively provided with a split wire guiding device 4 and a guide wheel group 5. The tow 9 is divided into two parts after passing through the split wire device 3 split wires and passes through the above-mentioned left and right sides respectively. Part of the traction and winding of the split guide device 4, the guide wheel set 5 and the winding device 6. At the same time, this embodiment is also provided with the power of the drafting device 1, the holding device 2 and the winding device 6 respectively. A control device for mechanism interlocking, so as to carry out interlocking control on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com