Patents

Literature

65results about How to "In line with the development concept" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fermented coconut cream/coconut pulp juice, coconut yogurt and preparation methods of fermented coconut cream/coconut pulp juice and coconut yogurt

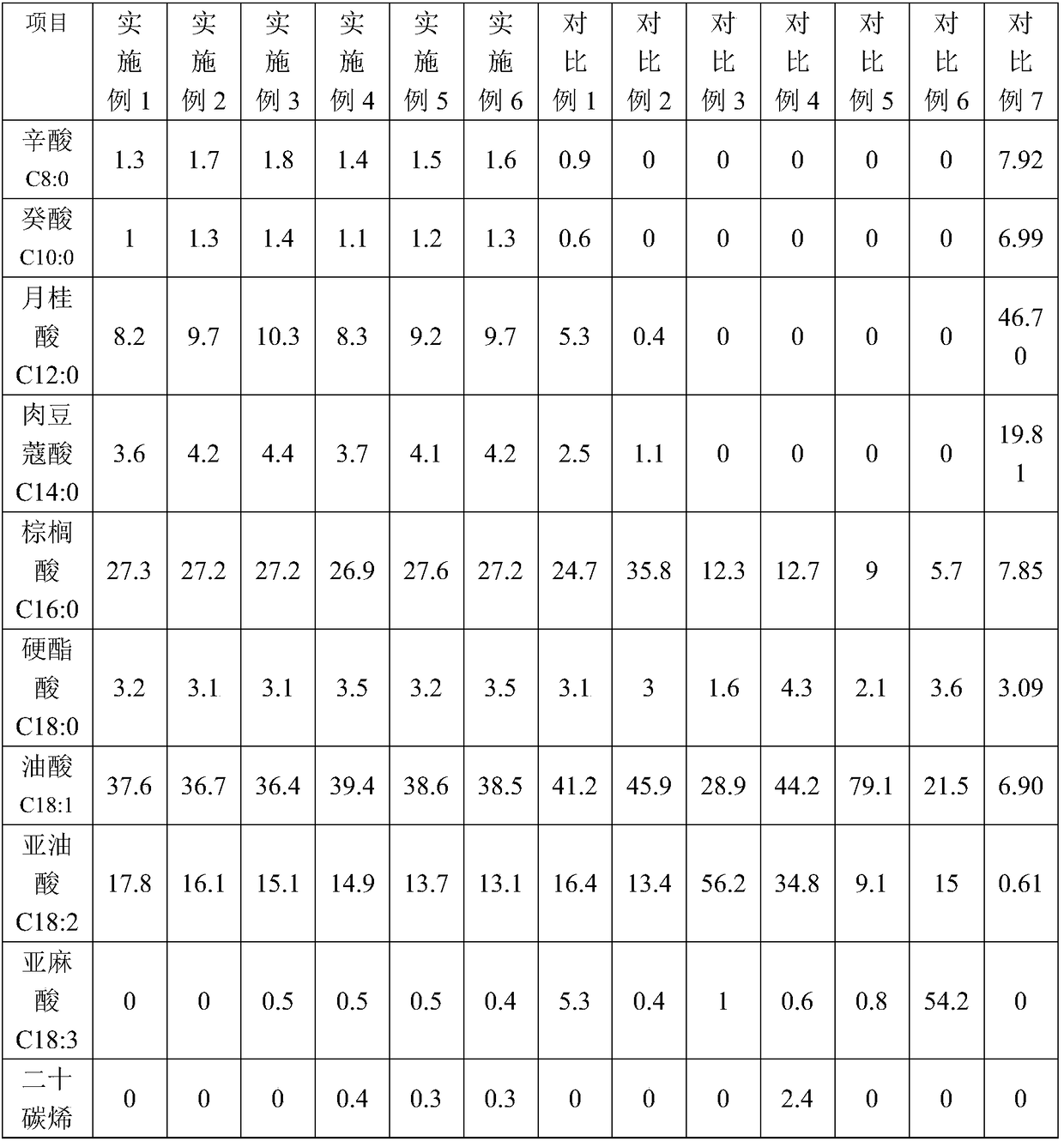

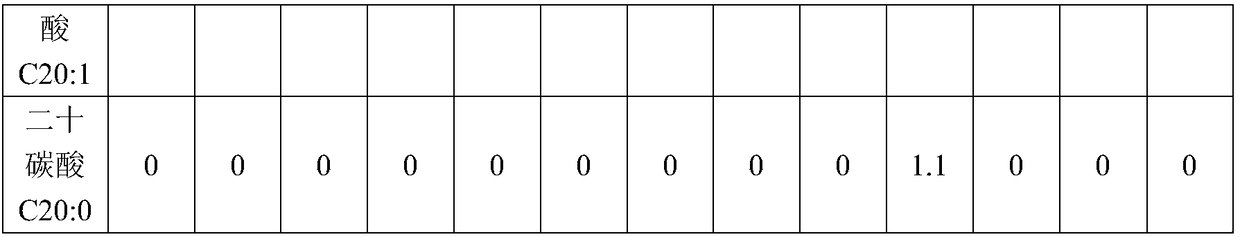

The invention relates to the technical field of foods and relates to fermented coconut cream / coconut pulp juice, coconut yogurt and preparation methods of fermented coconut cream / coconut pulp juice and coconut yogurt. The preparation method of the fermented coconut cream / coconut pulp juice comprises the following steps: removing partial grease from coconut cream / coconut pulp juice, and carrying out sterilization and cooling, so as to obtain a fermented raw material; and adding a first fermentation strain into the fermented raw material, so as to obtain the fermented coconut cream / coconut pulp juice. The preparation method of the coconut yogurt comprises the following steps: respectively and independently fermenting the coconut cream / coconut pulp juice and a milk product, so as to obtain the fermented coconut cream / coconut pulp juice and fermented yogurt; and mixing the fermented coconut cream / coconut pulp juice with the fermented yogurt with the fermented yogurt in proportion, and carrying out blending and sterilization, so as to obtain the coconut yogurt. The products provided by the invention have special flavors of coconuts and yogurt, stable tissue state and fine and smooth taste and are rich in nutrition and easy to digest and absorb.

Owner:卞寿斌

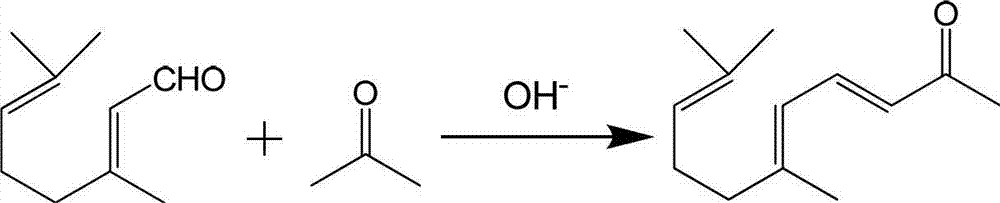

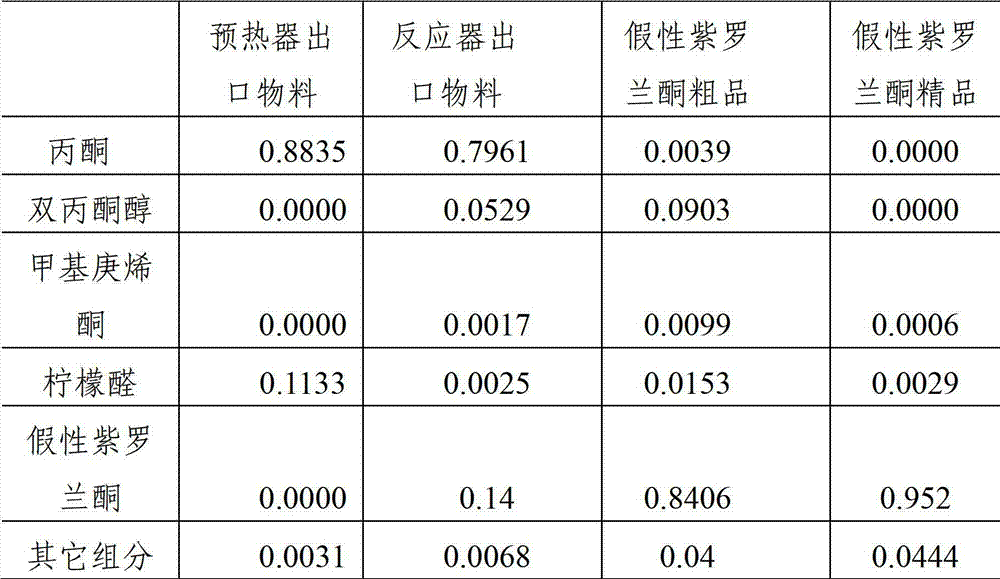

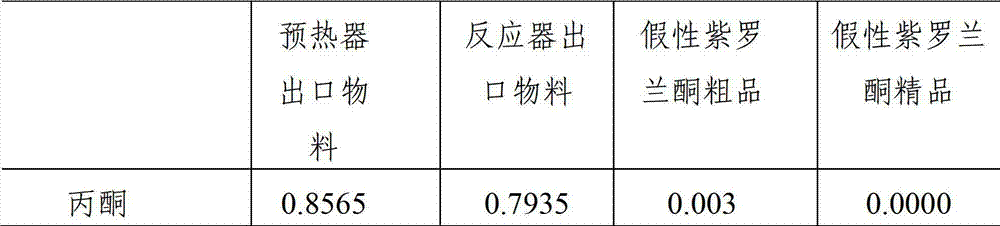

Method for continuously preparing pseudo ionone of vitamin A intermediate

ActiveCN103044223AIn line with the development conceptOvercome the shortcomings of low space-time yield and solid waste pollutionOrganic compound preparationCarbonyl compound preparationSide effectVitamin A Alcohol

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

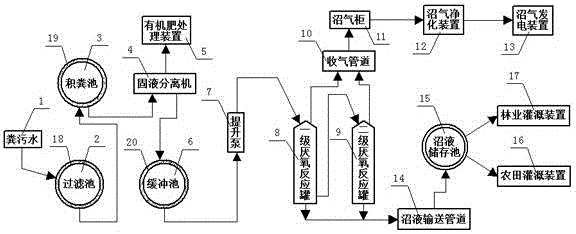

Large-scale piggery dung treatment ecological circulation system

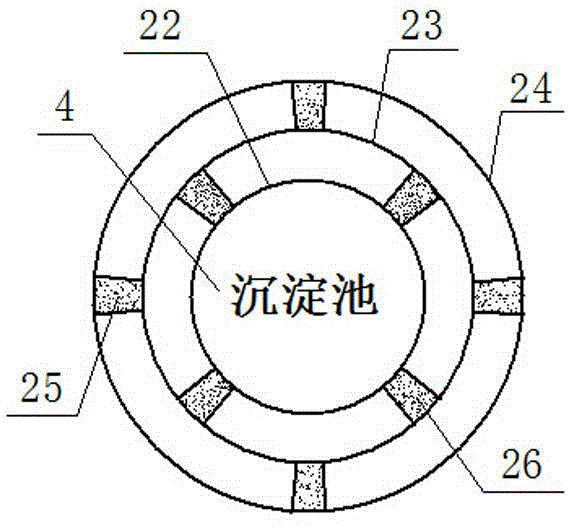

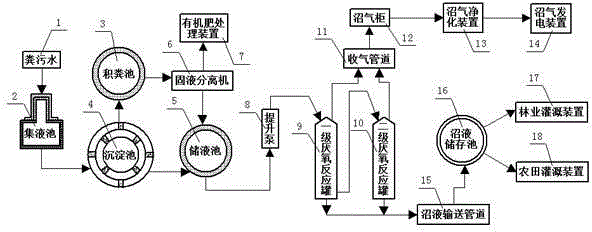

ActiveCN104817170AAvoid emissionsIn line with the development conceptBio-organic fraction processingClimate change adaptationOxidation resistantSlurry

The invention discloses a large-scale piggery dung treatment ecological circulation system which comprises a dung collection unit, a solid-liquid separation unit, an anaerobic fermentation unit, a biogas utilization unit and a biogas slurry utilization unit. The dung collection unit comprises a slurry collection tank, a dung accumulation tank, a settling tank and a slurry storage tank, the solid-liquid separation unit comprises a solid-liquid separator and an organic fertilizer treatment device, the anaerobic fermentation unit is a multistage anaerobic reaction device and comprises a primary anaerobic reaction tank and a secondary anaerobic reaction tank, the biogas utilization unit comprises a biogas cabinet, a biogas purification device and a biogas power generation device, the biogas slurry utilization unit comprises a biogas slurry storage tank, a forestry irrigation device and a farmland irrigation device, and high-temperature oxidation resistant plastic soft protection layers are arranged above the dung accumulation tank and the slurry storage tank. Dung water is fermented to generate biogas and biogas slurry, organic fertilizers are generated after solid-liquid separation, the possibility of secondary pollution caused by waste gas is avoided, waste is effectively and sufficiently reused, and comprehensive utilization rate is increased.

Owner:MUYUAN FOODS CO LTD

Circulation production process for glyphosate

ActiveCN101402652AHigh removal rateReduce pollutionGroup 5/15 element organic compoundsPhosphatePhosphorus trichloride

The invention discloses a technology for the circular production of glyphosate, which pertains to the technical field of pesticide. An alkyl ester process is adopted to produce the glyphosate; chlorine and yellow phosphorus are used for producing phosphorus trichloride; the phosphorus trichloride and methanol react to produce dimethyl phosphate which is taken as a raw material to prepare the glyphostate and glyphostate mother solution; triethylamine separated from the glyphostate mother solution is reused and after the triethylamine is separated, alkali mother solution is then obtained; after sodium is removed by a membrane process, the alkali mother solution is divided into strong solution and weak solution, with the strong solution being used for preparing a glyhosate ammonium aqua and the weak solution being electrolyzed to obtain sodium hydroxide solution, chlorine and hydrogen, wherein, sodium hydroxide is used for recovering the triethylamine, the sodium hydroxide solution is used for neutralizing thin methanol, the chlorine is used for synthesizing phosphorus trichloride and the hydrogen is used for other purposes. The technology for the circular production of glyphosate has good effect in triethylamine recovery, high recovery rate, low cost and high removal rate of sodium chloride in the alkali mother solution, forms large-scale circular production of the glyphosate, and is characterized by reduction in logistics cost, high comprehensive utilization, less environmental pollution, compliance with the development concept by industrial recycling economy and remarkable comprehensive benefits.

Owner:JIANGXI JINLONG CHEM

Organic fertilizer for vegetables and preparation method thereof

InactiveCN104230403AImprove absorption and utilizationReduce the cost of farmingFertilising methodsOrganic fertilisersParasitic plantChemistry

The invention discloses a preparation method of an organic fertilizer for vegetables. The preparation method comprises the following steps: (1) mixing the following raw materials in parts by mass: 200 parts of a 5%-8% palm essence solution, 290 parts of a 5%-8% bamboo essence solution and 50 parts of bamboo stem cells, adding water and fermenting for 7-8 days; (2) mixing 100 parts of a 5%-8% moran or intsia essence solution with 30 parts of moran or intsia stem cells, adding water and fermenting for 7-9 days; (3) adding 180 parts of a 5%-8% eichhornia crassipes or duckweed essence solution and 30 parts of eichhornia crassipes or duckweed stem cells into a mixture obtained in the step (2), adding water and fermenting for 8-9 days; (4) adding 100 parts of 5%-8% akala essence and 20 parts of akala stem cells into a mixture obtained in the step (3), adding water and fermenting for 6-8 days; (5) performing rotary separation on a fermented product prepared in the step (4) through a centrifugal separator at the speed of 15,000 r / min for 2 hours, and fermenting at 30-35 DEG C for 6-8 days.

