Double-effect regeneration absorption-generation system and regeneration third-class absorption heat pump

A technology of absorption heat pump and generation system, which is applied in adsorption machines, energy-saving heating/cooling, lighting and heating equipment, etc., can solve the problem of insufficient utilization of temperature difference, and achieve the effect of improving performance index and reducing heat load driven by high temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The first thing to explain is that in the expression of the structure and process, it will not be repeated if it is not necessary; the obvious process will not be expressed. The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

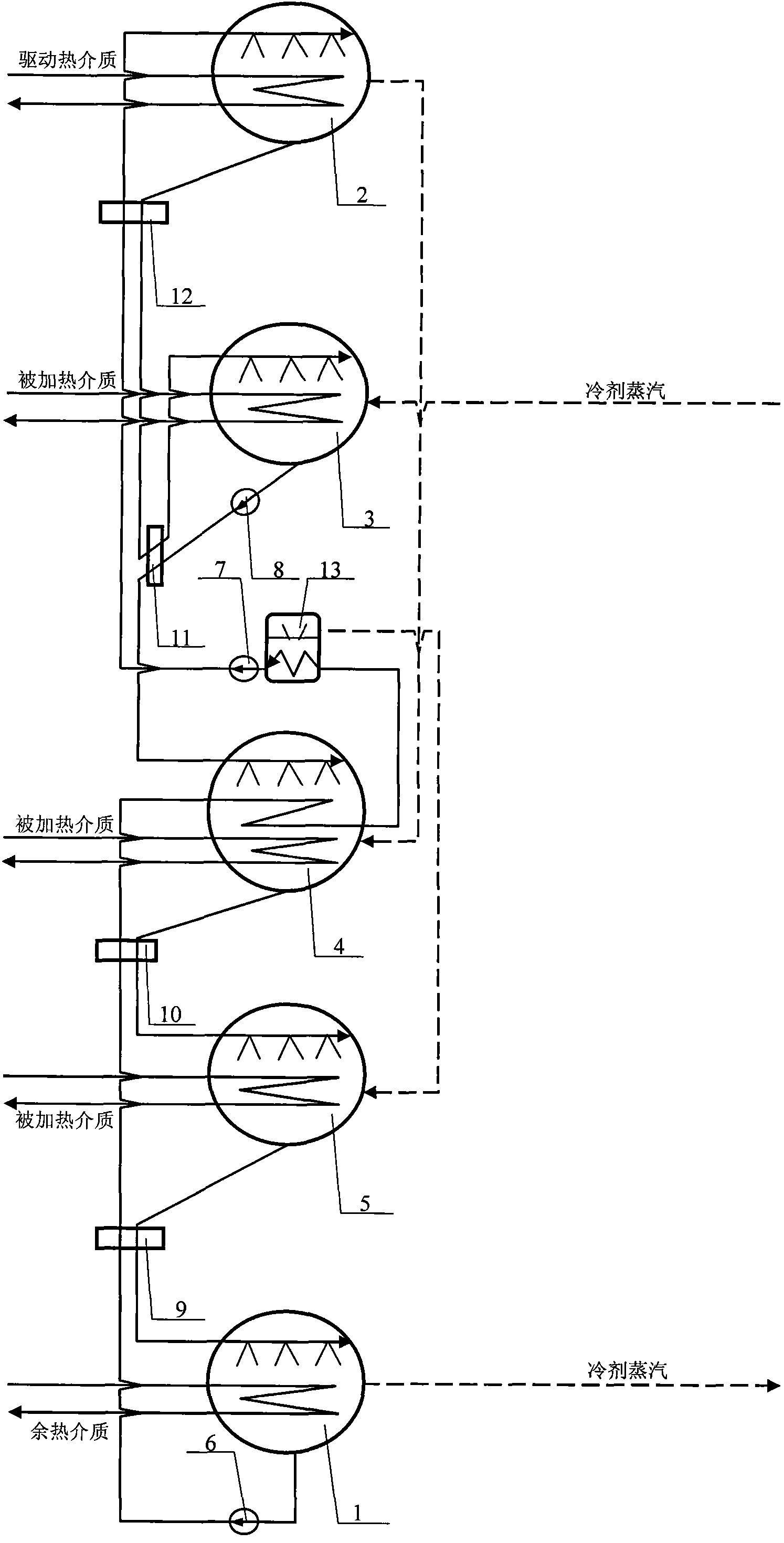

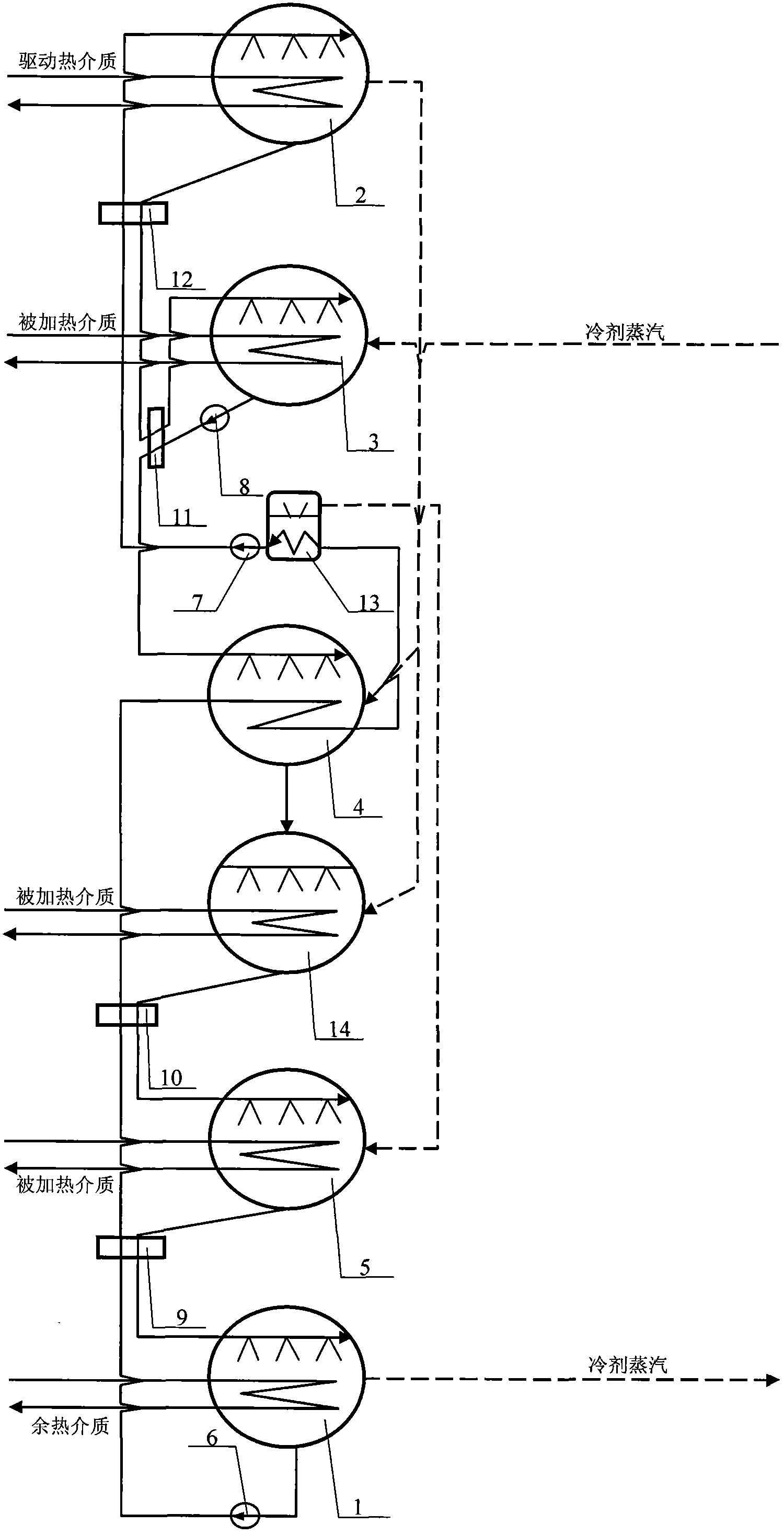

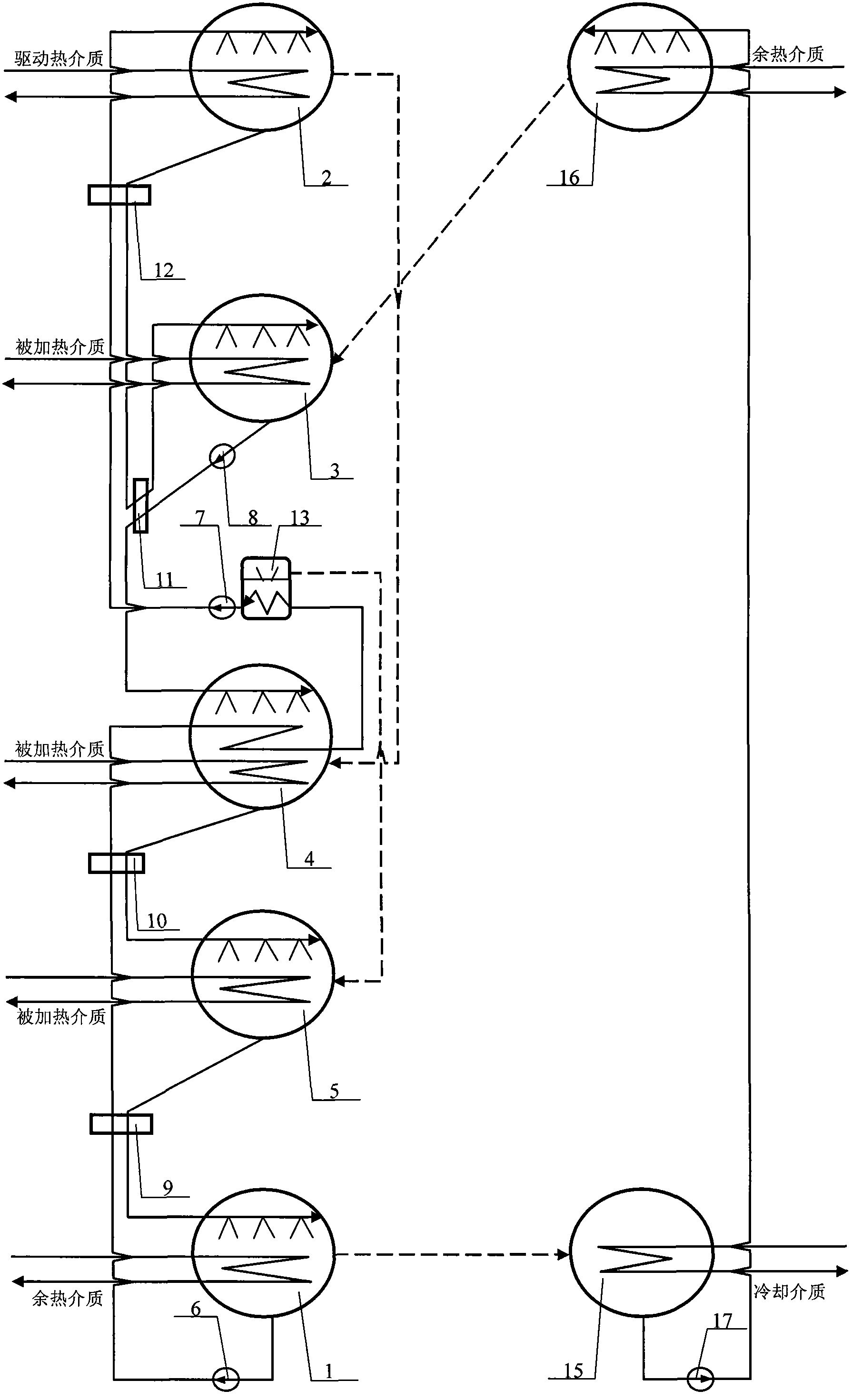

[0035] figure 1 The shown double-effect heat recovery absorption-generation system is realized in this way:

[0036] ① Structurally, it mainly consists of the first generator, the second generator, the first absorber, the second absorber, the third absorber, the first solution pump, the second solution pump, the third solution pump, the first solution Heat exchanger, the second solution heat exchanger, the third solution heat exchanger, the fourth solution heat exchanger and steam distribution chamber; the first generator 1 has a concentrated solution pipeline through the first solution pump 6, the first The solution heat exchanger 9, the second solution heat exchanger 10 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com