Patents

Literature

61 results about "Ternary phase diagram" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Positive electrode active material for lithium secondary cell and lithium secondary cell

ActiveUS7393476B2Improve cycle performanceIncrease energy densityMaterial nanotechnologyCell temperature controlCrystallographyComposite oxide

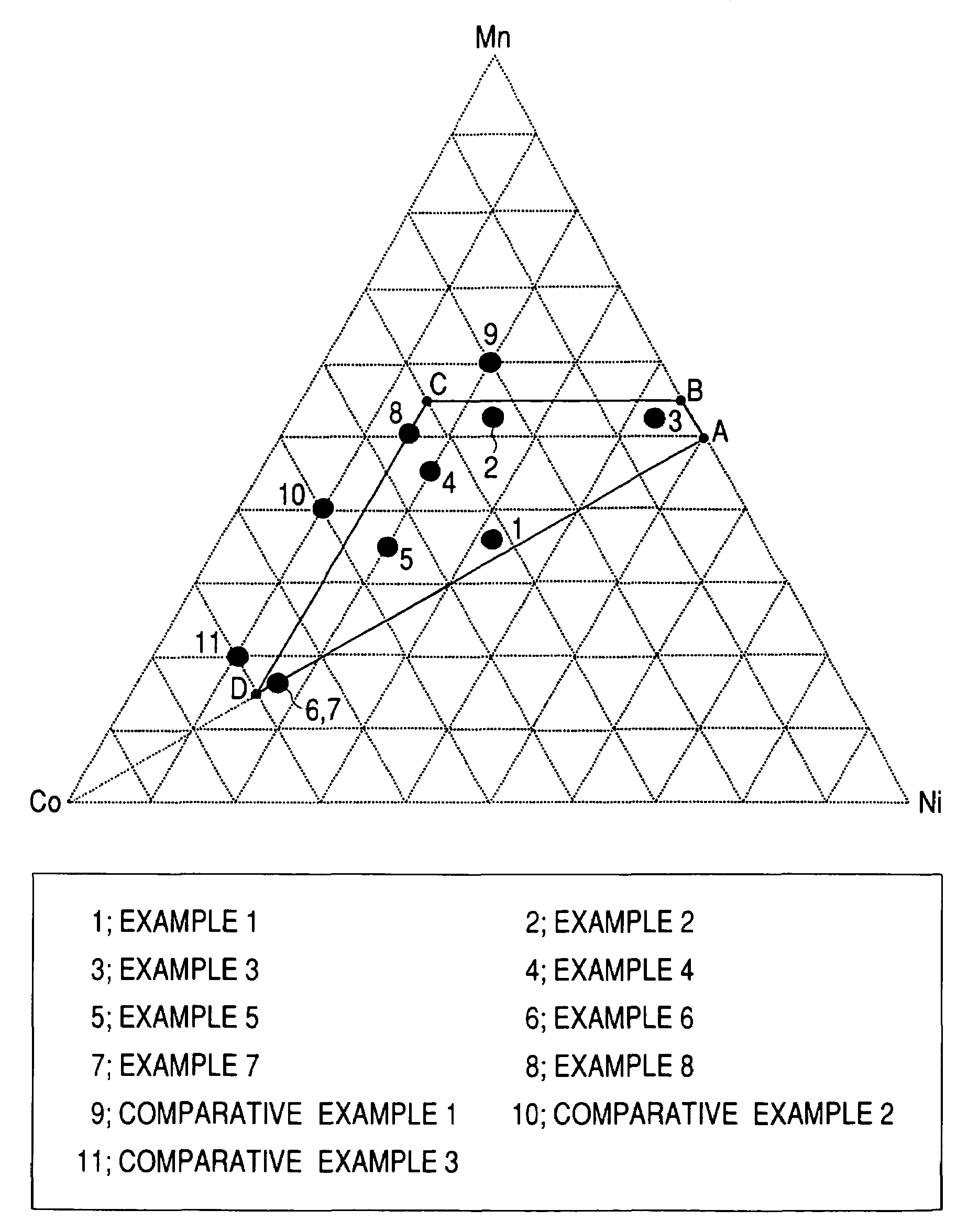

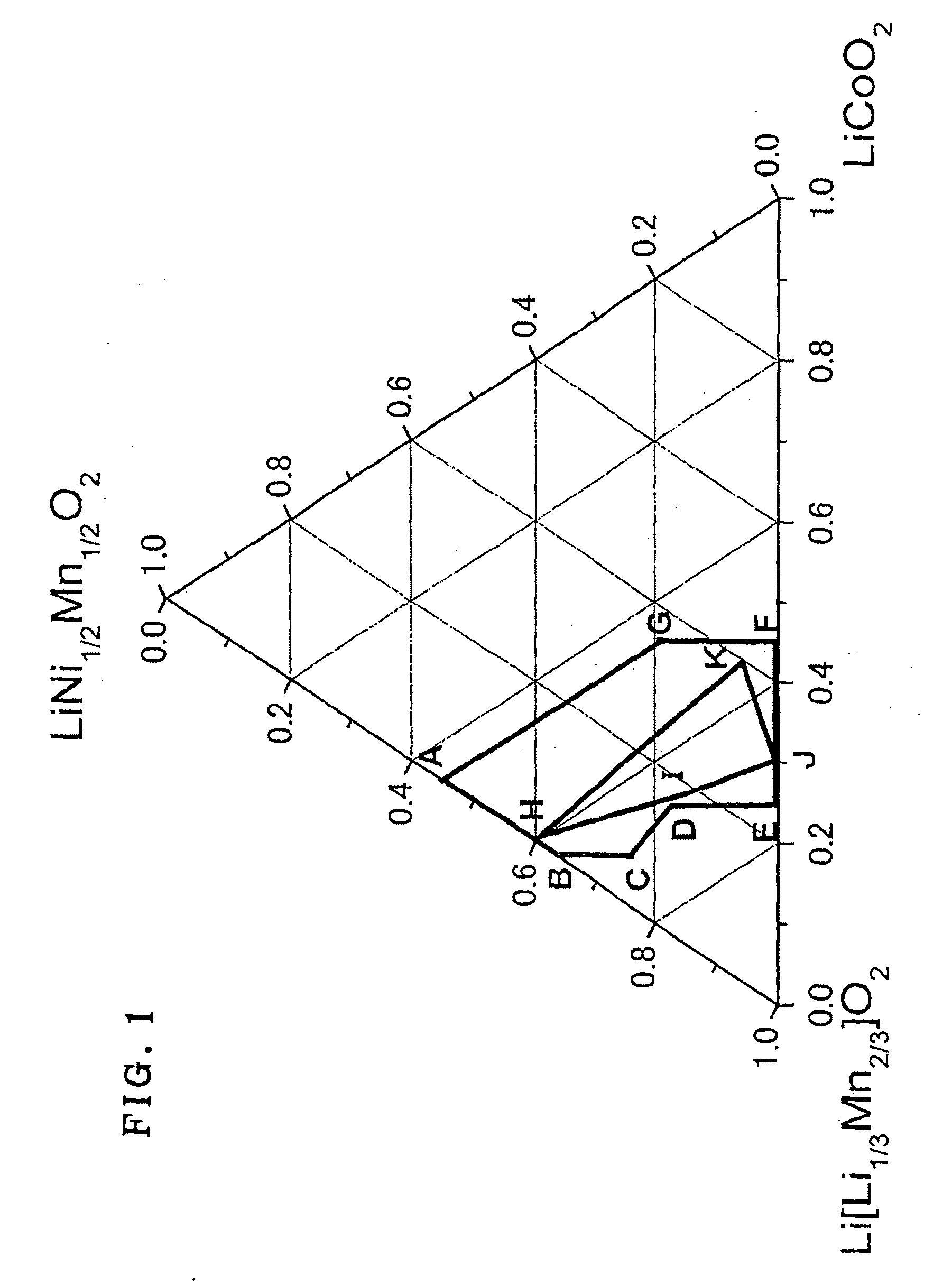

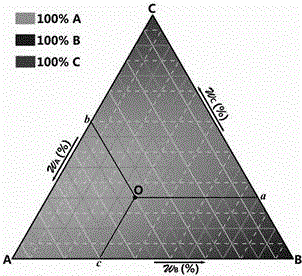

A positive active material for lithium secondary batteries, includes a composite oxide including an oxide which is represented by the composite formula LixMnaNibCocO2 and has an α-NaFeO2 structure, and an impurity phase including Li2MnO3. The values a, b, and c are within such a range that in a ternary phase diagram showing the relationship among these, (a, b, c) is present on the perimeter of or inside the quadrilateral ABCD defined by point A (0.5, 0.5, 0), point B (0.55, 0.45, 0), point C (0.55, 0.15, 0.30), and point D (0.15, 0.15, 0.7) as vertexes, and 0.95<x / (a+b+c)<1.35.

Owner:GS YUASA INT LTD

Active material for lithium secondary battery, lithium secondary battery, and method for producing the same

ActiveUS20100233542A1Decrease in battery performanceSufficient discharge capacityBatteries circuit arrangementsElectrode manufacturing processesX-rayCrystal structure

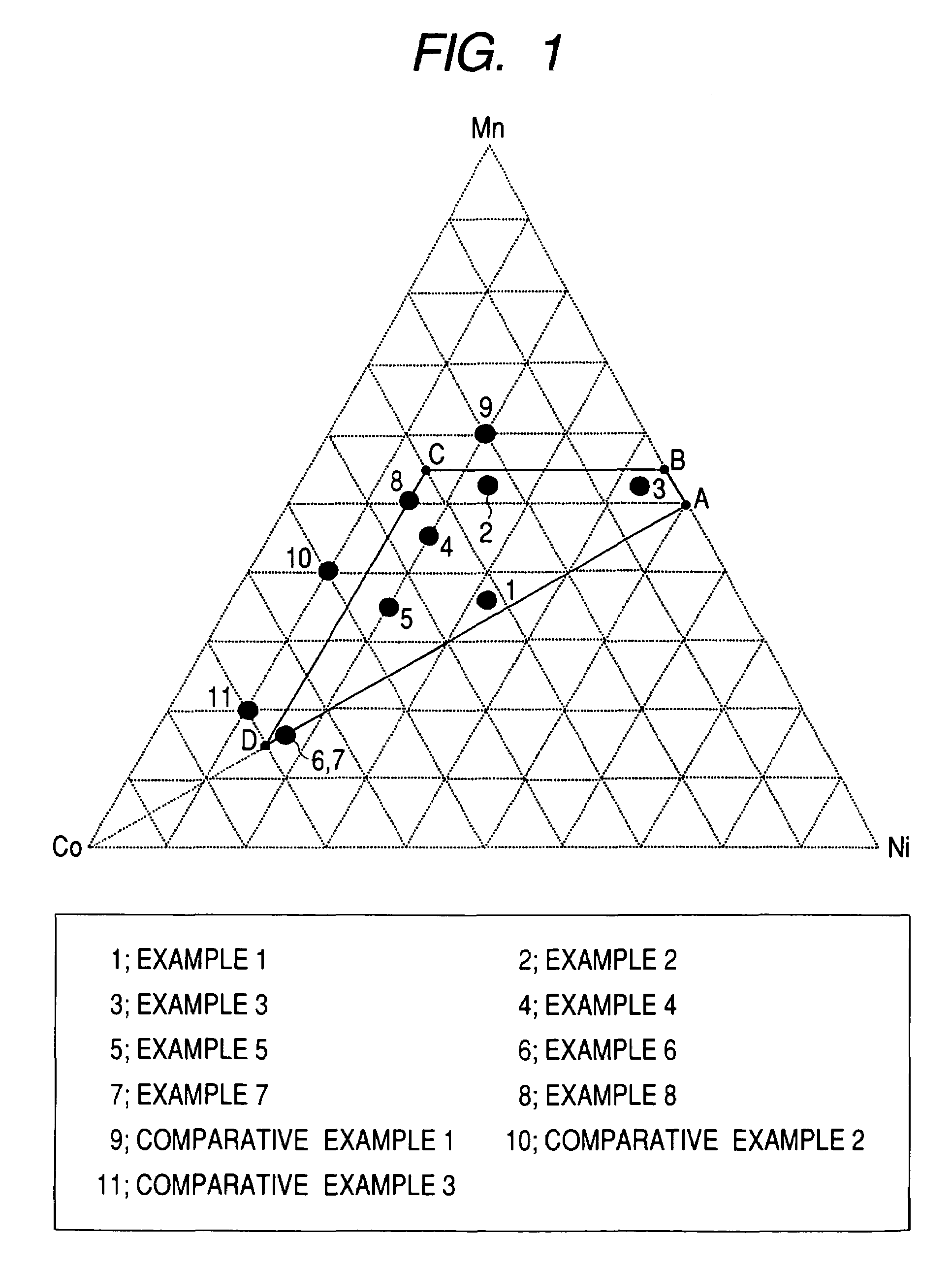

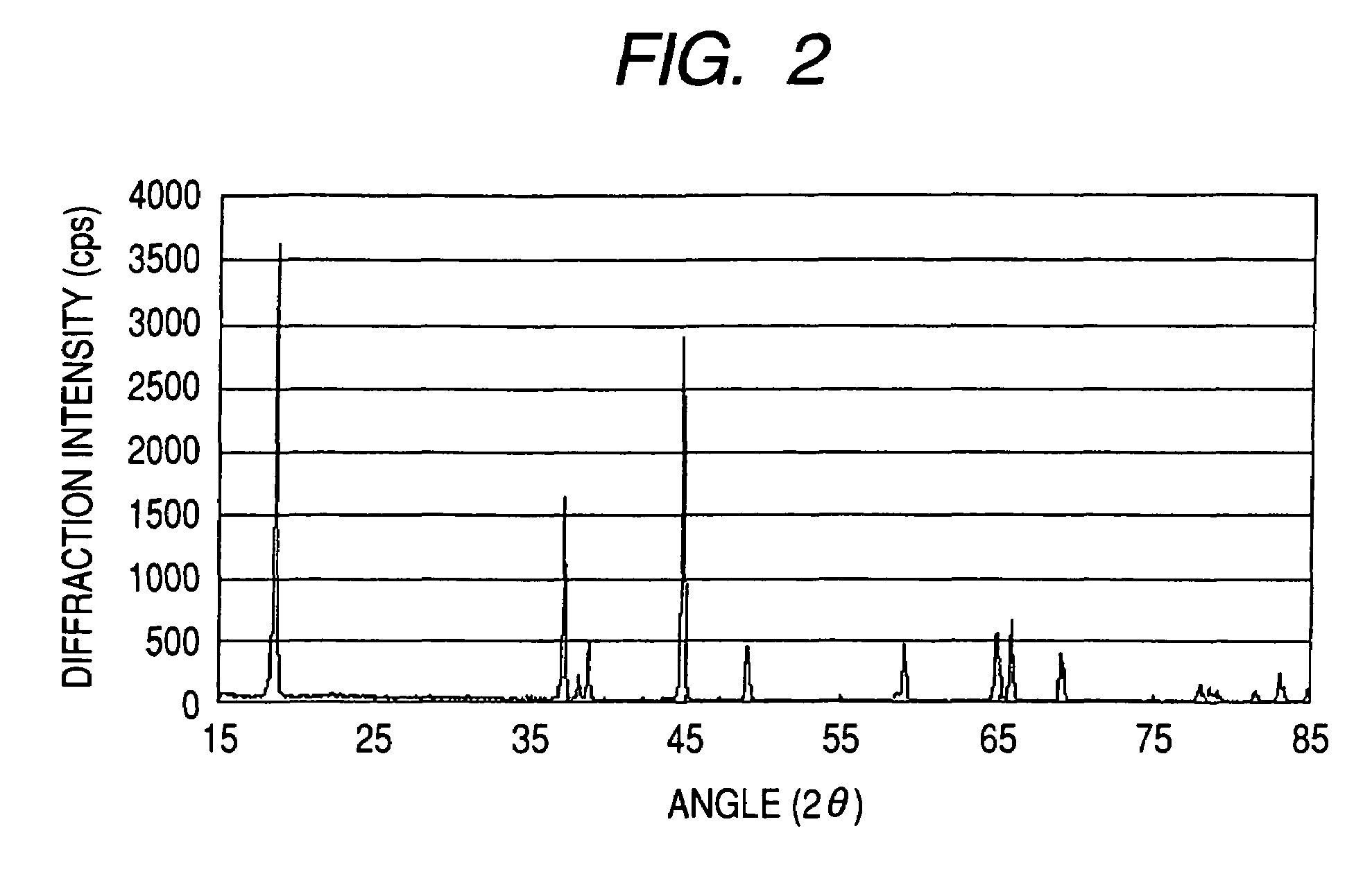

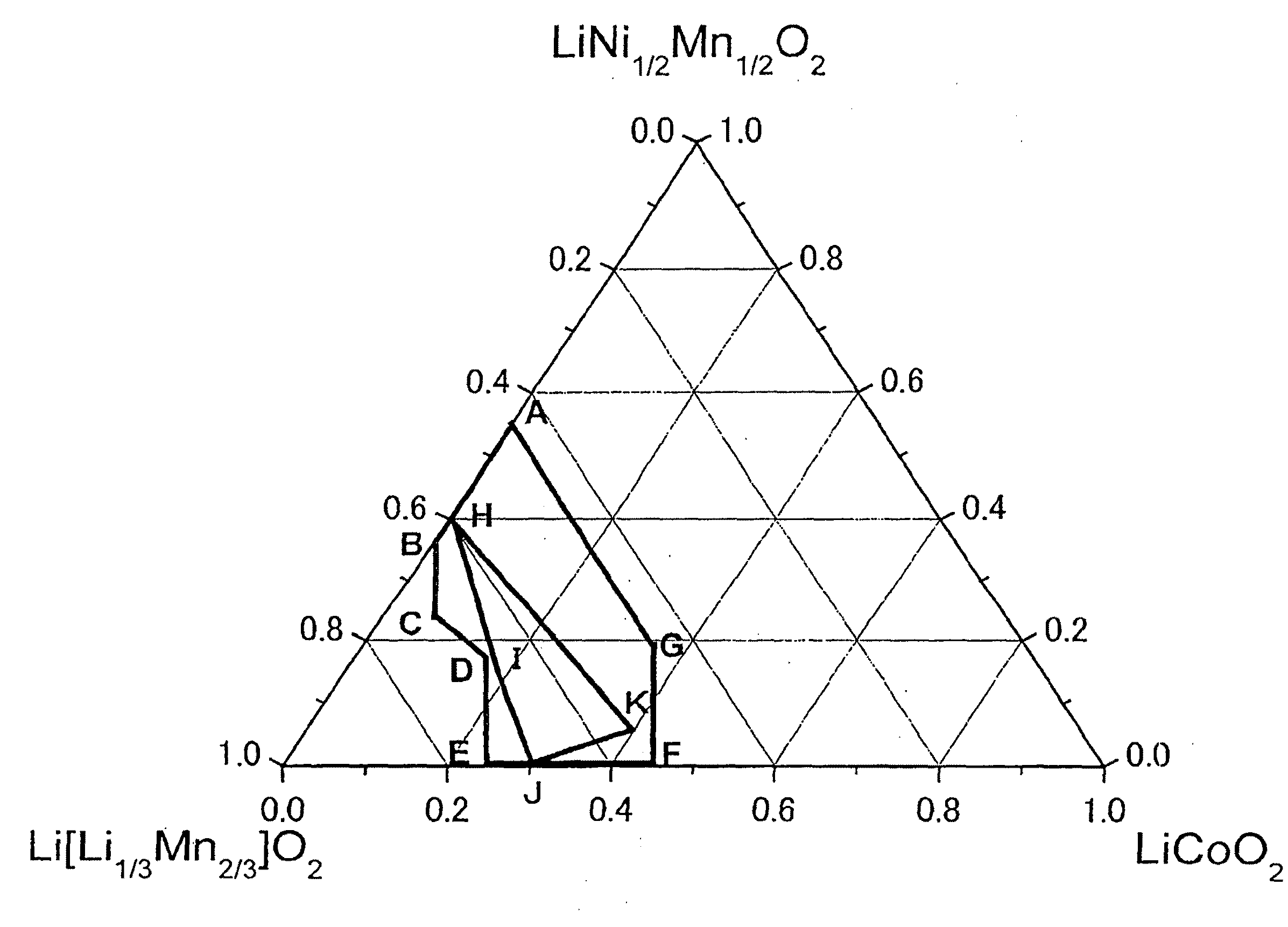

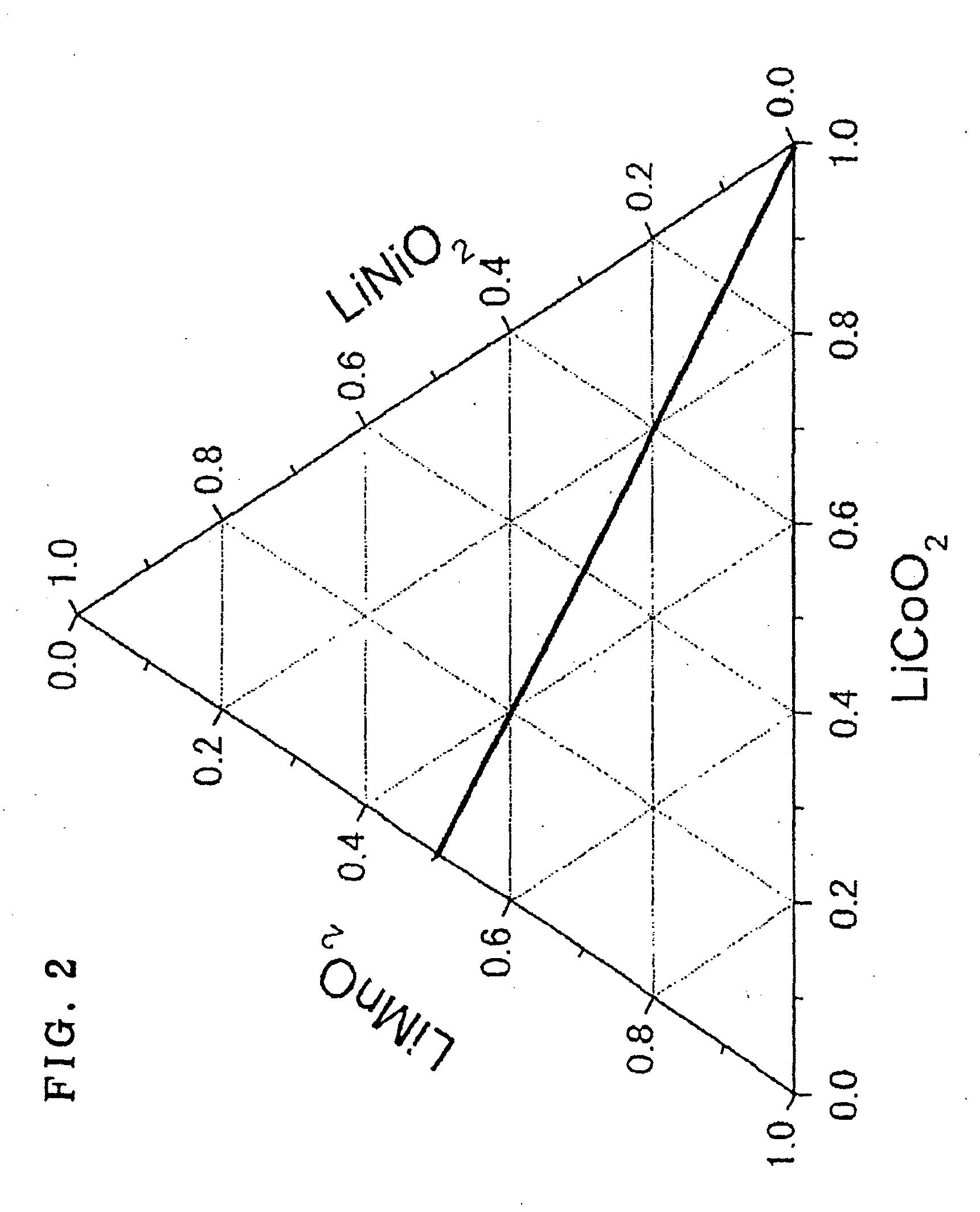

The present invention provides an active material for a lithium secondary battery with a high discharge capacity, particularly for a lithium secondary battery that can increase the discharge capacity in a potential region of 4.3 V or lower, a method for producing the same, a lithium secondary battery having a high discharge capacity, and a method for producing the same. The active material for a lithium secondary battery includes a solid solution of a lithium transition metal composite oxide having an α-NaFeO2 type crystal structure, in which the composition ratio of Li, Co, Ni, and Mn contained in the solid solution satisfies Li1+(1 / 3)xCo1−x−yNi(1 / 2)yMn(2 / 3)x+(1 / 2)y (x+y≦1, 0≦y and 1−x−y=z); in an Li[Li1 / 3Mn2 / 3]O2(x)-LiNi1 / 2Mn1 / 2O2(y)-LiCoO2(z) type ternary phase diagram, (x, y, z) is represented by values in a range present on or within a line of a heptagon (ABCDEFG) defined by the vertexes; point A(0.45, 0.55, 0), point B(0.63, 0.37, 0), point C(0.7, 0.25, 0.05), point D(0.67, 0.18, 0.15), point E(0.75, 0, 0.25), point F(0.55, 0, 0.45), and point G(0.45, 0.2, 0.35); and the intensity ratio between the diffraction peaks on (003) plane and (104) plane measured by X-ray diffractometry before charge-discharge is I(003) / I(104)≧1.56 and at the end of discharge is I(003) / I(104)>1. The invention provides a method for producing the active material for a lithium secondary battery using a coprecipitation method, a lithium secondary battery including a positive electrode containing the active material and a method for producing the lithium secondary battery.

