Thermoelectric conversion material

A technology of thermoelectric conversion materials and valence electrons, which is applied in the fields of thermoelectric device node lead-out materials, transportation and packaging, metal processing equipment, etc., can solve the problems of high cost, strong Te toxicity, etc., and achieve the effect of improving the performance index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0093]

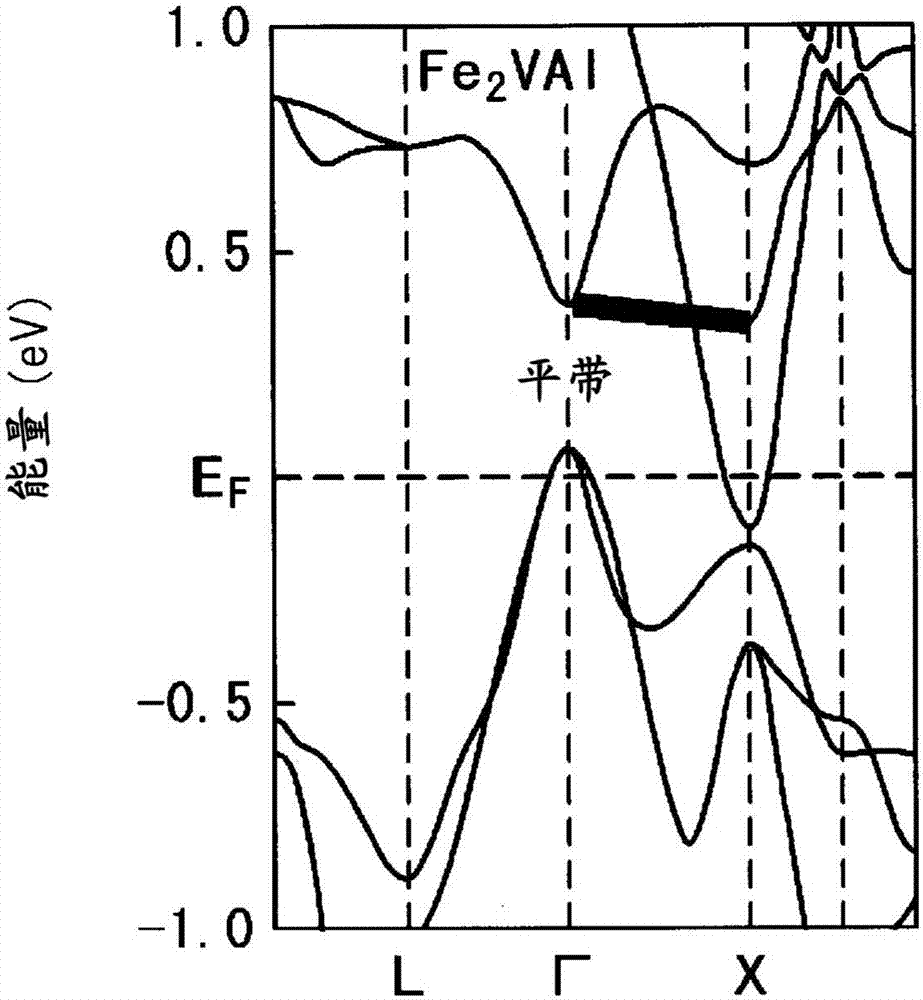

[0094] in the synthesis of Fe 2 TiSi series full Heusler alloy or Fe 2 TiSn-based full Heussler alloy (hereinafter referred to as Fe 2 TiA series full Heusler alloy), add appropriate additives, that is, replace any one of Fe, Ti, and A with appropriate elements, and control the average number of valence electrons VEC per atom, so that ΔVEC described later is called 02 TiA-based full Heusler alloys exhibit high performance indices.

[0095] The details will be described below.

[0096] First, the average number of valence electrons VEC (hereinafter, may also be referred to as VEC) per atom will be described.

[0097] The so-called VEC is the average number of electrons in the outermost shell of an atom, and is a value obtained by dividing the total number of valence electrons Z of the compound by the number a of atoms in the unit cell.

[0098] For example Fe 2 In the case of TiSi, iron (Fe) has 8 valence electrons, titanium (Ti) has 4 valence electrons, and sil...

Embodiment

[0241] Hereinafter, this embodiment will be described in more detail based on examples. It should be noted that the present invention is not limited to the following examples.

[0242] The thermoelectric conversion material of the present invention was produced by the following method.

[0243] First, for the containment with 2 L2 represented by E2E3 1 A thermoelectric conversion material of a full Heusler alloy having a type crystal structure uses iron (Fe), titanium (Ti), and silicon (Si) as raw materials for the main components of each of the E1 site, E2 site, and E3 site. In addition, copper (Cu), vanadium (V), and tin (Sn) were used as raw materials of the main component substituted at each of the E1-position, E2-position, or E3-position. Then, each raw material is weighed so that the produced thermoelectric conversion material has a desired composition.

[0244] Next, the raw material was placed in a container formed of stainless steel in an inert gas atmosphere, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com