Owner:万物生(深圳)生物科技控股有限公司

Botanic organic fertilizer and preparation method thereof

InactiveCN104311359AReduce the cost of farmingEasy to transportBio-organic fraction processingOrganic fertiliser preparationDistilled waterOrganic fertilizer

The invention relates to a preparation method of a botanic organic fertilizer. The preparation method comprises the following steps: (1) according to mass fraction, mixing 300 parts of 5-10% palm essence solution, 40 parts of 5-10% bamboo essence solution and 60 parts of bamboo stem cells, adding a moderate amount of distilled water for uniformly stirring, and fermenting for 7-8 days; (2) re-mixing 190 parts of 5-10% Moran or Merbau essence solution and 10 parts of Moran or Merbau stem cells, and fermenting for 7-9 days; (3) adding 180 parts of 5-10% Eichornia crassipes or duckweed essence solution and Eichornia crassipes or duckweed stem cells into the mixture obtained from the step (2), and fermenting for 7-9 days; (4) adding 100 parts of 5-10% akala parasitic plant essence solution and 10 parts of akala parasitic plant stem cells into the mixture obtained from the step (3), and fermenting for 6-8 days; and (5) after fermenting 100 parts of milk for 7 days, adding the milk into the mixture obtained from the step (4), and fermenting for 7 days to obtain the product botanic organic fertilizer.

Owner:万物生(深圳)生物科技控股有限公司

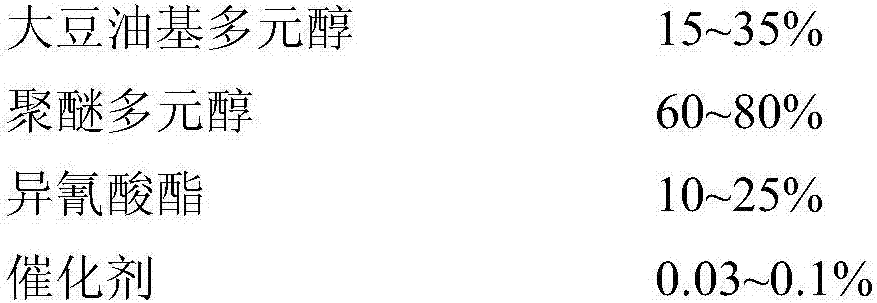

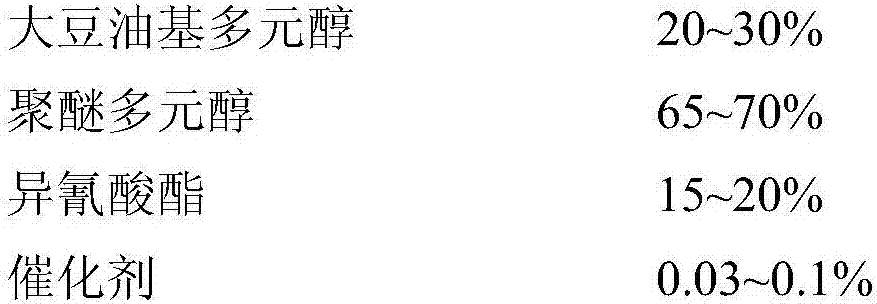

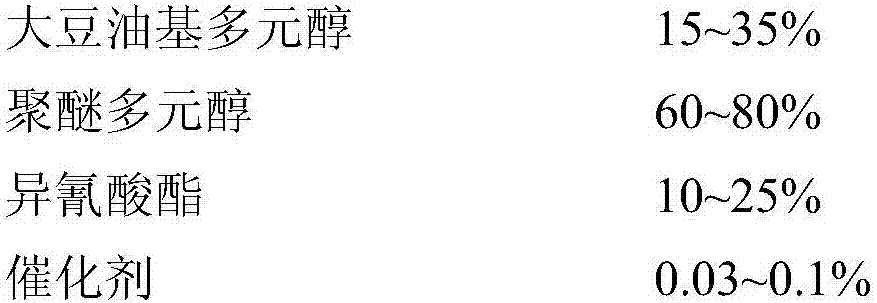

Environment-friendly soybean oil-based moisture-cured polyurethane wood adhesive

InactiveCN107474785AFully reflect the friendlinessReduce consumptionPolyureas/polyurethane adhesivesAdhesiveEconomic benefits

The invention discloses an environment-friendly soybean oil-based moisture-cured polyurethane wood adhesive, which comprises the following raw materials in percentage by mass: 15-35% of soybean oil-based polyol, 60-80% of polyether polyol, 10-25% of isocyanate, and 0.03-0.1% of catalyst. No solvents are added into the adhesive, so that the environment-friendly, healthy and safe requirements of the green adhesive can be met. The adhesive can be moisture-cured at room temperature, and has good adhesion performance after being applied in the field of wood adhesives. The invention further discloses a preparation method of the environment-friendly soybean oil-based moisture-cured polyurethane wood adhesive, and the preparation method comprises simple steps, is convenient to construct, has high economic benefits and is beneficial to industrial production.

Owner:郑州华普密封材料有限公司

Yoghourt coconut jelly and making method thereof

InactiveCN106136163AAdd flavorNutritiousMilk preparationFood ingredient as mouthfeel improving agentFresh coconutSucrose

The invention discloses yoghourt coconut jelly which is made from, by weight, 10-25% of coconut milk, 25-35% of fermented milk and 5-15% of edible gum. The fermented milk is a finished product formed in the mode that by weight percentage, 1-12% of cane sugar and 20-30% of coconut water are added in a milk product with the milk product as reference, the mixture is heated and sterilized, and lactic acid bacteria are inoculated to be fermented for 2-10 h. By adding fresh coconut water for fermentation, the flavor of the coconut is improved, sufficient nutrients are provided for lactic acid bacteria, and nutrient of yoghourt is increased. By adding fresh coconut milk, the special flavor and nutrients of coconuts are maintained, and the unique tropical area characteristic is given to the jelly.

Owner:海南椰语堂食品有限公司

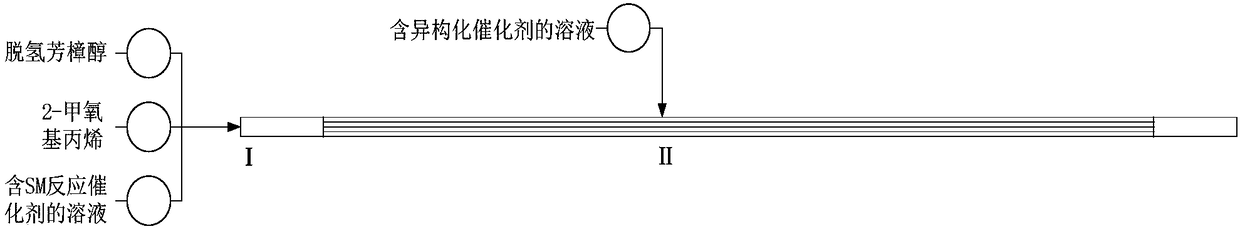

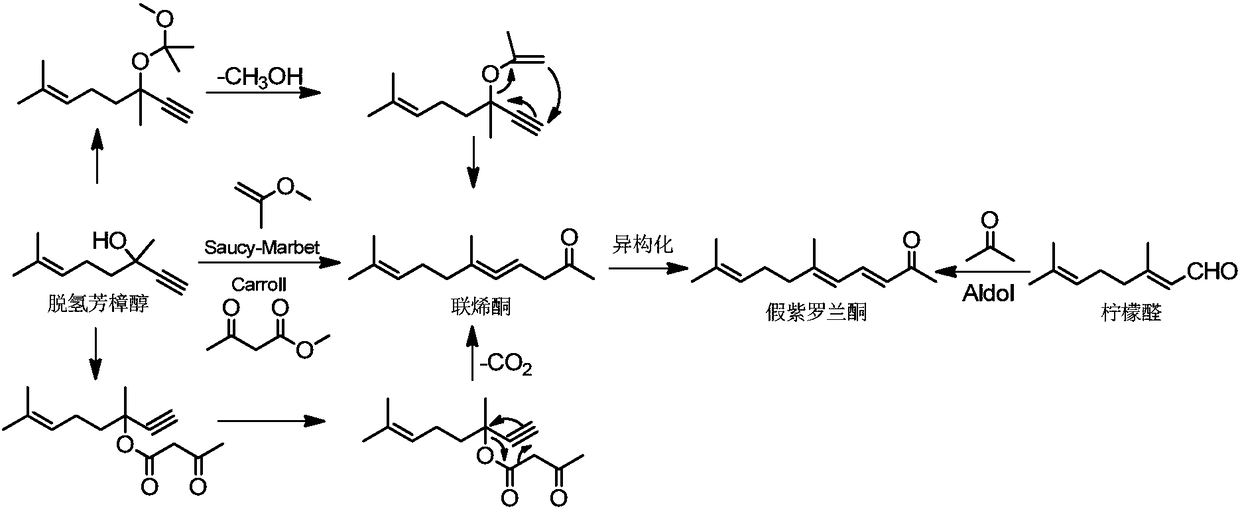

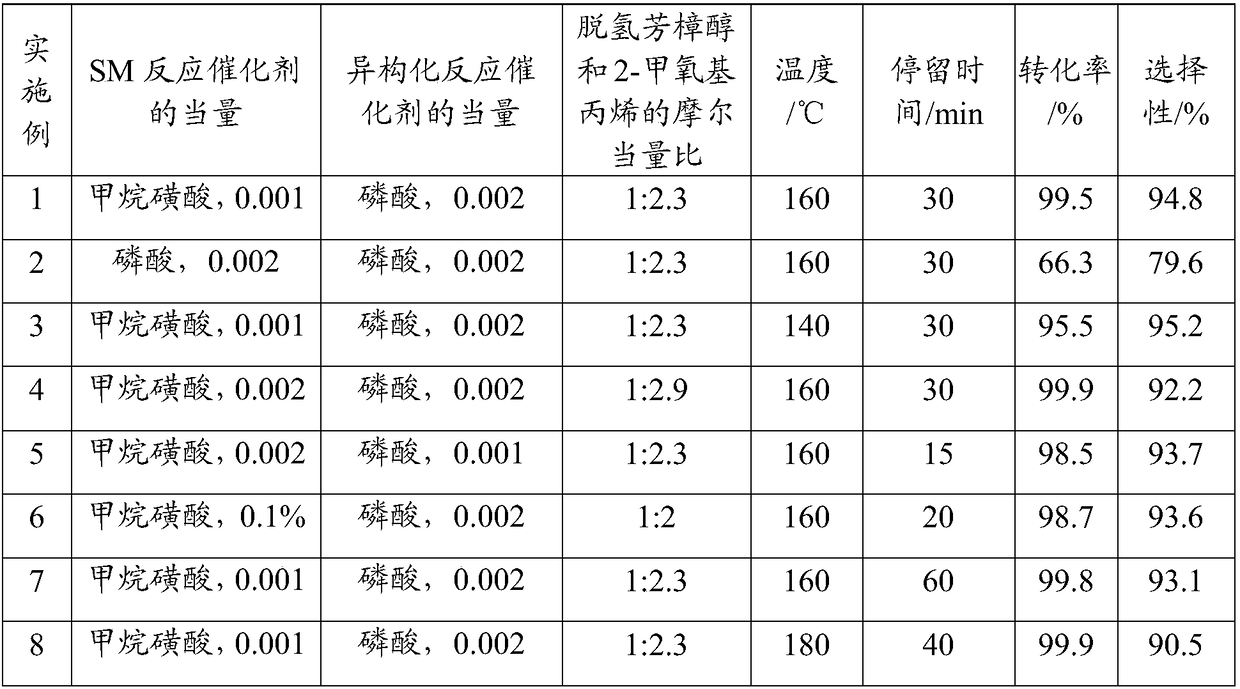

Pseudoionone synthesis method

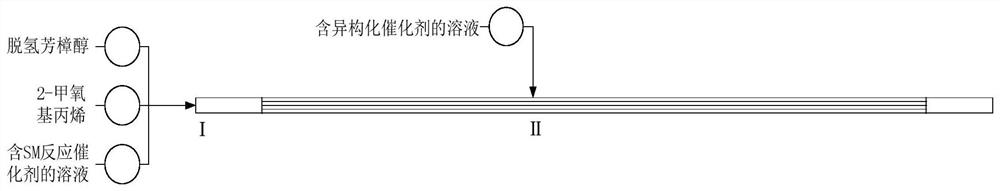

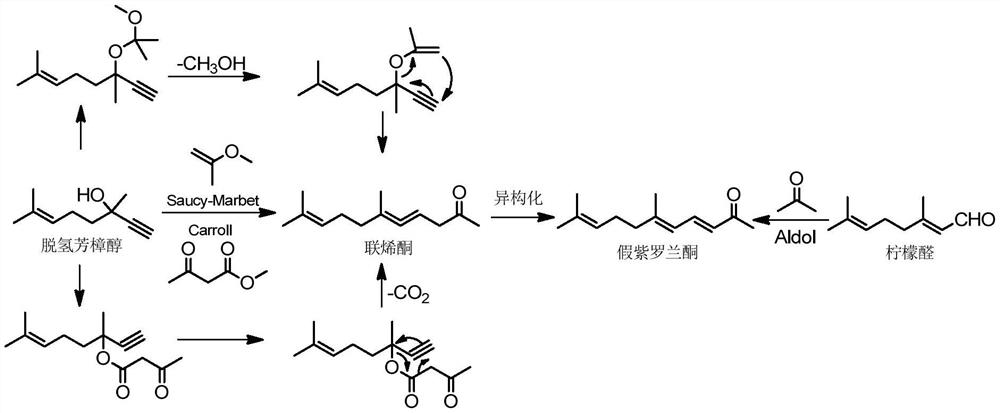

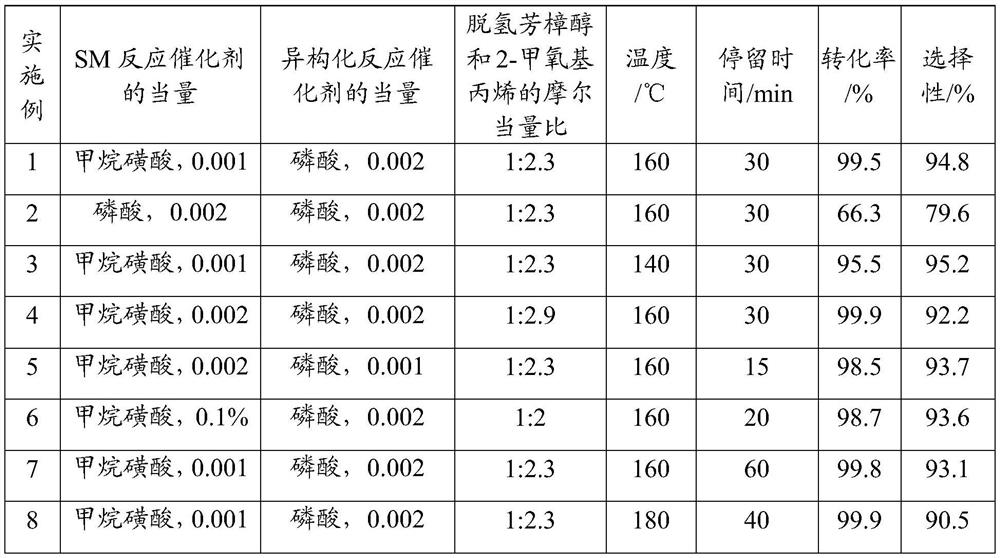

ActiveCN108530279AImprove efficiencyFew reaction stepsOrganic compound preparationCarbonyl compound preparationContinuous production2-Methoxypropene

The invention relates to a pseudoionone synthesis method which includes the step of sequentially performing Saucy-Marbet reaction and isomerization reaction of hotrienol and 2-methoxypropene in a micro-channel reactor to prepare pseudoionone. Therefore, continuous production of the pseudoionone is realized, the method is high in efficiency, yield and selectivity and less in pollution and conformsto green chemical development concept, and reaction steps are fewer.