Owner:GS YUASA INT LTD

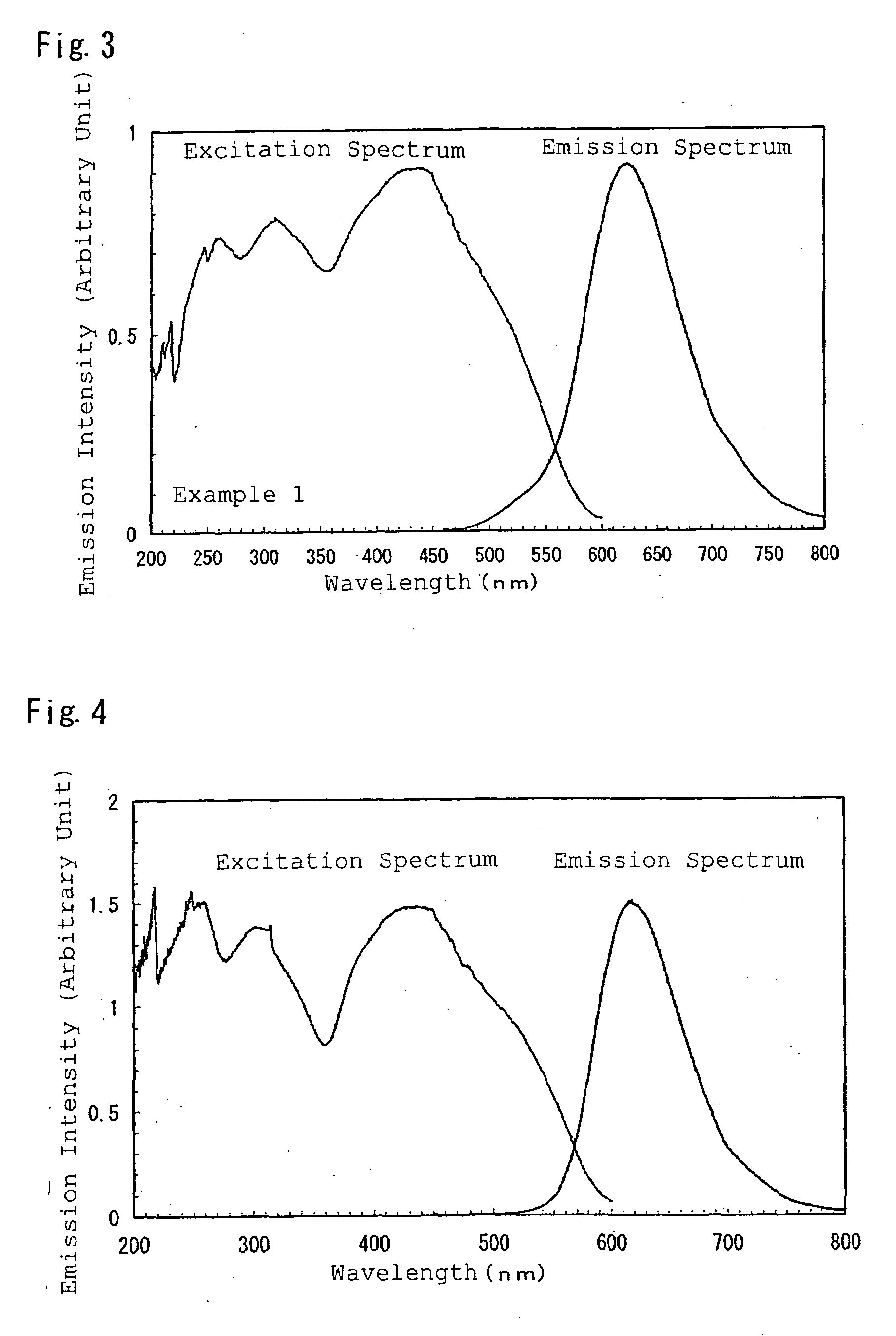

Phosphor, Production Method Thereof and Light Emitting Instrument

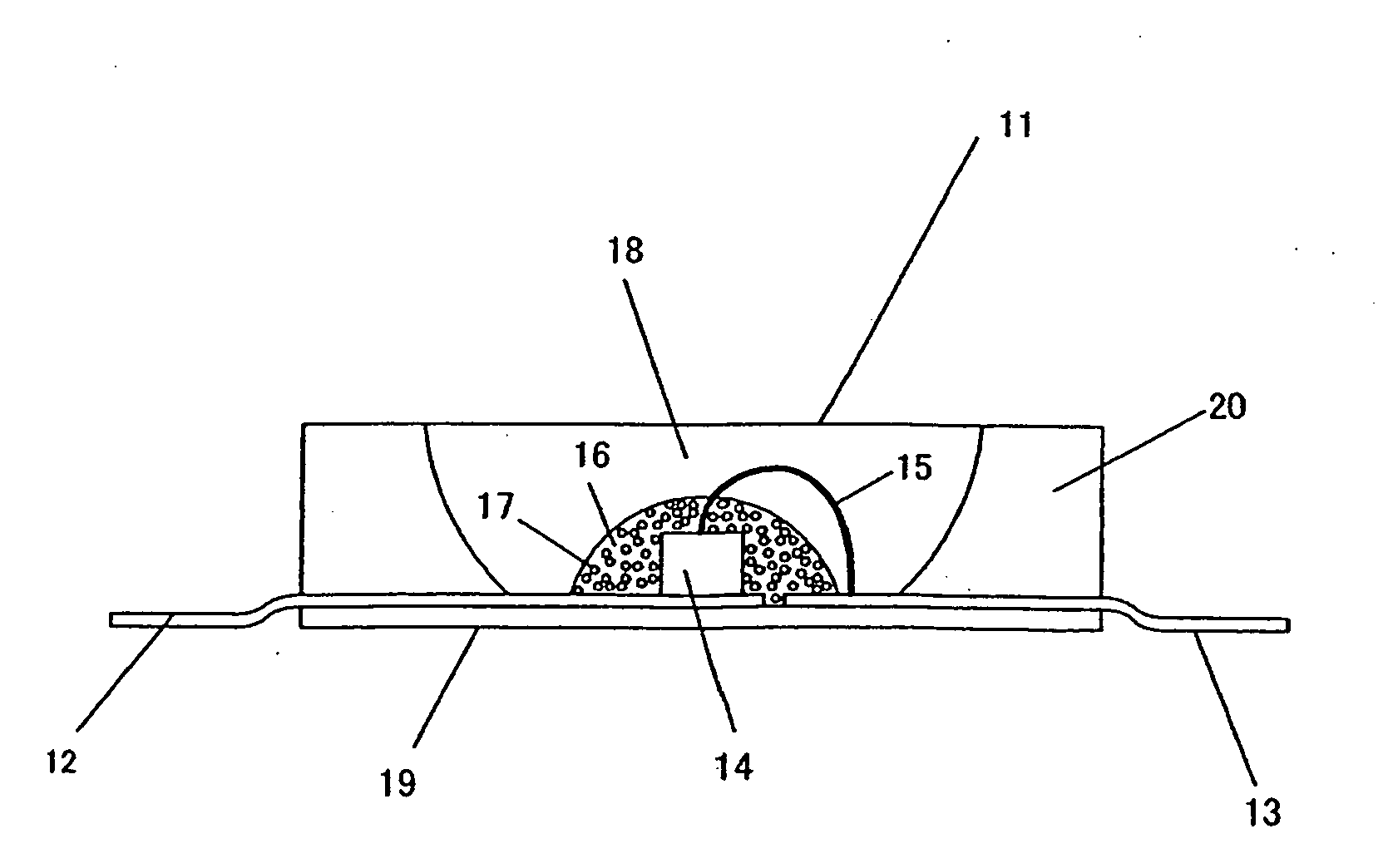

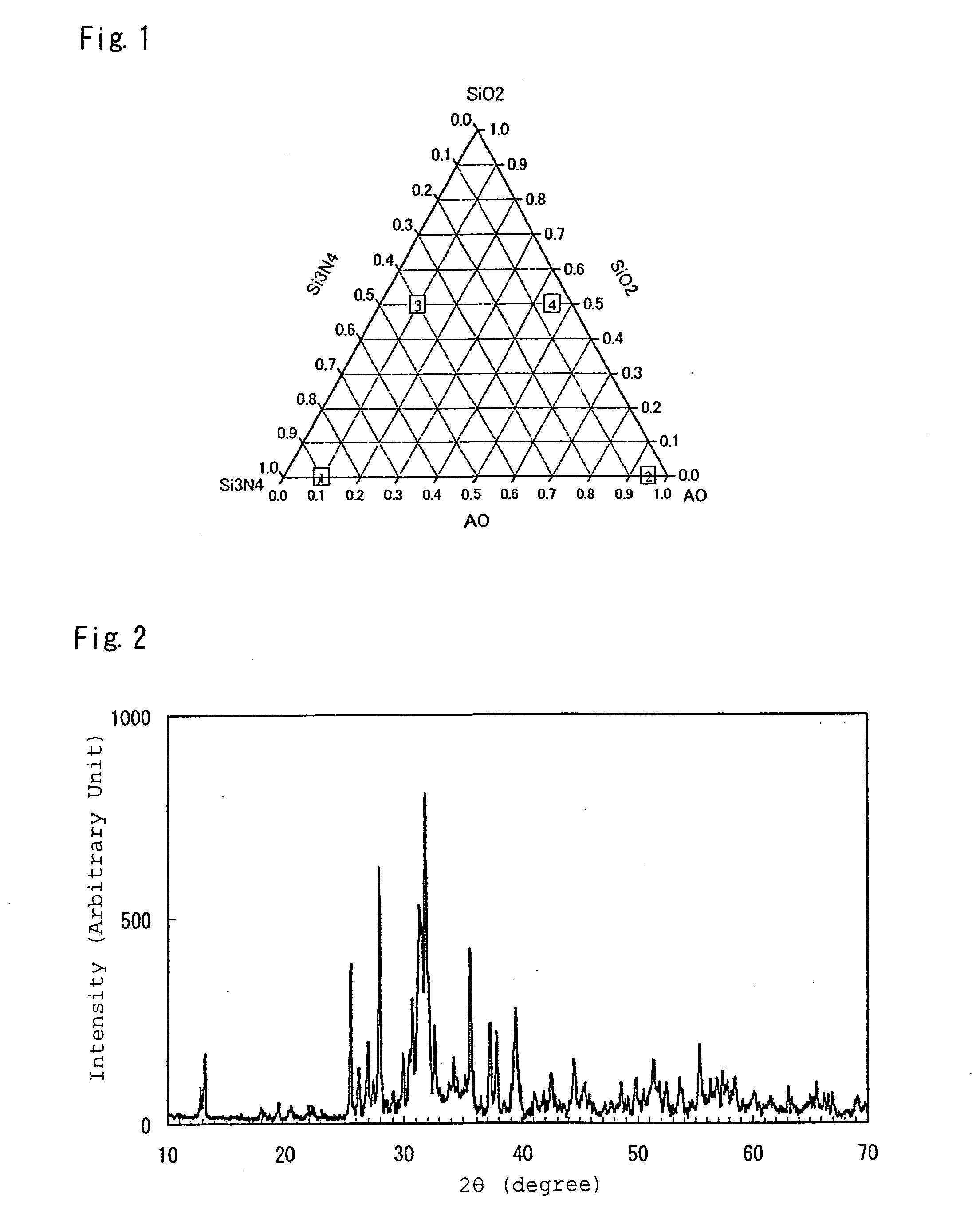

ActiveUS20080143246A1Without luminance deteriorationIncrease production capacityDischarge tube luminescnet screensCathode ray tubes/electron beam tubesAlkaline earth metalRare earth

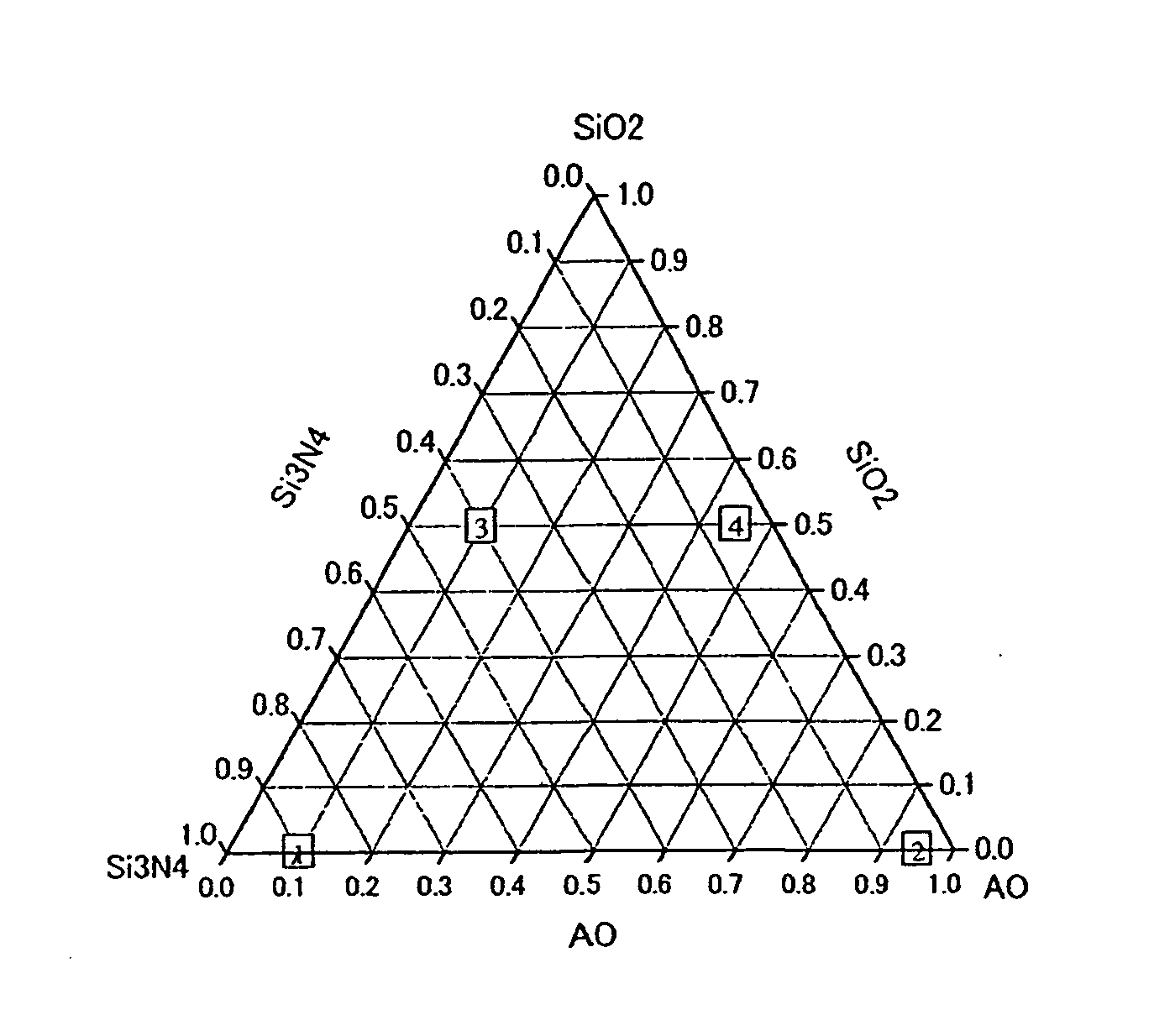

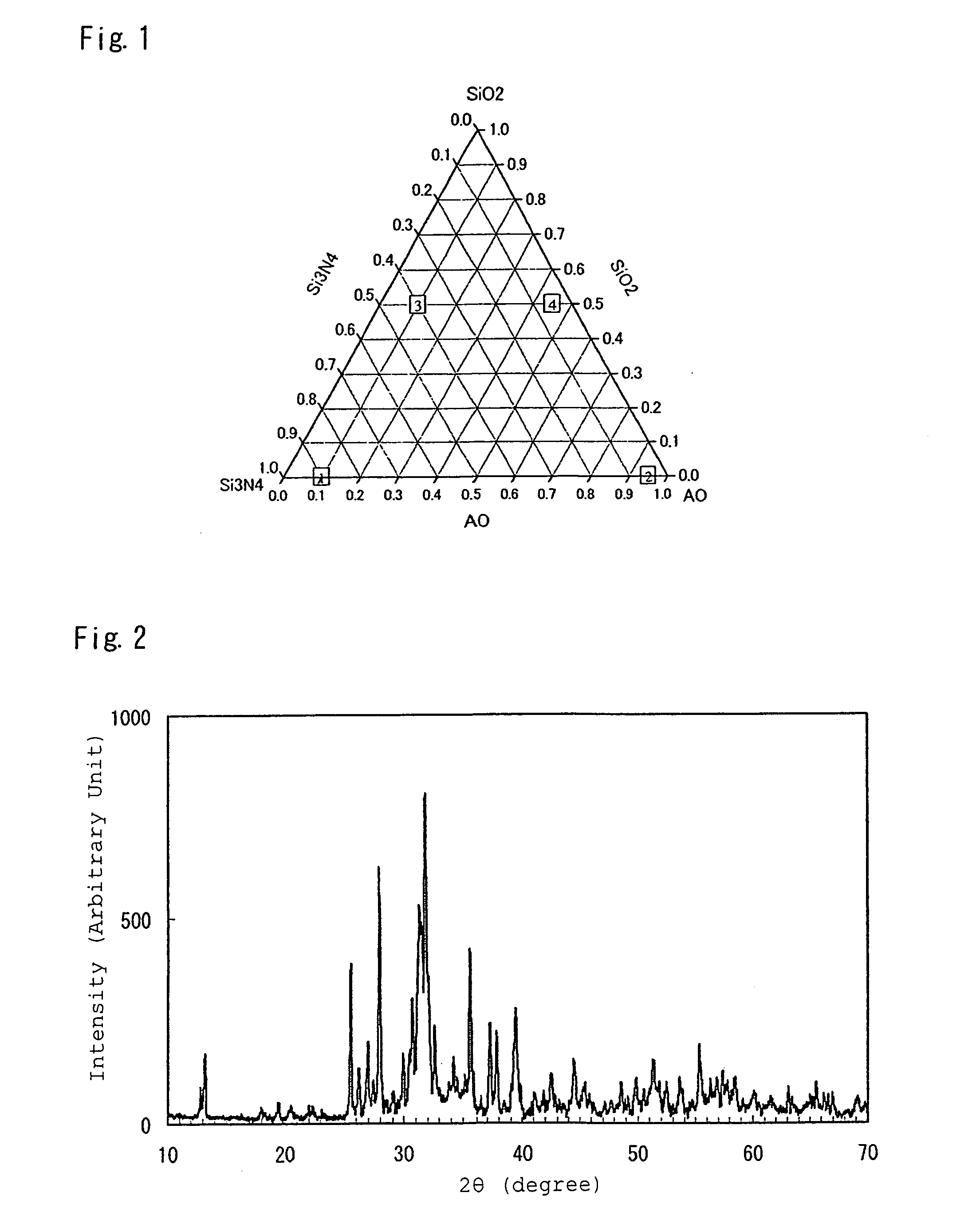

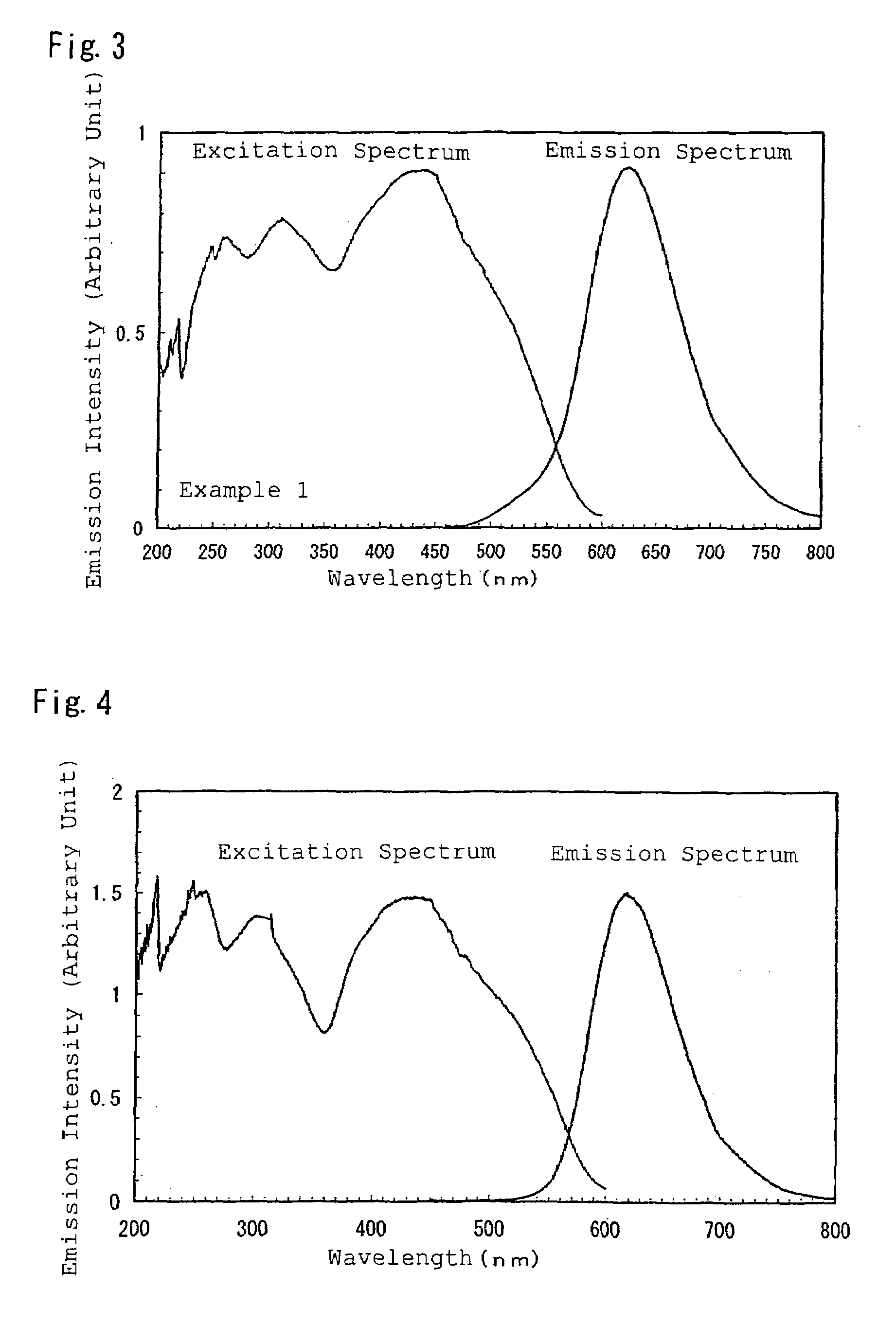

The present invention aims at providing a chemically stabilized inorganic phosphor, among oxynitride phosphors including alkaline earths, which oxynitride phosphor emits orange or red light at longer wavelengths at higher luminance than conventional sialon phosphors activated by rare earths. The present invention further aims at providing a light emitting instrument based on the phosphor, for a lighting instrument excellent in color rendering property and for an image displaying apparatus excellent in durability.The solving means resides in provision of a fundamental phosphor comprising:a composition on a pseudo-ternary phase diagram including AO (A is one kind or two or more kinds of element(s) selected from Mg, Ca, Sr, and Ba; and AO is oxide of A), Si3N4, and SiO2 as end members, respectively, and satisfying all of the following conditions:in a composition formula, pAO-qSi3N4-rSiO2 (p+q+r=1),0.1≦p≦0.95, (1)0.05≦q≦0.9, and (2)0≦r≦0.5, and (3)at least a metallic element M (M is one kind or two or more kinds of element(s) selected from Mn, Ce, Nd, Sm, Eu, Tb, Dy, Ho, Er, Tm, and Yb) dissolved, in a solid state, in the composition.

Owner:NAT INST FOR MATERIALS SCI

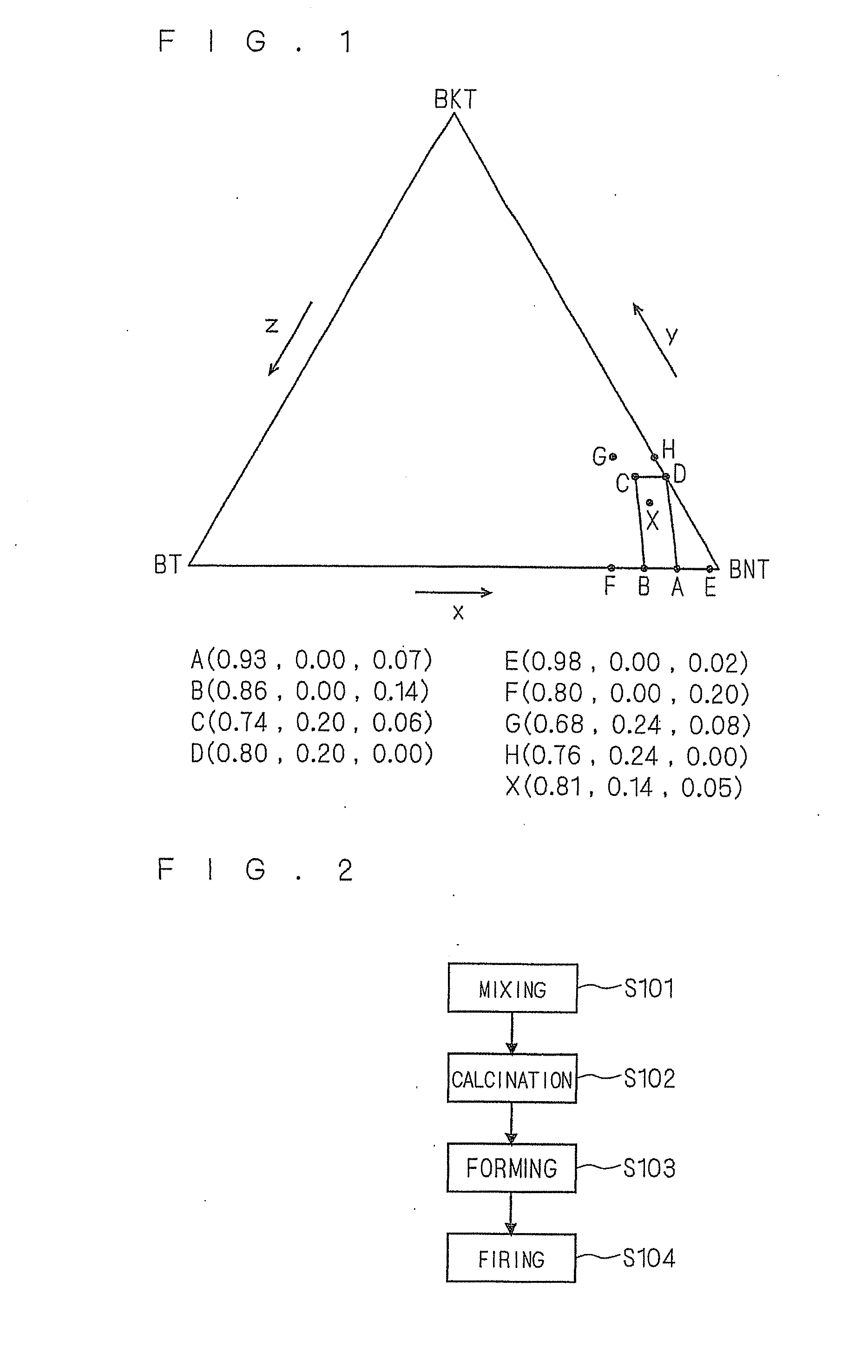

Piezoelectric/electrostrictive ceramics composition, piezoelectric/electrostrictive ceramics sintered body, piezoelectric/electrostrictive element, manufacturing method of piezoelectric/electrostrictive ceramics composition, and manufacturing method of piezoelectric/electrostrictive element

ActiveUS20100123370A1Large electric field-induced strainLarge displacementPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksBorder lineCeramic

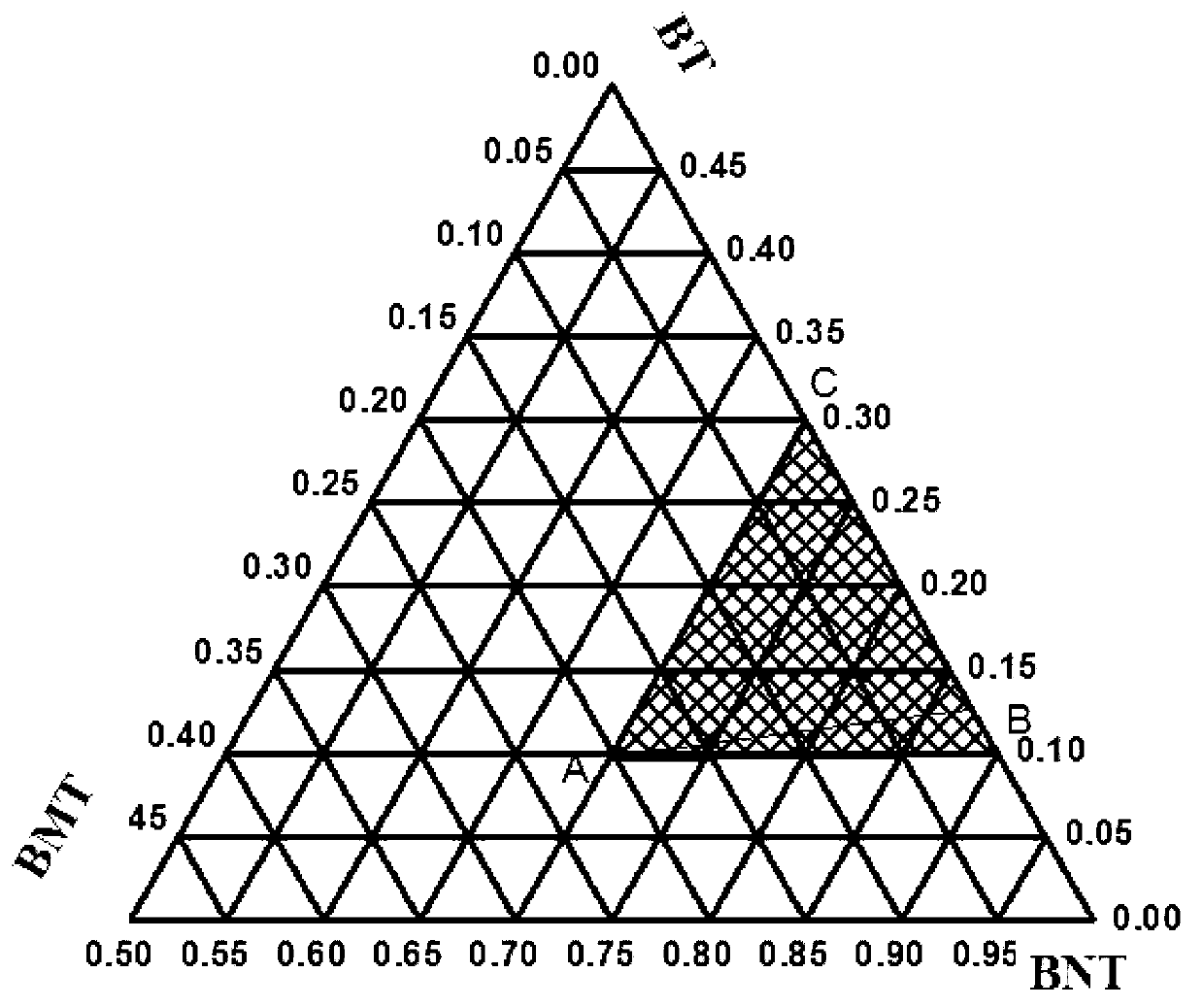

[Object] To provide piezoelectric / electrostrictive ceramics and a piezoelectric / electrostrictive element with a large electric field-induced strain without performing an aging treatment.[Solving Means] Piezoelectric / electrostrictive ceramics have the composition represented by the general formula: xBNT-yBKT-zBT (x+y+z=1) wherein at least one kind among A-site elements are allowed to become deficient from stoichiometry in which a point (x, y, z) representing content ratios x, y and z of (Bi1 / 2Na1 / 2)TiO3, (Bi1 / 2K1 / 2)TiO3 and BaTiO3 is within a range (also including a border line) of a quadrangle ABCD with a point A, a point B, a point C and a point D as vertices in a ternary phase diagram. Vacancies are formed in an A-site of a perovskite structure by allowing the A-site elements to become deficient from stoichiometry. An amount of A-site vacancies becomes at least 2 mol % to at most 6 mol %.

Owner:NGK INSULATORS LTD +1

Phosphor, production method thereof and light emitting instrument

ActiveUS7540977B2Increase production capacityGood chemical stabilityGas-filled discharge tubesDischarge tube luminescnet screensAlkaline earth metalRare earth

The present invention aims at providing a chemically stabilized inorganic phosphor, among oxynitride phosphors including alkaline earths, which oxynitride phosphor emits orange or red light at longer wavelengths at higher luminance than conventional sialon phosphors activated by rare earths. The present invention further aims at providing a light emitting instrument based on the phosphor, for a lighting instrument excellent in color rendering property and for an image displaying apparatus excellent in durability.The solving means resides in provision of a fundamental phosphor comprising:a composition on a pseudo-ternary phase diagram including AO (A is one kind or two or more kinds of element(s) selected from Mg, Ca, Sr, and Ba; and AO is oxide of A), Si3N4, and SiO2 as end members, respectively, and satisfying all of the following conditions:in a composition formula, pAO-qSi3N4-rSiO2(p+q+r=1),0.1≦p≦0.95 (1),0.05≦q≦0.9 (2), and0≦r≦0.5 (3), andat least a metallic element M (M is one kind or two or more kinds of element(s) selected from Mn, Ce, Nd, Sm, Eu, Tb, Dy, Ho, Er, Tm, and Yb) dissolved, in a solid state, in the composition.

