Smelting process for controlling spring steel inclusions

A technology for controlling springs and inclusions, applied in the smelting field of spring steel, can solve the problems of difficulty in controlling spherical oxide inclusions, formation of cracks at the junction of substrates, no deformability, etc. Beneficial for shaping and reducing phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

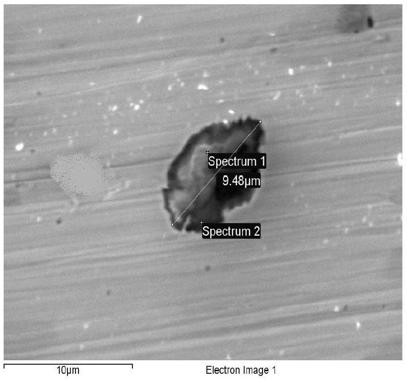

[0021] The process flow of the spring steel produced by the present invention: KR molten iron pretreatment → BOF top-bottom double-blowing converter → LF refining furnace → RH refining furnace → 220 m3 continuous casting CCM. By modifying the slag system, the plasticity of inclusions is optimized, the number and size of inclusions are reduced, and the shape of inclusions is as follows: figure 1As shown, the width size is less than 9 μm, the aspect ratio is 4, the total oxygen content is ≤15ppm, and the nitrogen content is ≤30ppm.

[0022] 1) After the molten iron is desulfurized by KR, the mass fraction of S is 0.0035%, which reduces the desulfurization pressure of the refining furnace and creates good conditions for the deoxidation of the refining furnace and the formation of acid slag.

[0023] 2) Before adding steel scrap to the converter, adjust the bottom blowing of the furnace body to the full-range argon blowing mode to avoid nitrogen increase during the smelting proces...

Embodiment 2

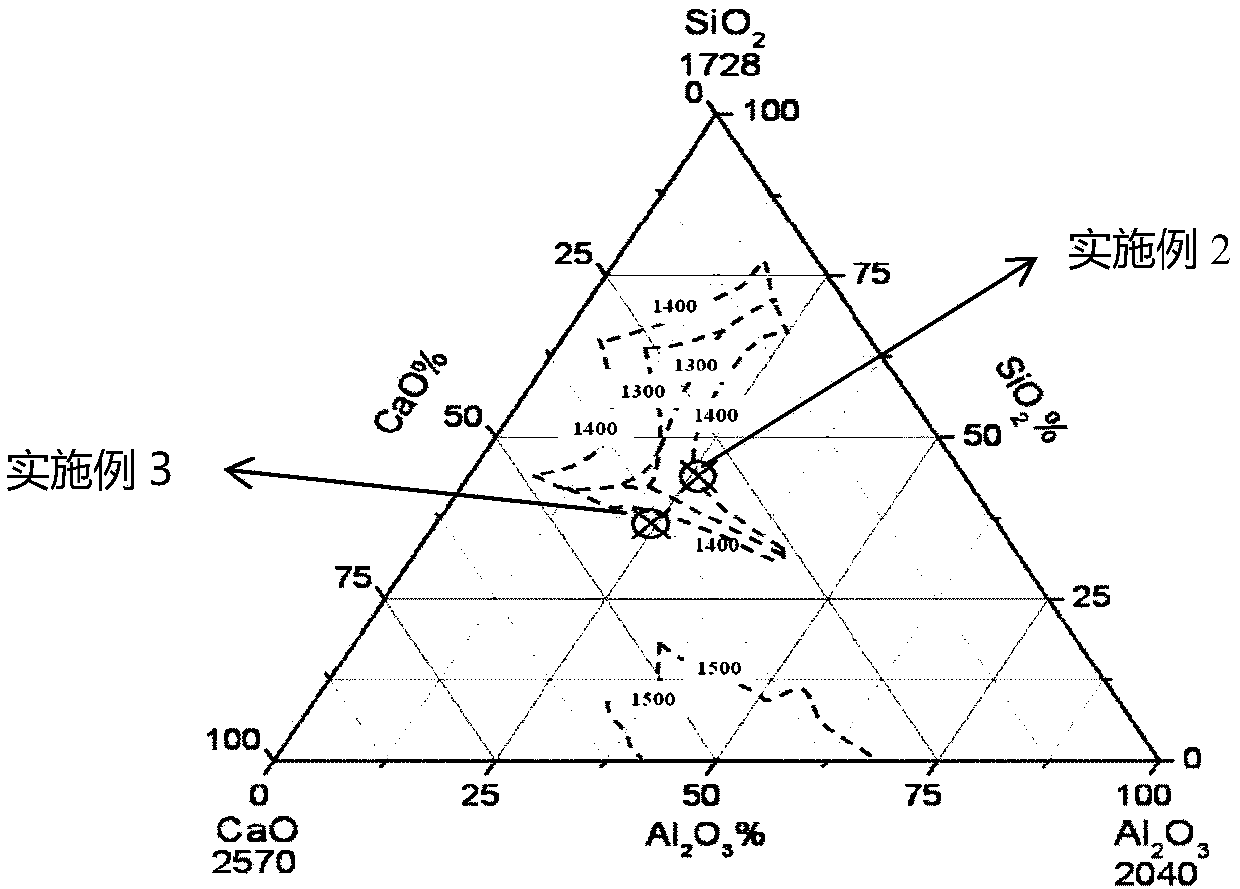

[0031] The process flow of the spring steel produced by the present invention: KR molten iron pretreatment → BOF top-bottom double-blowing converter → LF refining furnace → RH refining furnace → 220 m3 continuous casting CCM. By modifying the slag system, optimizing the plasticity of the inclusions, reducing the number and size of the inclusions, the total oxygen content of the prepared spring steel is ≤12ppm, and the nitrogen content is ≤25ppm; the projection of the inclusion composition on the position of the ternary phase diagram is as follows figure 2 As shown, it can be seen from the figure that the composition of the inclusions in the ternary phase diagram is closer to the low melting point region, the inclusions are easy to float up and removed, and the inclusions are smaller and easier to deform. Concrete preparation steps are as follows:

[0032] 1) The molten iron is desulfurized by KR with a mass fraction of S of 0.004%, which reduces the desulfurization pressure o...

Embodiment 3

[0041] The process flow of the spring steel produced by the present invention: KR molten iron pretreatment → BOF top-bottom double-blowing converter → LF refining furnace → RH refining furnace → 220 m3 continuous casting CCM. By modifying the slag system, optimizing the plasticity of inclusions, reducing the number and size of inclusions, the width size is less than 10μm, the aspect ratio is 3, the total oxygen content is ≤12ppm, and the nitrogen content is ≤25ppm; the inclusion composition is projected on the position of the ternary phase diagram as figure 2 As shown, it can be seen from the figure that the composition of the inclusions in the ternary phase diagram is closer to the low melting point region, the inclusions are easy to float up and removed, and the inclusions are smaller and easier to deform. Concrete preparation steps are as follows:

[0042] 1) After the molten iron is desulfurized by KR, the mass fraction of S is 0.0045%, which reduces the desulfurization p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com