Owner:ZHEJIANG NHU CO LTD +1

Method for co-producing synthesis gas through treatment of high-concentration salt and high-COD sewage

ActiveCN105585058AIn line with the development conceptImprove use valueGasification processes detailsWater/sewage treatmentHigh concentrationTotal solid content

The invention discloses a method for co-producing synthesis gas through treatment of high-concentration salt and high-COD sewage. High-concentration salt and high-COD sewage are concentrated, the mass fraction of the total solid content of the high-concentration salt and the high-COD sewage ranges from 10% to 60%, and then the concentrated materials and oxygen are mixed and atomized on a nozzle; then the mixture enters a pressurizing coal gasifier, splitting, converting and oxidizing reactions are carried out under the working condition of 2 Mpa to 8 Mpa and 1,250 DEG C to 1,500 DEG C, and water gas is generated; finally, the water gas is washed and dedusted, and the clean synthesis gas is obtained. The synthesis gas can be used for producing synthesis ammonia, methyl alcohol, ethanediol and other chemical products, and the utilization value of the sewage is improved. Harmful waste hard to treat is converted into raw materials for producing chemical products, remarkable social and economic benefits are achieved, and the method conforms to the development concept of circular economy.

Owner:HUBEI SANNING CHEM

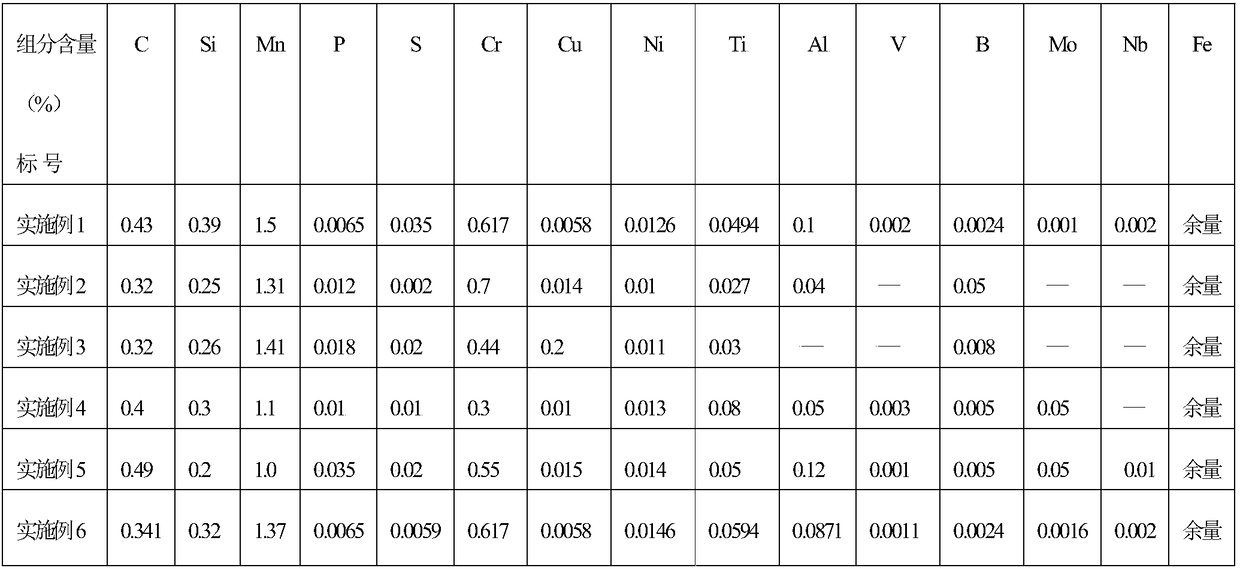

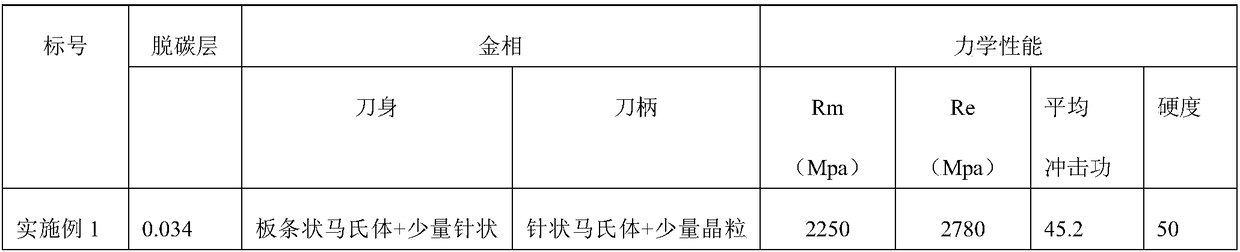

Steel specially for agricultural cultivator wear part and production technology thereof

The invention provides steel specially for an agricultural cultivator wear part. The steel comprises, by mass, 0.30 to 0.50% of C, 0.20 to 0.40% of Si, 1.0 to 1.5% of Mn, less than or equal to 0.035%of P, less than or equal to 0.035% of S, 0.30 to 0.70% of Cr, less than or equal to 0.20% of Cu, less than or equal to 0.015% of Ni, less than or equal to 0.080% of Ti, 0.040 to 0.12% of Al, less thanor equal to 0.0030% of V, less than or equal to 0.050% of B, less than or equal to 0.050% of Mo, less than or equal to 0.01% of Nb and the balance of Fe. In production, the components are used, heated, molded, quenched through water and finally molded. The steel specially for an agricultural cultivator wear part has toughness, plasticity, impact resistance, bending resistance, breaking resistanceand wear resistance meeting the manufacturing requirements of the wear part of the agricultural cultivator, can be quenched through tap water during heat treatment without tempering and is environmentally friendly.

Owner:代超群

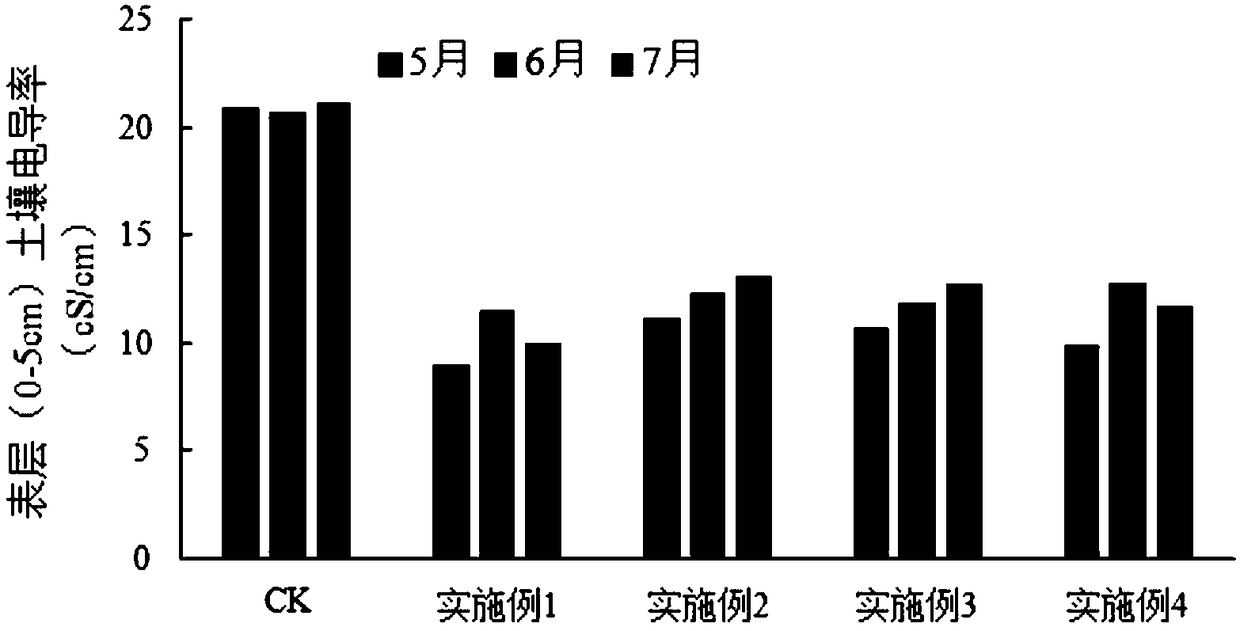

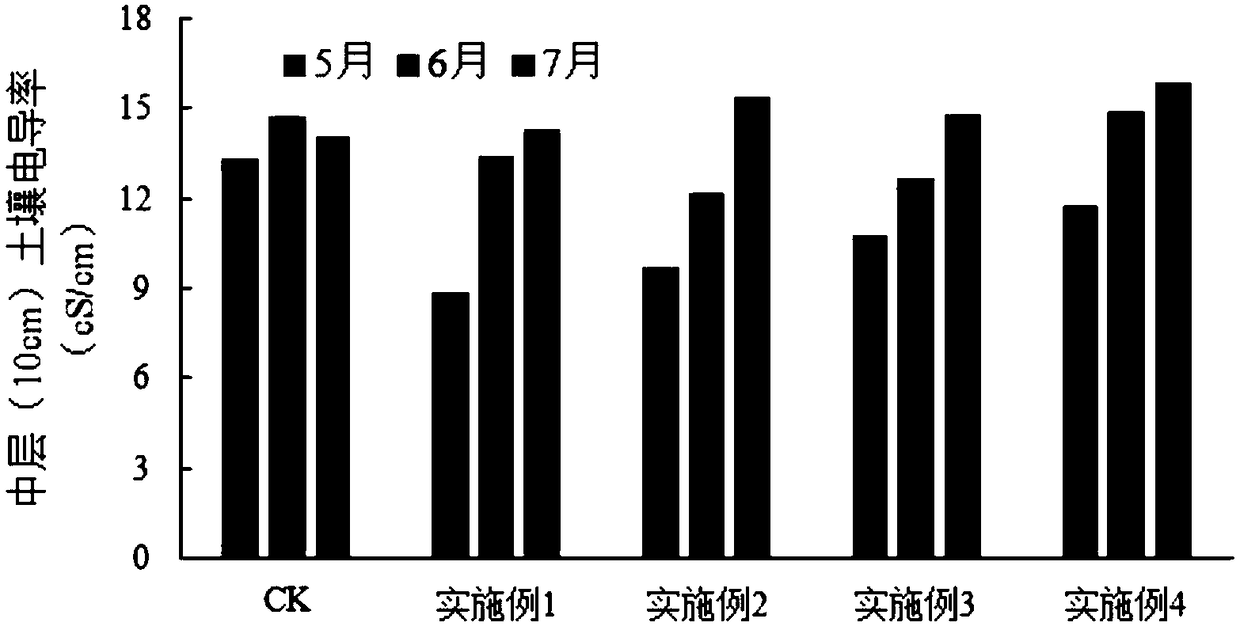

Solid-liquid synergistic saline-alkali soil conditioner and preparation method thereof

InactiveCN108865148ALow costEasy to use on a large scaleOther chemical processesExcrement fertilisersSolid phasesHumic acid

The invention belongs to the technical field of saline-alkali soil improvement fertilizers, particularly relates to a solid-liquid synergistic saline-alkali soil conditioner, and further discloses a preparation method for the solid-liquid synergistic saline-alkali soil conditioner. According to the solid-liquid synergistic saline-alkali soil conditioner, according to the actual conditions of soil,effective measures are taken according to local conditions, carbon manure decomposed materials, humic acid and acidic residues serve as solid components, and wood vinegar serves as a liquid component. The prepared saline-alkali soil conditioner has the advantages that under different periods and soil conditions, the solid components and the liquid components are used, so that the physicochemicalenvironment of the soil can be effectively improved, the growth of plants can be promoted, and the growth and development of fruits can be promoted.

Owner:BEIJING SANJU GREEN ENERGY TECH CO LTD

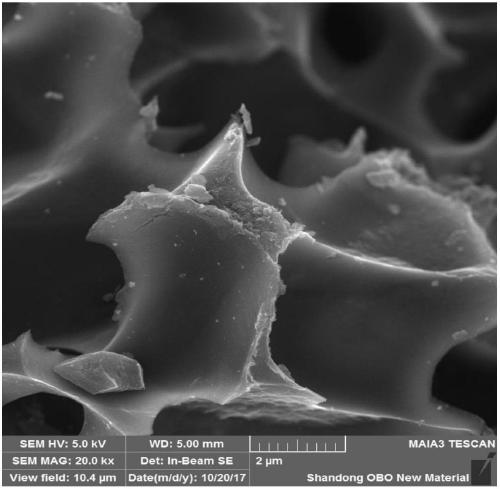

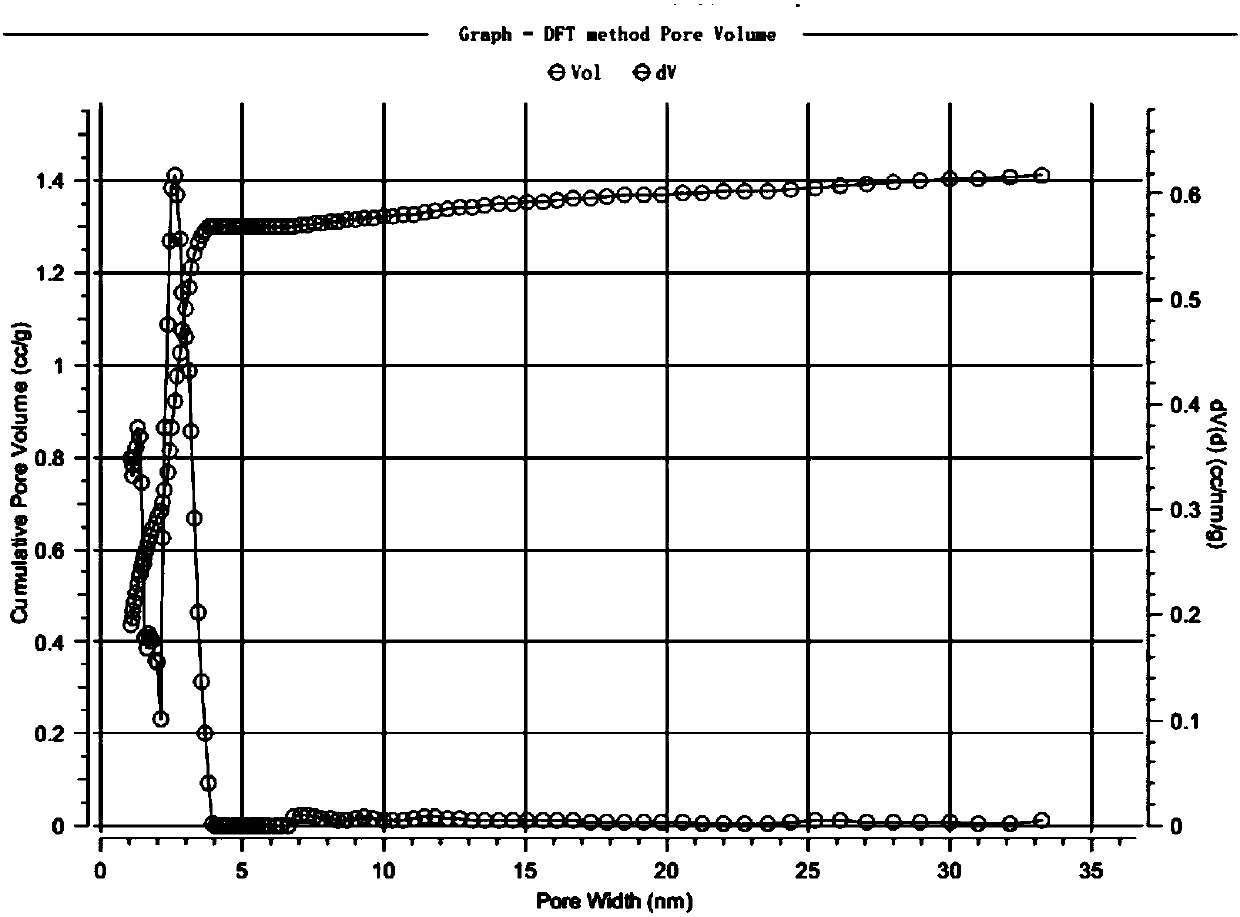

High-electric-conductivity phenolic-resin-based graphene-modified activated carbon, and preparation method and application thereof

PendingCN110316733AOvercome Difficult Dispersion ProblemsReturn to normal structureCarbon compoundsActivated carbonHydrothermal synthesis