Owner:NAT INST FOR MATERIALS SCI

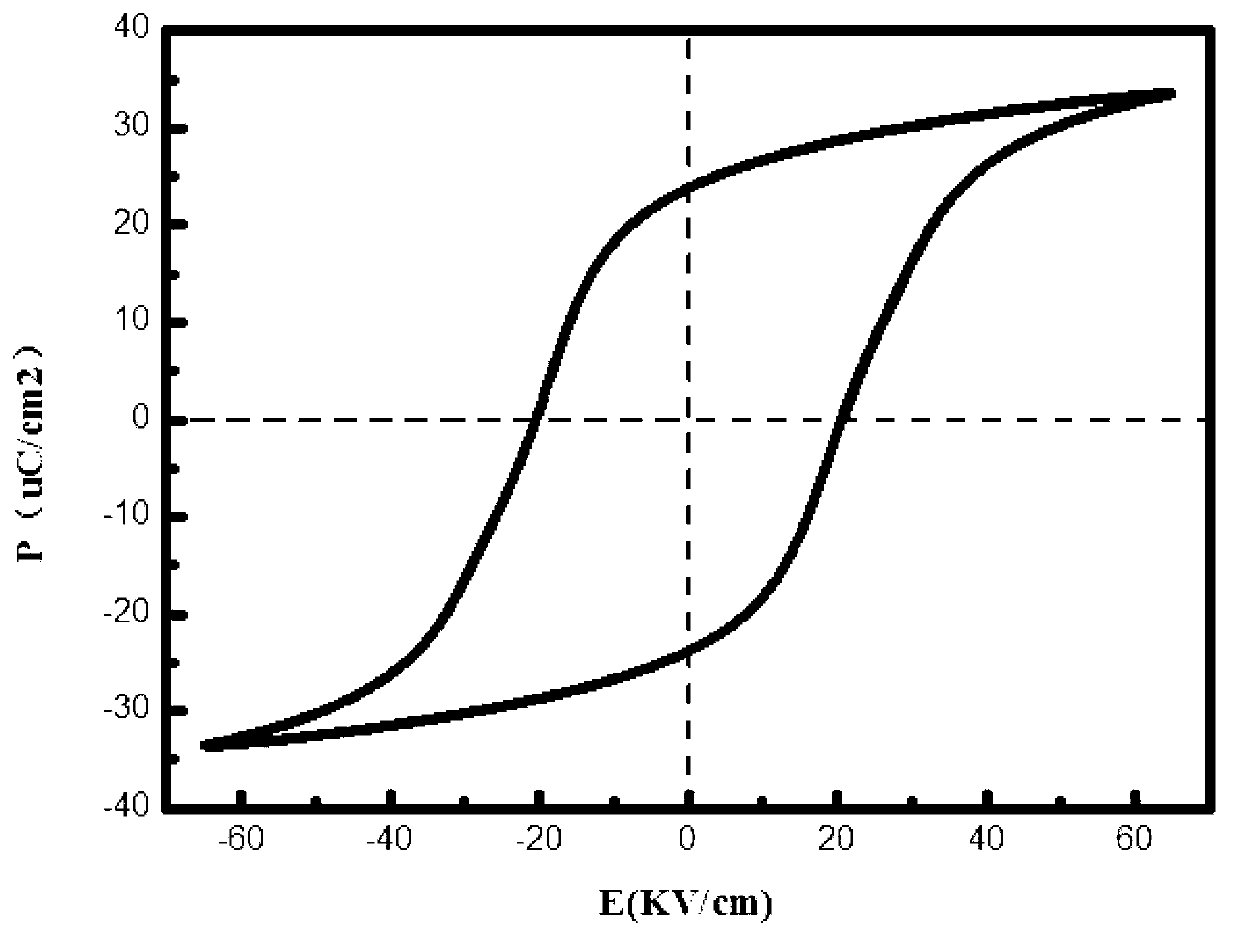

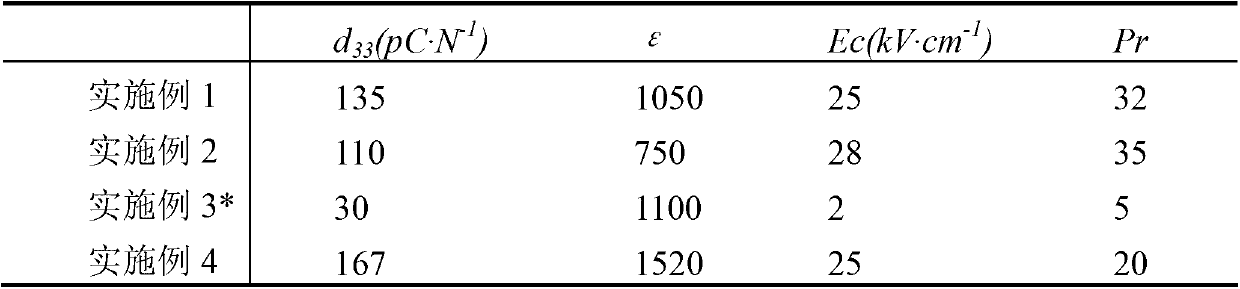

Bi0.5Na0.5TiO3-BaTiO3-BiMg0.5Ti0.5O3 lead-free piezoelectric ceramic material

The invention provides a Bi0.5Na0.5TiO3-BaTiO3-BiMg0.5Ti0.5O3 lead-free piezoelectric ceramic material, relates to a multicomponent system lead-free piezoelectric ceramic compound and belongs to the perovskite structure piezoelectric ceramic field. The composition provided by the invention can be expressed by a general formula of xBi0.5Na0.5TiO3-yBaTiO3-zBiMg0.5Ti0.5O3, wherein the numeric area of x, y and z is indicated by the shadow area of a ternary phase diagram (the area comprises the boundary line). The lead-free piezoelectric ceramic composition further contains oxide Bi2O3; and the content of oxide Bi2O3 is 1% of the content of Bi ions in the composition. The coercive field of the system changes with the three-component system components between 20kV / cm and 40 kV / cm; the piezoelectric coefficient d33 and the electromechanical coupling coefficient Kp are increased with the increase of the value of y in the polarizable component range; d33 is unequal from 100pC / N to 170 pC / N, while Kp is from 0.1 to 0.3. Besides, the depolarization temperature of the ceramics is slightly reduced between 80 DEG C and 120 DEG C with the increase of y.