The invention provides a preparation method of resin-based graphene-modified activated carbon. The preparation method includes the following steps: hydrothermally reacting a phenolic compound with analdehyde compound and graphene oxide to obtain a composite; in a protective atmosphere, carbonizing the composite obtained by the previous step to obtain a carbonized material; mixing the carbonized material obtained in the previous step with an activator, and then activating the mixture in a protective atmosphere to obtain a primary activated carbon product; subjecting the primary activated carbon product obtained in the previous step to heat treatment under the protection of a reducing gas and / or a protective atmosphere to obtain the resin-based graphene-modified activated carbon. The preparation method has the advantages that raw materials, including the phenolic compound, the aldehyde compound and the graphene oxide, are subjected to hydrothermal synthesis to achieve uniform dispersionof graphene in resin, so that catalysts, initiators and curing agents are reduced, the performance of the composite is ensured, and the problem of difficulty in dispersion of the graphene in the resin is solved.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

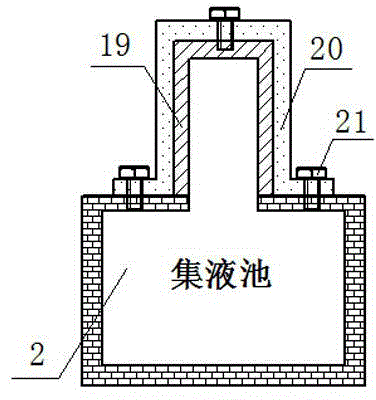

Comprehensive utilization system for feces in large-scale breeding industry

InactiveCN104787979AIn line with the development conceptNo secondary pollutionBio-organic fraction processingClimate change adaptationForest industryAnimal feces

The invention discloses a comprehensive utilization system for feces in a large-scale breeding industry. The comprehensive utilization system comprises a feces collecting unit, a solid-liquid separating unit, an anaerobic fermentation unit, a biogas utilization system and a biogas slurry utilization system, wherein the feces collecting unit comprises a filter tank and a manure pit; the solid liquid separating unit comprises a solid-liquid separator, a buffer pool and an organic fertilizer treatment device; the anaerobic fermentation unit is a multi-grade anaerobic reaction device and comprises a first-degree anaerobic reaction tank and a second-degree anaerobic reaction tank; the biogas utilization system comprises a biogas cabinet, a biogas purification device and a biogas generation device; the biogas slurry utilization system comprises a biogas slurry storage pool, a farmland irrigation device and a forestry irrigation device; an annular sterilizing device is arranged at the periphery of each of the filter tank, the manure pit and the buffer pool; a plastic film layer is arranged above the filter tank, the manure pit and the buffer pool. Feces wastewater is fermented to produce biogas and biogas slurry, and the organic fertilizer is produced through solid-liquid separation, so that secondary pollution of waste gas is avoided, the feces wastewater is fully reutilized, and the comprehensive utilization rate is increased.

Owner:MUYUAN FOODS CO LTD

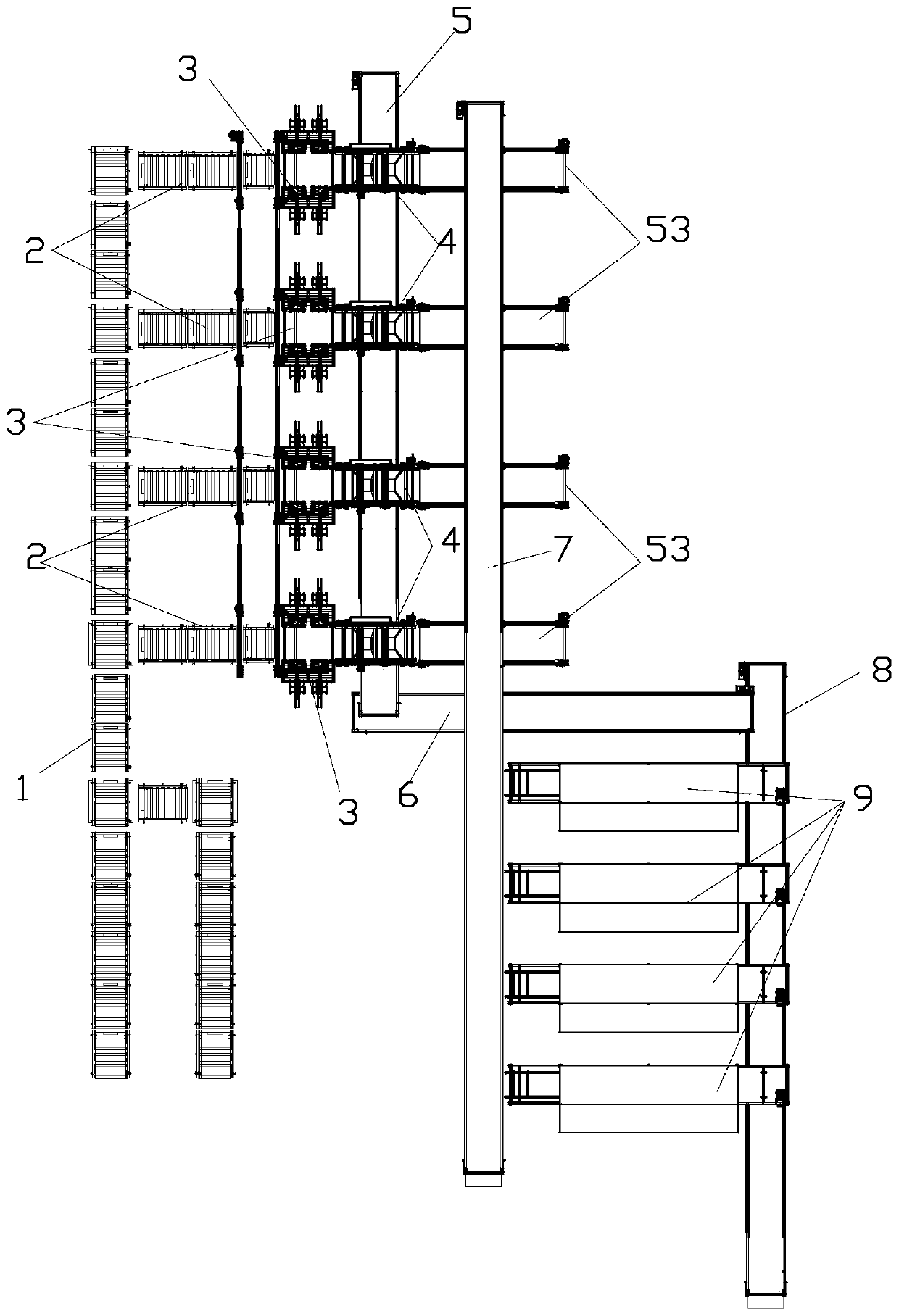

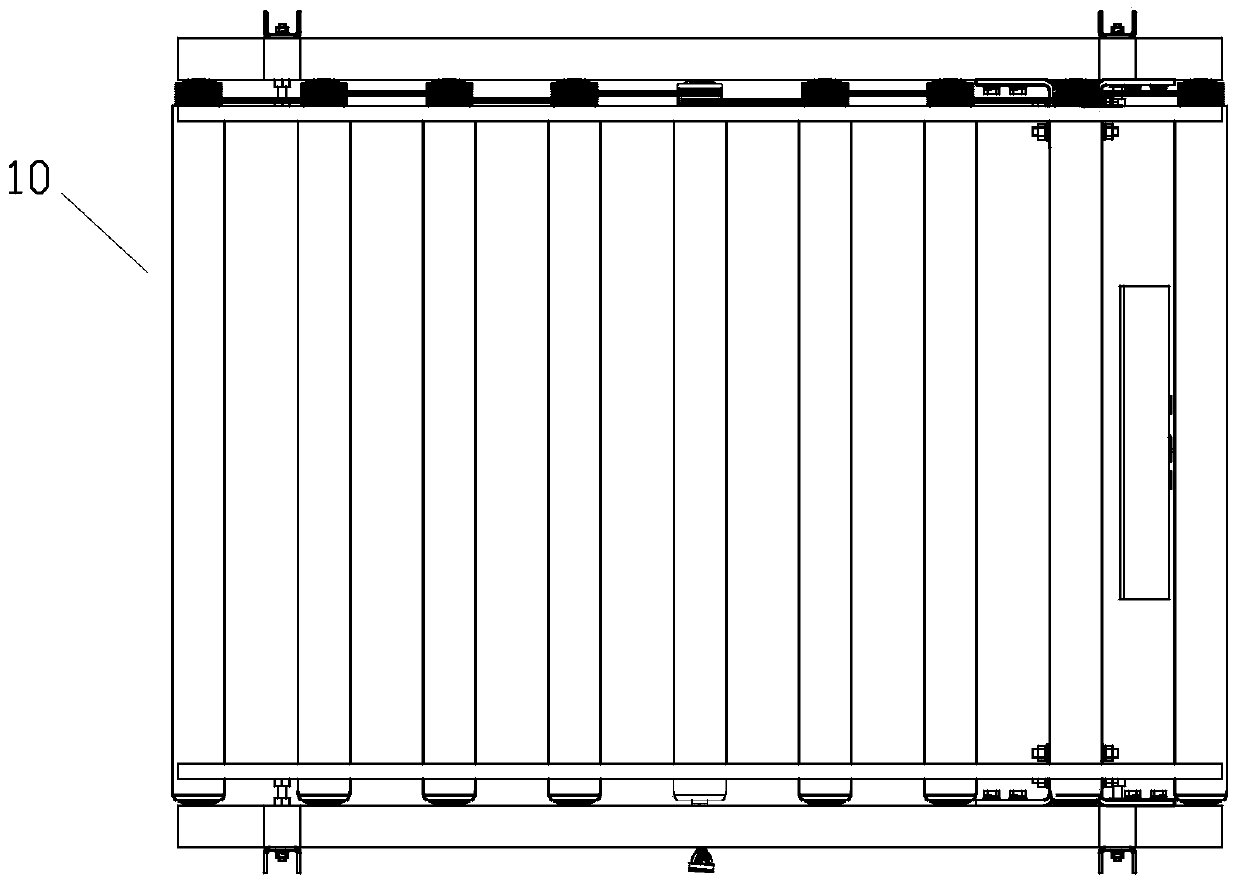

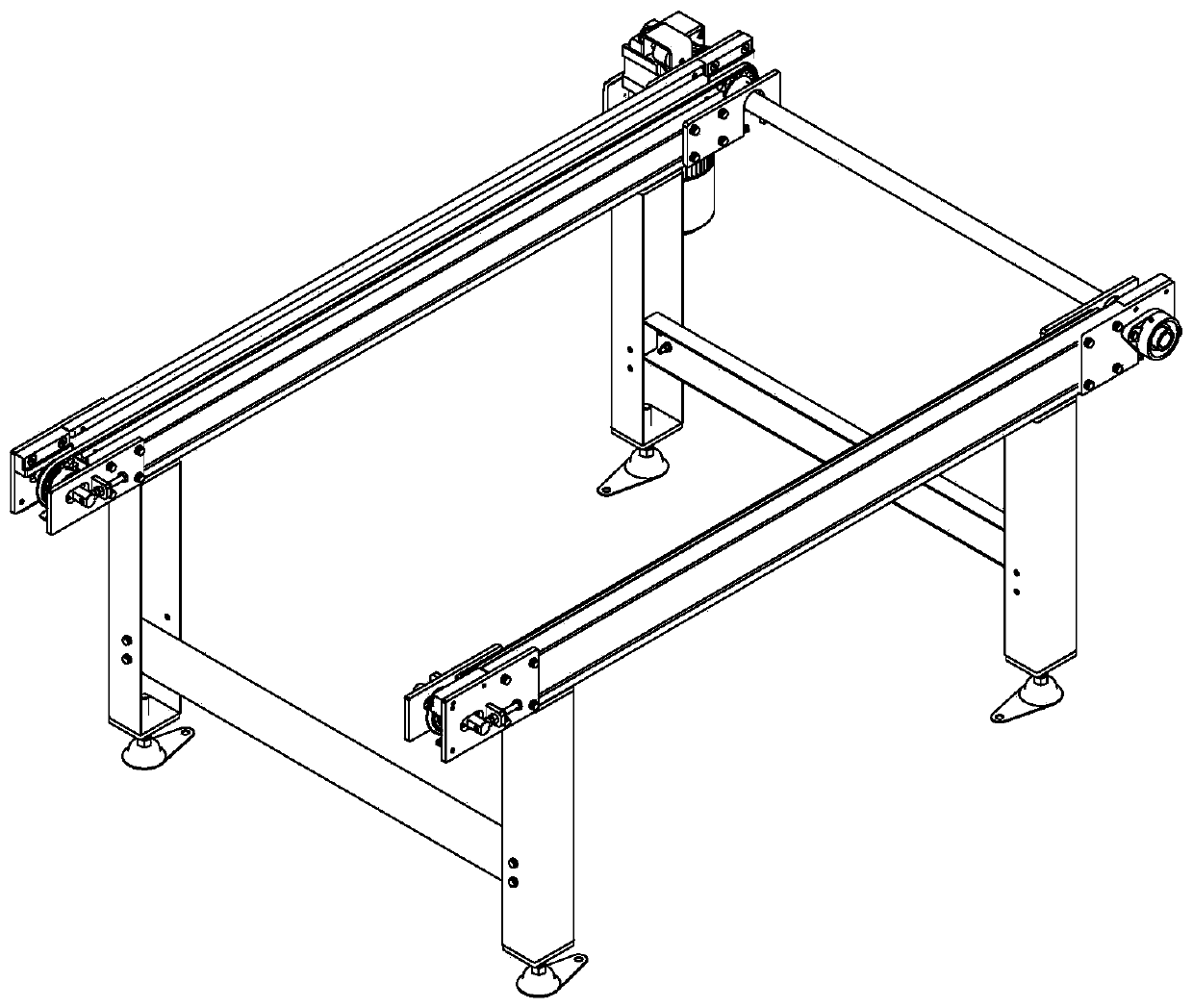

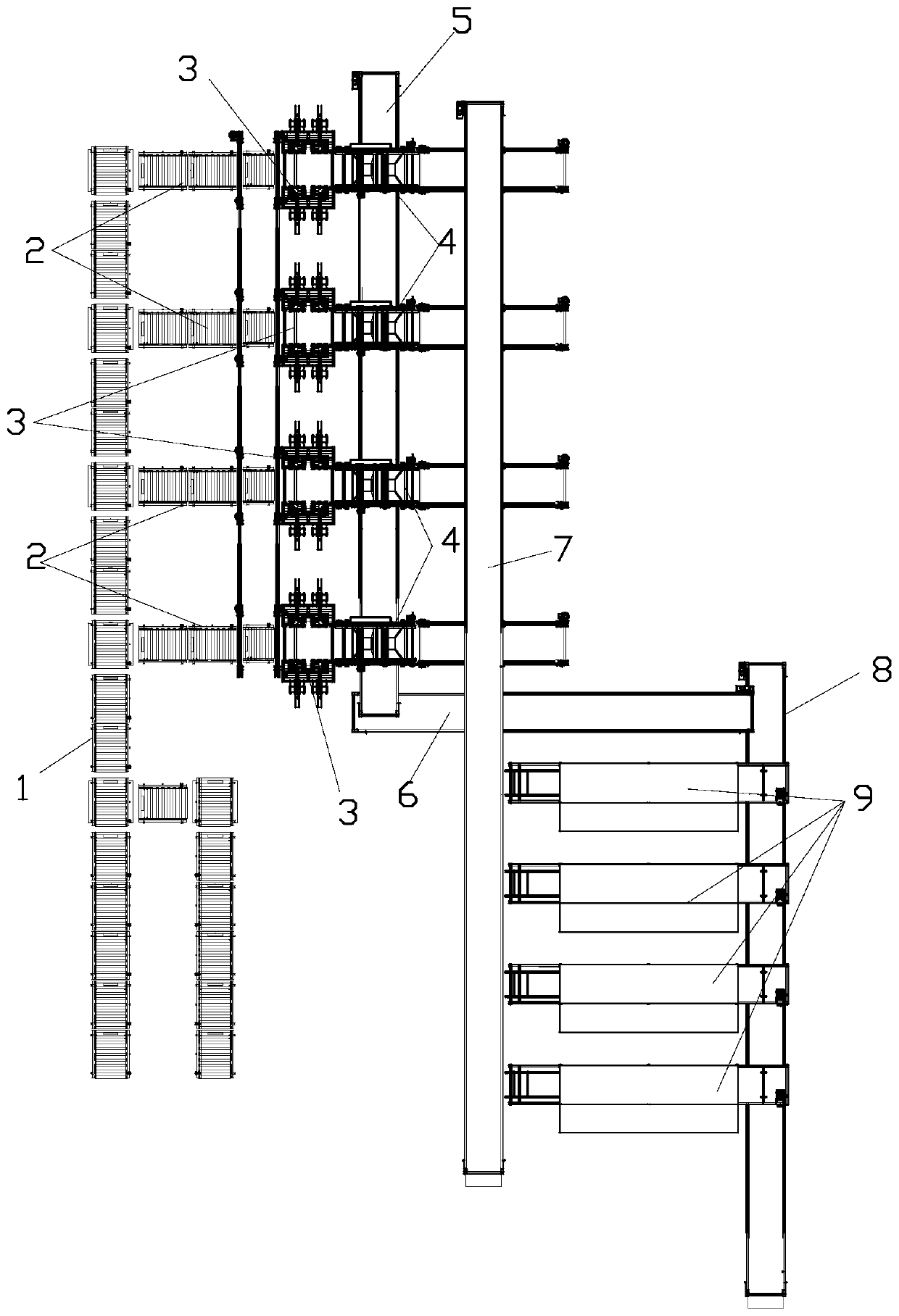

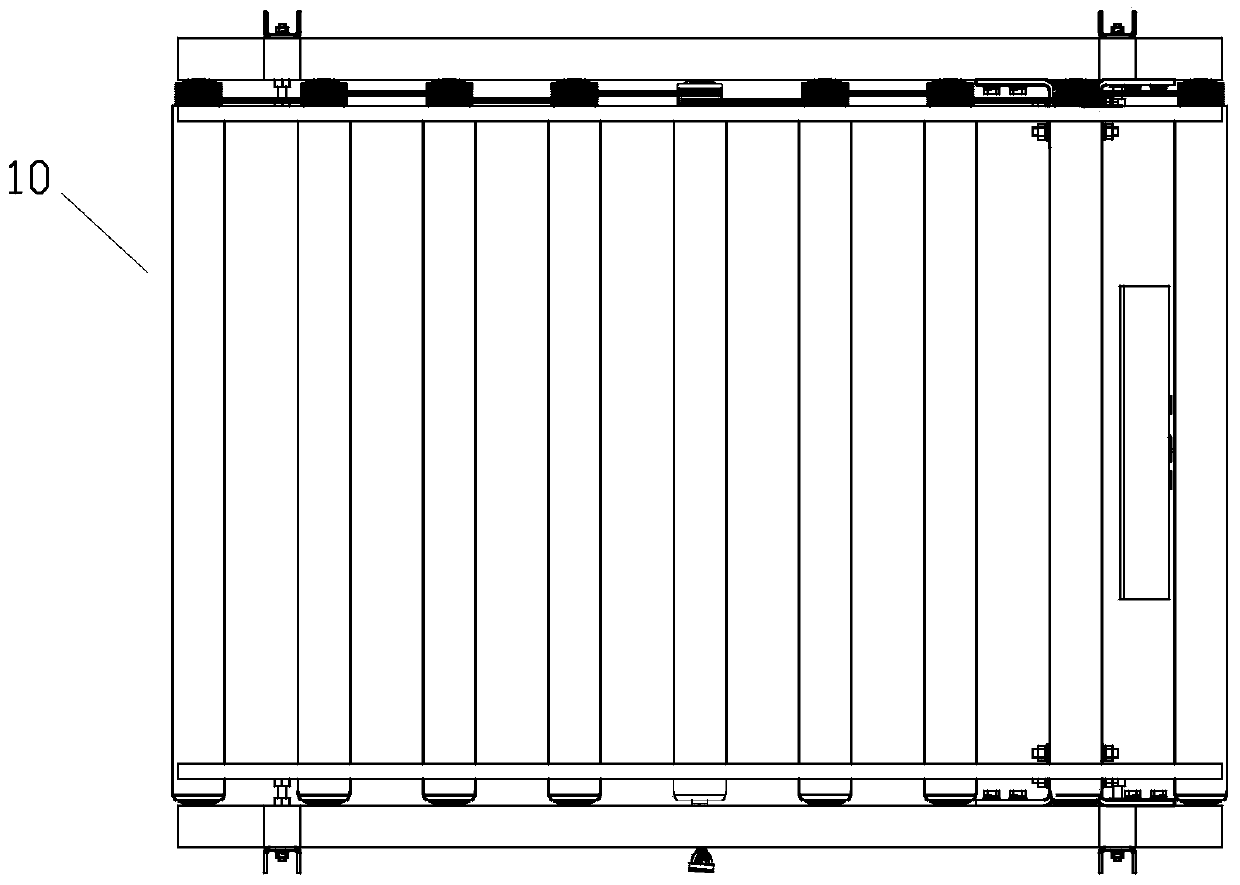

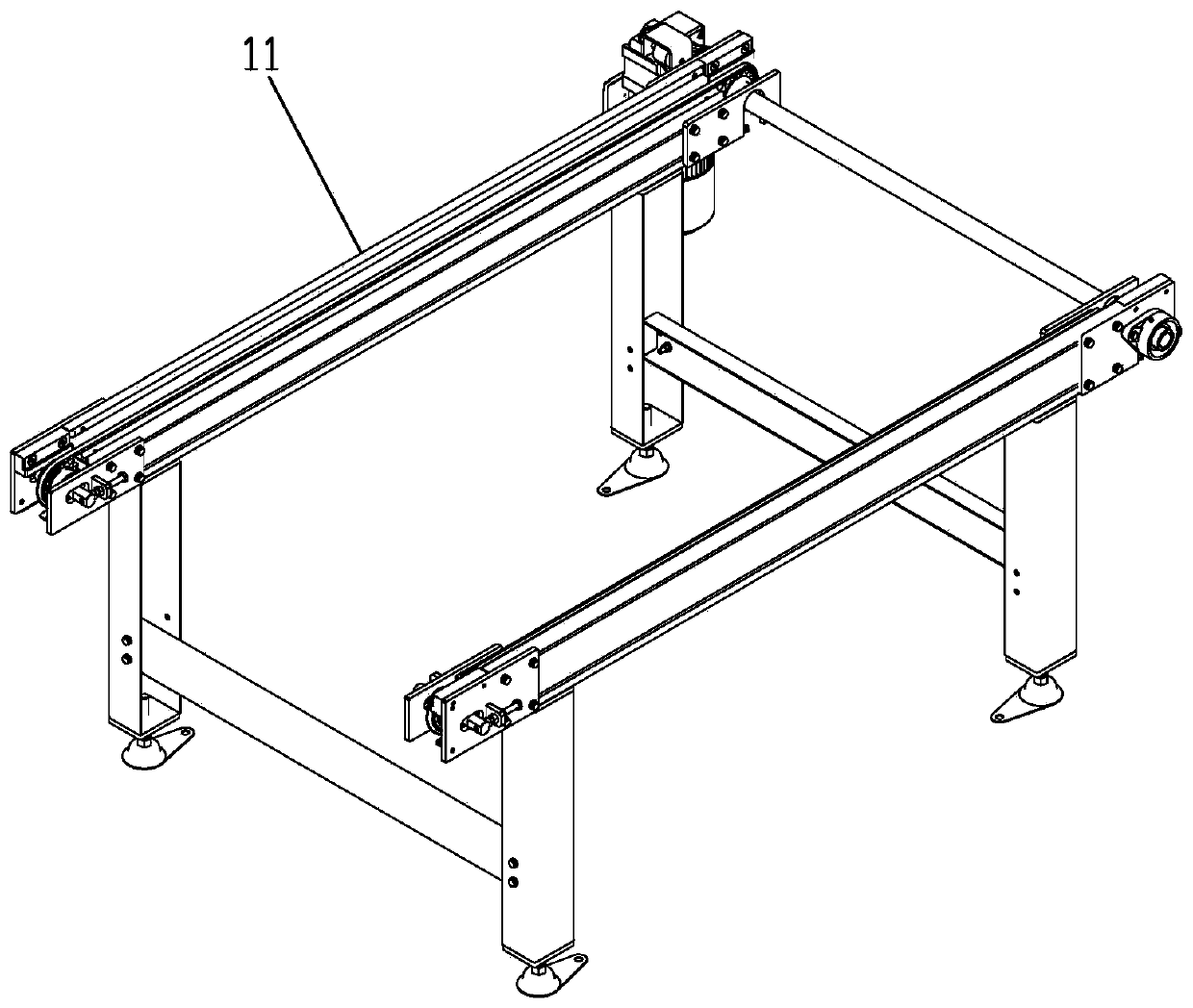

Automatic cocoon harvesting assembly line used in industrial silkworm breeding operation

PendingCN111109209AIn line with the development conceptImprove cocoon harvesting efficiencyAnimal husbandryAgricultural scienceAgricultural engineering

The invention discloses an automatic cocoon harvesting assembly line used in industrial silkworm breeding operation. The automatic cocoon harvesting assembly line comprises a breeding frame tray disassembling machine, a frame-bottom cocoon harvesting machine and a cocoon harvesting machine, wherein the breeding frame tray disassembling machine splits a breeding frame assembly into breeding frames;the breeding frame tray disassembling machine is connected with the frame-bottom cocoon harvesting machine; the frame-bottom cocoon harvesting machine sweeps the bottoms of the breeding frames; the frame-bottom cocoon harvesting machine is connected with the cocoon harvesting machine; and the cocoon harvesting machine sweeps cocoon cages. Aiming at the defects in the existing cocoon harvesting technology, the invention designs a set of automatic cocoon harvesting assembly line, and an assembly line type cocoon harvesting process is realized through the breeding frame tray disassembling machine, the frame-bottom cocoon harvesting machine and the cocoon harvesting machine in sequence, so cocoon harvesting efficiency is greatly improved, and a cocoon harvesting amount in unit time is improved in a doubling manner; the machines for cocoon harvesting all work in an automatic mode, so input labor cost is reduced, expenditure is saved, the development concept of innovative enterprises is met, and human errors caused by manual cocoon harvesting are avoided.

Owner:SHENGZHOU MOSANG HI TECH CO LTD

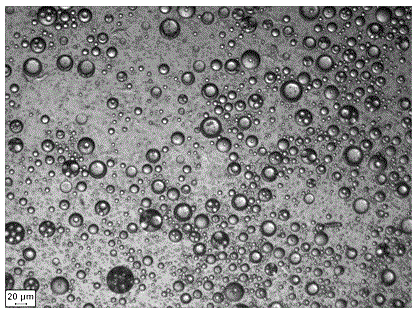

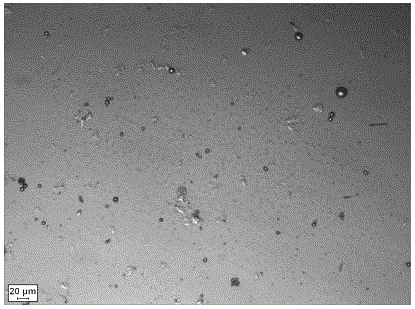

Preparation method of fully biodegradable and biocompatible composite microspheres

The invention discloses a preparation method for completely biodegradable and biocompatible composite microspheres. An oil-in-water type Pickering emulsion with stable cellulose nanocrystals is prepared based on the reproducibility, biodegradability and biocompatibility of cellulose nanocrystals, and then the completely biodegradable and biocompatible composite microspheres are prepared by a solvent evaporation technology. According to the method provided by the invention, cellulose nanocrystal whiskers prepared from natural plants are low in cost, the operation is simple and large-scale popularization is easy; the composite microspheres prepared according to the method provided by the invention are completely biodegradable and biocompatible and environmental-friendly, and conform to the current idea of development.

Owner:深圳前海福瑞达科技有限公司

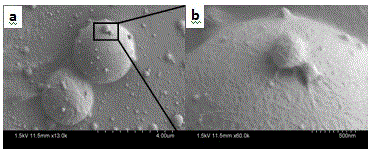

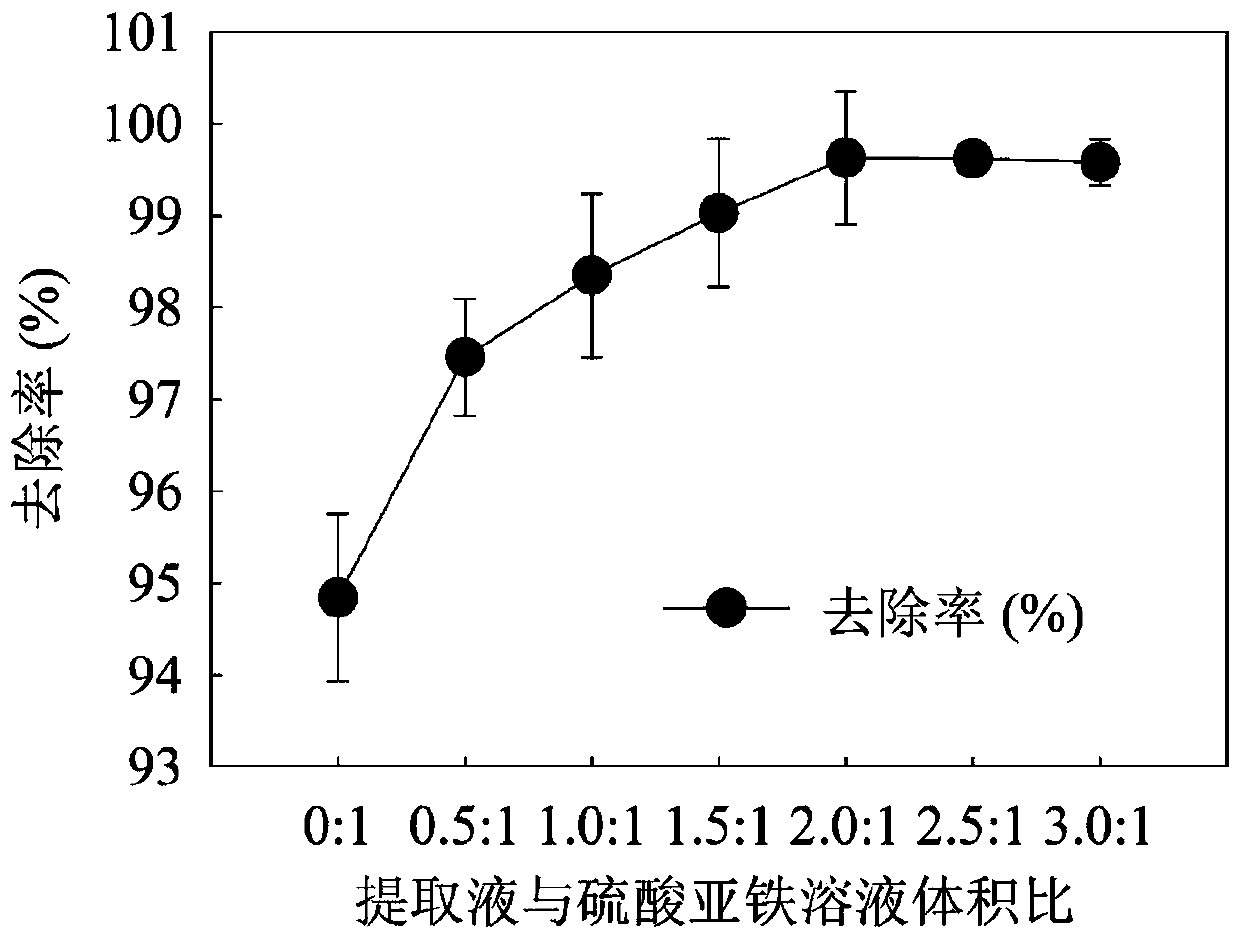

Method for producing green modified nanometer Fe-Sn double-metal particles by utilizing pine bark