Owner:BEIJING UNIV OF TECH

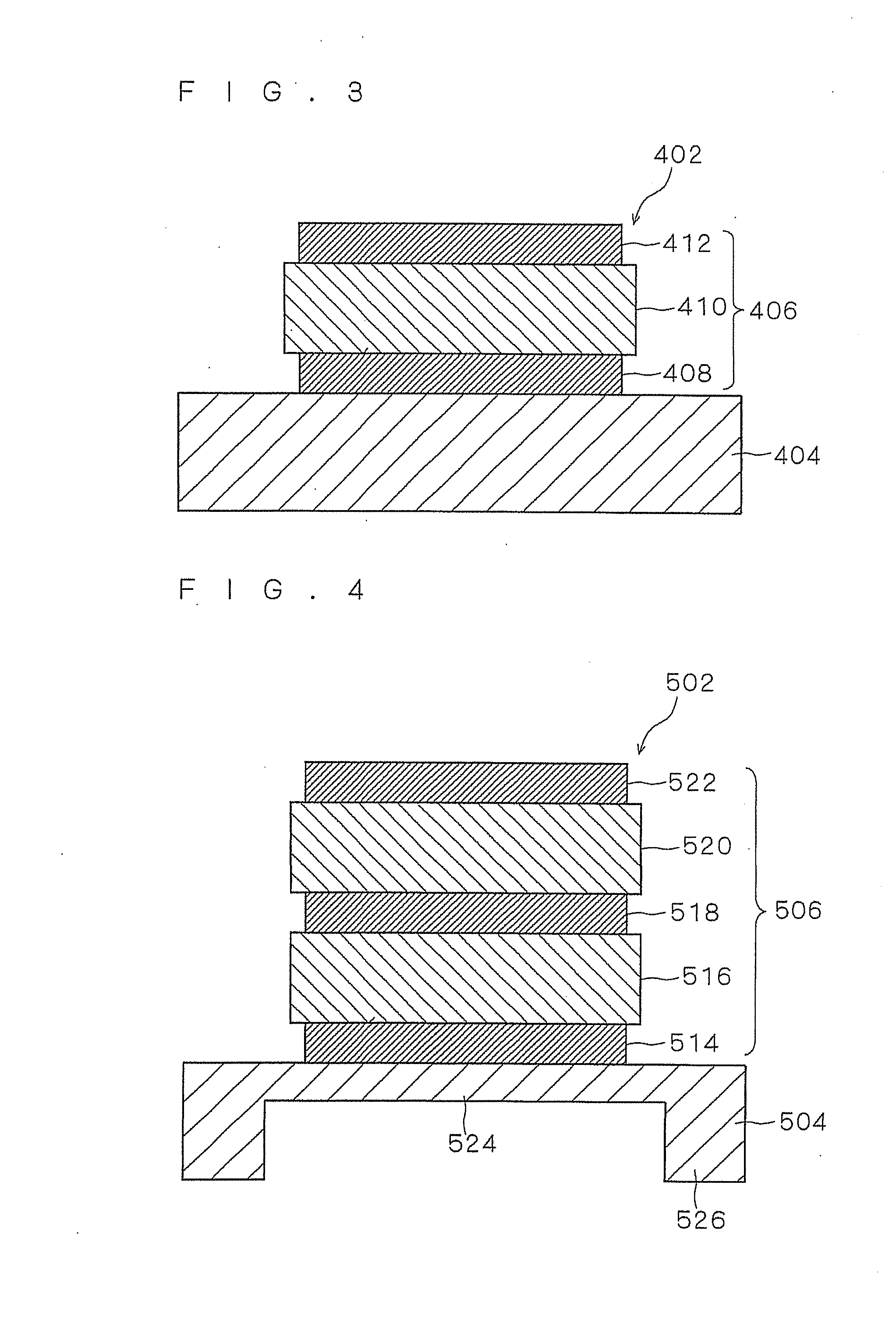

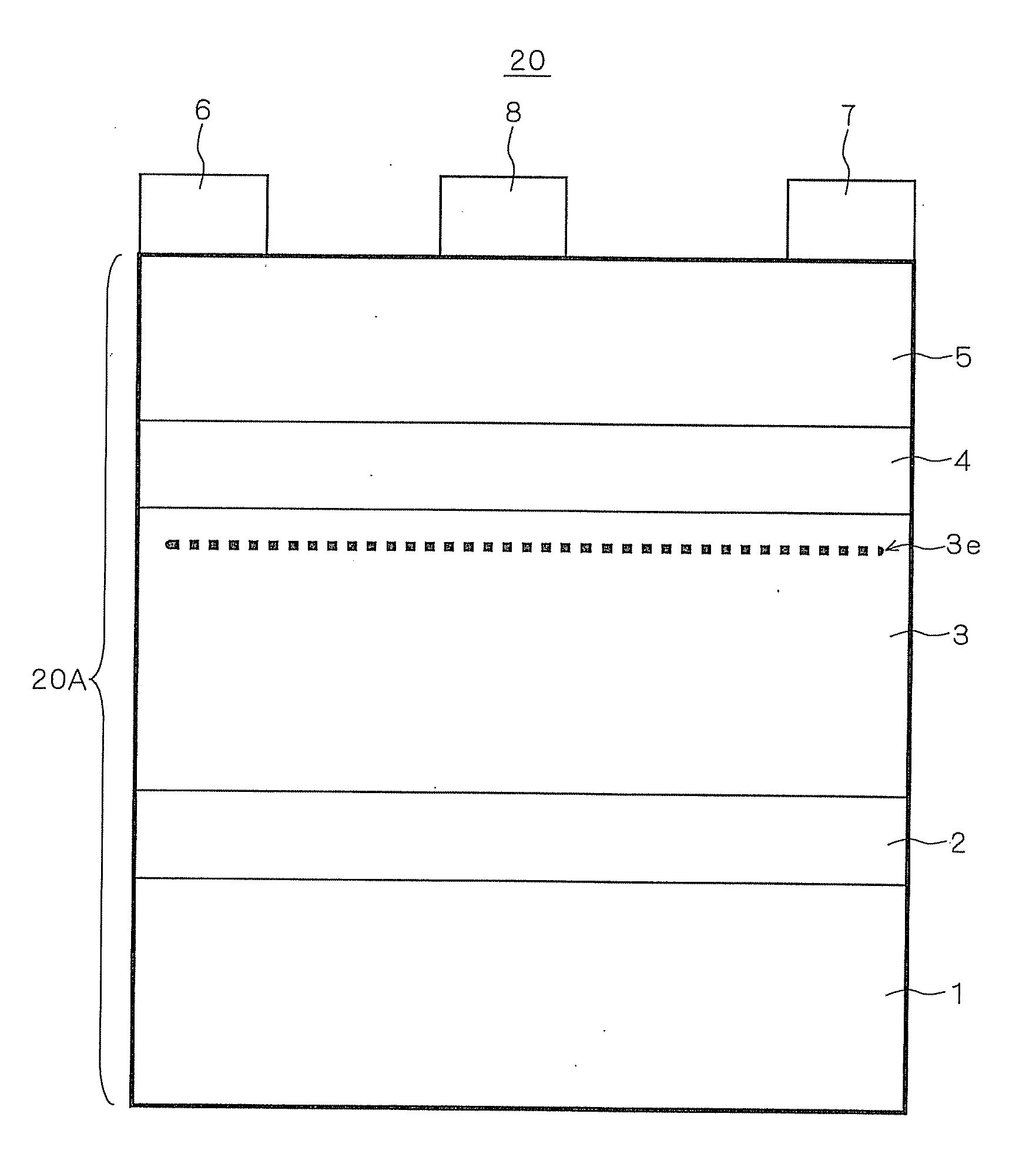

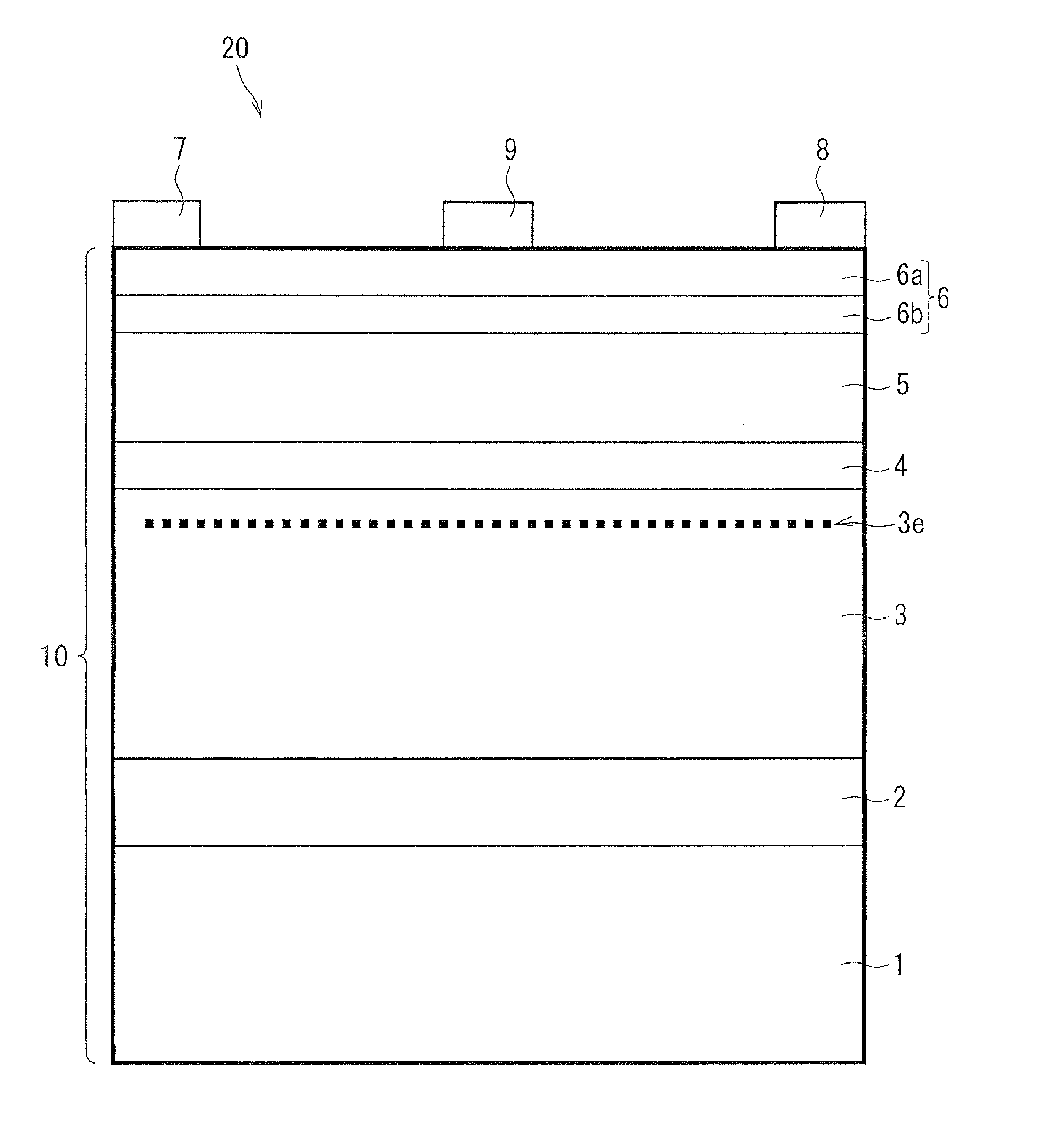

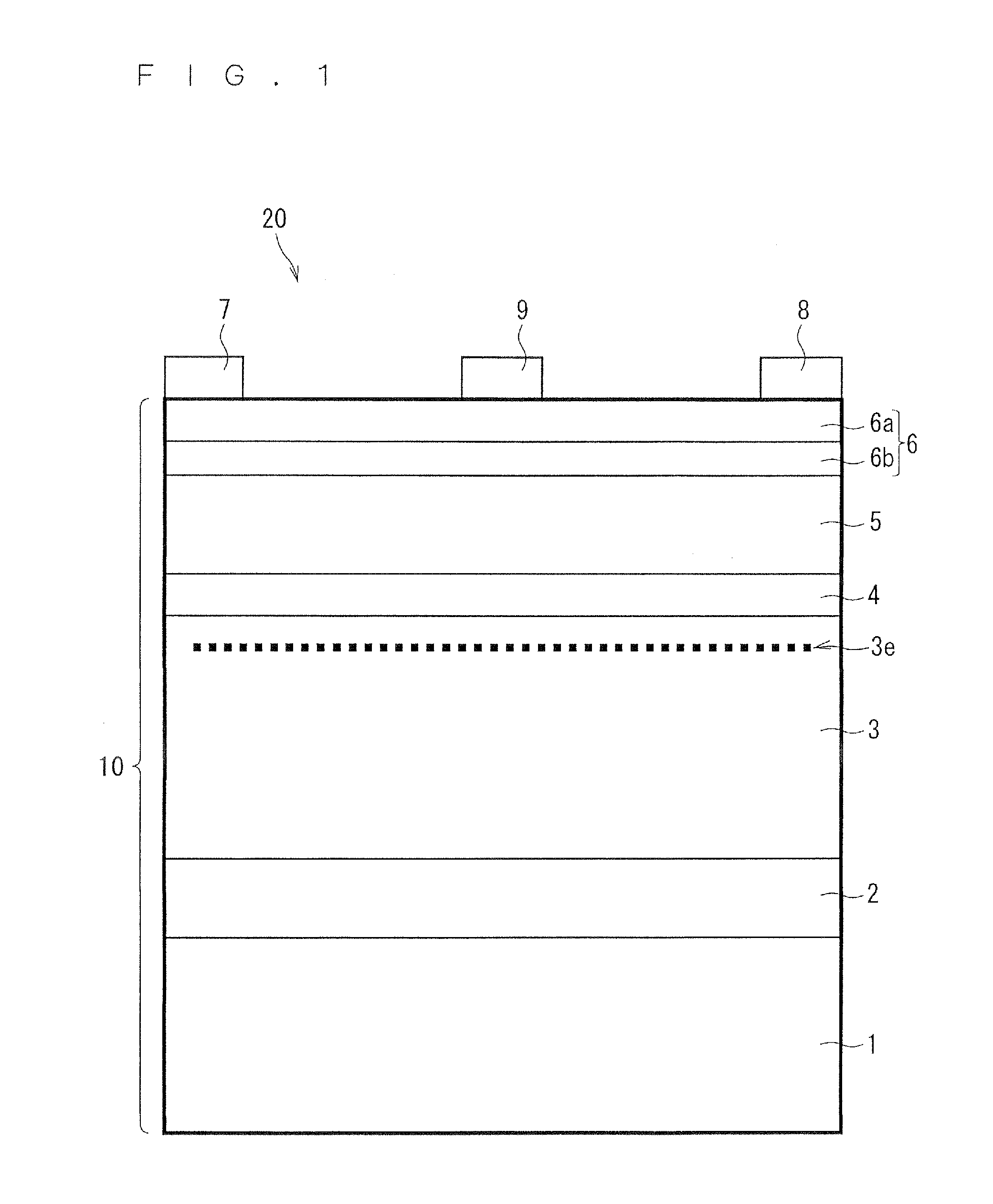

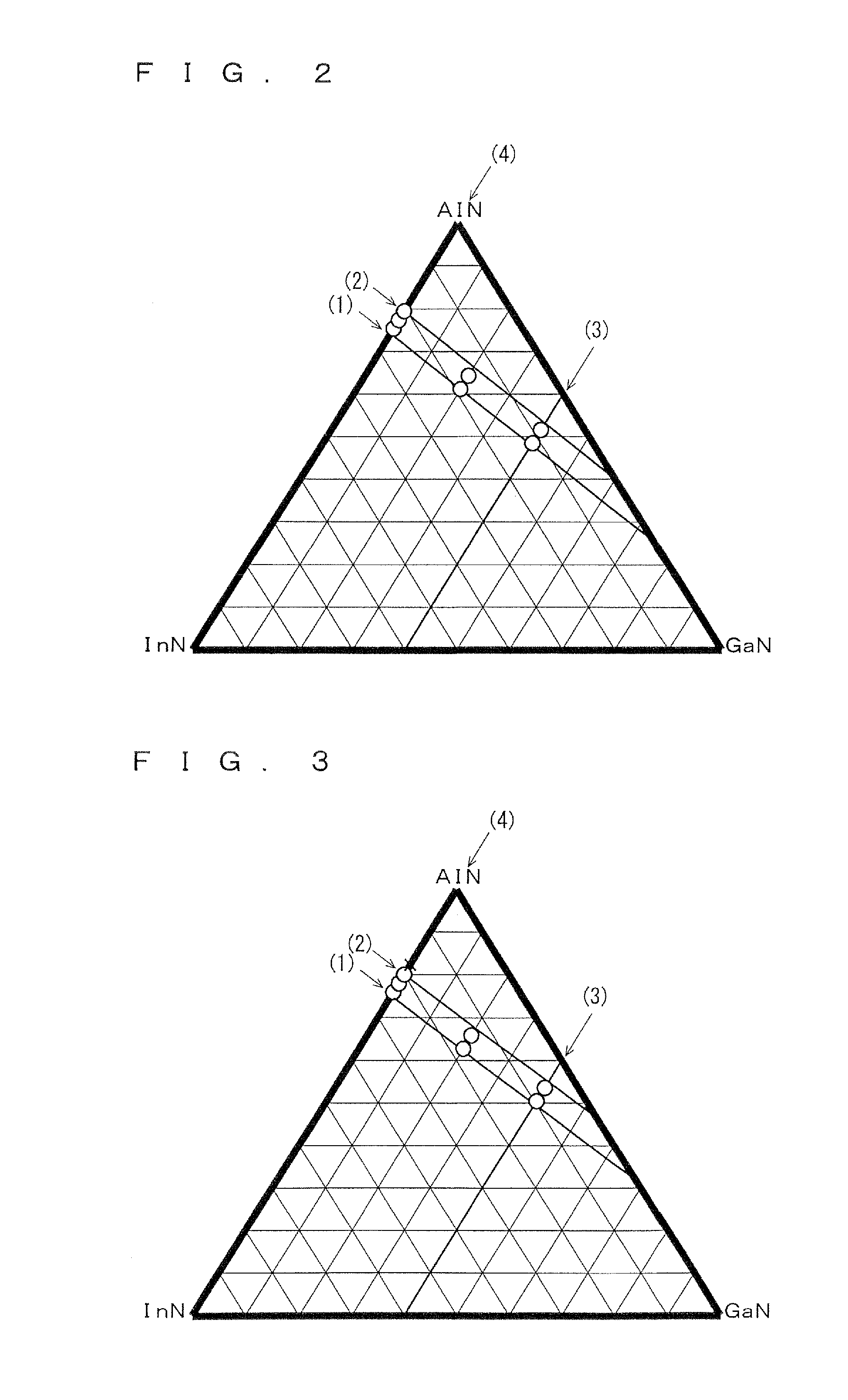

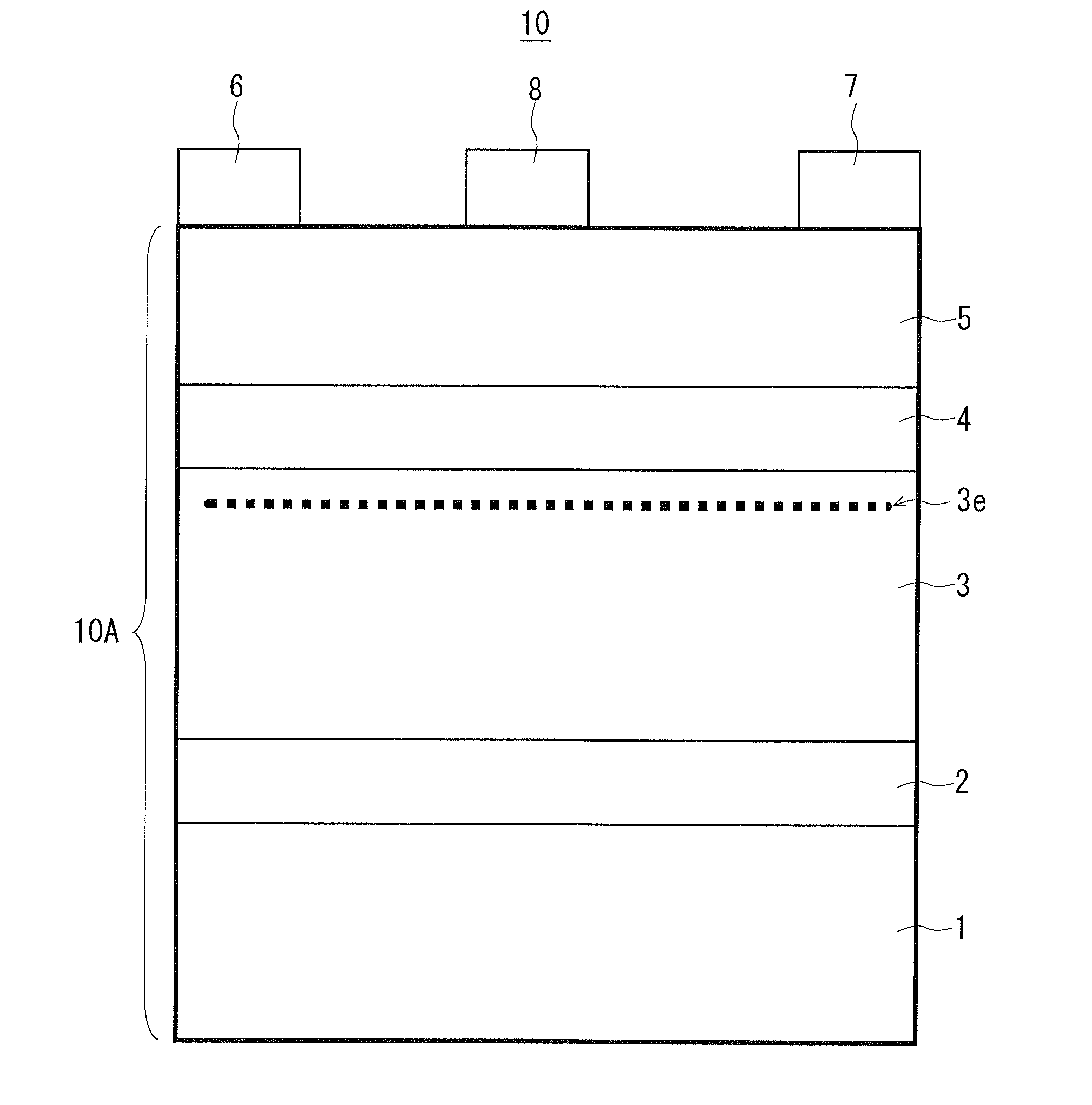

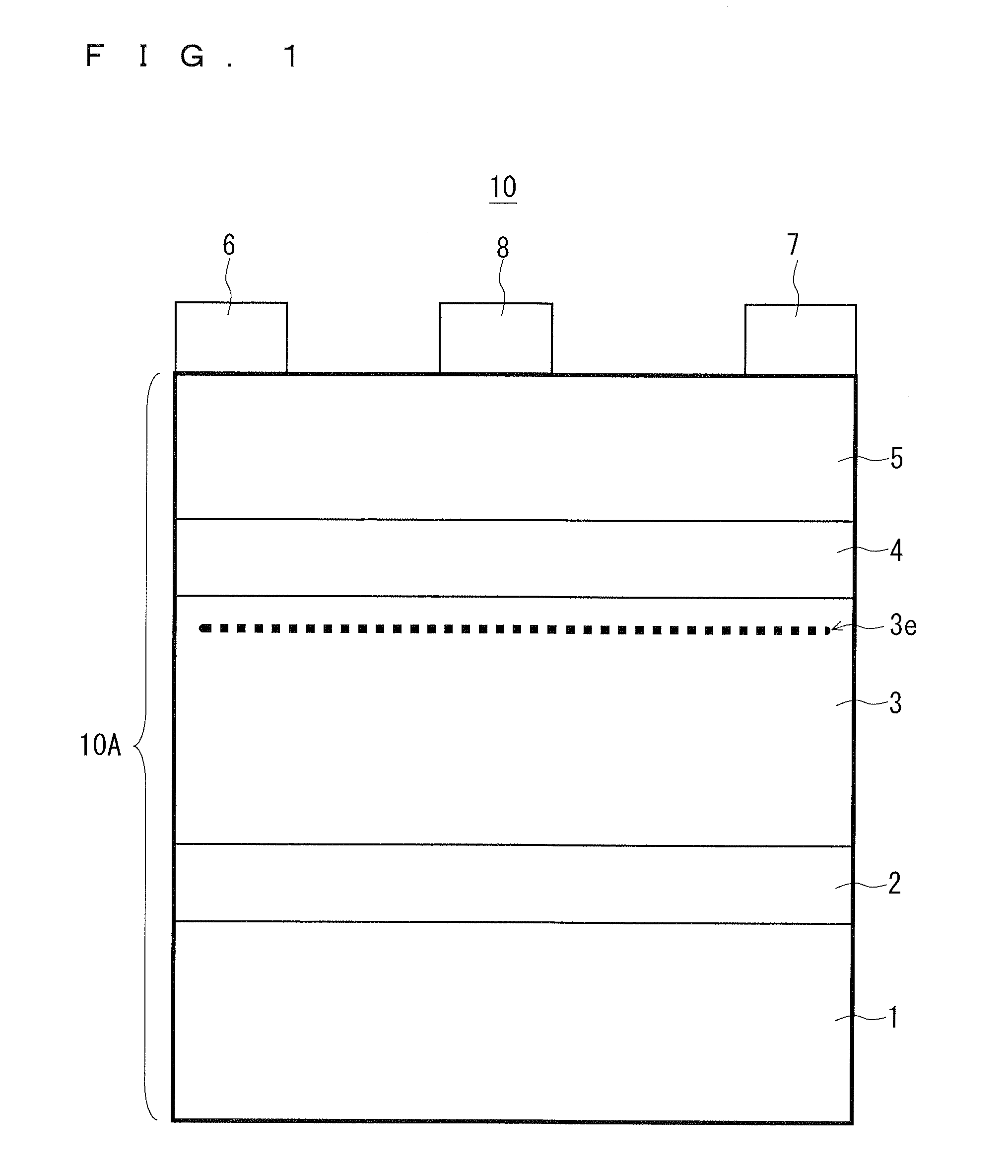

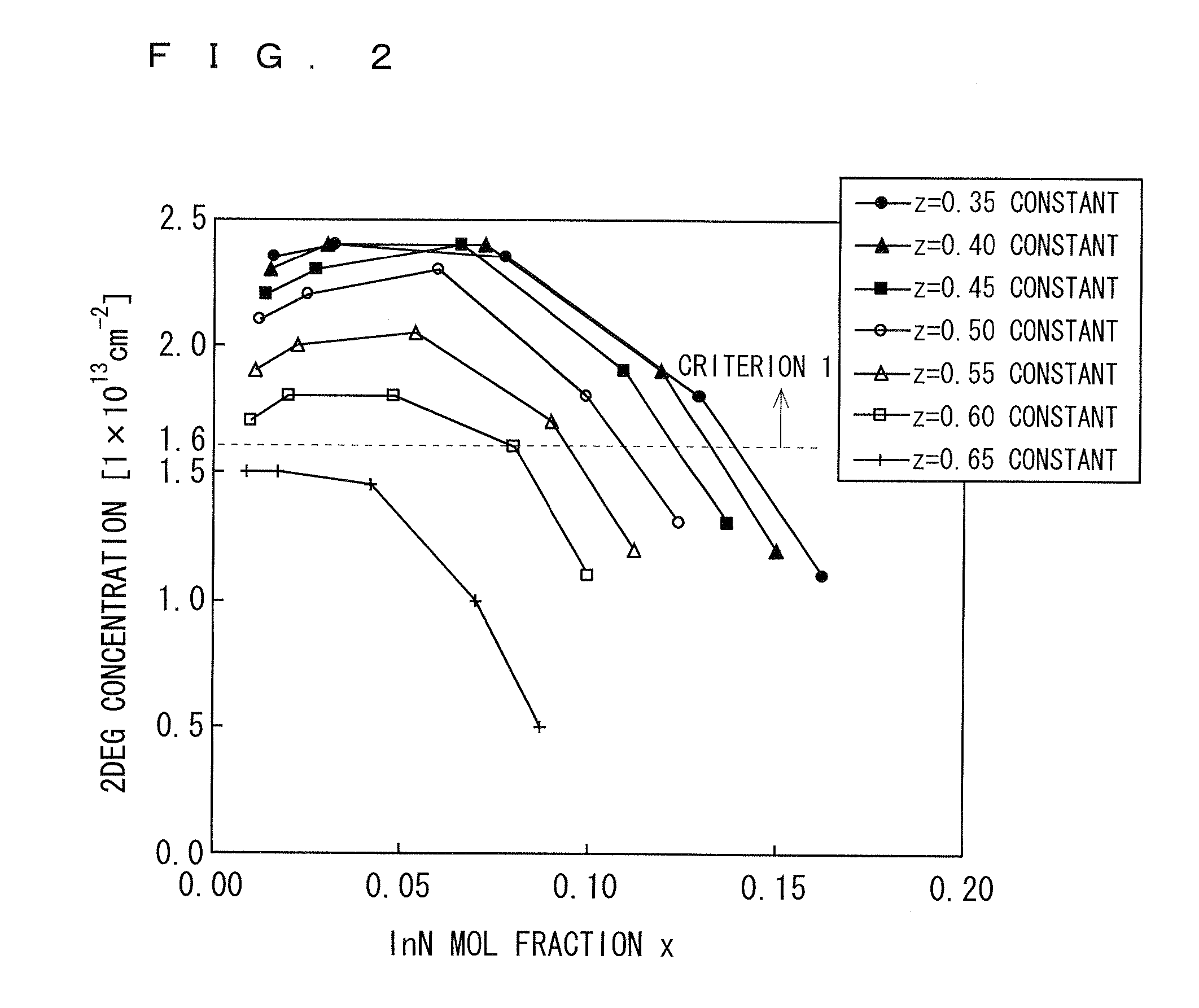

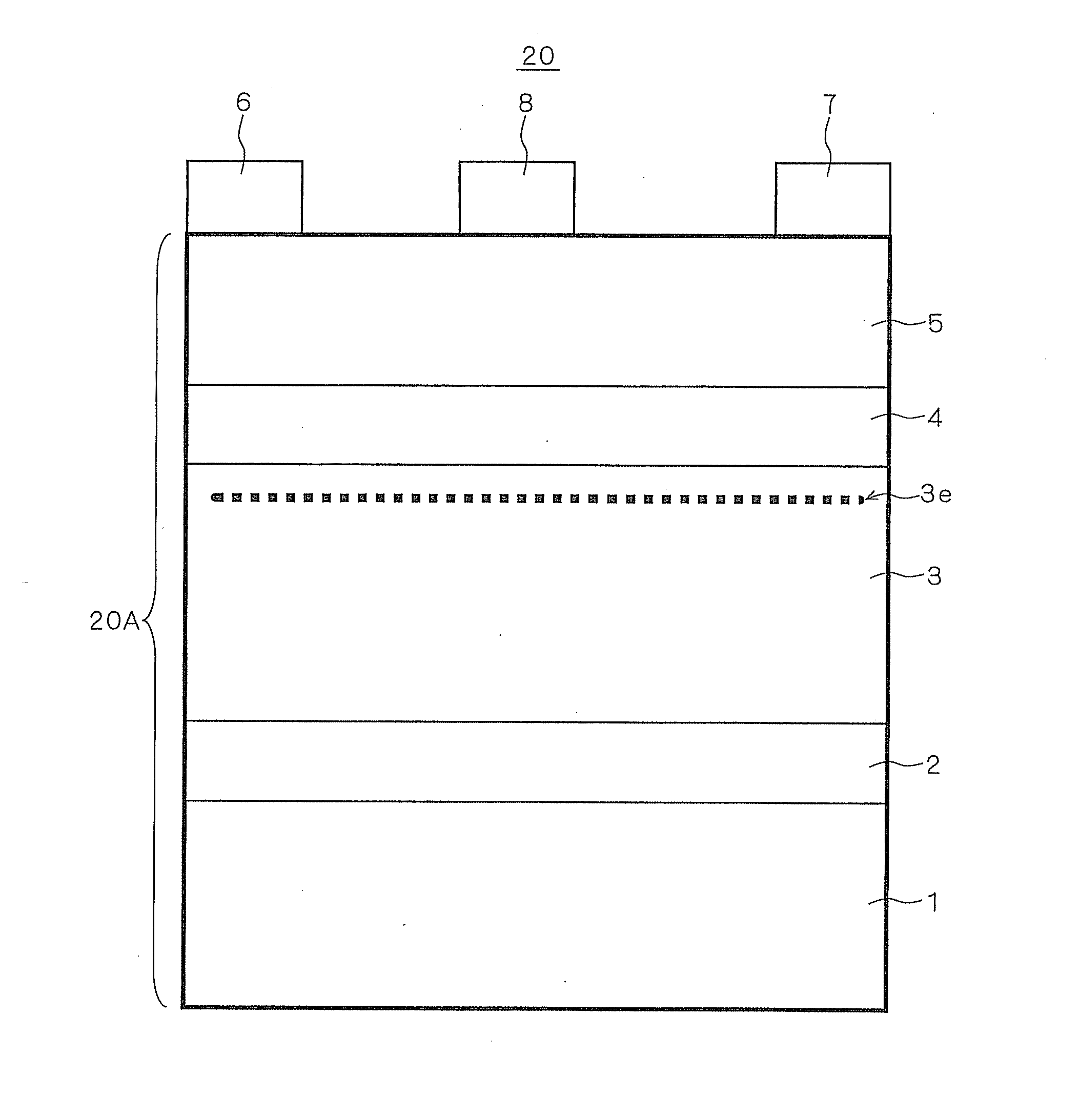

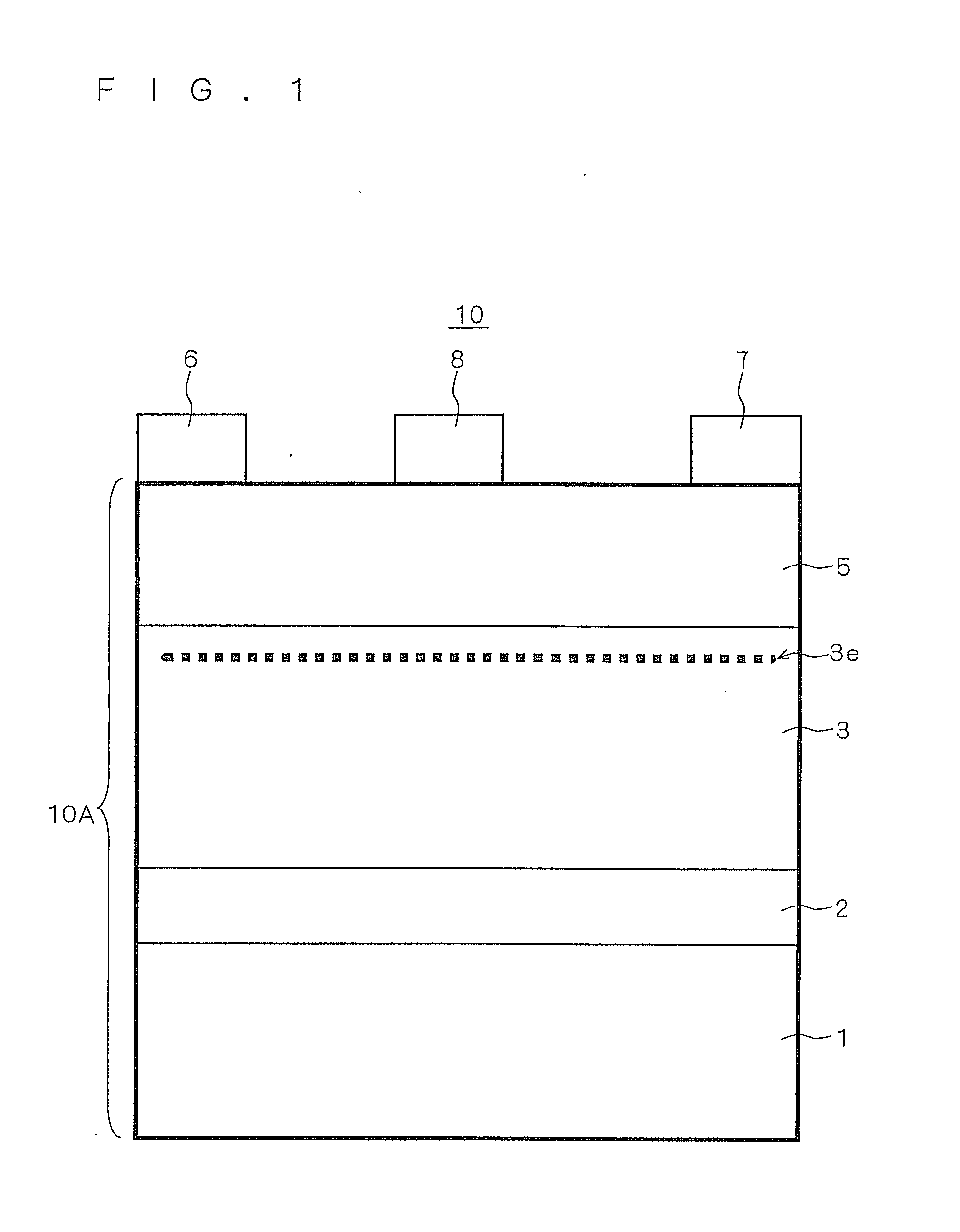

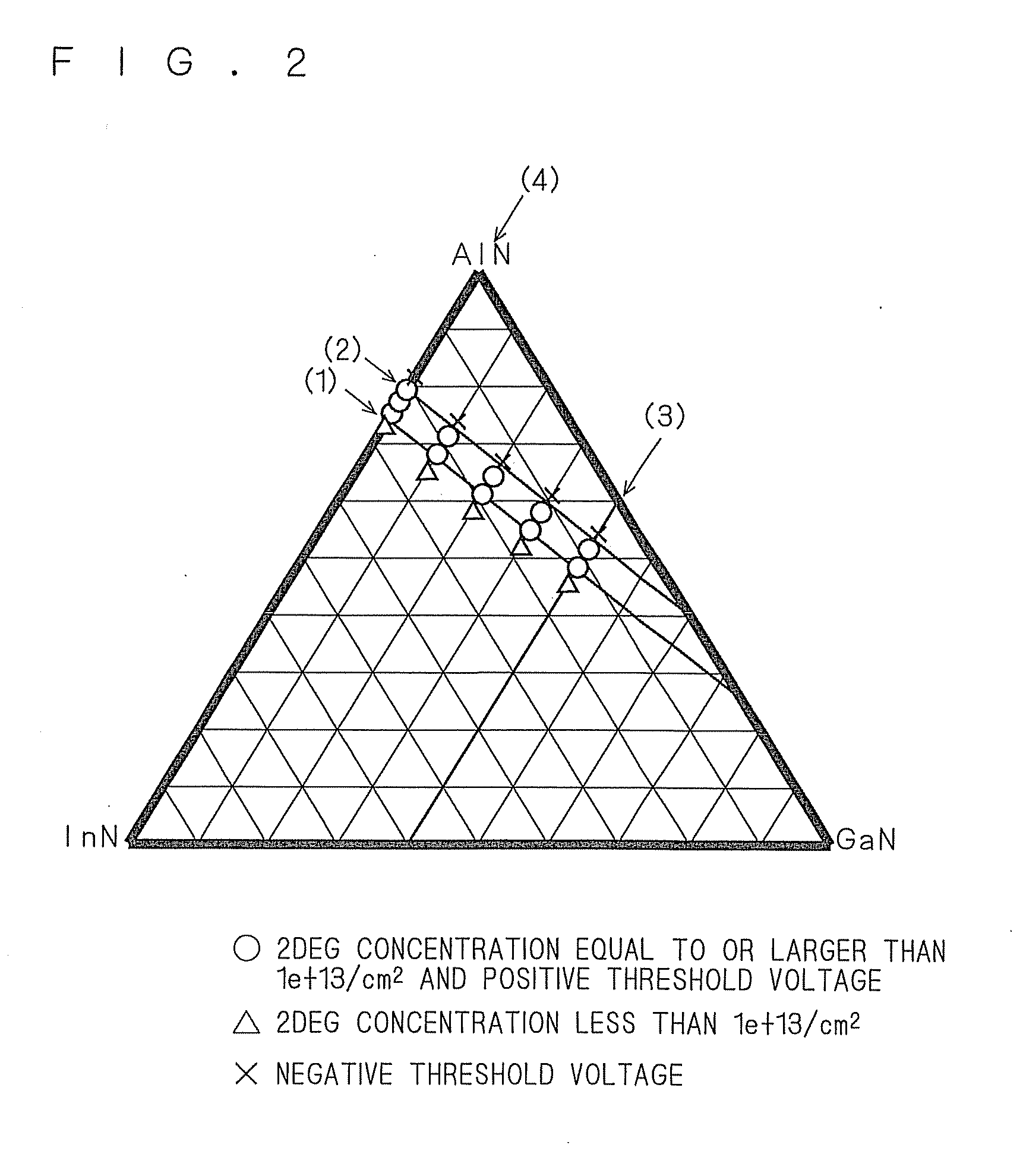

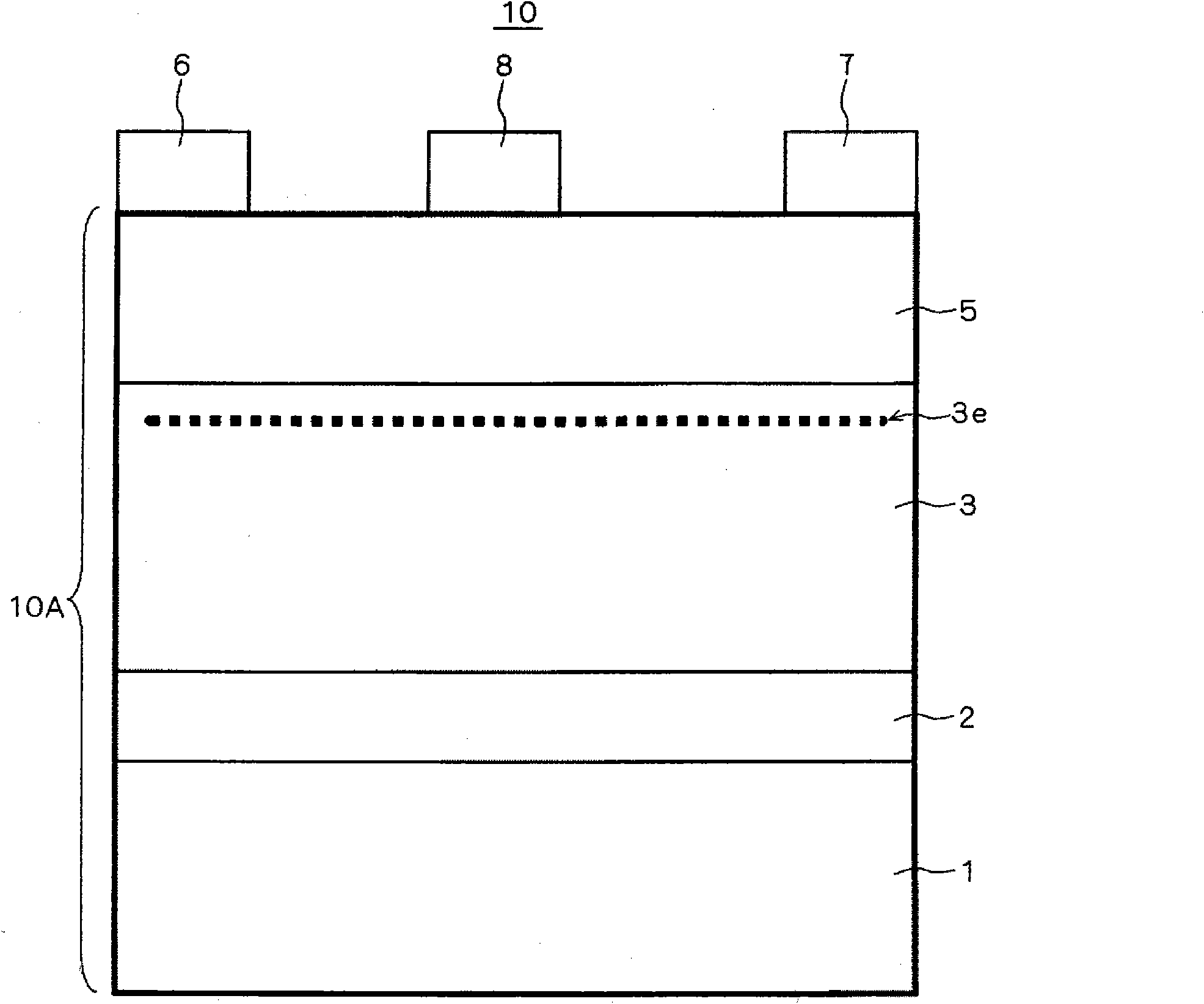

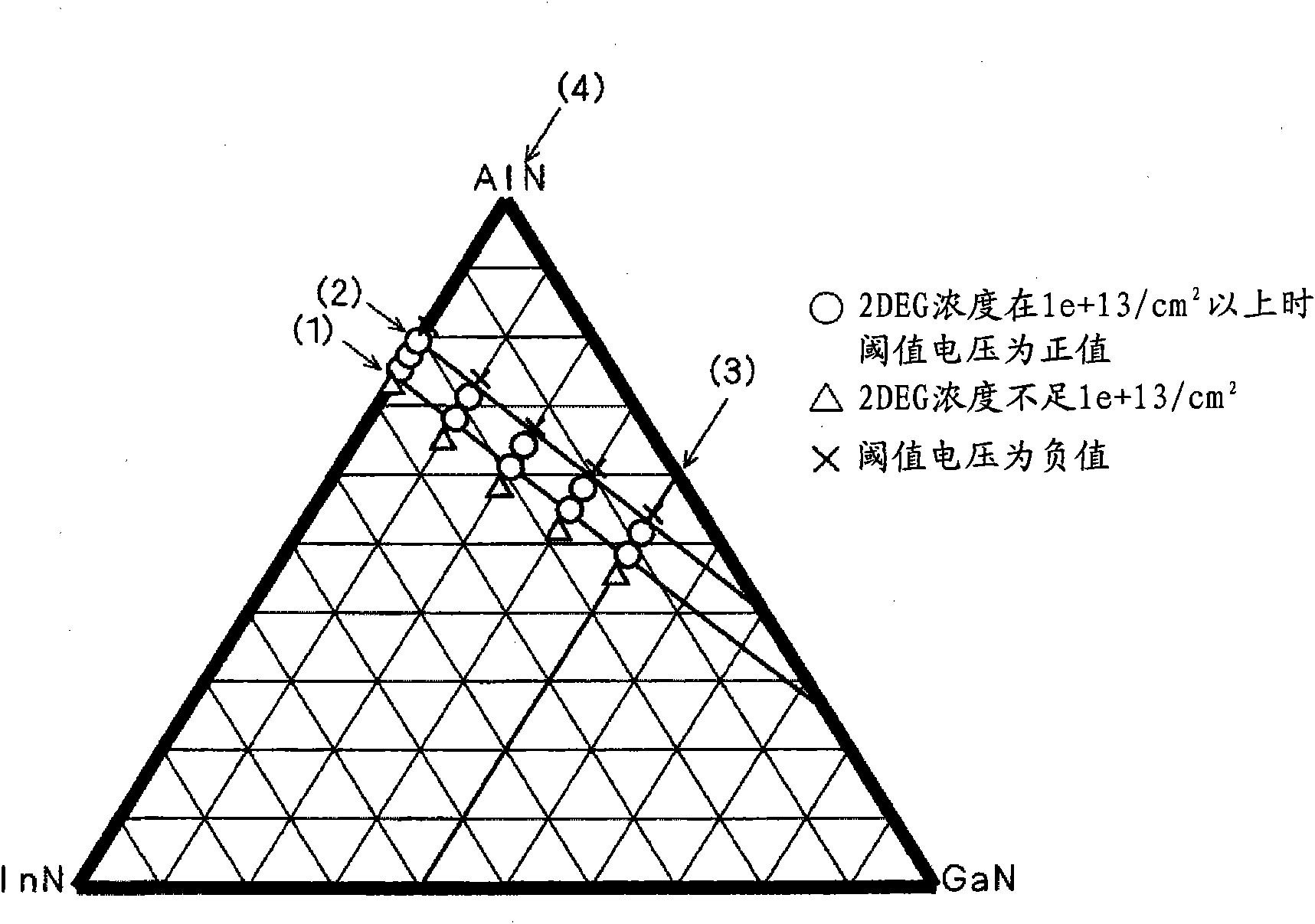

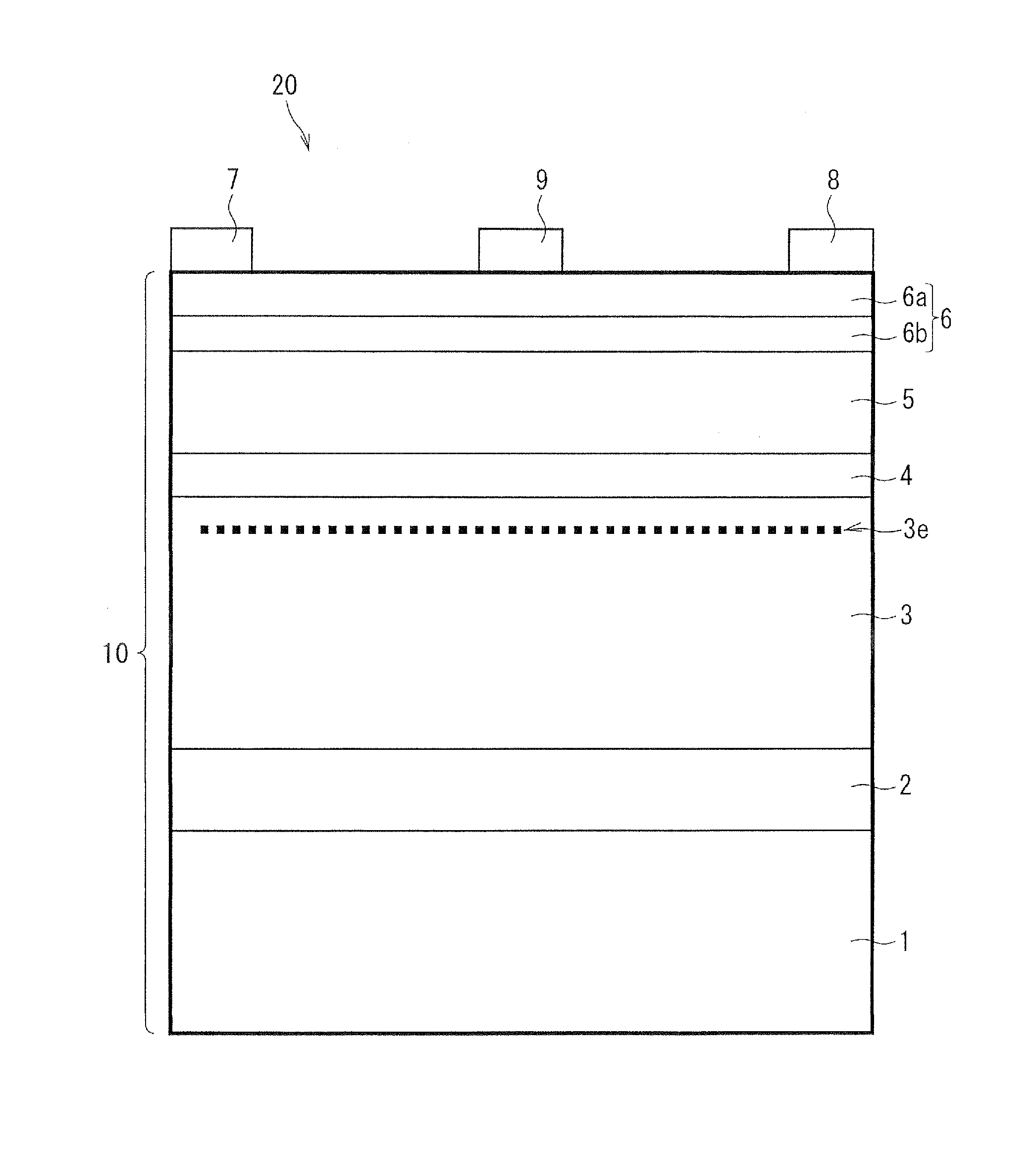

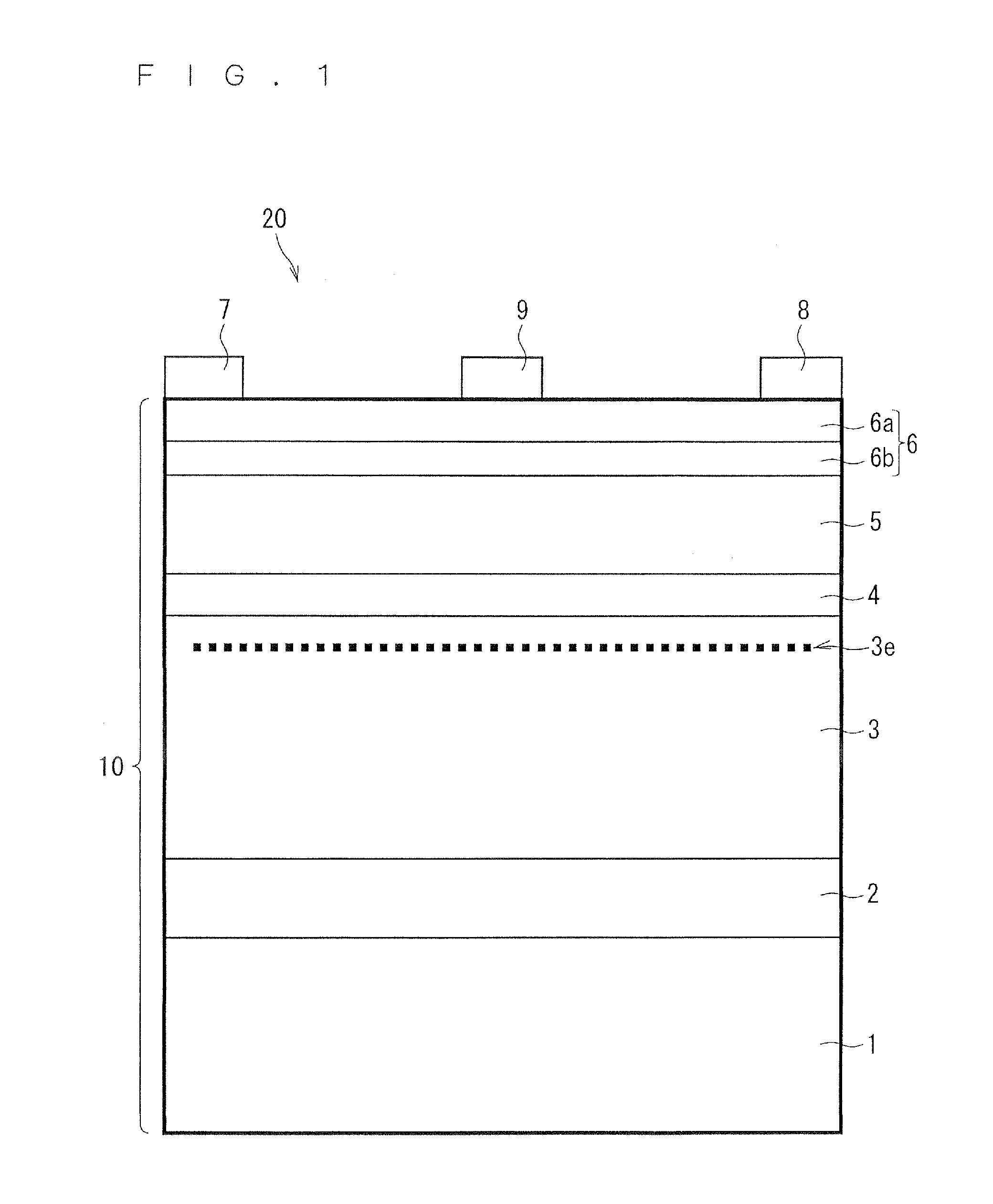

Epitaxial substrate for semiconductor device, semiconductor device, and process for producing epitaxial substrate for semiconductor device

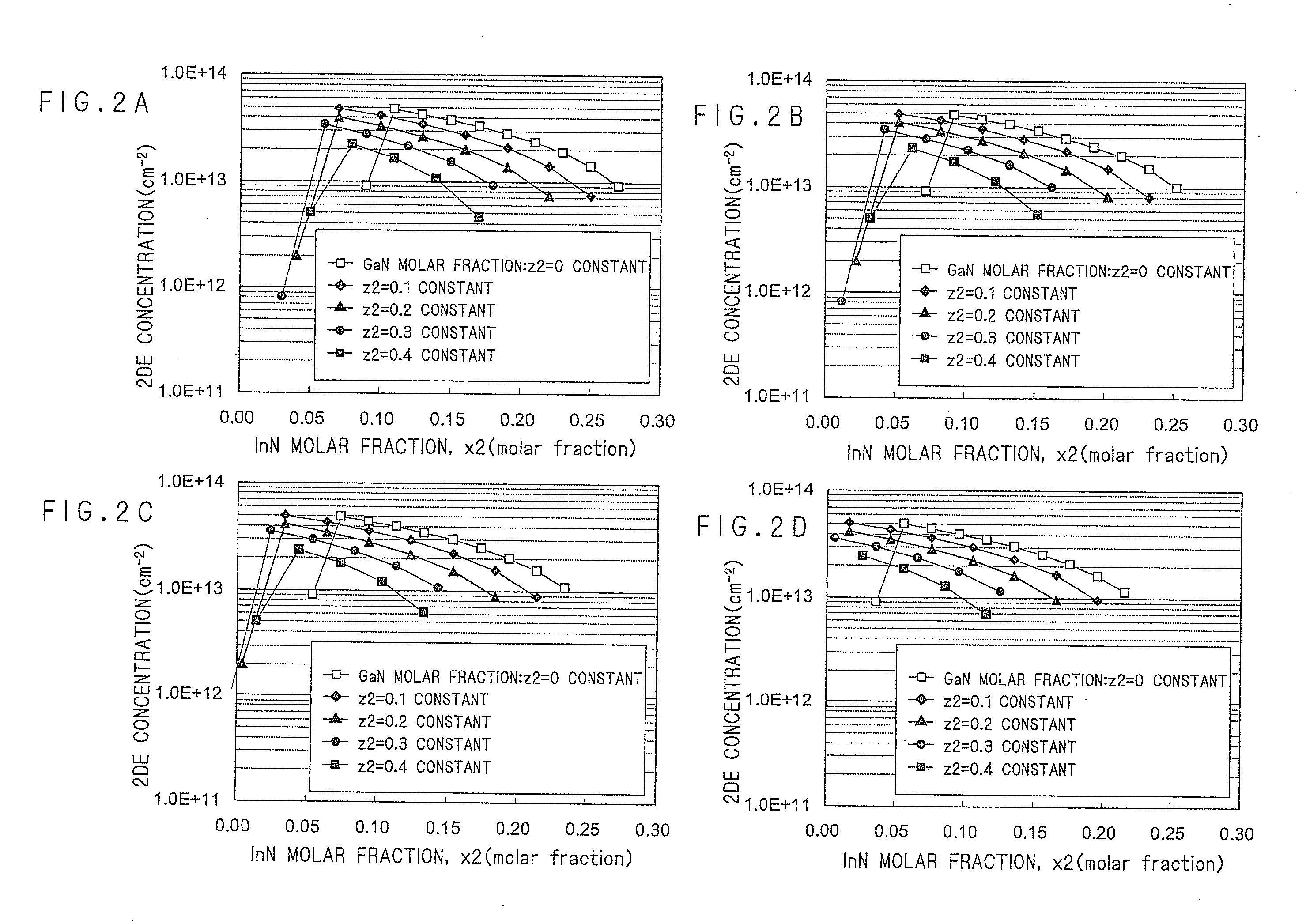

ActiveUS20110024796A1Small internal stressIncrease concentrationPolycrystalline material growthLiquid-phase epitaxial-layer growthDevice materialNitride

Provided is an epitaxial substrate having excellent two-dimensional electron gas characteristics and reduced internal stress due to strains. A channel layer is formed of a first group III nitride represented by Inx1Aly1Gaz1N (x1+y1+z1=1) so as to have a composition in a range determined by x1=0 and 0≦y1≦0.3. A barrier layer is formed of a second group III nitride represented by Inx2Aly2Gaz2N (x2+y2+z2=1) so as to have a composition, in a ternary phase diagram with InN, AlN and GaN being vertices, in a range surrounded by five straight lines determined in accordance with the composition (AlN molar fraction) of the first group III nitride.

Owner:PROMISING FUTURE +1

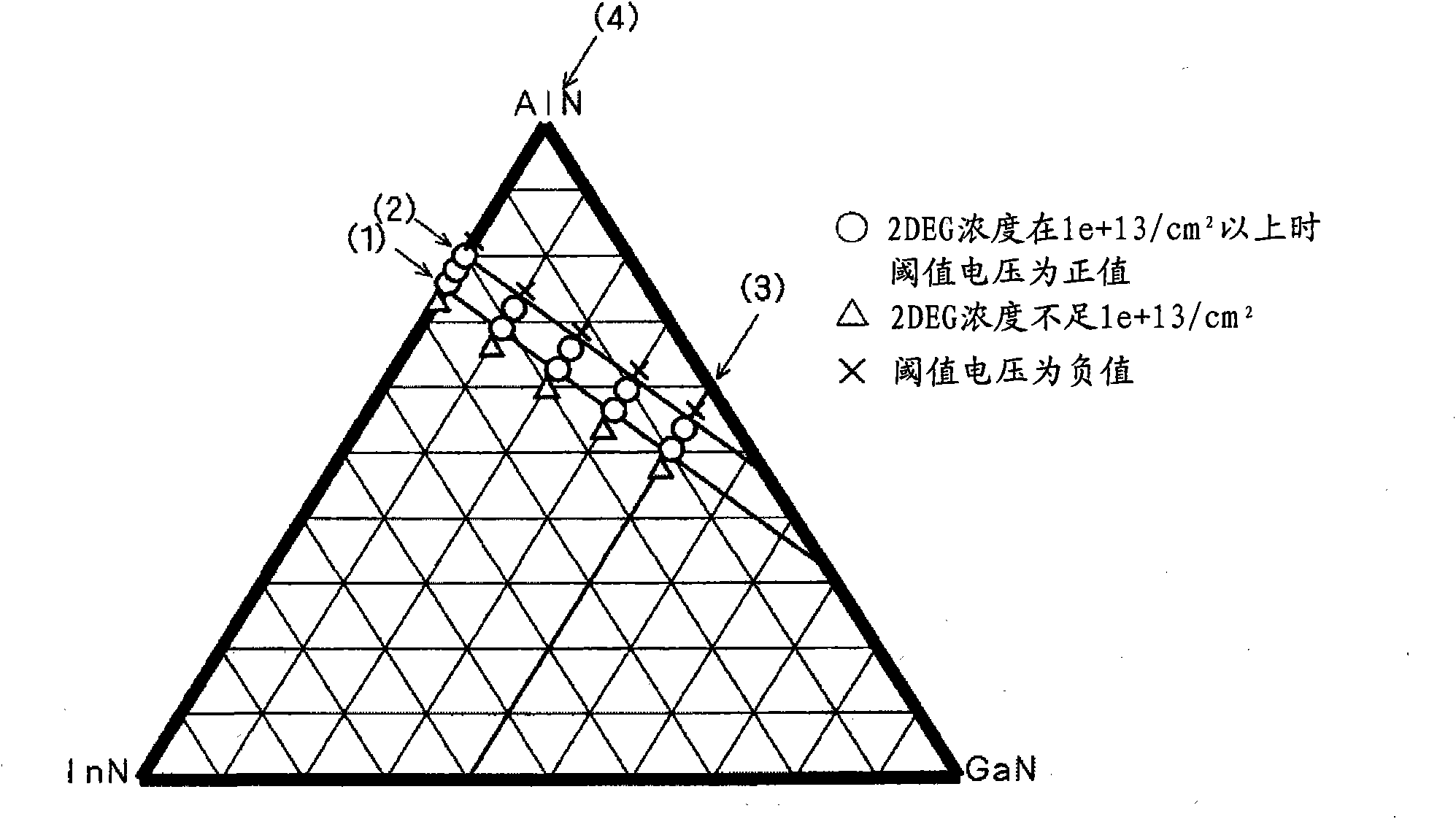

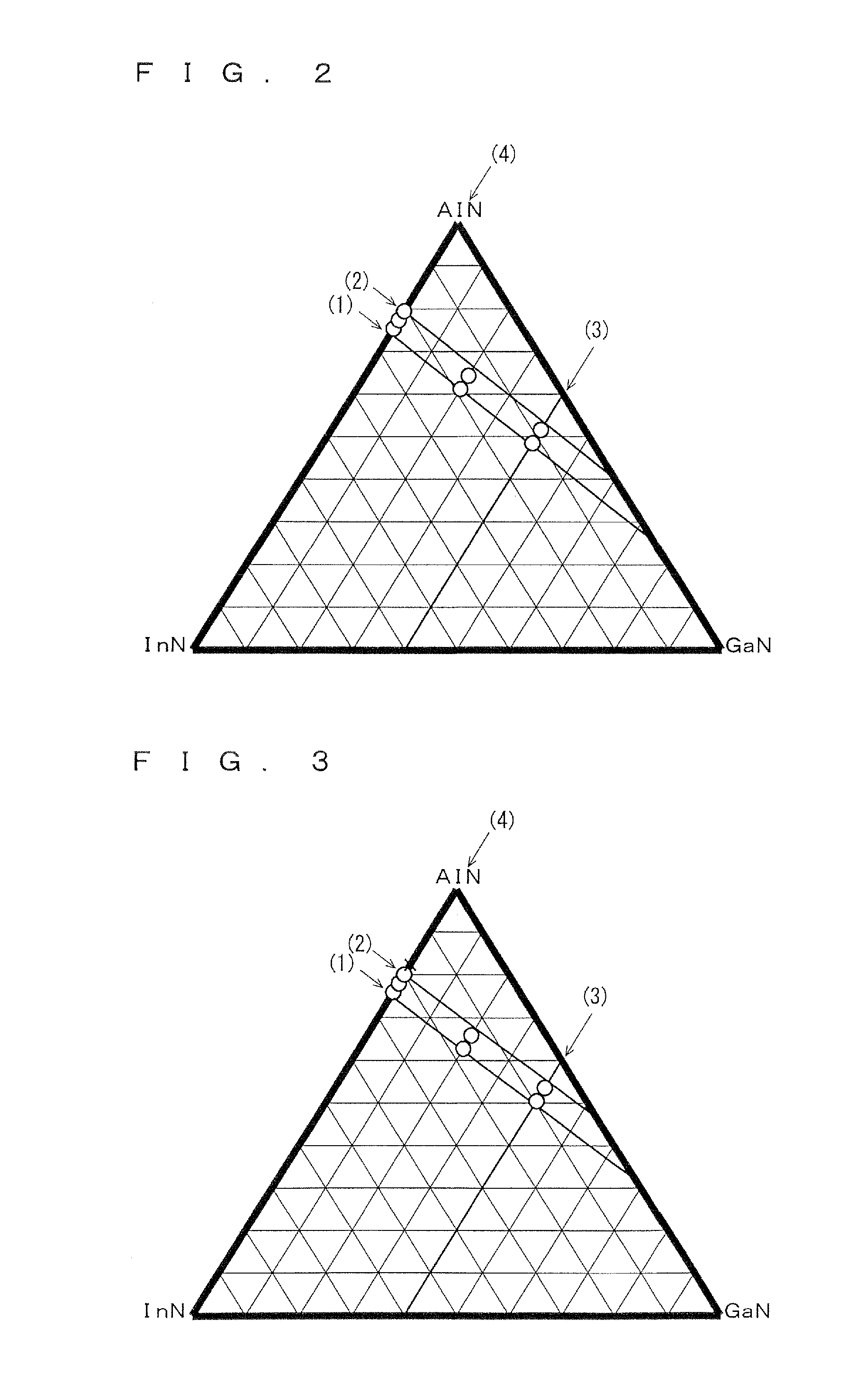

Epitaxial substrate for semiconductor device, semiconductor device, method of manufacturing epitaxial substrate for semiconductor device, and method of manufacturing semiconductor device

ActiveUS20130168734A1Reduce sheet resistanceLower on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesCrystallinityNitride

Provided is a semiconductor device of normally-off operation type having a low on-resistance. An epitaxial substrate for it includes: a base substrate; a channel layer made of a first group-III nitride having a composition of Inx1Aly1Gaz1N at least containing Al and Ga and x1=0 and 0≦y1≦0.3; and a barrier layer made of a second group-III nitride having a composition of Inx2Aly2Gaz2N at least containing In and Al. The composition of the second group-III nitride is, in a ternary phase diagram for InN, AlN, and GaN, in a certain range that is determined in accordance with the composition of the first group-III nitride. The barrier layer has a thickness of 3 nm or less. A low-crystallinity insulating layer is further formed on the barrier layer. The low-crystallinity insulating layer is made of silicon nitride and has a thickness of 3 nm or less.

Owner:NGK INSULATORS LTD

Two-dimensional continuous component sample, and preparing method and application thereof in quick determination of phase diagram high flux

ActiveCN105891243AImprove throughputIncrease the number ofPreparing sample for investigationMaterial analysis using radiation diffractionChemical physicsHigh flux

The invention discloses a two-dimensional continuous component sample and a preparing method and application thereof in quick determination of phase diagram high flux. The two-dimensional continuous component sample is a sheet in an equilateral triangle shape, and the component distribution of the two-dimensional continuous component sample is the same as that of a ternary phase diagram expressed by the equilateral triangle. The two-dimensional continuous component sample can be prepared with a solid reaction method, a 3d printing method and a slurry or turbid liquid mixing method, and is subjected to annealing or quenching at the proper temperature to meet the application of phase diagram determination and material screening. According to the two-dimensional continuous component sample and the preparing method and application thereof in quick determination of phase diagram high flux, the number of samples, with different components, synthesized at a single time can be greatly increased, and higher-flux sample support can be provided for high-flux material screening and ternary phase diagram quick determination.

Owner:SHANGHAI UNIV

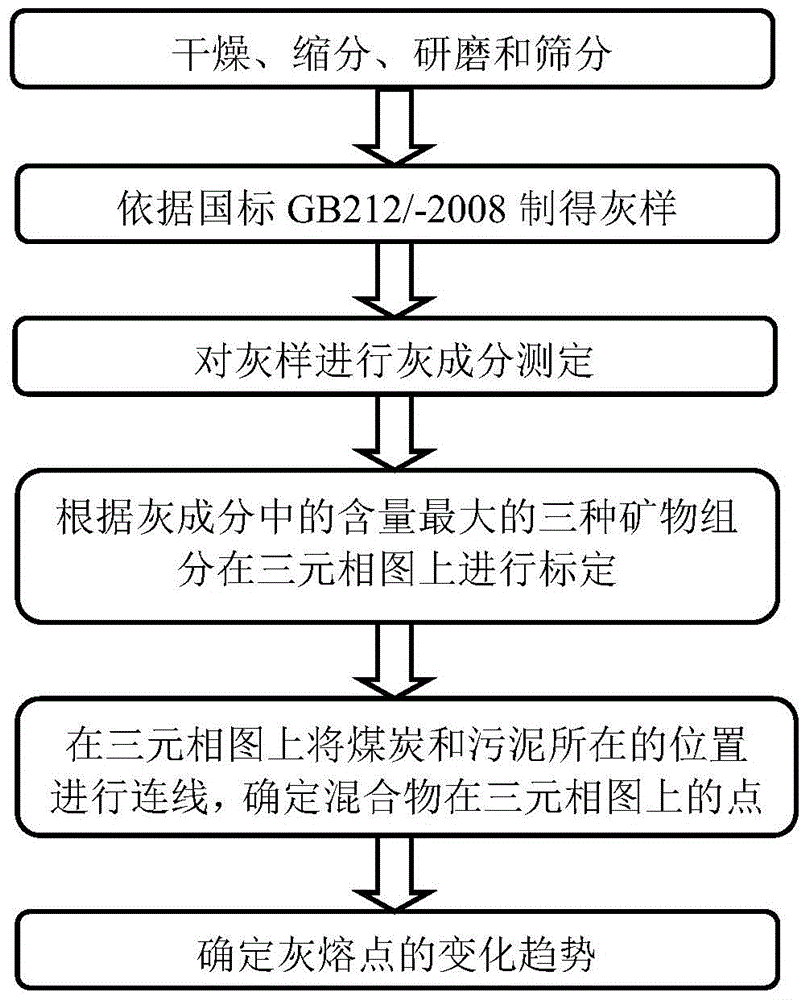

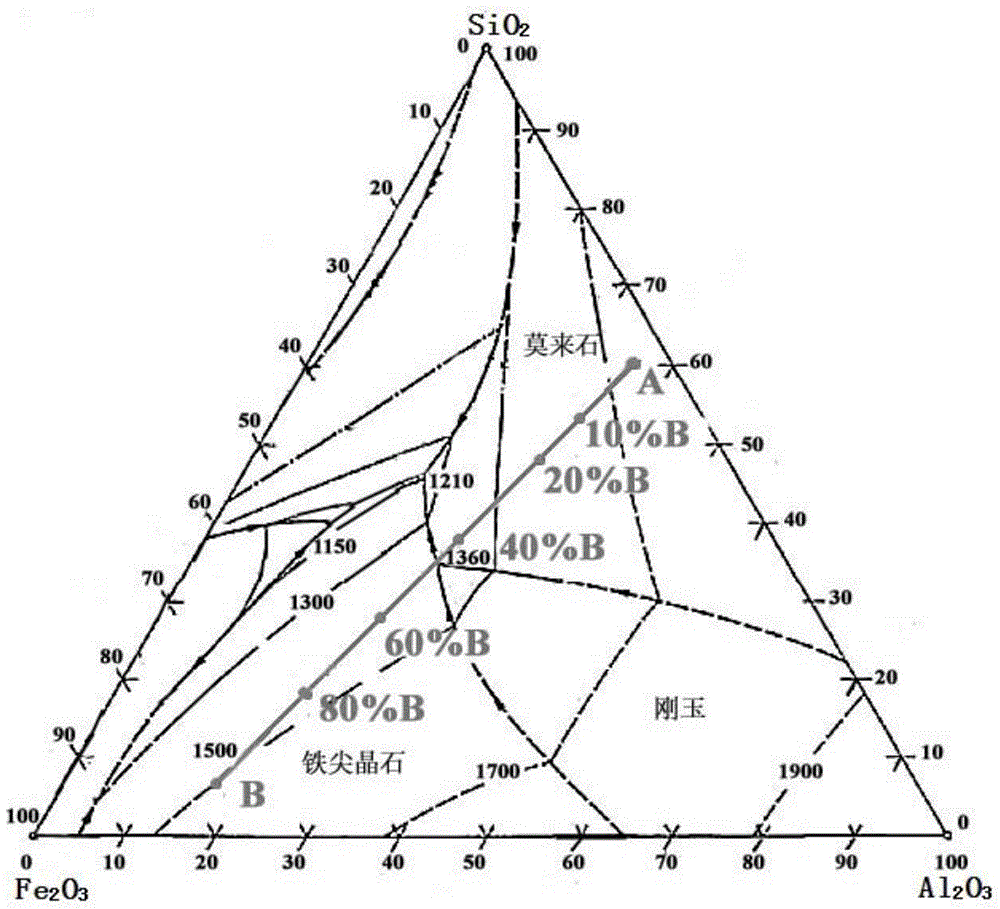

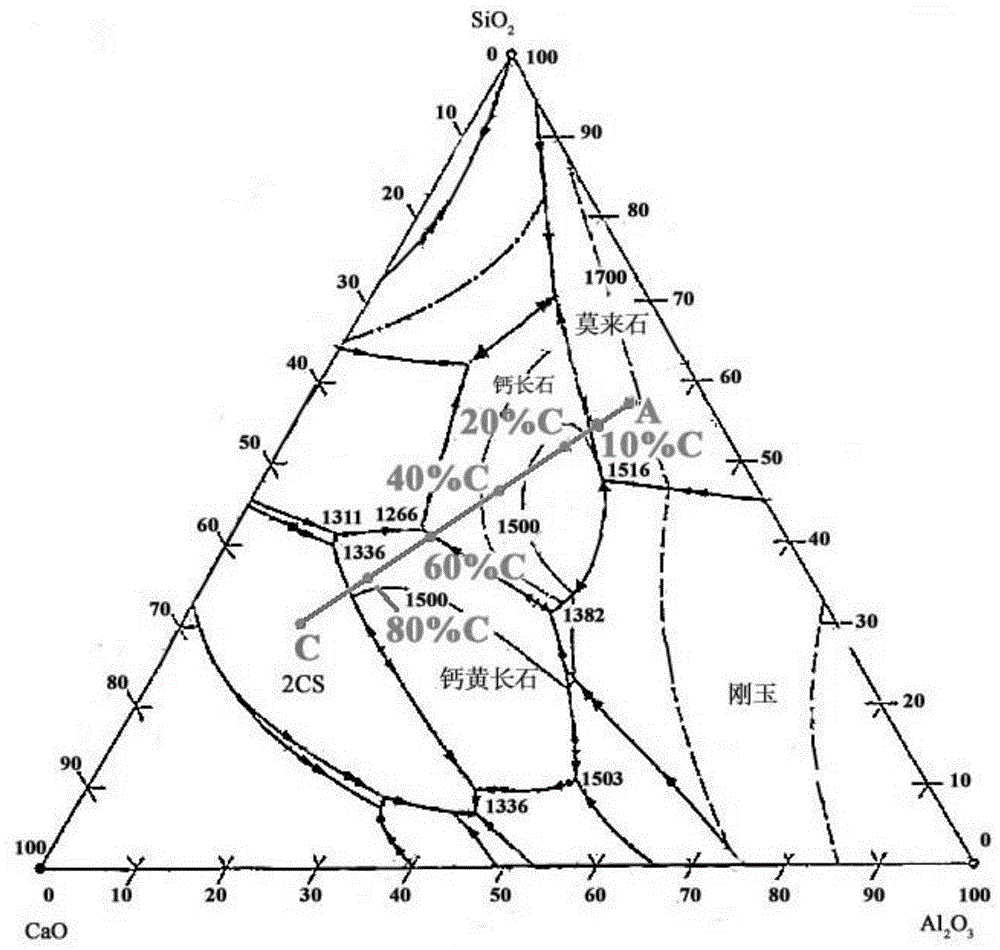

Method for forecasting ash fusion point variation trend after coal and sludge combined firing

InactiveCN104569283AForecasting the change trend of ash melting pointLight in massChemical analysis using combustionSpecial data processing applicationsSludgeComposition analysis

The invention discloses a method for forecasting the ash fusion point variation trend after coal and sludge combined firing. The method comprises the following steps: (1) drying a coal and sludge mixed sample, splitting, grinding, screening the processed mixed sample with a sieve, and drying the mixed sample powder passing through the sieve; (2) preparing an ash sample by adopting a rapid ashing method; (3) performing ash composition analysis on the ash sample, and detecting the species and the contents of mineral constituents; (4) selecting three mineral constituents with the maximum content and selecting corresponding ternary phase diagrams; (5) labeling points on which coal and sludge are located on the ternary phase diagrams and connecting the points on which the coal and the sludge are located into a line; and (6) obtaining the ash fusion point variation trend along with the content of the sludge in the mixed sample. The method can be used for quickly and effectively forecasting the ash fusion point variation trend of the coal and sludge mixed sample along with the content of the sludge to bring convenience for efficiently determining the species of the coal and the sludge in the coal and sludge mixed sample and the ash fusion property variations probably caused after the coal is mixed with the sludge in the initial stage.

Owner:HUAZHONG UNIV OF SCI & TECH

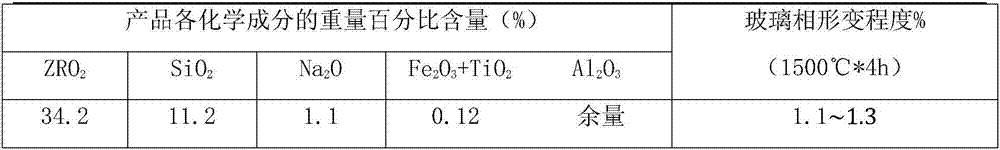

Production method of deformation-resistant fusion-cast zirconia corundum

The invention provides a production method of deformation-resistant fusion-cast zirconia corundum. The deformation-resistant fusion-cast zirconia corundum is prepared by 20 to 60 percent of clinker and 40 to 80 percent of raw material, wherein the clinker is prepared from the following raw materials: 1.2 to 1.6 percent of sodium oxide, 25 to 33 percent of zirconium oxide, 17 to 19 percent of silicon oxide and 46 to 53 percent of aluminum oxide, and the raw material is prepared from the following raw materials by weight percent: 20 to 50 percent of zircon sand, 38 to 67 percent of calcined aluminum oxide powder, 6 to 20 percent of desilicated zirconia and 1 to 3 percent of sodium carbonate. A main chemical component of the fusion-cast zirconia corundum still belongs to a ternary phase diagram of Al2O3.ZRO2.SiO2, the original advantages of the fusion-cast zirconia corundum brick are sufficiently reserved; and however, by adding main components of baddeleyite and controlling the introduction of impurities, the tensile strength is improved, the deformation rate under the condition of 1500 DEG C can be reduced to 1.2 percent or smaller for 4 hours, the pollution on glass fluid is reduced, the glass quality is improved, and the production method is particularly suitable for producing and manufacturing top-grade glass.

Owner:江苏徐耐新材料科技股份有限公司

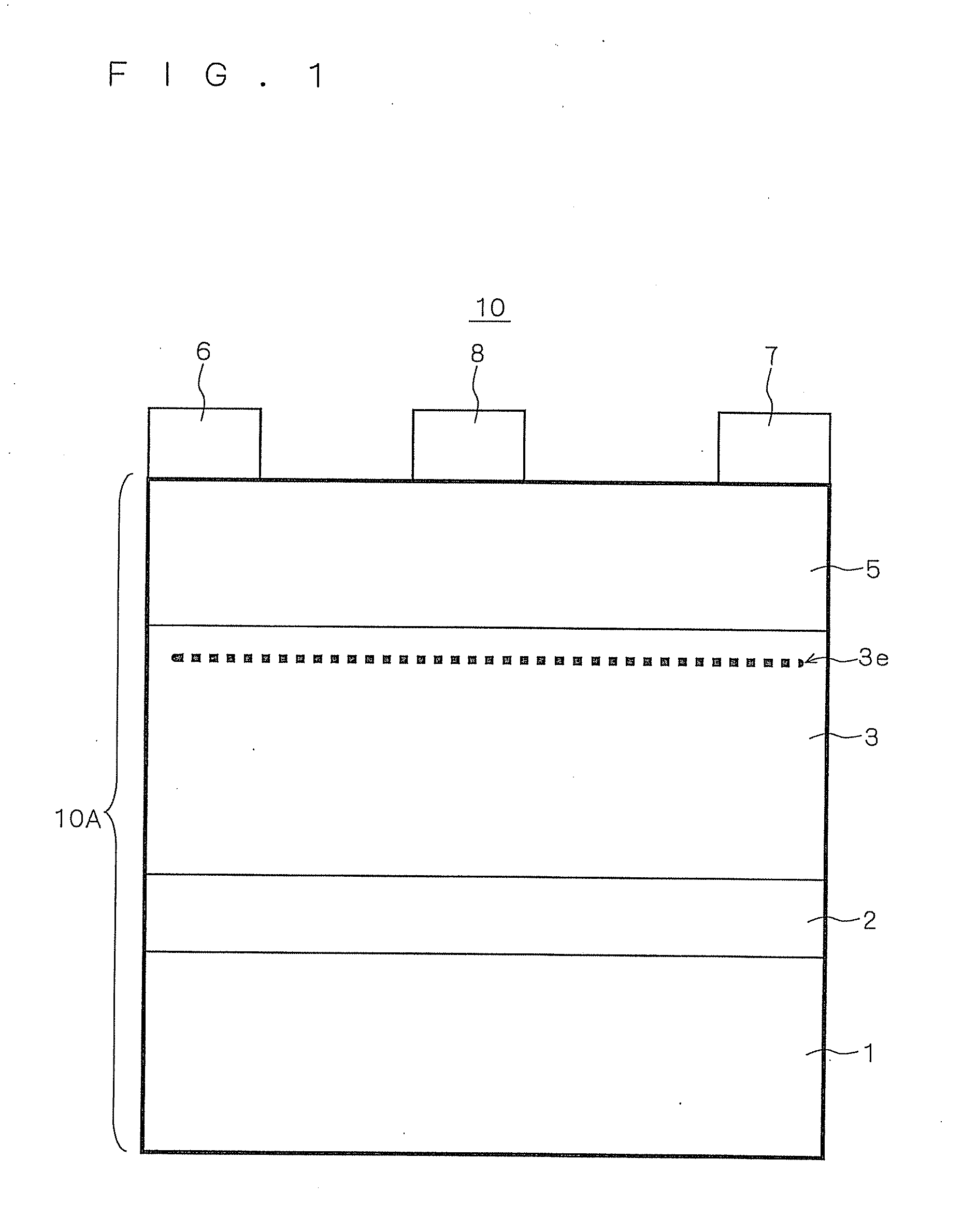

Epitaxial substrate for semiconductor device, semiconductor device, and method of manufacturing epitaxial substrate for semiconductor device

ActiveUS20100289029A1Inhibit deteriorationReduce the temperaturePolycrystalline material growthLiquid-phase epitaxial-layer growthTernary phase diagramSemiconductor

An epitaxial substrate having preferable two dimensional electron gas characteristic and contact characteristic is provided in the present invention. A channel layer is formed on a base substrate with GaN. A spacer layer is formed on the channel layer with AlN. A barrier layer is formed on the spacer layer with group III nitride having a composition of InXAlyGazN (wherein x+y+z=1) and at least including In, Al, and Ga such that the composition of the barrier layer is within the range surrounded with four lines defined in accordance with the composition on a ternary phase diagram with InN, AlN, and GaN as vertexes.