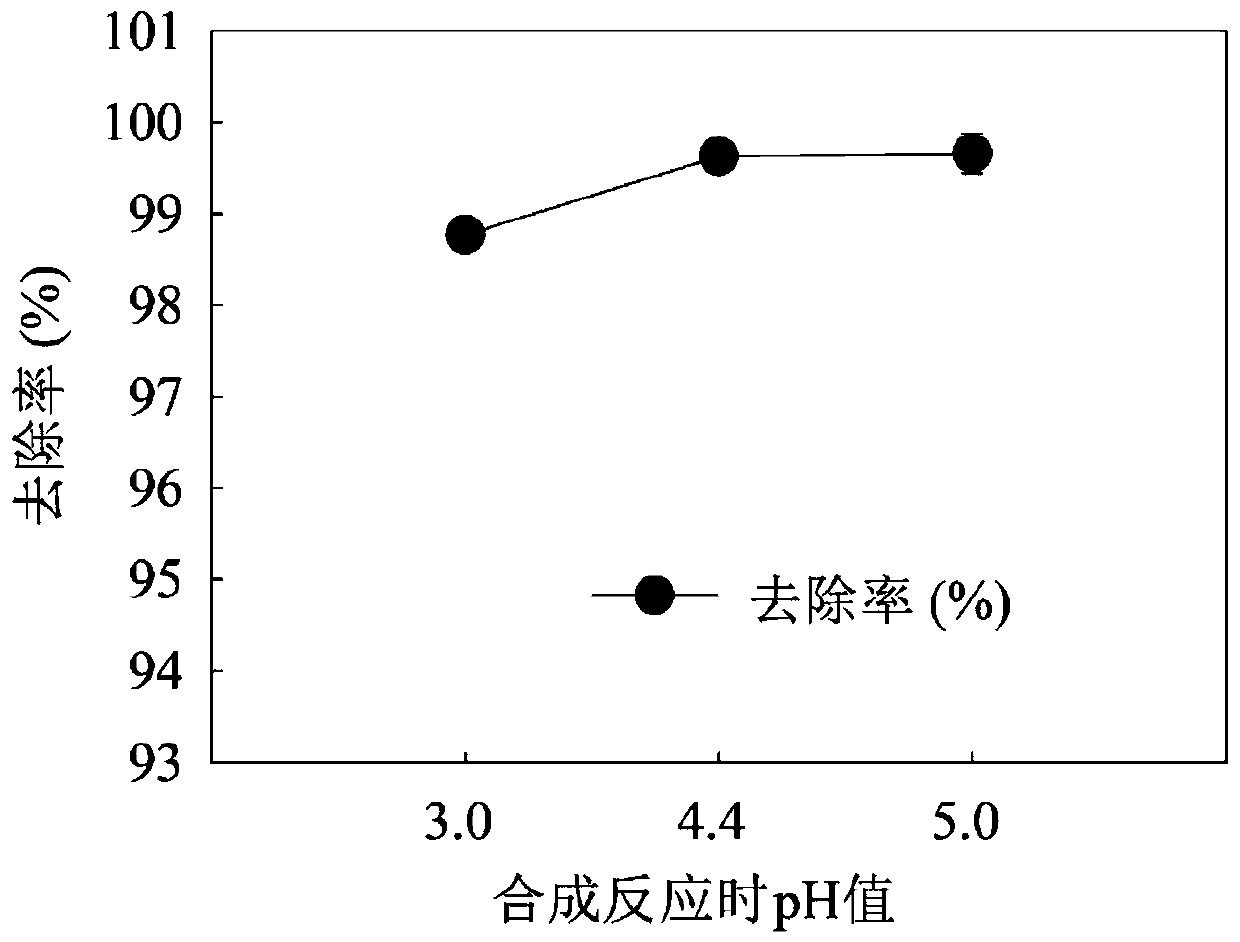

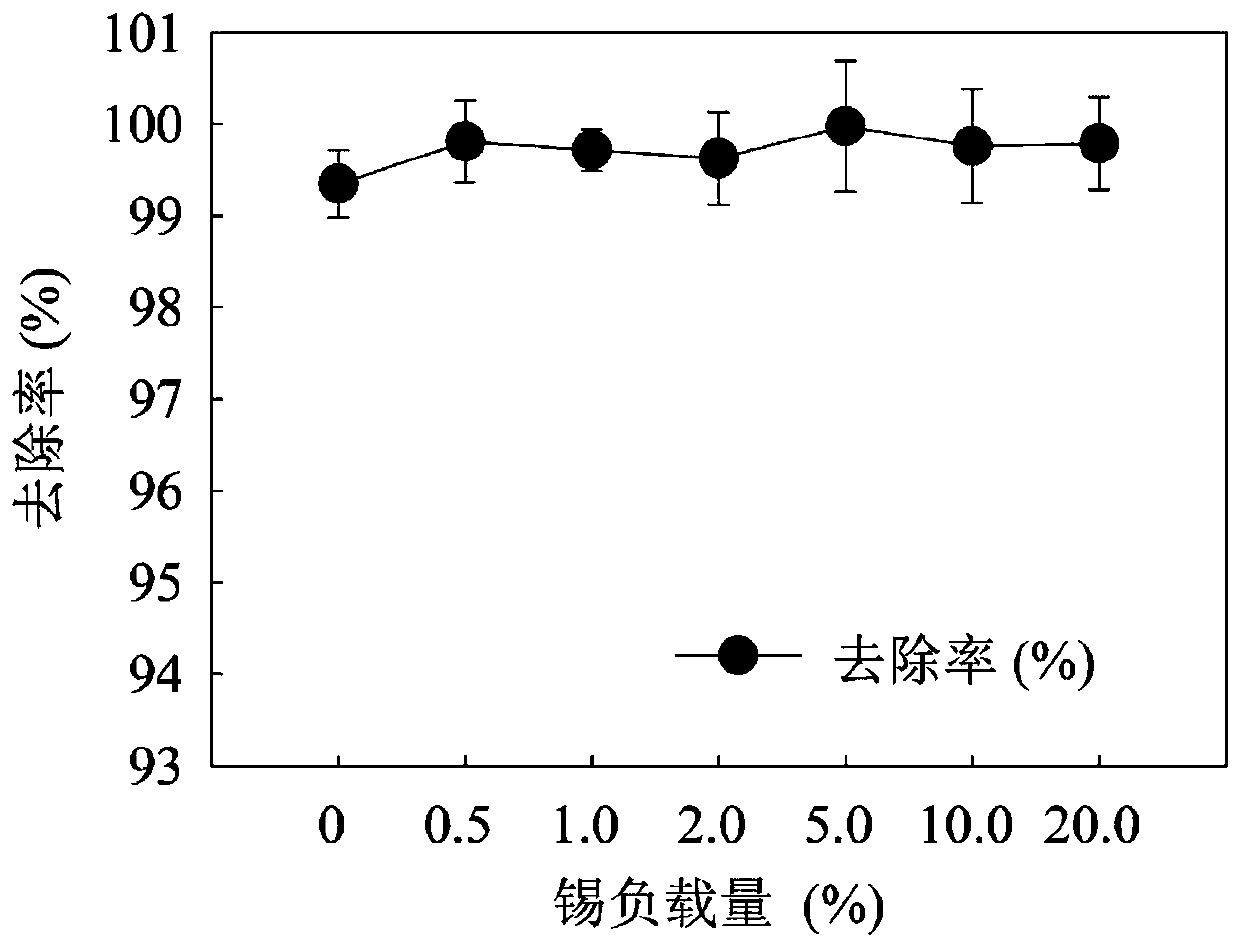

ActiveCN109732098AEasy to get materialsLow costWater/sewage treatmentWaste water treatment from textile industryPotassium borohydrideMaterials science

The invention provides a method for producing green modified nanometer Fe-Sn double-metal particles by utilizing pine bark and belongs to the technical field of nanometer materials and waste water treatment. The method comprises the following steps: crushing dried pine bark, soaking the crushed pine bark in absolute methanol, and carrying out ultrasonic treatment and filtering to obtain pine barkextract; mixing the pine bark extract and a ferrous sulfate solution to obtain a ferric salt and pine bark extract mixture, and then adding a potassium borohydride solution to obtain a suspension of pine bark modified nanometer ferric particles; and then adding a stannous chloride solution, generating pine bark modified nanometer Fe-Sn double-metal particles and carrying out washing by utilizing deionized water and acetone. The removal rate of reactive brilliant blue KN-R in waste water is as high as more than 99%.

Owner:BEIJING UNIV OF TECH

Pipelined cocoon harvesting process for industrialized silkworm rearing work

ActiveCN111066746AIn line with the development conceptImprove cocoon harvesting efficiencyAnimal husbandryAnimal scienceZoology

The invention discloses a pipelined cocoon harvesting process for industrialized silkworm rearing work. The process comprises the following steps of (1) splitting a rearing frame group one by one; (2)harvesting cocoons at bottoms of frames; and (3) harvesting cocoons on cocoon cages. A set of pipelined cocoon harvesting process is designed, and is realized by the steps of splitting the rearing frame group one by one, harvesting the cocoons at the bottoms of the frames and harvesting the cocoons on the cocoon cages successively, so that the cocoon harvesting efficiency is greatly increased, and the cocoon harvesting rate in unit time is doubled; and moreover, the cocoon harvesting steps are all automatically realized, and thus, on one hand, the input labor cost is reduced, the expenditureis reduced, and the development idea of an innovative enterprise is met, and on the other hand, human error generated by manual cocoon harvesting is avoided.

Owner:SHENGZHOU MOSANG HI TECH CO LTD

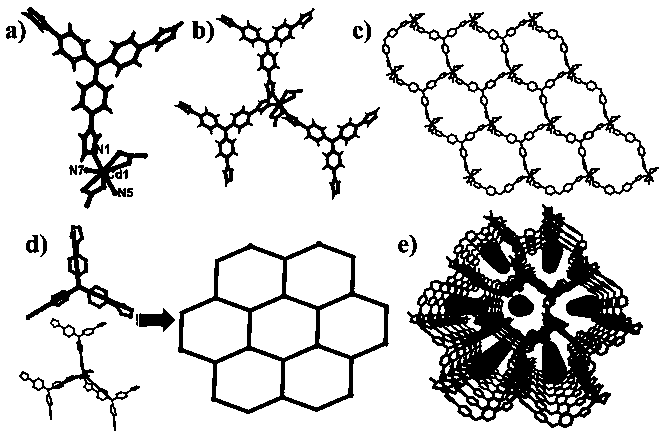

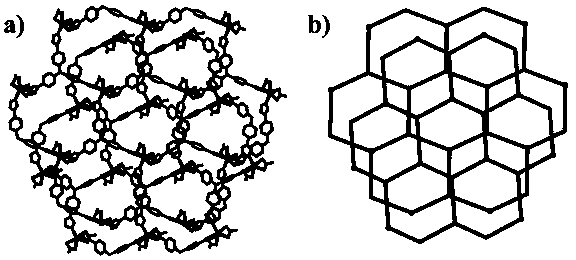

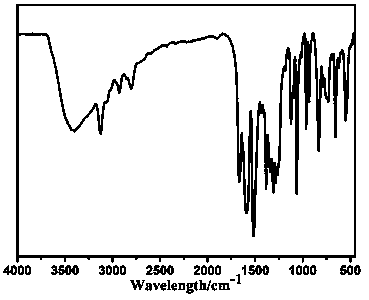

Metal organic framework molecular material of electron-rich system and application thereof in photocatalytic reduction of heavy metal ions

ActiveCN111004397AEfficient CatalysisWith n-type semiconductor characteristicsWater/sewage treatment by irradiationWater treatment compoundsDimethyl formamidePhoto catalysis

The invention relates to a novel metal organic framework molecular material of an electron-rich system. The molecular formula of the metal organic framework molecular material is C27H21CdN9O7, the chemical formula of the metal organic framework molecular material is [Cd(TIPA)(NO3)2].H2O, and the metal organic framework molecular material is called Cd-TIPA (TIPA=tris-(4-imidazolylphenyl) amine) forshort. The compound belongs to a monoclinic system and a C2 space group, and the topological structure is a utp type. The synthesis method specifically comprises the following steps: uniformly mixingCd(NO3)2.6H2O and TIPA in a mixed solvent of distilled water and N,N-dimethyl formamide, then transferring the mixture into a reaction kettle to react for 70-80 hours at 90-100 DEG C, cooling to a room temperature, separating out crystals, washing and drying to obtain Cd-TIPA. The novel metal organic framework molecular material can be used as a photocatalyst for catalytic reduction of heavy metal ions, in particular, Cr (VI) and Mn (VII).

Owner:HENAN UNIVERSITY

Tropical functional low-calorie coconut flavor blend oil

Owner:海南符氏食品有限公司

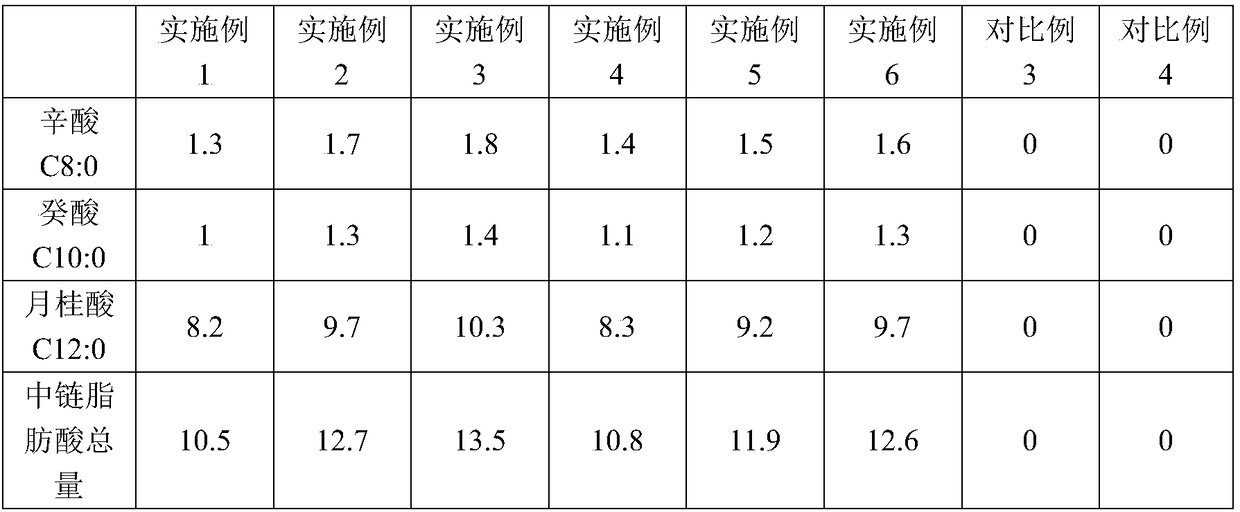

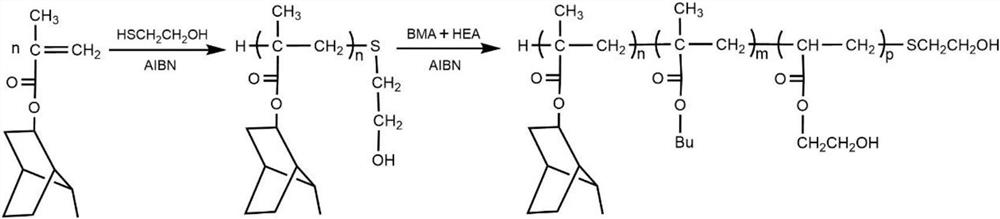

Preparation method of bromo-pyrrolecarbonitrile grafted block type acrylic acid self-polishing resin and environmentally-friendly marine antifouling composition

ActiveCN112608400AImprove stabilityNot easy to precipitateAntifouling/underwater paintsPaints with biocidesEngineeringPyrrole

The invention relates to the field of polymer synthesis, and discloses a preparation method of bromo-pyrrolecarbonitrile grafted block type acrylic acid self-polishing resin and an environmentally-friendly marine antifouling composition. The bromo-pyrrolecarbonitrile grafted block type acrylic acid self-polishing resin is a block type polymer and contains a block easy to hydrolyze and a block difficult to hydrolyze. According to the invention, after the resin is applied to the surface of a marine facility (such as the bottom of a ship) as a coating material component, a unique dynamic hydration layer can be formed after the block easy to hydrolyze meets water, so that the effect of actively inhibiting fouling can be achieved; an anti-fouling agent bromo-pyrrolecarbonitrile is grafted on the block difficult to hydrolyze, so that fouling can be passively eliminated and inhibited; and the marine antifouling composition can effectively reduce the use amount of cuprous oxide, can also be applied to a copper-free tin-free self-polishing system, and is environmentally-friendly.