Owner:NGK INSULATORS LTD

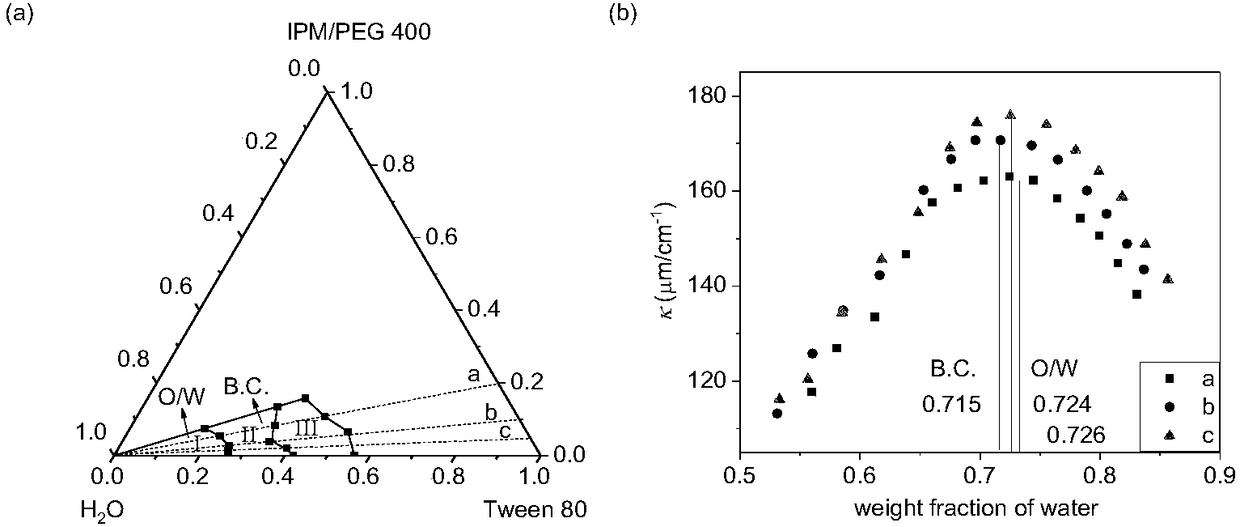

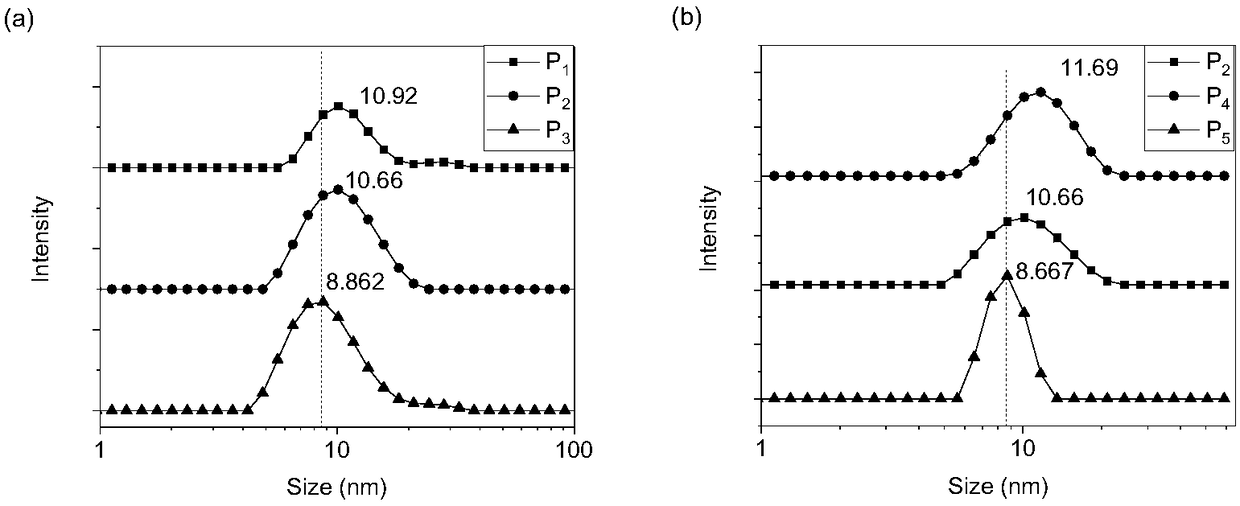

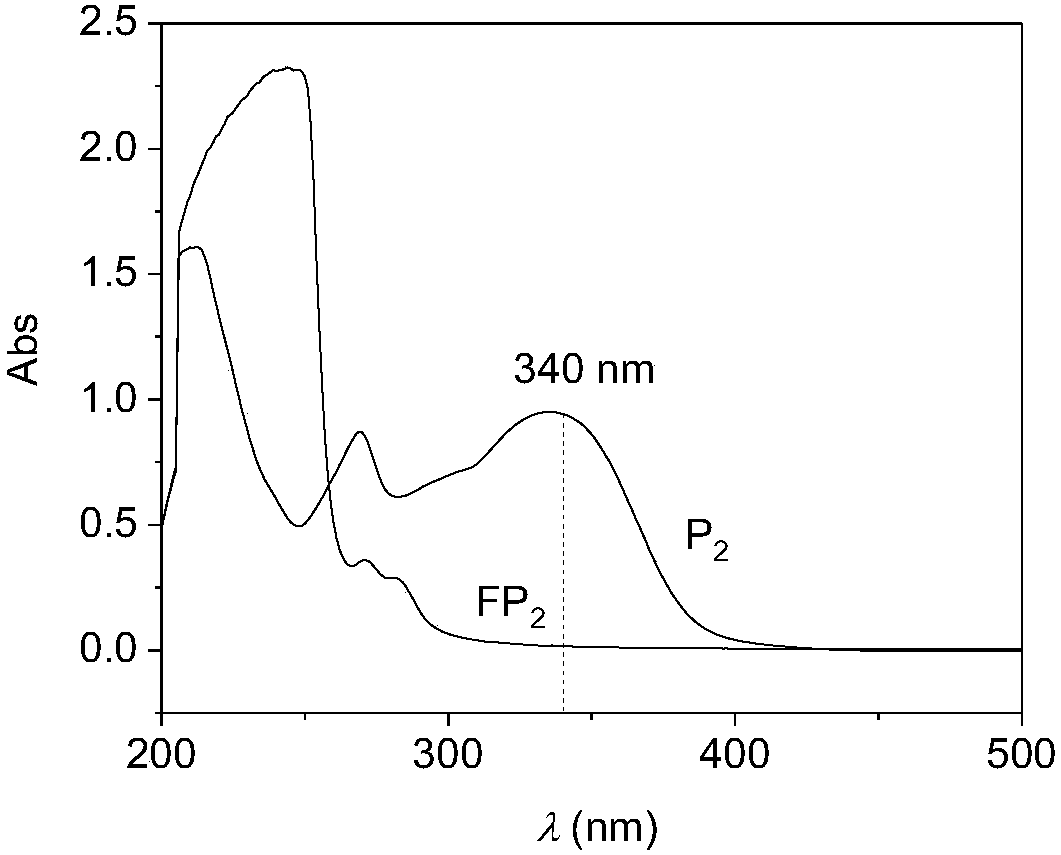

Construction of Tween 80-based biocompatible microemulsion and in vitro release and oxidation resistance study of carried apigenin

ActiveCN108113964AImprove solubilityGood sustained releaseOrganic active ingredientsAntinoxious agentsApigeninOrganism

The invention relates to construction of Tween 80-based biocompatible microemulsion and in vitro release and oxidation resistance study of carried apigenin. A pseudo-ternary phase diagram is adopted for constructing Tween80 / IPM / PEG400 / H2O biocompatible microemulsion, and partition is carried out by utilizing conductivity, so that structure of the microemulsion is changed from a bicontinuous phase(B.C.) to an O / W type. Further the O / W type microemulsion is selected as an apigenin carrier, saturation solubility experiments show that the constructed microemulsion obviously improves solubility ofthe apigenin, and compared with the solubility in water, the solubility is improved by 300 times when the microemulsion is taken as the carrier. In vitro release experiments show that the microemulsion has better slow-release effect on the apigenin, and a releasing process of the apigenin in the microemulsion accords with first-order kinetics and is under concentration diffusion control. A medicine still has better antioxidant activity in the microemulsion and has better clearing effect on ABTS<+>.. Release rate of the apigenin in the microemulsion, accumulated release rate and antioxidant activity can be regulated and controlled by changing a mass ratio of a surfactant to oil (S / O) and water content.

Owner:海生健康科技(青岛)有限公司

Epitaxial substrate for semiconductor device, semiconductor device, and process for producing epitaxial substrate for semiconductor device

ActiveUS20110024795A1Improve mobilityReduce the temperatureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialNitride

Provided is an epitaxial substrate capable of manufacturing a HEMT device that has excellent two-dimensional electron gas characteristics and is capable of performing normally-off operation. A channel layer is formed of a first group III nitride represented by Inx1Aly1Gaz1N (x1+y1+z1=1) so as to have a composition in a range determined by x1=0 and 0≦y1≦0.3. A barrier layer is formed of a second group III nitride represented by Inx2Aly2Gaz2N (x2+y2+z2=1) so as to have a composition, in a ternary phase diagram with InN, AlN and GaN being vertices, in a range surrounded by four straight lines determined in accordance with the composition (AlN molar fraction) of the first group III nitride and to have a thickness of 5 nm or less.

Owner:NGK INSULATORS LTD

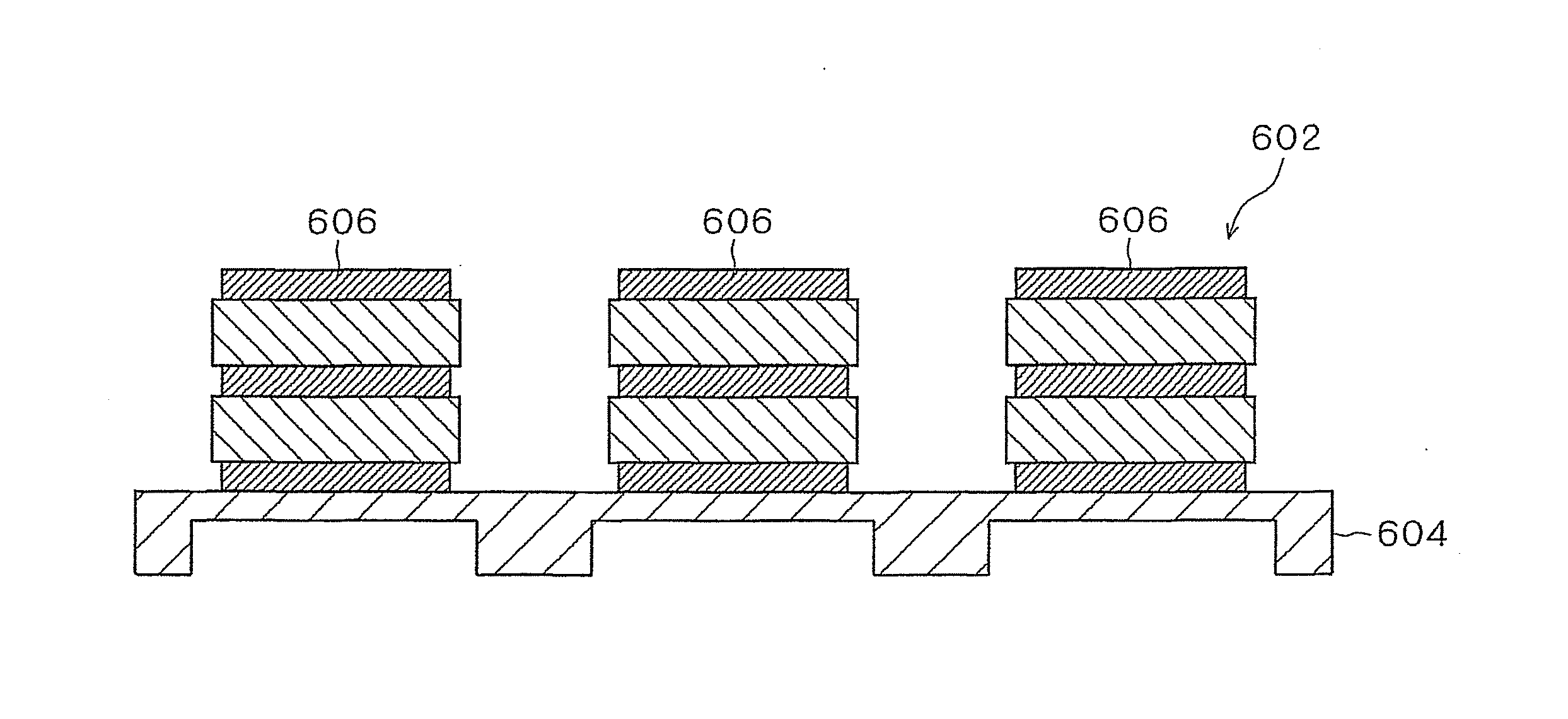

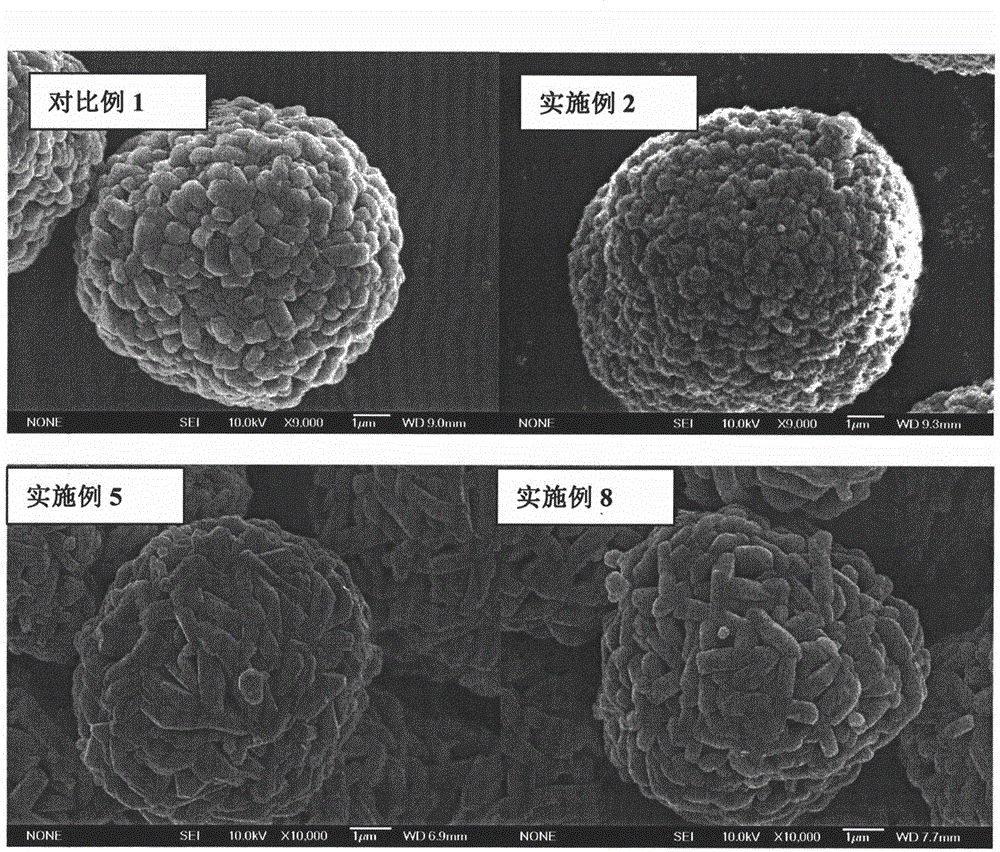

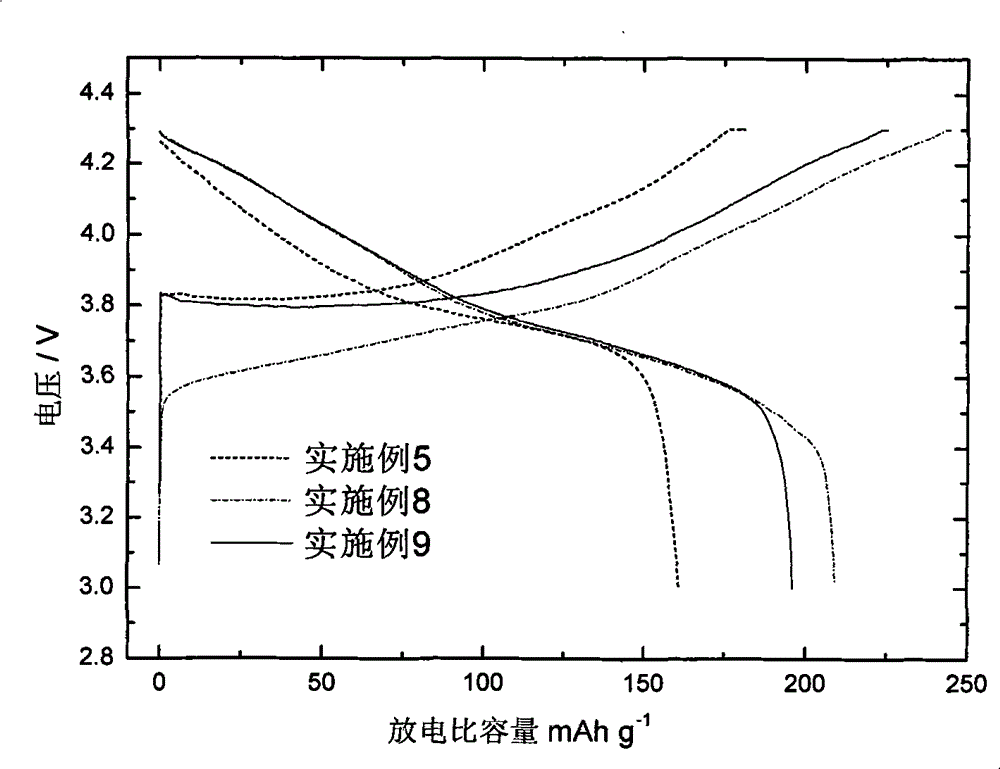

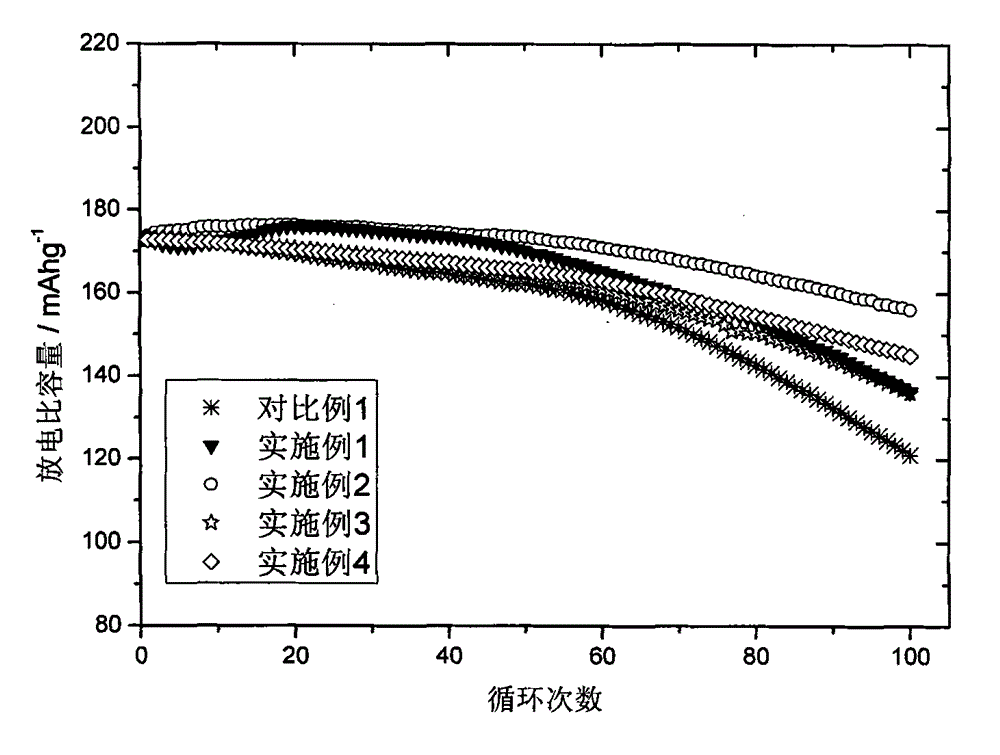

Core-shell structure positive material based on phase diagram design and design method of core-shell structure positive material

InactiveCN104979528AImprove electrochemical performanceExtended service lifeCell electrodesManganeseCore component

The invention discloses a design method of a spherical or sphere-like lithium ion battery material based on Ni-Co-Mn ternary phase diagram analysis. A positive material is designed as follows: a core component is positioned at a high-capacity area (Ni is more than or equal to 0.7 and less than or equal to 1, and Co is more than or equal to 0 and less than or equal to 0.3) of a phase diagram according to the influence of different contents of Ni, Co and Mn to the performances of the positive material, and a shell material is positioned in a high-safety area (Ni is more than or equal to 1 / 3 and less than or equal to 0.5, and Mn is more than or equal to 1 / 3 and less than or equal to 0.5), so that the Li[(NinCo(1-m-n)Mnm)b(NicCodMn(1-c-d)a)]O2 material has high safety and compounding performances of a high-capacity material, wherein a is more than or equal to 0, b is less than or equal to 1, a+b is equal to 1, n is more than or equal to 1 / 3 and less than or equal to 0.5, m is more than or equal to 1 / 3 and less than or equal to 0.5, d is more than or equal to 0.7 and less than or equal to 1, c is more than or equal to 0 and less than or equal to 0.3, and d+c is less than or equal to 1. A core-shell structure material can show high specific capacity, high circulatory stability and high safety by the complementation of core and shell functions of the core-shell structure. Compared with a homogeneous-phase multielement material, the material disclosed by the invention has the advantages that the large-scale preparation cost is not increased, the repeatability is high, the batch stability is good, the production management is facilitated, and the large-scale commercialization application needs can be met.

Owner:张联齐

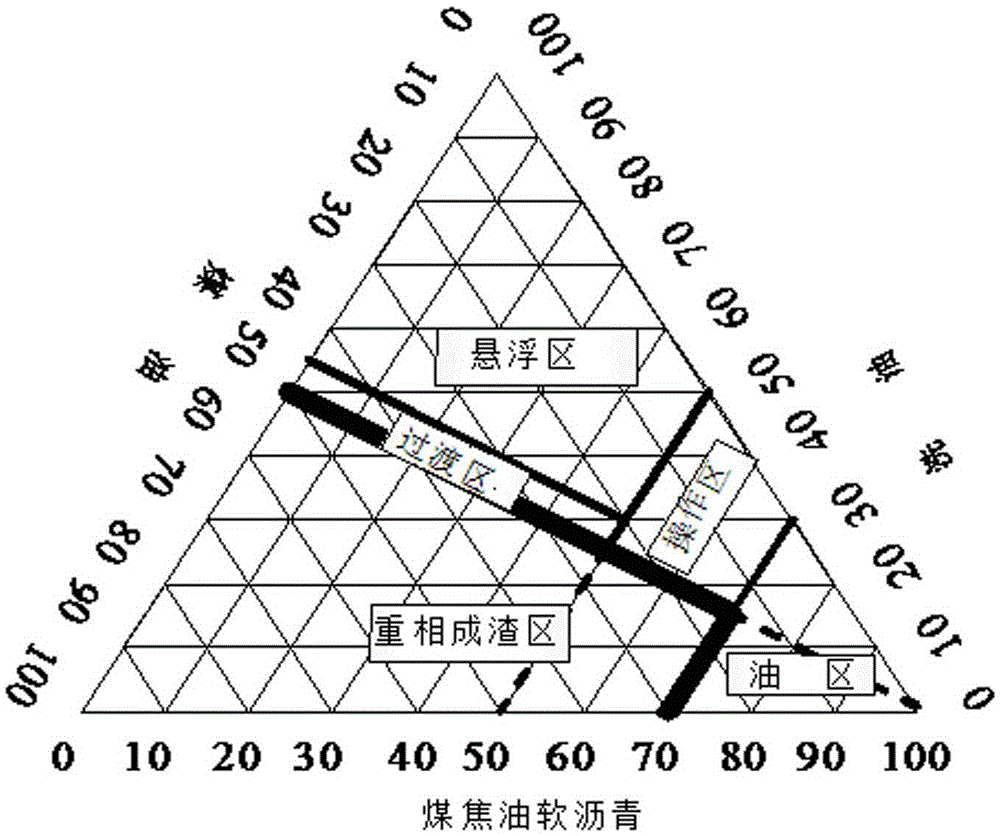

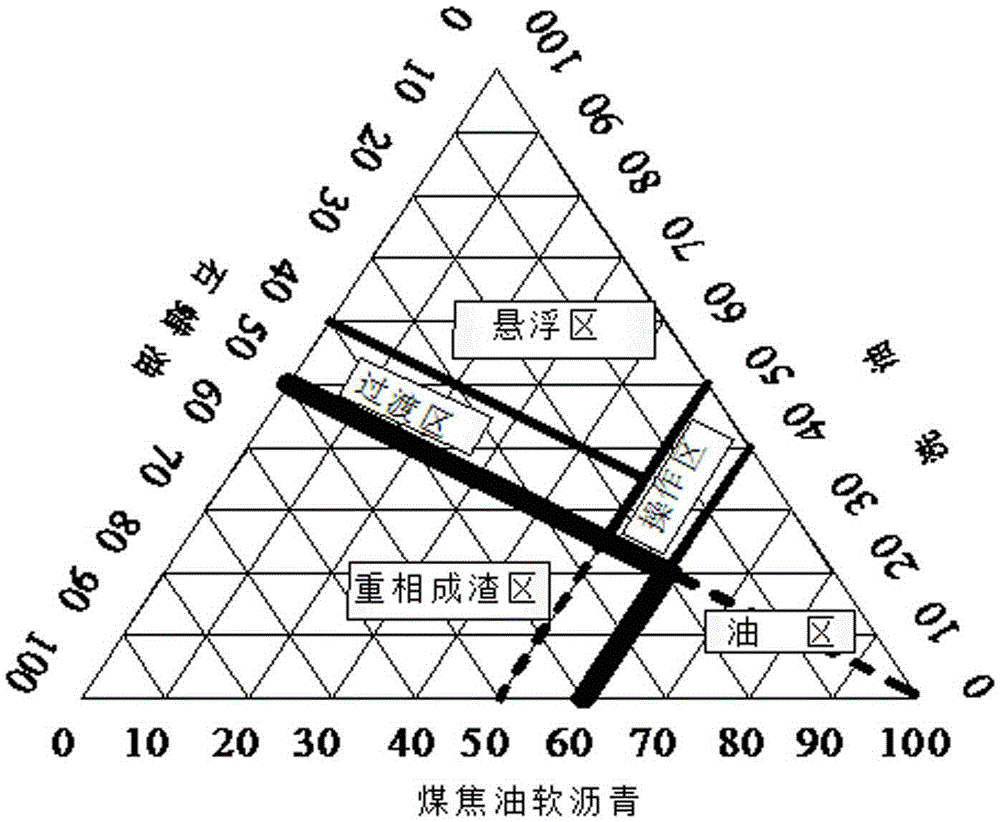

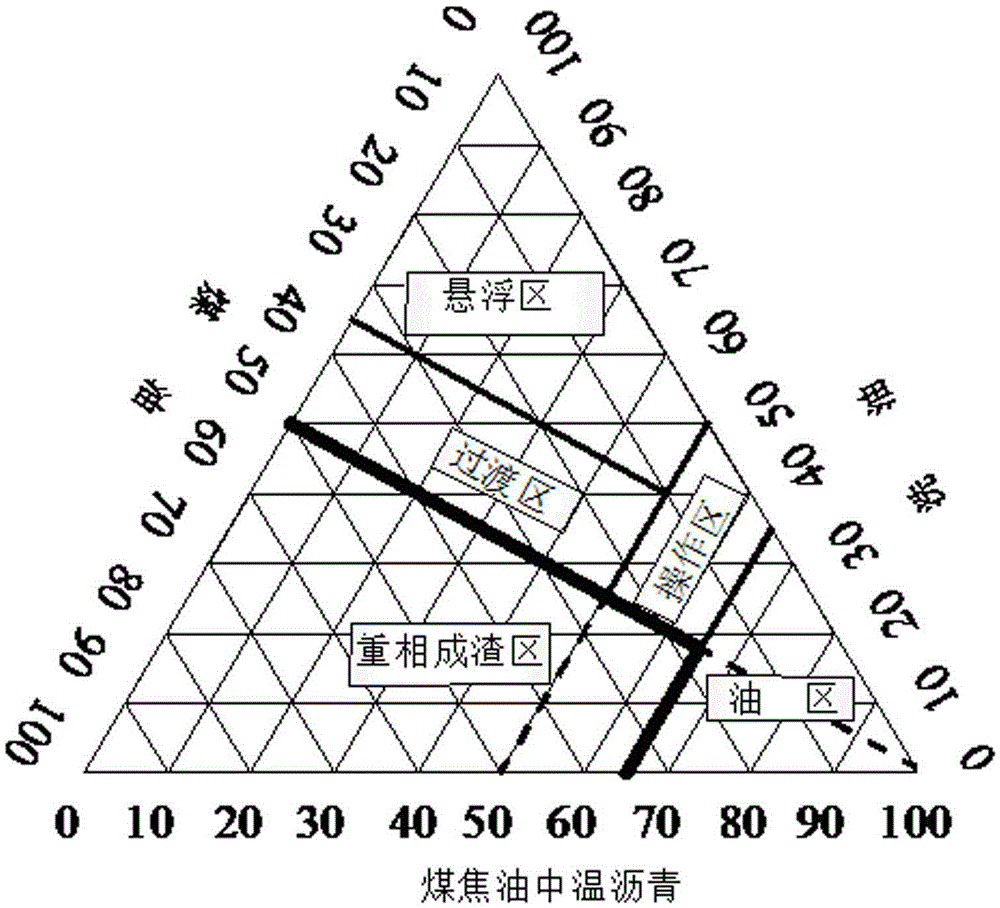

Method for determining parameters of solvent method based refined asphalt preparing process by utilizing phase diagram

ActiveCN105255510AAvoid phenomena such as unqualified qualitySmooth production runWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionAromatic solventsAsphalt

A method for determining parameters of a solvent method based refined asphalt preparing process by utilizing a phase diagram comprises the following steps that 1, asphalt is mixed with the mixed solvent prepared by an aromatic solvent and an aliphatic solvent; 2, heating and mixing are performed, settlement is performed at the temperature of 100-150 DEG C, the upper-layer substance of the material completing settlement is taken out to serve as a light phase, the remaining serves as a heavy phase, and the flow state of the heavy phase is observed; 3, the aromatic and aliphatic solvents in the light phase and the heavy phase are respectively evaporated out; 4, the quinoline insoluble content of refined asphalt is detected; 5, the experiment steps are repeated to draw the ternary phase diagram so as to determine the parameters of the solvent method based refined asphalt preparing process. By means of the method, operating parameters for preparing refined asphalt can be rapidly determined, production operation can be smooth, and the economical efficiency of device operation is improved.

Owner:UNIV OF SCI & TECH LIAONING

Thymol nanoemulsion and preparation method thereof

InactiveCN107550862AImprove stabilityNo adhesionSenses disorderAntimycoticsDistilled waterElectron microscope

The invention discloses thymol nanoemulsion and a preparation method thereof. The thymol nanoemulsion is mainly prepared from the following components in parts by weight: 30 to 50 parts of EL-40, 1 to10 parts of 1,2-propylene glycol, 1 to 10 parts of thymol and an sufficient amount of distilled water. According to the thymol nanoemulsion and the preparation method thereof, a thymol nanoemulsion prescription is screened by drawing a pseudo-ternary phase diagram, and the prepared thymol nanoemulsion has a particle size of 10 to 100nm and high stability; the obtained nanoemulsion is oil-in-watertype nanoemulsion, can be infinitely diluted with water, and under a transmission electron microscope, is spherical and nonadhesive. Detection with the transmission electron microscope shows that thediameters of drops are distributed between 10 and 100nm and the nanoemulsion is apparently yellow or colorless transparent liquid and has high stability.