Owner:ZHEJIANG UNIV

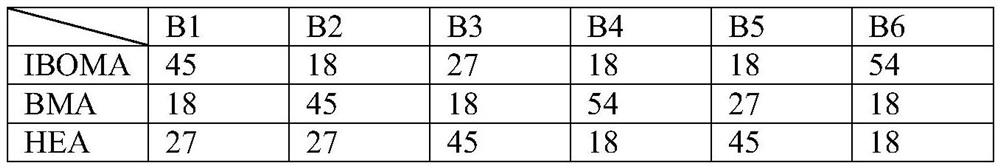

Large bottomless cultivation net box and construction method thereof

InactiveCN107232106AIncrease the space for breedingLow production costClimate change adaptationPisciculture and aquariaBiologyBuoy

The invention relates to a cultivation net box, in particular to a large bottomless cultivation net box, and belongs to the technical field of cultivation net boxes. The large bottomless cultivation net box is characterized in that the whole large bottomless cultivation net box is of a cuboid structure and includes a buoy combination floating on the surface of water, the buoy combination is rectangular, each long side of the buoy combination is composed of a row of buoys, each short side of the buoy combination is composed of at least two rows of buoys through connection, the buoys on the long and short sides are fixedly connected with an anchor which sinks at the bottom of the water through ropes, and the ropes stretch the long and short sides towards the two sides and fix the long and short sides; the lower portion of the buoy combination is fixedly connected with a purse seine, and the lower edge of the purse seine is fixedly connected with a rectangular iron chain which sinks at the bottom of the water. According to the large bottomless cultivation net box, the production cost is reduced, the weight of the net box is reduced, and the wind and wave resistance properties are improved; according to conditions of a sea area, the shape of the net box is flexibly combined, the layout is flexible, and the adaptability is high.

Owner:SHANGHAI OCEAN UNIV

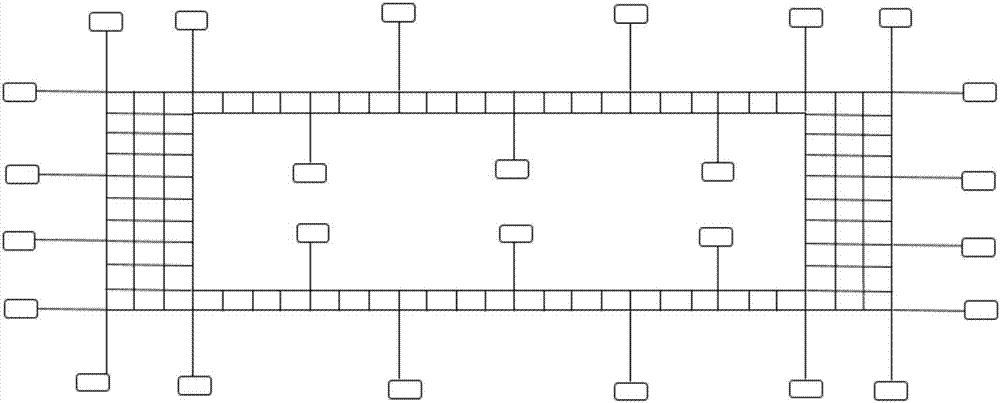

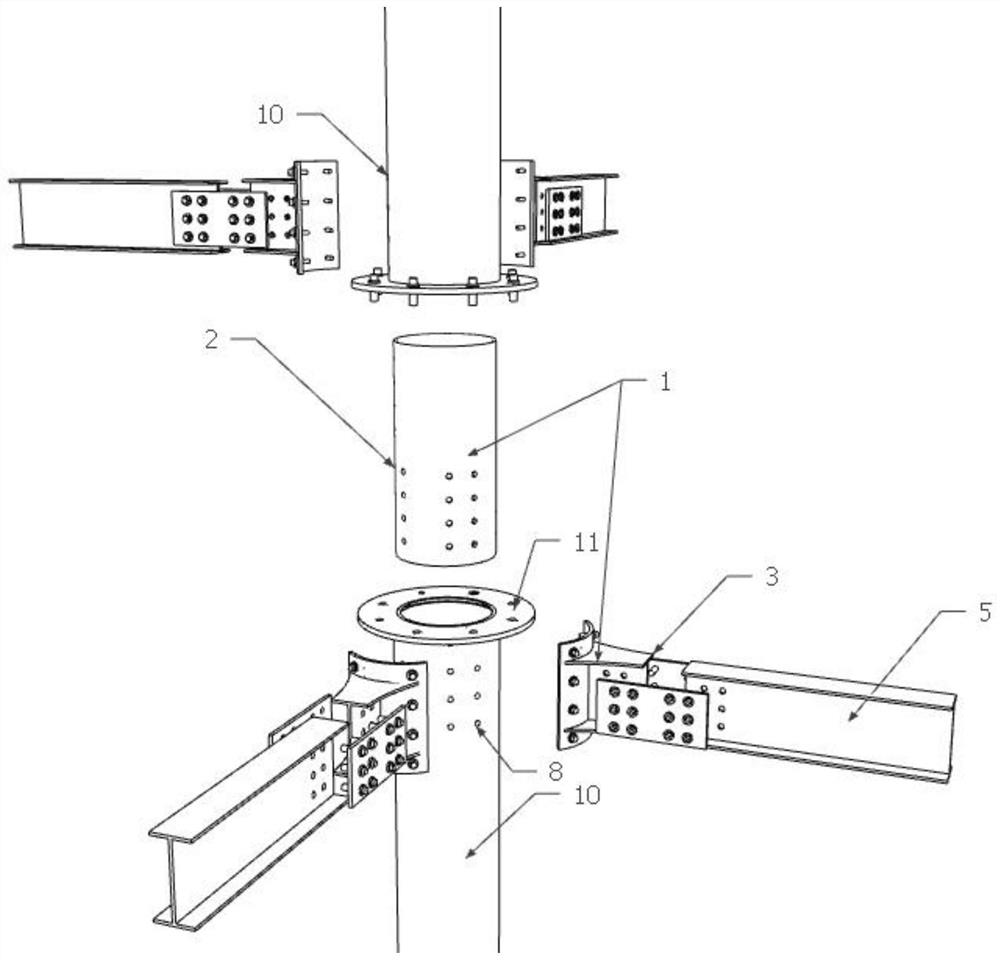

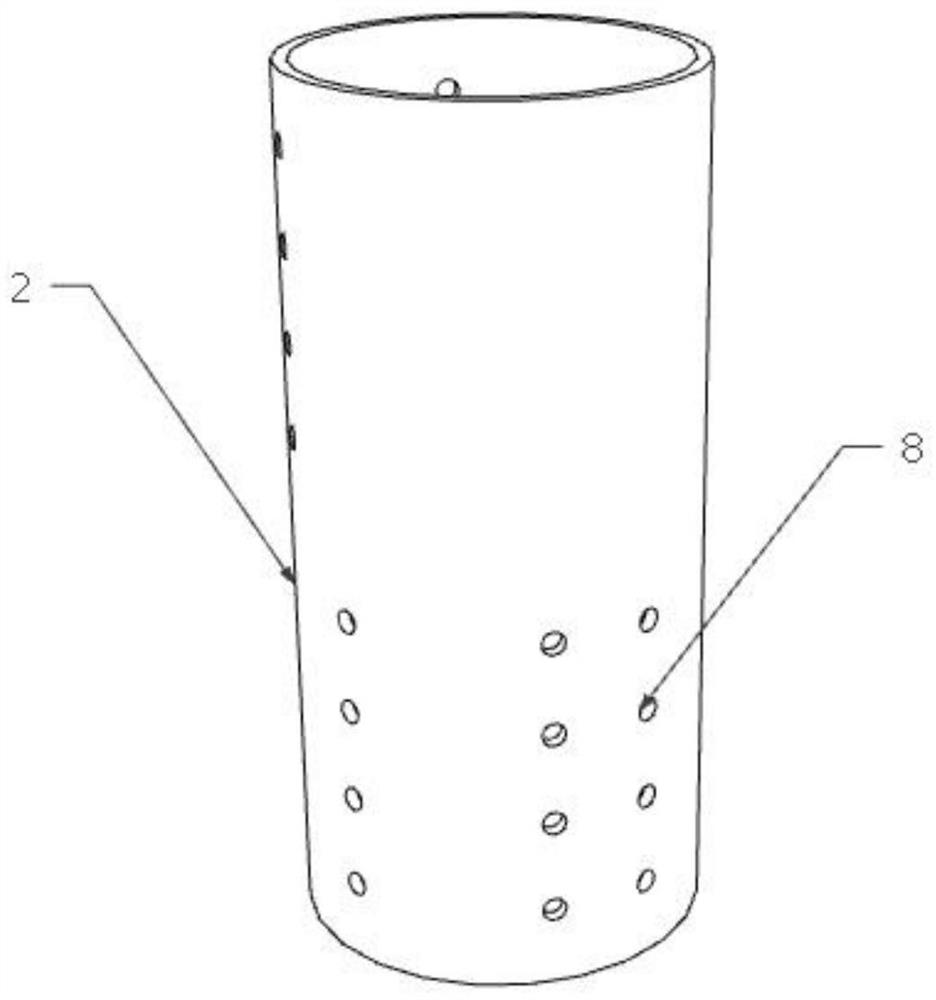

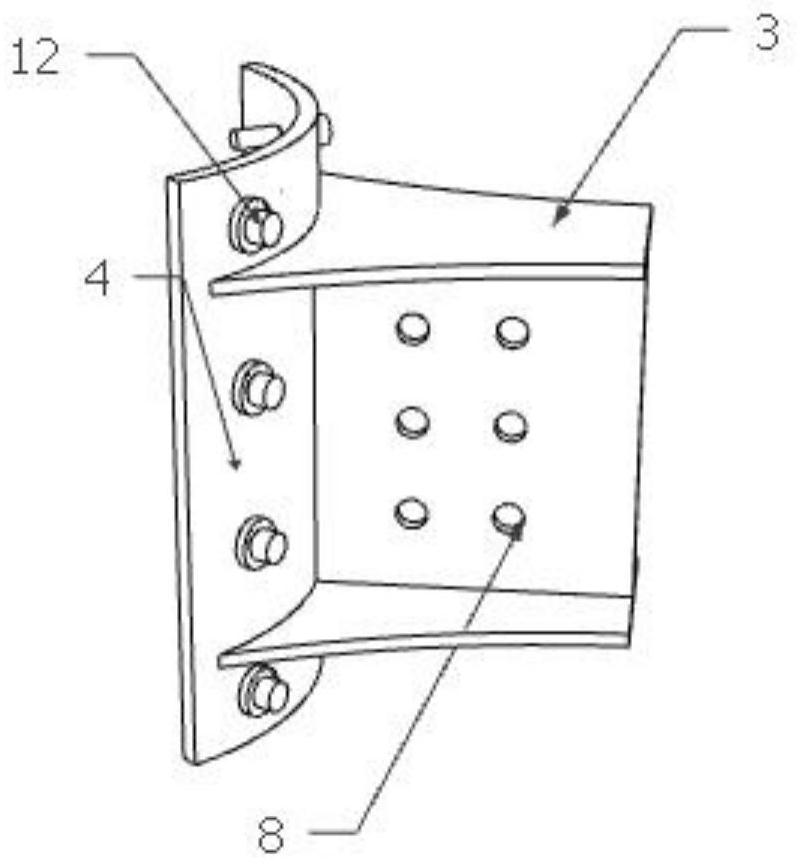

Fabricated beam-column joint connecting device and application thereof

InactiveCN112127476AImprove assembly rateEasy to repair and replaceBuilding constructionsEngineeringMechanical engineering

The invention discloses a fabricated beam-column joint connecting device and application thereof, and belongs to the technical field of buildings and structural engineering. The beam-column joint connecting device comprises an inner sleeve and a connecting piece, wherein the connecting piece comprises an arc-shaped steel plate, H-shaped steel, a first connecting steel plate and a second connectingsteel plate; the H-shaped steel is connected with the protruding side of the arc-shaped steel plate; and a plurality of reserved holes are formed in the inner sleeve, the arc-shaped steel plate, a web of the H-shaped steel, the first connecting steel plate and the second connecting steel plate.

Owner:JIANGNAN UNIV

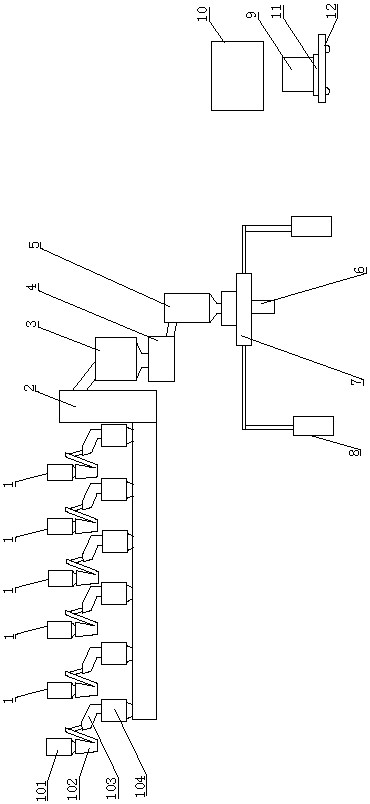

Fluoride-free low-nitrogen-sulfur ferro-molybdenum smelting raw material, ferro-molybdenum green smelting system and ferro-molybdenum green smelting method

ActiveCN111763835AIn line with the development conceptMeet environmental policy requirementsSlagMaterials science

The invention relates to the technical field of ferromolybdenum smelting, in particular to a fluoride-free low-nitrogen-sulfur ferromolybdenum smelting raw material, a ferromolybdenum green smelting system and a ferromolybdenum green smelting method. The method discloses a high-temperature-resistant magnesium alloy which comprises 4-5 parts of molybdenum oxide, 0.2-0.4 part of quick lime, 1.2-2 parts of iron phosphorus, 0.5-1.2 parts of metal silicon powder, 0.2-0.4 part of aluminum particles, 0.4-0.9 part of steel scraps and 0.05 * 10 <-3 >-0.25 * 10 <-3 > parts of magnesium bars. Through thedesign of the fluoride-free low-nitrogen-sulfur ferromolybdenum smelting raw material, the problems that in the prior art, in current ferromolybdenum smelting, more or less nitratine is used as a heat supplementing agent, a certain amount of nitrogen dioxide gas is generated after the nitratine reaction, environment-friendly equipment is not in place, a certain amount of nitrogen dioxide is discharged into air, and the environment is polluted are solved; and meanwhile, in order to improve the fluidity of slag in traditional smelting, fluorite can be used, and calcium fluoride in the fluoritecan pollute the environment to a certain extent as well.