Owner:CHENGDU LINGXI SHANGPIN TECH CO LTD

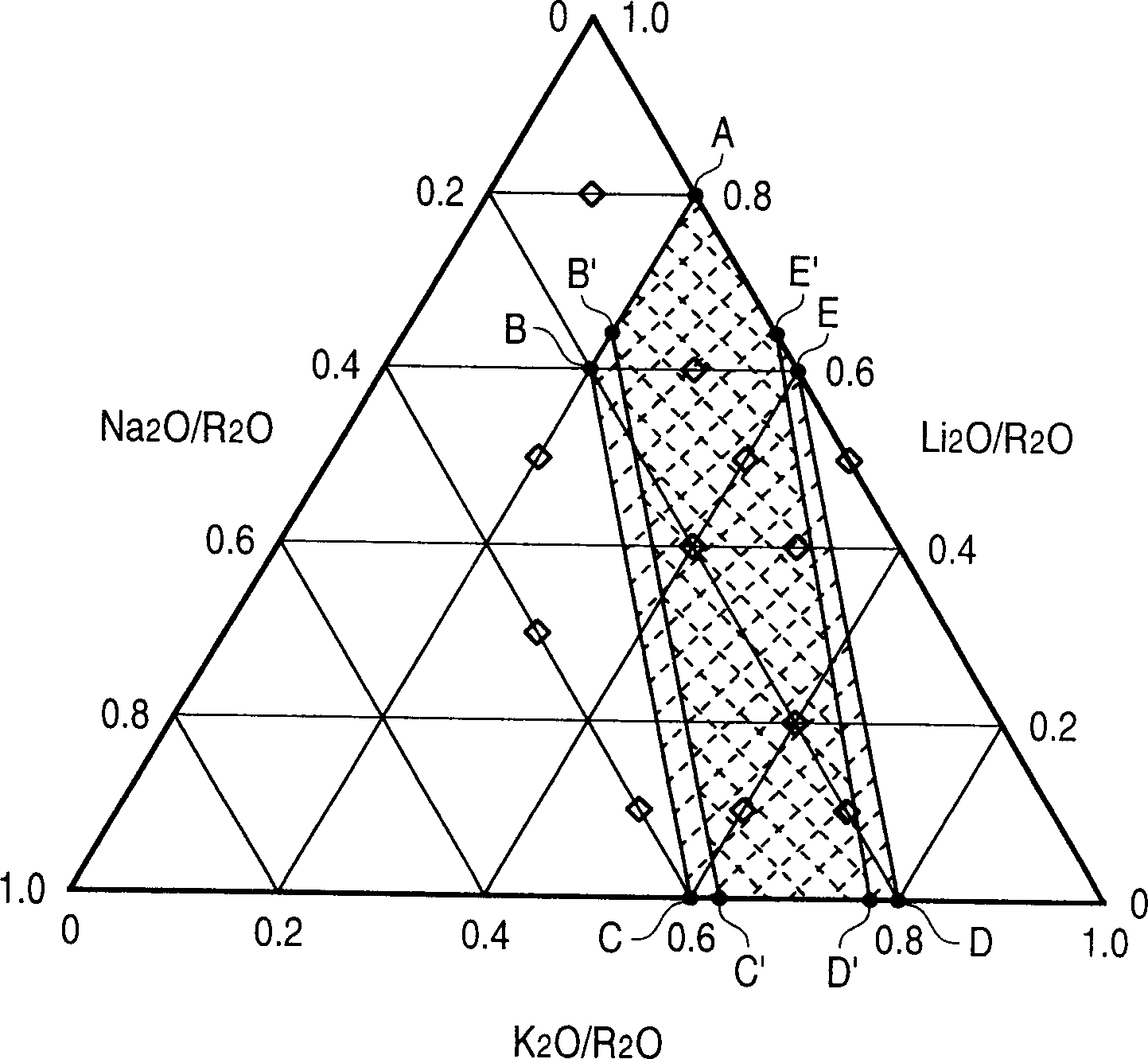

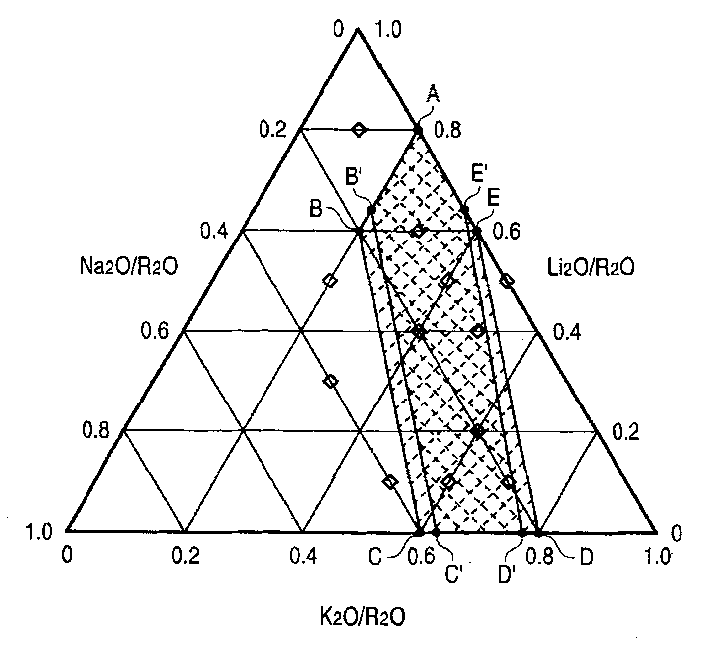

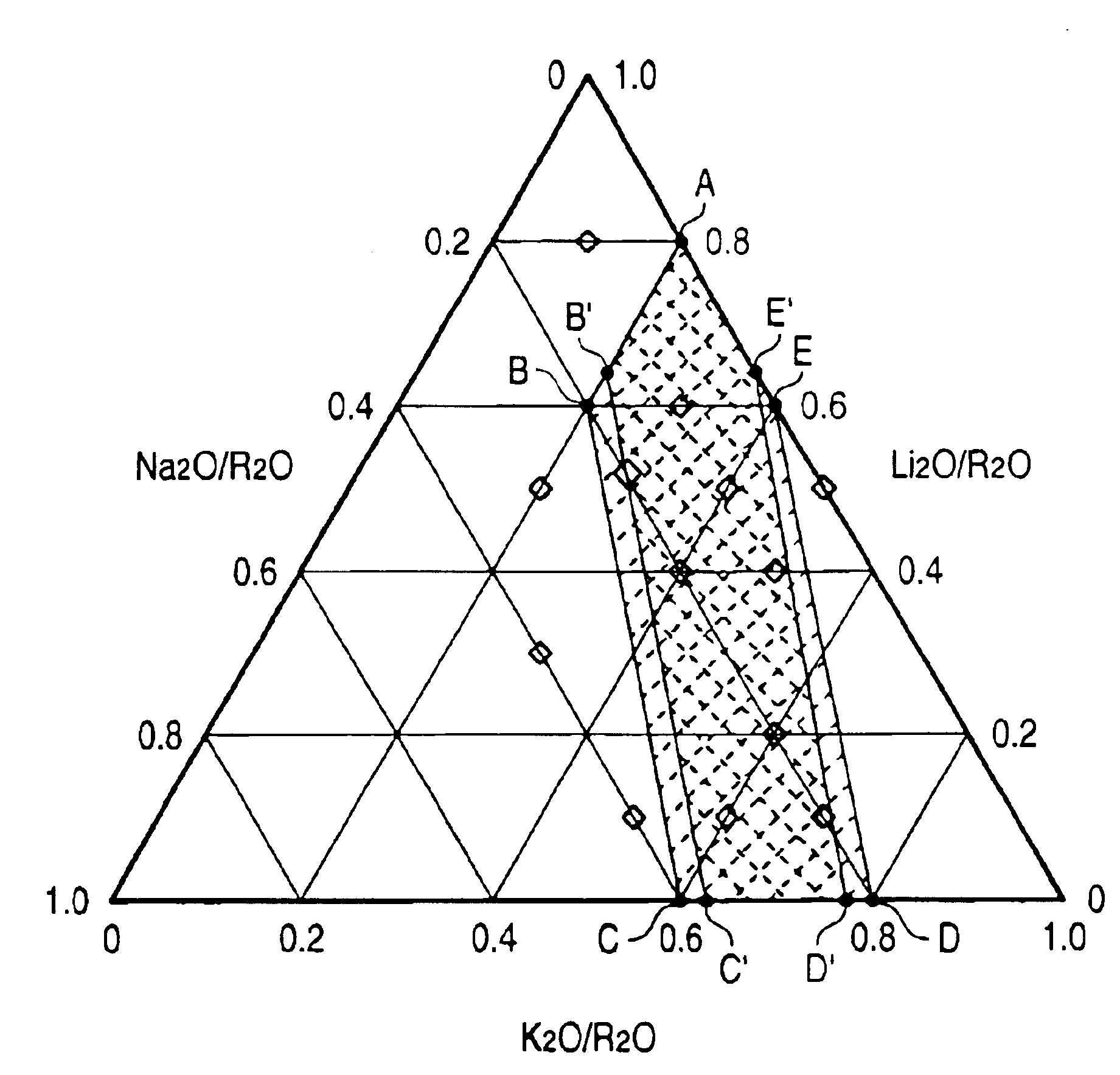

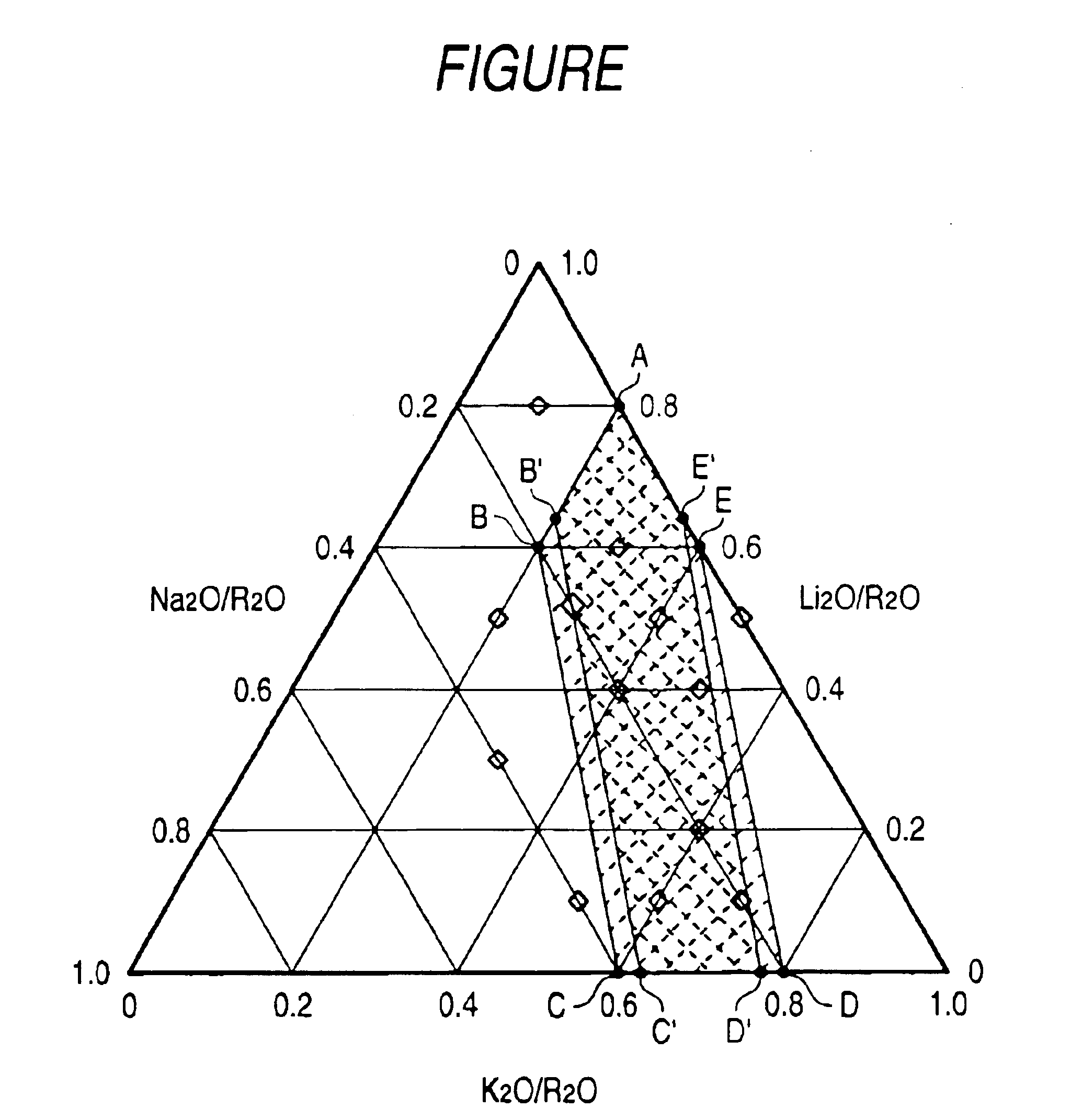

Display screen glass for CRT

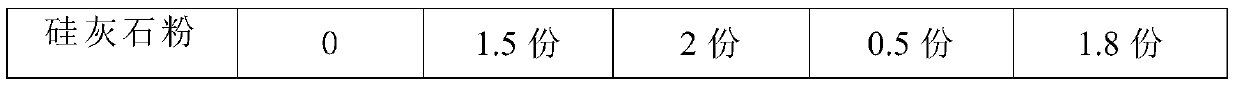

Panel glass, for a cathode ray tube, which has an SrO / (SrO+BaO) ratio of from 0.35 to 0.70, an X-ray absorption coefficient of 36.0 cm-1 or more at the wavelength of 0.6 angstrom, wherein Na2O / R2O, K2O / R2O and Li2O / R2O (R2O: Na2O+K2O+Li2O) molar ratios fall within a range surrounded by the points A (0, 0.2, 0.8), B (0.2, 0.2, 0.6), C (0.4, 0.6, 0), D (0.2, 0.8, 0) and E (0, 0.4, 0.6) in the ternary phase diagram as shown in FIG 1.

Owner:NIPPON ELECTRIC GLASS CO LTD

Epitaxial substrate for semiconductor element, semiconductor element, and process for producing epitaxial substrate for semiconductor element

ActiveCN101981658AImprove mobilityInhibit deteriorationPolycrystalline material growthSemiconductor/solid-state device manufacturingNitrideElectron

Disclosed is an epitaxial substrate that can realize the preparation of an HEMT element which has good two-dimensional electron gas properties and can realize normally-off operation. The epitaxial substrate comprises a channel layer formed of a first group III nitride represented by Inx1Aly1Gaz1N wherein x1 + y1 + z1 = 1 and which has a composition satisfying x1 = 0 and 0 <= y1 <= 0.3. The epitaxial substrate further comprises a barrier layer formed of a second group III nitride represented by Inx2Aly2Gaz2N wherein x2 + y2 + z2 = 1 and which has a composition that falls within an area surrounded by four straight lines determined dependent upon the composition of the first group III nitride (AlN molar fraction) on a ternary phase diagram in which InN, AlN, and GaN constitute vertices. The barrier layer has a thickness of not more than 5 nm.

Owner:NGK INSULATORS LTD

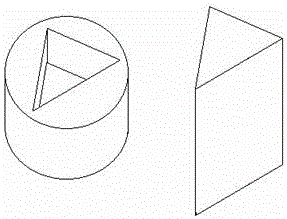

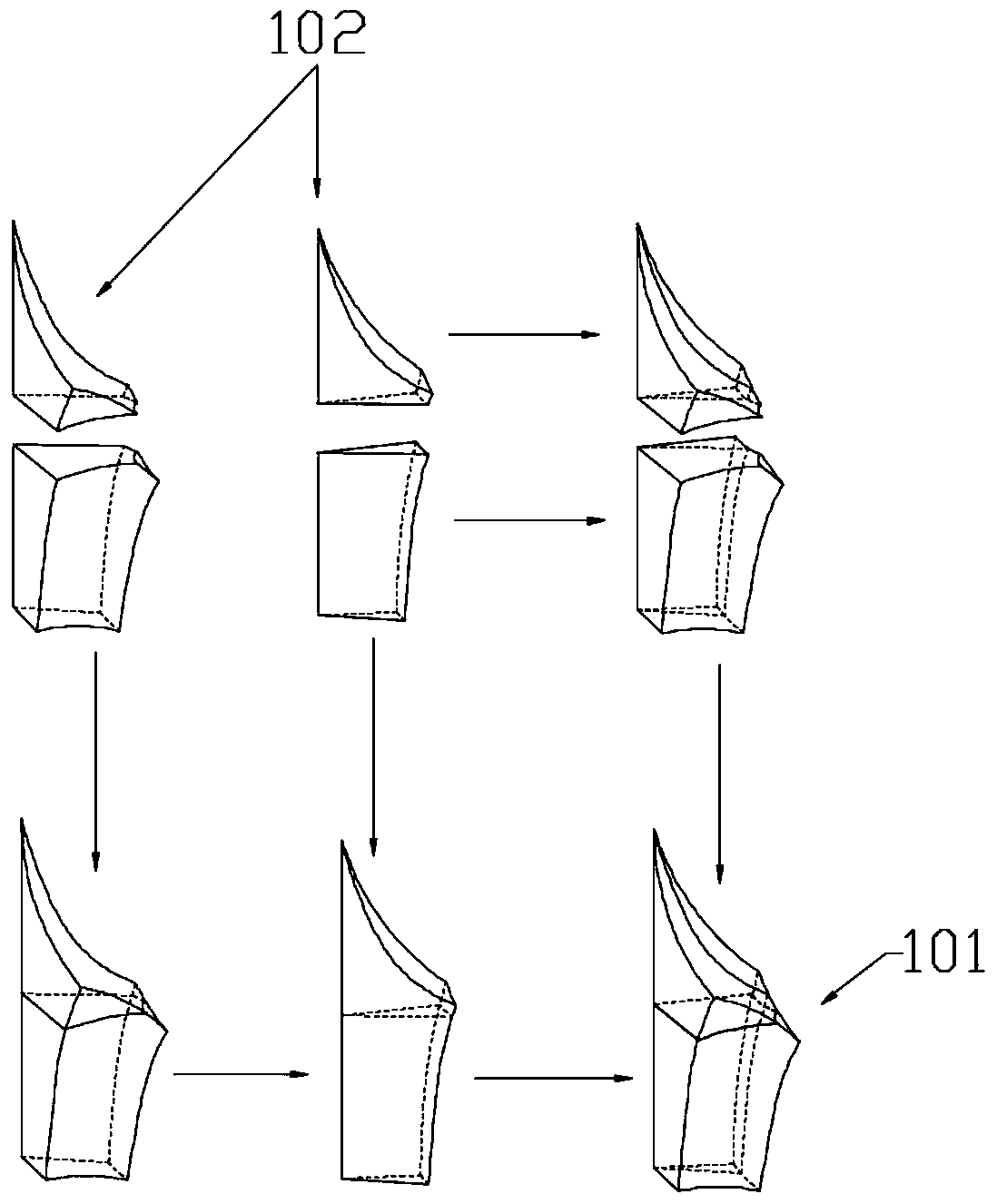

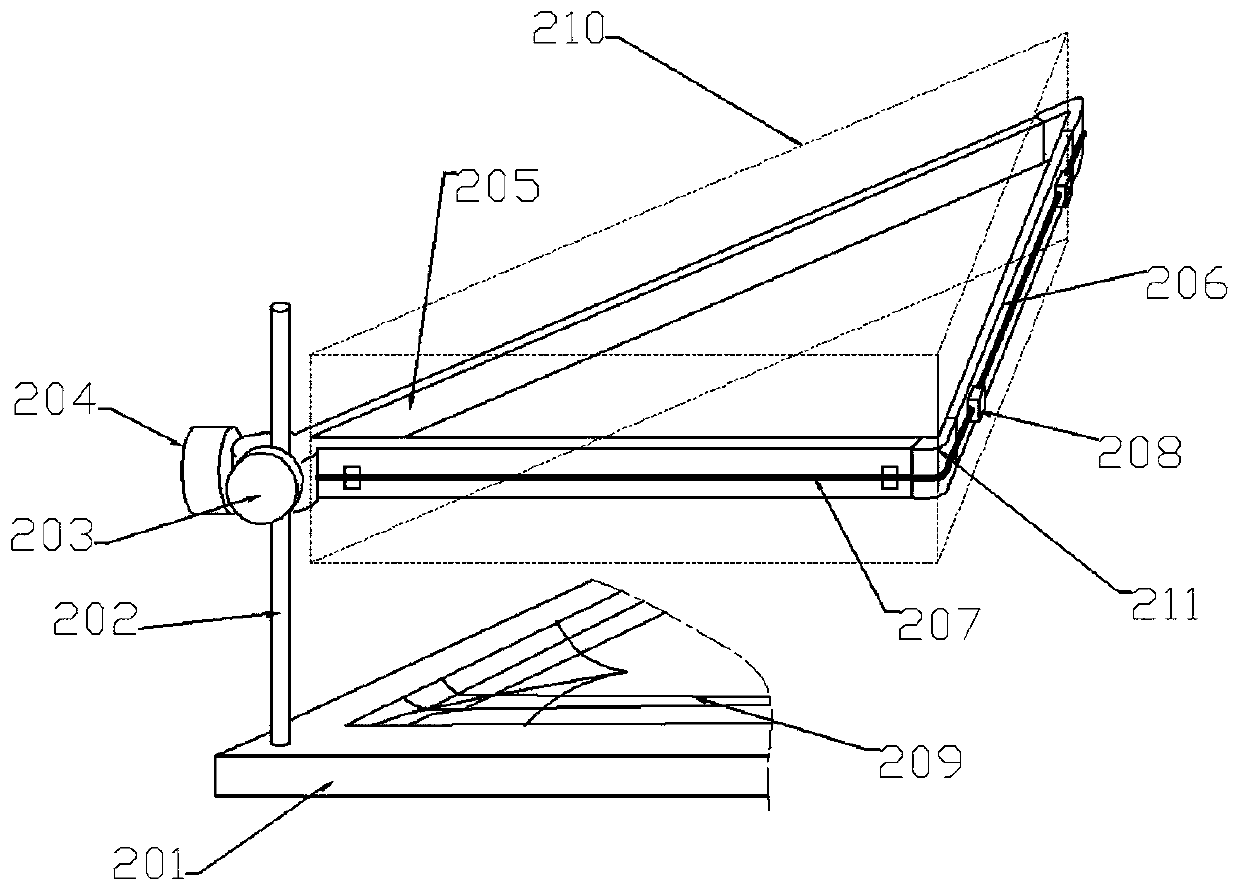

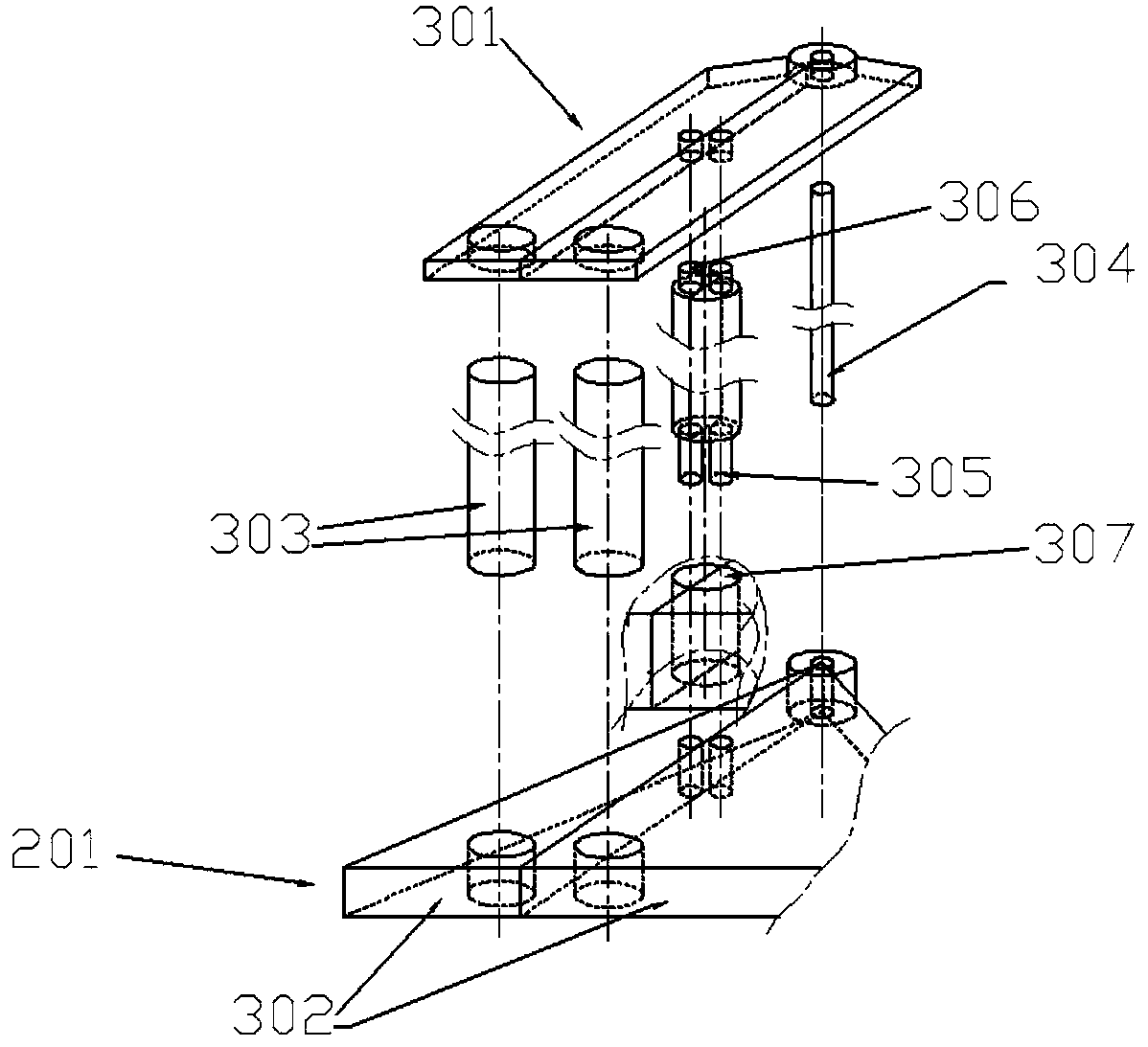

Ternary phase diagram 3D model and 3D printing method thereof

ActiveCN110415596AIncrease diversityIncrease flexibilityAdditive manufacturing apparatusAdditive manufacturing with liquidsEngineeringTernary phase diagram

The invention provides a ternary phase diagram 3D model and a 3D printing method thereof. The ternary phase diagram 3D model comprises a 3D model body; the 3D model body is formed by combining a plurality of single bodies; the 3D model body is provided with a plurality of horizontal sections and vertical sections; the horizontal sections and the vertical sections divide the corresponding single bodies into a plurality of sub bodies; a plurality of vertical holes and horizontal holes are further formed in the 3D model body; and the horizontal holes penetrate from one side of the 3D model body to the other side and intersect with the corresponding vertical holes. The model can display various cross sections and projection of a ternary phase diagram, can be designed, manufactured and improvedat any time according to requirements by a user, and is low in cost and suitable for teaching and science and technology innovation.

Owner:SHANDONG UNIV OF SCI & TECH

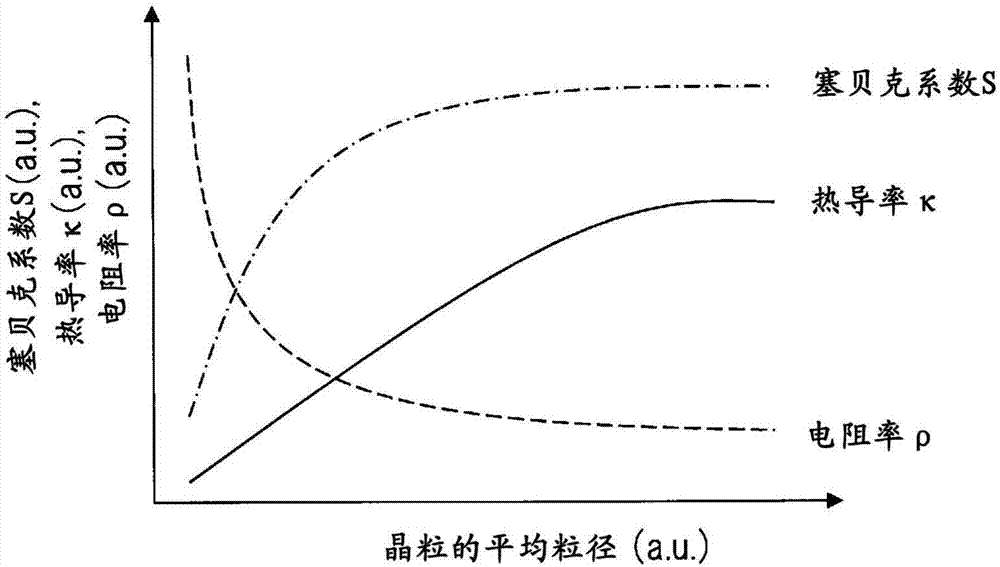

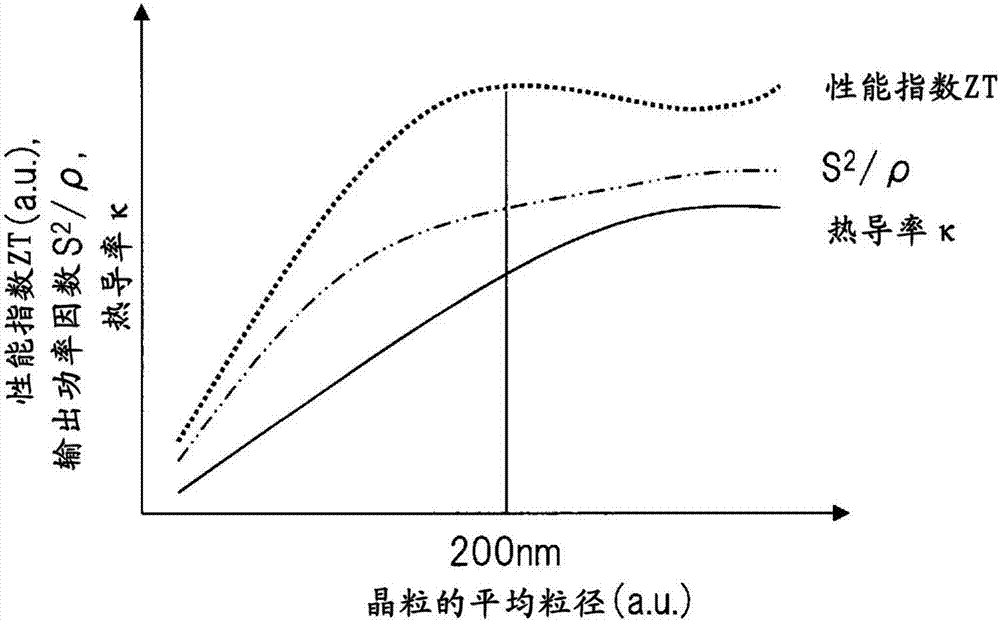

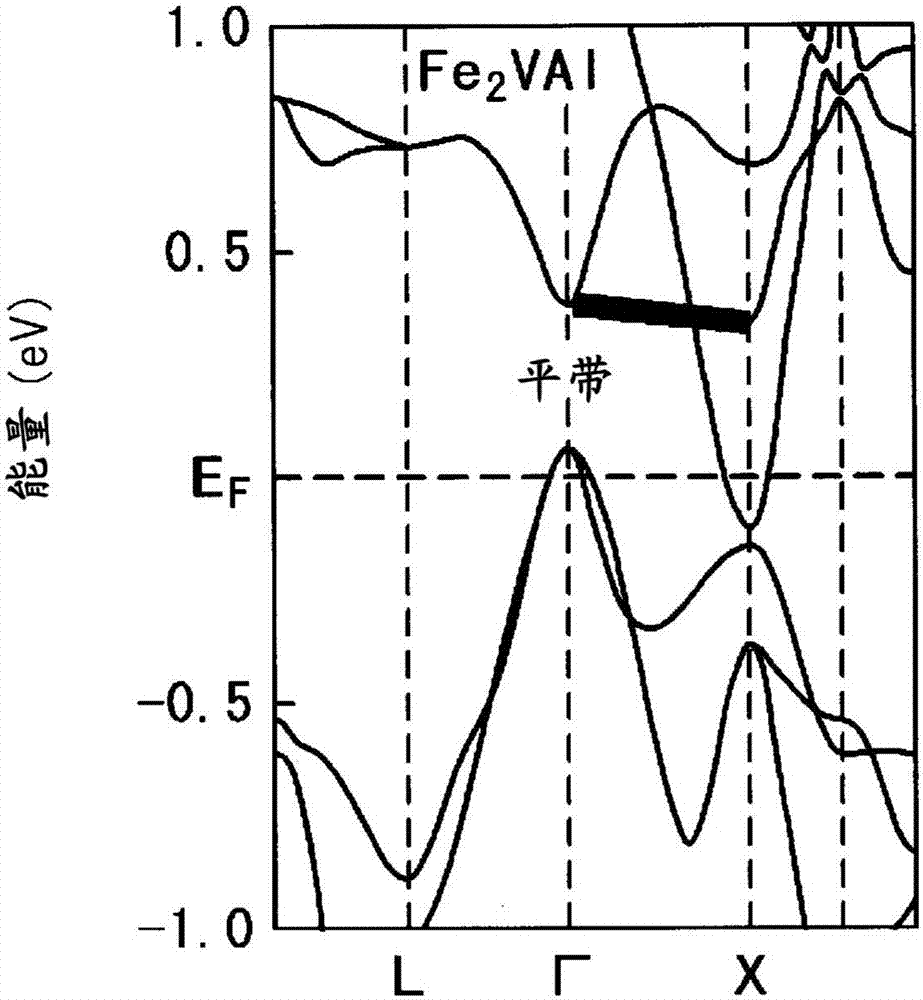

Thermoelectric conversion material

ActiveCN107534078AImprove performance indexTransportation and packagingMetal-working apparatusMetallurgyThermoelectric conversion

Owner:HITACHI METALS LTD

Epitaxial substrate for semiconductor device, semiconductor device, method of manufacturing epitaxial substrate for semiconductor device, and method of manufacturing semiconductor device

ActiveUS8860084B2Lower on-resistanceHigh two-dimensional electron concentrationSemiconductor/solid-state device manufacturingSemiconductor devicesCrystallinityNitride

Provided is a semiconductor device of normally-off operation type having a low on-resistance. An epitaxial substrate for it includes: a base substrate; a channel layer made of a first group-III nitride having a composition of Inx1Aly1Gaz1N at least containing Al and Ga and x1=0 and 0≦y1≦0.3; and a barrier layer made of a second group-III nitride having a composition of Inx2Aly2Gaz2N at least containing In and Al. The composition of the second group-III nitride is, in a ternary phase diagram for InN, AlN, and GaN, in a certain range that is determined in accordance with the composition of the first group-III nitride. The barrier layer has a thickness of 3 nm or less. A low-crystallinity insulating layer is further formed on the barrier layer. The low-crystallinity insulating layer is made of silicon nitride and has a thickness of 3 nm or less.

Owner:NGK INSULATORS LTD

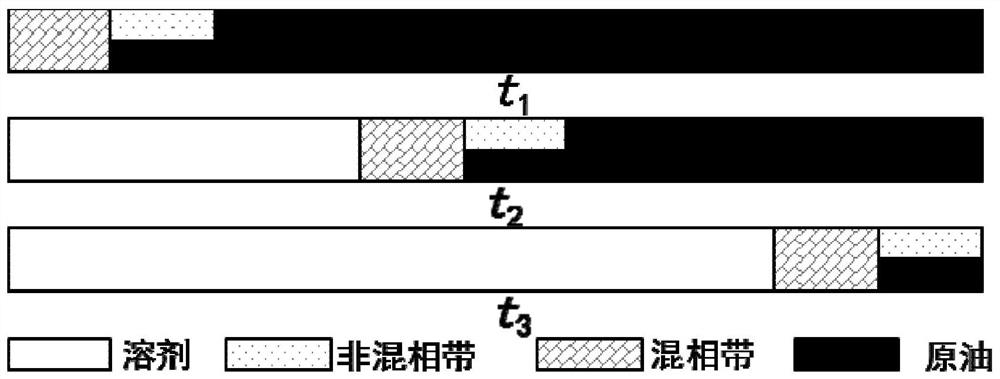

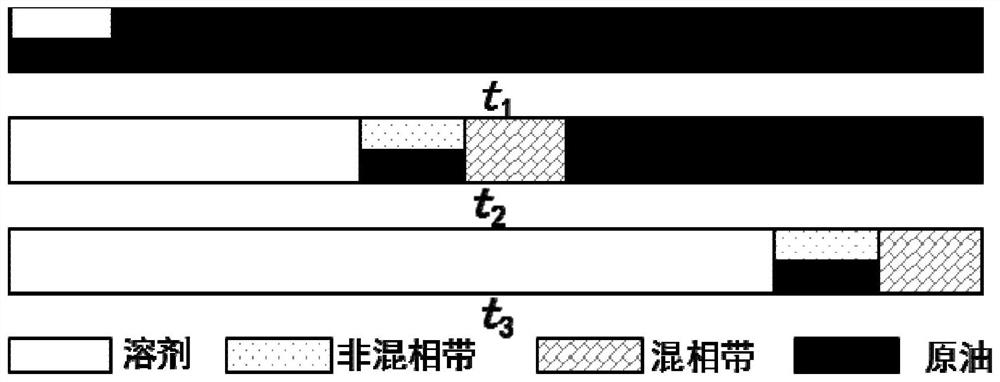

Method for judging mixed phase mechanism of gas with high content of hydrogen sulfide and carbon dioxide

The invention discloses a method for judging a mixed phase mechanism of gas with high content of hydrogen sulfide and carbon dioxide. The method comprises the following steps of: S1, collecting oil reservoir and injected gas related basic data; S2, simulating a multi-stage contact process of gas with high content of H2S and CO2 and crude oil by utilizing a phase balance calculation model, and drawing a multi-stage contact experiment quasi-ternary phase diagram of the gas with high content of H2S and CO2 under the oil reservoir temperature condition; S3, drawing a thin tube characteristic curveof the gas with high content of H2S and CO2 under the oil reservoir temperature condition by utilizing a thin tube experiment; and S4, judging the mixed phase mechanism of the gas with high content of H2S and CO2 through the quasi-ternary phase diagram in the S2 and the thin tube characteristic curve in the S3. According to the method disclosed by the invention, the mixed phase mechanism of the gas with high content of H2S and CO2 can be rapidly judged by drawing the quasi-ternary phase diagram and the thin tube characteristic curve.

Owner:PETROCHINA CO LTD

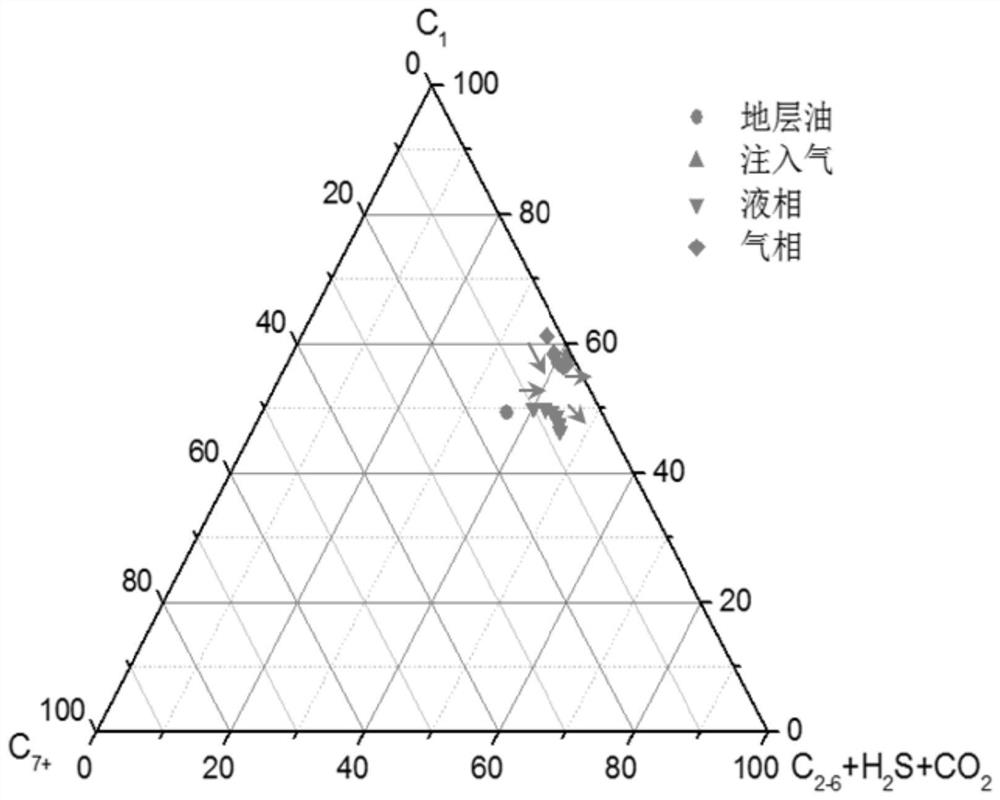

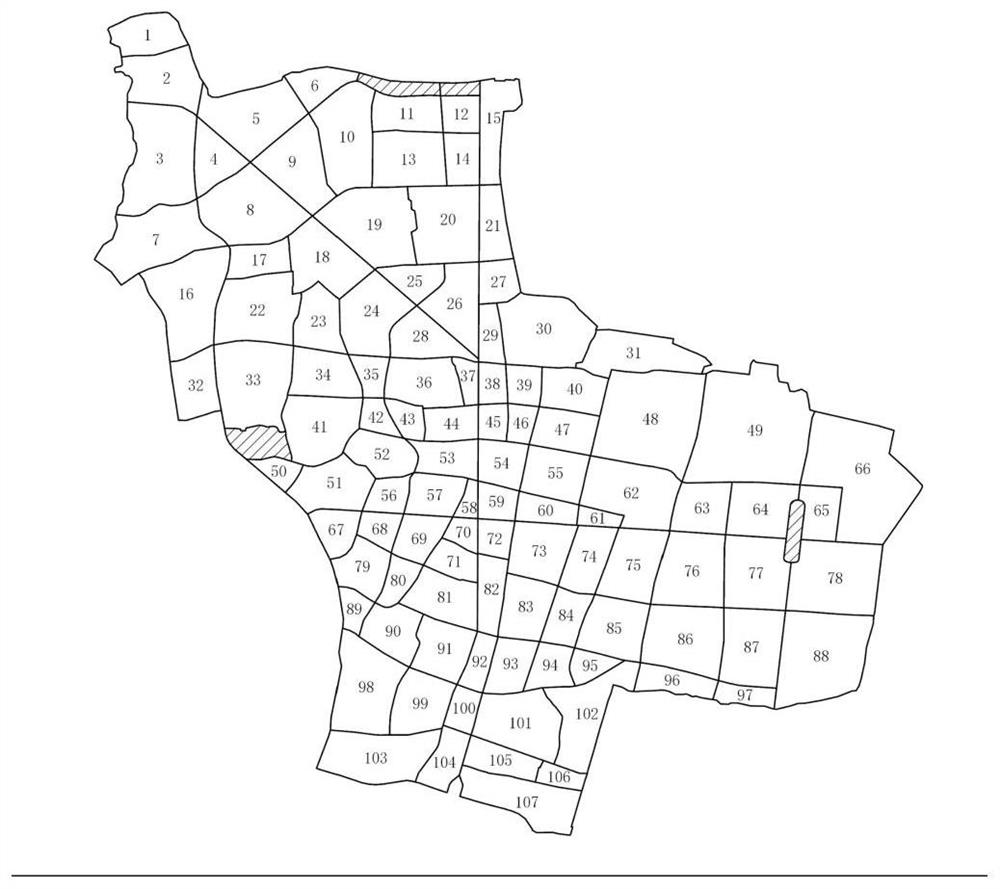

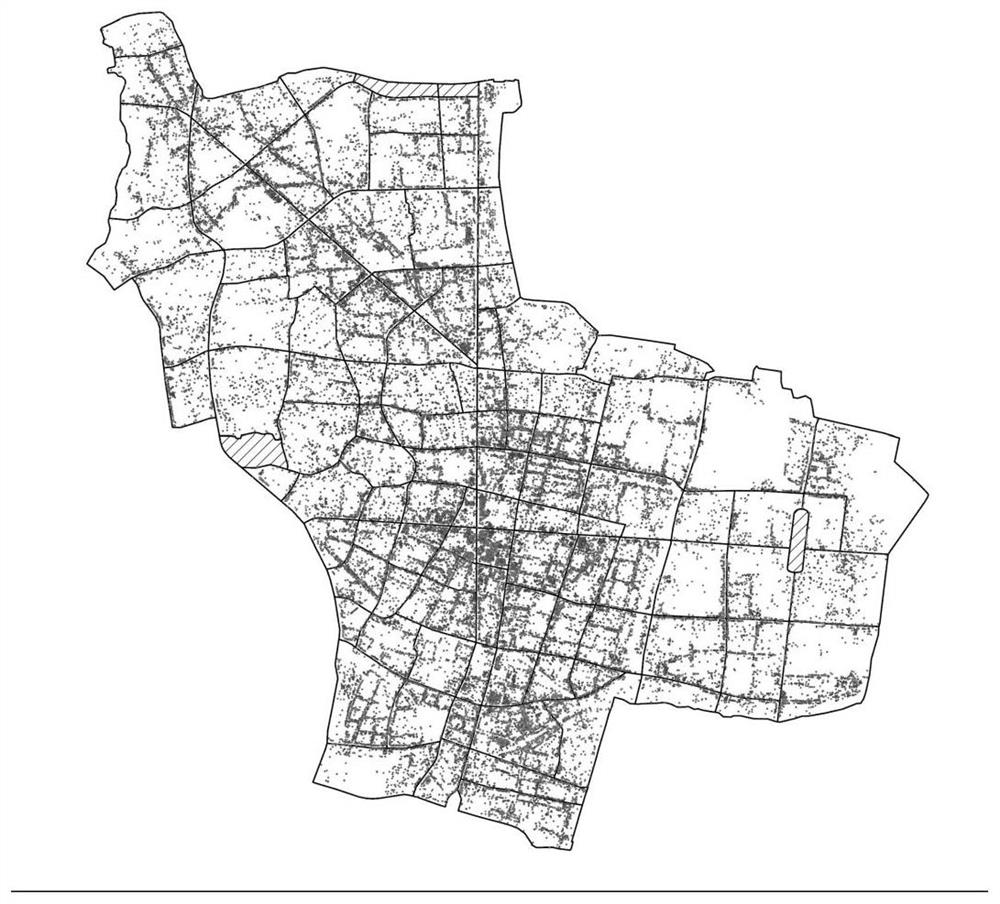

Urban block function mixing degree expression method based on POI data

ActiveCN114003828AGeographical information databasesSpecial data processing applicationsAlgorithmCity block

The invention discloses an urban block function mixing degree expression method based on POI (Point of Interest) data, which relates to the field of urban block function research, and comprises the following steps: acquiring urban POI data information, determining the nature of the data information, classifying and cleaning the data information, acquiring an actual mixing degree and a calculated mixing degree, and acquiring a weight coefficient through Pearson correlation analysis; obtaining a function mixing index of each block, producing a ternary phase diagram, and generating different function grading statistical maps through the ternary phase diagram. An urban functional space structure is combined with POI big data, and a relatively intuitive means is provided for identifying information such as dominant functions, function mixing degrees and function change trends between streets in one time; meanwhile, the distribution characteristics and rules of the urban super block function mixture generate certain integral cognition, and influence factors in the urban super block function mixture can be further discussed on the basis of the distribution characteristics and rules.

Owner:SOUTHEAST UNIV

Panel glass for cathode ray tube

InactiveUS6956000B2Reduce the temperatureImprove the overall coefficientCathode-ray/electron-beam tube vessels/containersFlat glassX-ray

Panel glass, for a cathode ray tube, which has an SrO / (SrO+BaO) ratio of from 0.35 to 0.70, an X-ray absorption coefficient of 36.0 cm−1 or more at the wavelength of 0.6 angstrom, wherein Na2O / R2O, K2O / R2O and Li2O / R2O (R2O: Na2O+K2O+Li2O) molar ratios fall within a range surrounded by the points A (0, 0.2, 0.8), B (0.2, 0.2, 0.6), C (0.4, 0.6, 0), D (0.2, 0.8, 0) and E (0, 0.4, 0.6) in the ternary phase diagram as shown in FIG. 1.

Owner:NIPPON ELECTRIC GLASS CO LTD

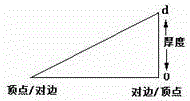

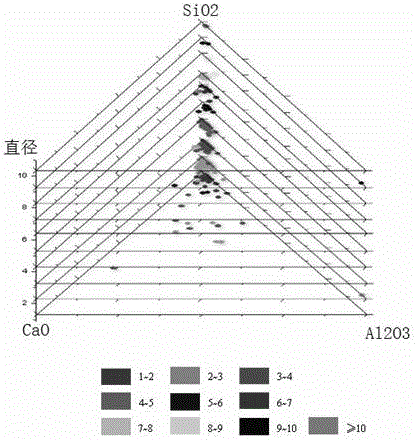

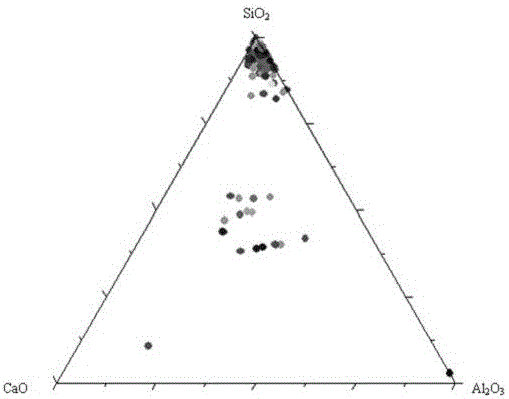

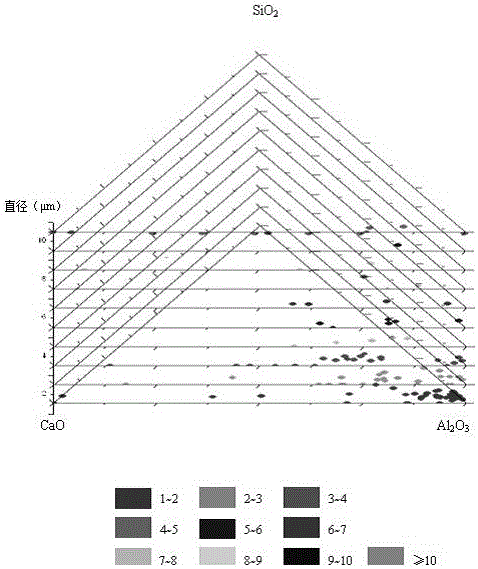

Method for representing inclusions of different sizes, in tire cord steel, in ternary phase diagrams

InactiveCN106204682AIndicates the distribution of different sizesGood deformabilityDrawing from basic elements3D modellingPoint densityTernary phase

The invention relates to a method for representing inclusions of different sizes, in tire cord steel, in ternary phase diagrams. The method comprises the steps of screening data obtained by surface distribution statistics of the inclusions, determining three main components of the inclusions in a sample, and performing normalization processing by weight percentage; then classifying the inclusions by size; and finally projecting the inclusions of the different sizes into the ternary phase diagrams in sequence, filling the ternary phase diagrams with different colors, and superposing the ternary phase diagrams in sequence to form a two-dimensional diagram and a three-dimensional diagram. The ternary phase diagrams of the inclusions of the different sizes are superposed in sequence and filled with the different colors to form a three-dimensional ternary phase diagram, so that distribution situations of the different sizes of the inclusions can be accurately and visually represented, the larger the numerical value of longitudinal coordinates is and the larger the sizes of the inclusions are, and the higher the point density is and the larger the number of the inclusions is; and by observing the ternary phase diagrams, whether the components of the inclusions fall into a region with good deformation capability or not can be known, thereby providing a favorable basis for a production process of the tire cord steel.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

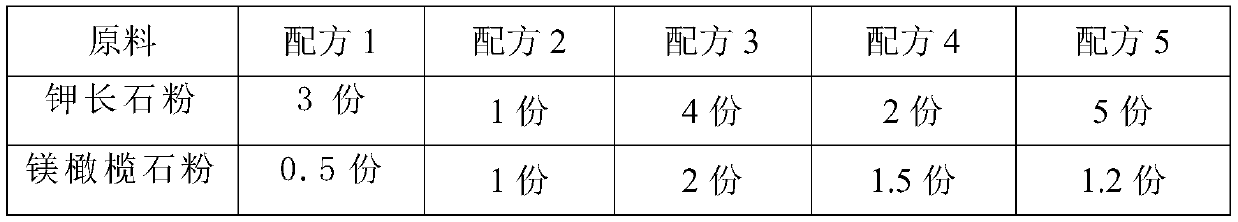

Non-crusting high-magnesium tundish hollow particle covering agent and production method thereof

The invention provides a non-crusting high-magnesium tundish hollow particle covering agent and a production method thereof. The non-crusting high-magnesium tundish hollow particle covering agent is prepared from raw materials comprising, by weight, 85-95 parts of 90 light-burnt magnesia powder or 91 dead-burned magnesia powder, 2-10 parts of calcite or magnesite powder, 1-6 parts of composite melting point modifier, 1-3.5 parts of composite bonding agent and less than or equal to 0.2 part of water reducing agent. Compared with the prior art, The non-crusting high-magnesium tundish hollow particle covering agent has the beneficial effects that for the first time, a potassium feldspar and forsterite composite material is introduced into a tundish magnesium covering agent; according to the magnesia-calcium oxide-silicon oxide ternary phase diagram, the melting point and viscosity of the product are adjusted reasonably, the hardening phenomenon of the covering agent is effectively eliminated, and the requirements of a steel mill for sampling, temperature measuring and other operations are met. The technology of the non-crusting high-magnesium tundish hollow particle covering agent isin the domestic leading position.

Owner:鞍山市和丰耐火材料有限公司

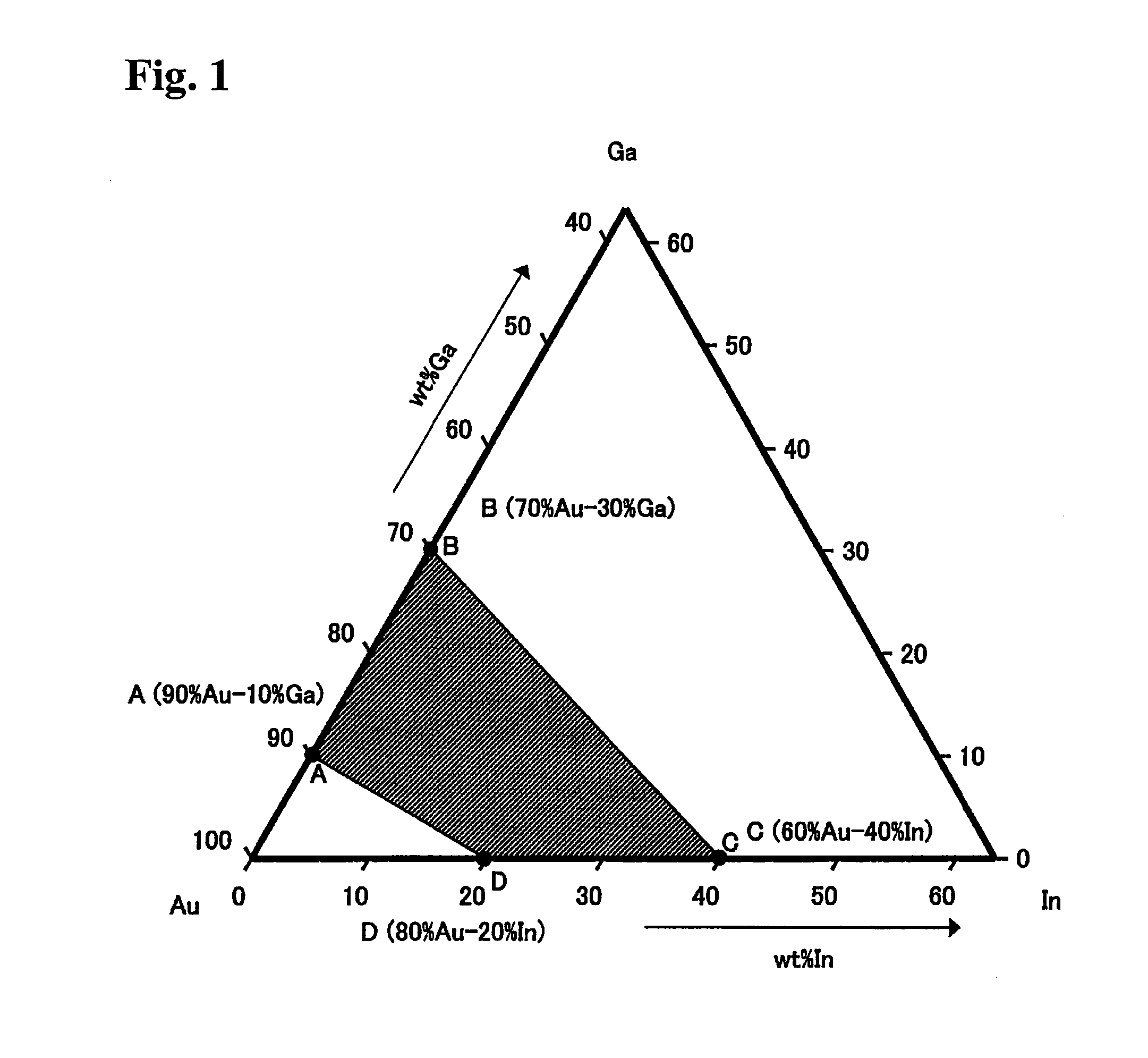

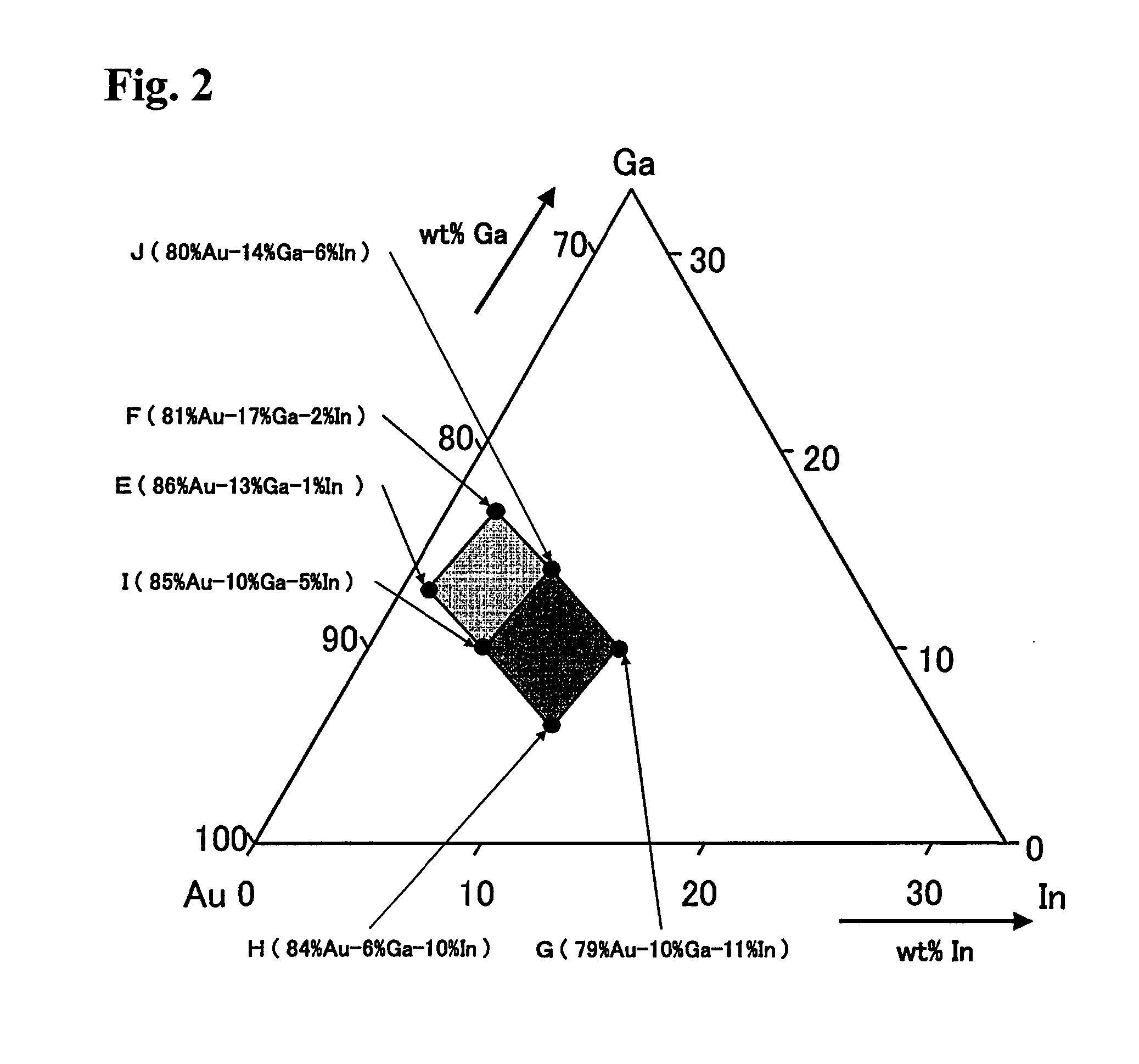

Au-Ga-In BRAZING MATERIAL

ActiveUS20140356226A1Suitable melting propertyIncrease temperature differenceCooking-vessel materialsSemiconductor/solid-state device detailsTernary phase diagramLiquidus

A brazing material which can be melted at a suitable temperature at which damage is not given to a device inside a package upon sealing, and besides the brazing material is not remelted, e.g., upon mounting to a board, and which has a low temperature difference between a liquidus and a solidus. The brazing material is made of a Au—Ga—In ternary alloy, wherein weight concentrations of the elements lie within a region of a polygon with a point A (Au: 90%, Ga: 10%, In: 0%), a point B (Au: 70%, Ga: 30%, In: 0%), a point C (Au: 60%, Ga: 0%, In: 40%) and a point D (Au: 80%, Ga: 0%, In: 20%) as vertexes (excluding lines on which In and Ga become 0%), in a Au—Ga—In ternary phase diagram.

Owner:TANAKA PRECIOUS METAL IND

Method for preparing W/O type arbutin lacquer wax based microemulsion

The invention discloses a method for preparing a W / O type arbutin lacquer wax based microemulsion. The method comprises the steps of: preparing mixed surfactants of different HLB values, and uniformlymixing the mixed surfactants with different cosurfactants proportionally, so as to obtain mixed emulsifiers marked as M1; weighing a certain amount of lacquer wax based isopropyl ester marked as M2,preparing the mixed emulsifiers and the lacquer wax based isopropyl ester in accordance with that M1: M2 is equal to (1: 9) to (9: 1), putting M1 and M2 into a beaker, and carrying out uniform stirring; placing the beaker on a magnetic stirrer, dropwise adding purified water under the condition that the revolution rate is 100r / min, and recording added water volume marked as M3 during phase change;screening out the mixed surfactant with the optimal HLB value and the cosurfactant with the optimal HLB value and a ratio of the surfactant to the cosurfactant by adopting a pseudo-ternary phase diagram method, and determining experimental parameters when a microemulsion area is maximum; preparing arbutin aqueous solutions of different concentrations, selecting an appropriate formula according toan optimized ternary phase diagram, and preparing the W / O type arbutin microemulsion. According to the method disclosed by the invention, the operation is simple, ambient conditions such as high shear and high temperatures are not required, and the W / O type arbutin microemulsion with stable properties can be spontaneously produced.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

3D printing multivariate phase diagram establishing method for improving material course teaching

InactiveCN111531871AImprove teaching qualityAdditive manufacturing apparatusAdditive manufacturing with liquidsProcess engineeringCoursework

The invention discloses a 3D printing multivariate phase diagram establishing method for improving material course teaching. The method comprises the following steps of firstly carrying out the analysis of a needed ternary phase diagram, and carrying out the three-dimensional modeling of a local phase region; and finally, forming the established model by adopting a 3D technology and then carryingout assembling. The multivariate phase diagram establishing method solves the problem that the three-dimensional spatial distribution of the multivariate phase diagram is difficult to vividly expressin material phase diagram teaching, visually and efficiently displays the three-dimensional spatial distribution to students, injects new vitality for classroom teaching, helps the students visually understand the multivariate complex phase diagram, and improves the teaching quality.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com