Owner:日照瑞华新材料科技有限公司 +2

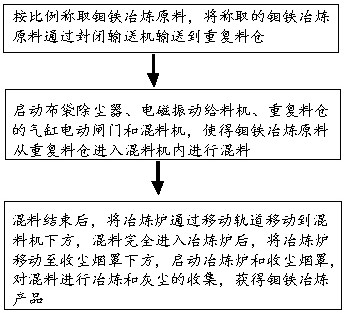

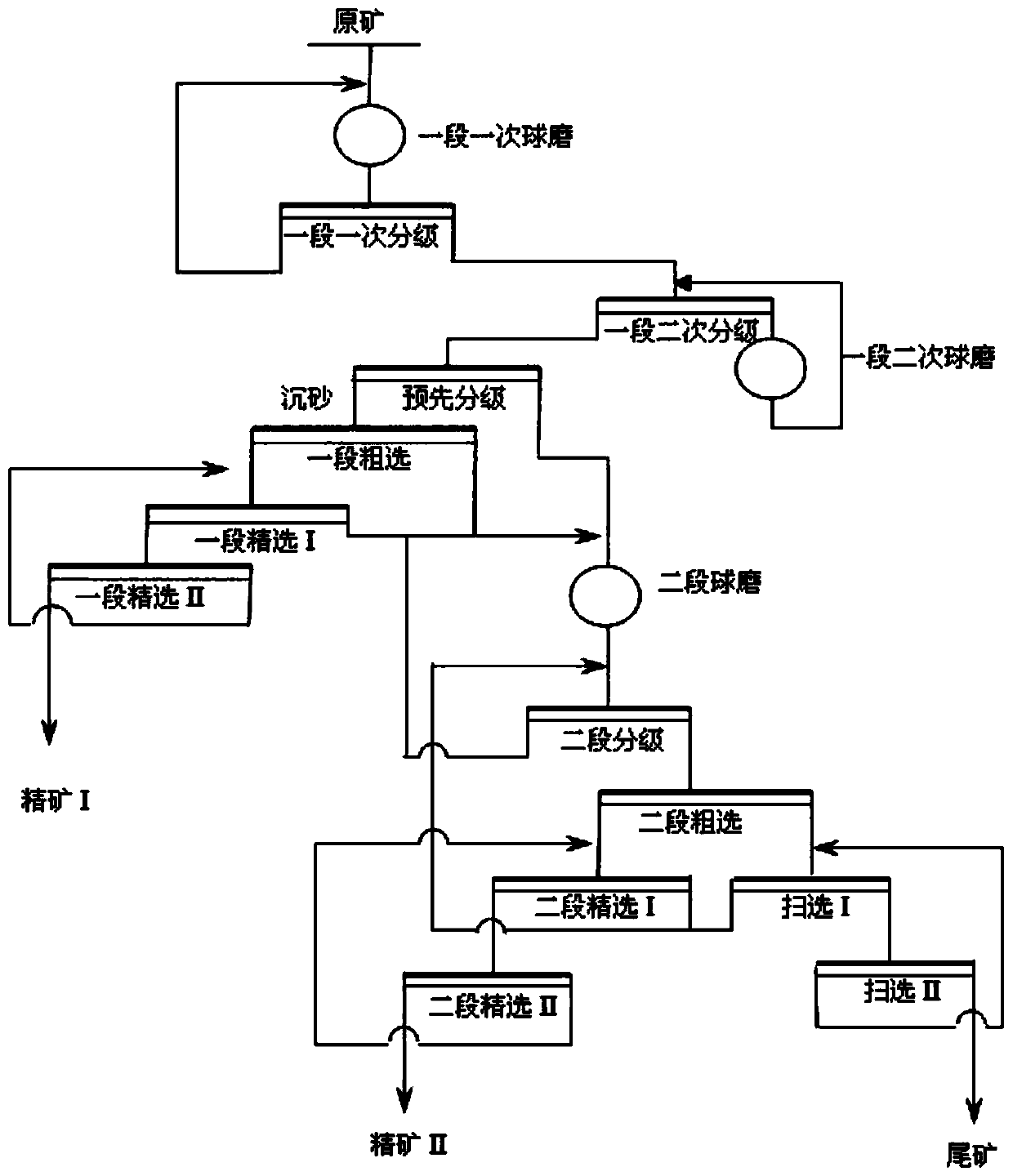

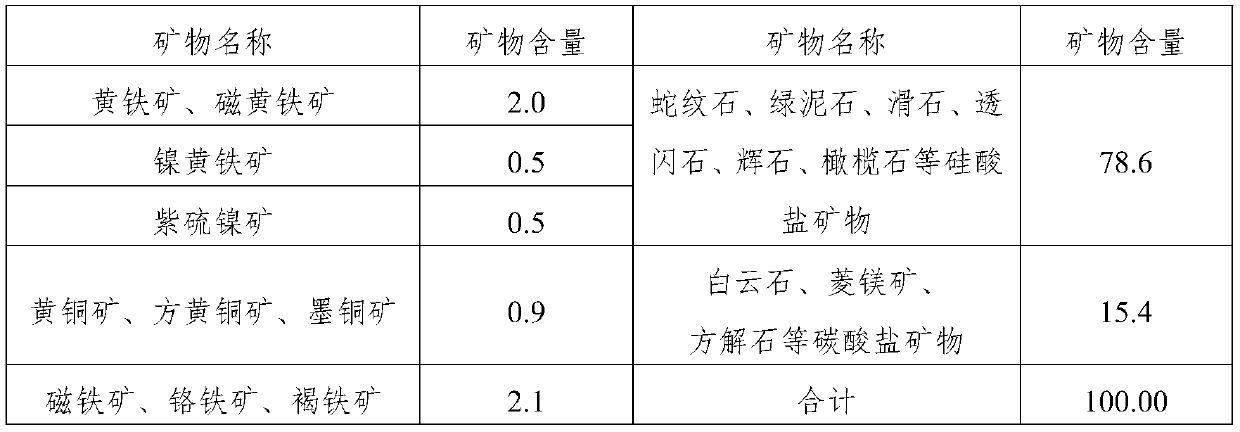

Asynchronous simultaneous separation process of poor and difficult-to-separate nickel-copper ore

ActiveCN111282710AImprove sorting indexImproving and increasing the efficiency of flotation operationsSolid separationEngineeringCopper sulfide

The invention discloses an asynchronous simultaneous separation process of poor and difficult-to-separate nickel-copper ore. A cyclone centrifugal separation beneficiation technology is adopted, a part of gangue and metal minerals with low nickel-copper grade and fine granularity and meeting secondary flotation conditions are separated in advance in an ore grinding loop before flotation of the low-grade poor and difficult-to-separate copper sulfide ore, and directly enter the secondary flotation, so that the recovery rate of nickel-copper metal and the concentrate quality are improved. According to the asynchronous simultaneous separation process of the poor and difficult-to-separate nickel-copper ore, a process for pre-grading an ore grinding product by utilizing centrifugal gravity ore beneficiation equipment is applied to the ore grinding loop of a copper-nickel ore beneficiation flow. The asynchronous simultaneous separation process of the poor and difficult-to-separate nickel-copper ore can improve the flotation operation efficiency of each section, reduces the process energy consumption, achieves the purpose of improving the final copper-nickel separation index, and is economical, applicable, simple and good in beneficiation effect.

Owner:JINCHUAN GROUP LIMITED

Triethanolamine-modified gutter oil-based method for preparation of metal cutting fluid

A triethanolamine-modified gutter oil-based method for preparation of metal cutting fluid comprises the following steps: filtering gutter oil to remove insoluble substances, adding the filtrate into a reaction vessel, adding an inorganic acid aqueous solution of the same volume, warming up and stirring for a reaction, cooling the reaction system to room temperature, standing for liquid separation, washing an oil phase by the use of water of the same volume for three times so as to obtain acid-treated gutter oil; and adding the acid-treated gutter oil into a reaction kettle, adding triethanolamine while stirring, stirring at room temperature for a reaction, successively adding auxiliary base oil, chlorinated paraffin, petroleum sodium sulfonate, alkylphenol polyoxyethylene, sodium napthionate, s-triazine and benzotriazole, and stirring to obtain the required product. The method is simple to operate and easy to realize. By the method, the metal cutting fluid with excellent performance can be obtained, and comprehensive utilization of wastes can be realized.

Owner:XIJING UNIV

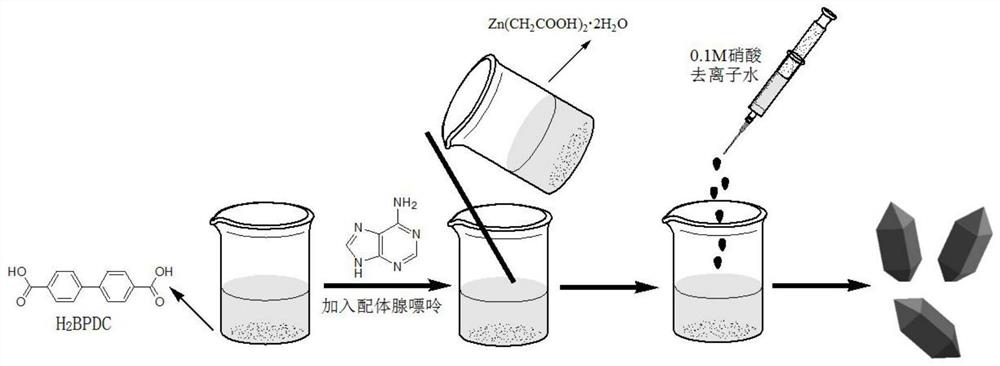

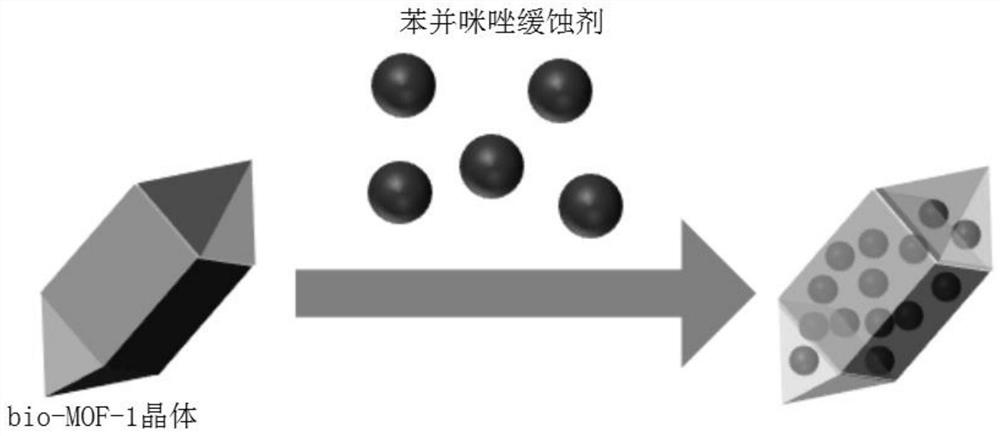

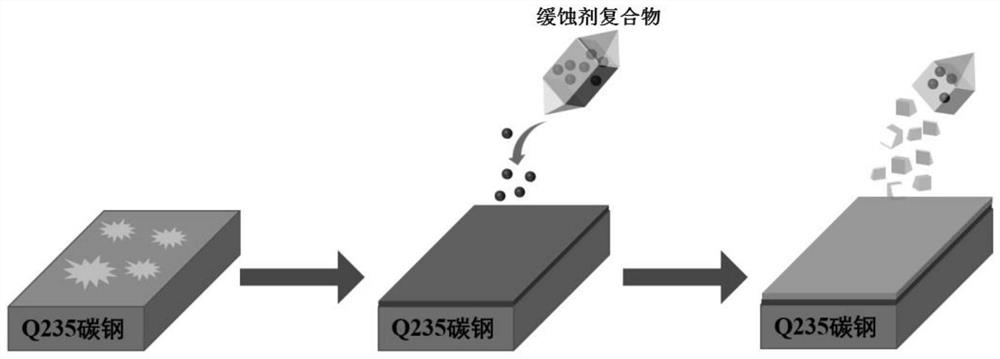

Compound of biological metal organic framework packaging corrosion inhibitor as well as preparation method and application of compound

The invention belongs to the technical field of marine steel corrosion protection, and particularly relates to a biological type metal organic framework packaging corrosion inhibitor compound and a preparation method and application thereof.From the active adsorption molecule design level, firstly, a biological type metal organic framework (bio-MOF-1) with corrosion inhibition components is synthesized through a hydrothermal synthesis method; and then the compound is used as a carrier to package a corrosion inhibitor object, so that the synergistic corrosion inhibition effect of the active components of the compound is fully exerted, and the compound is used for inhibiting corrosion of carbon steel and other metal material products serving in a seawater circulation system. In a corrosion induction stage of a metal corrosion area, an object imidazole molecule is firstly diffused to inhibit corrosion, and when corrosion is further intensified, an aromatic heterocyclic organic ligand is dissociated to generate a synergistic corrosion inhibition effect with imidazole, so that an excellent anti-corrosion effect is achieved. The preparation method is simple in synthesis and high in yield, and the obtained corrosion inhibitor compound has the characteristics of targeted protection, dual corrosion inhibition, efficient effect and the like.

Owner:SUN YAT SEN UNIV

A kind of synthetic method of pseudoionone

ActiveCN108530279BIn line with the development conceptRealize continuous productionOrganic compound preparationCarbonyl compound preparationChemical industryIsomerization

Owner:ZHEJIANG NHU CO LTD +1

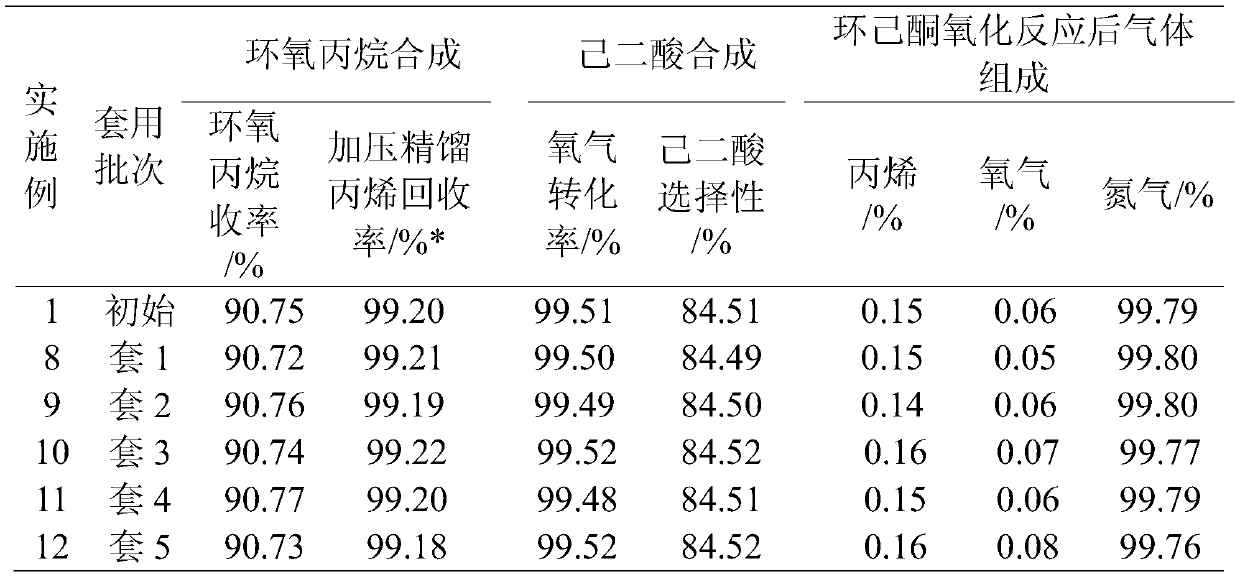

A method for safely synthesizing propylene oxide and coproducing adipic acid

ActiveCN109293601BAtom utilization is highReasonable useOrganic compound preparationCarboxylic compound preparationCyclohexanoneAdipic acid

Belonging to the technical field of organic chemical industry, the invention relates to a method for safe synthesis of propylene oxide and co-production of adipic acid. The method for safe synthesis of propylene oxide and co-production of adipic acid provided by the invention utilizes a pressurized rectification device to recover propylene, at the same time utilizes hydrogen peroxide decomposed oxygen to oxidize cyclohexanone for preparation of adipic acid and removal of oxygen in the gas phase, thus not only realizing co-production of high value-added adipic acid, but also ensuring the intrinsic safety of the process. At the same time, propylene and nitrogen in tail gas are recycled and reused, thereby realizing recovery and utilization of resources. The method provided by the invention has the advantages of high atom utilization, intrinsic safe process, rational utilization of resources, low VOC emission, etc.

Owner:JIANGSU YANGNONG CHEM GROUP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com