Method for producing green modified nanometer Fe-Sn double-metal particles by utilizing pine bark

A technology of pine bark and nano-iron, applied in chemical instruments and methods, textile industry wastewater treatment, water/sewage treatment, etc., can solve the problems of high cost, environmental pollution of chemical agents, and restriction of the use of modified nano-iron particles. , to achieve low cost, reduce synthesis cost, and realize the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

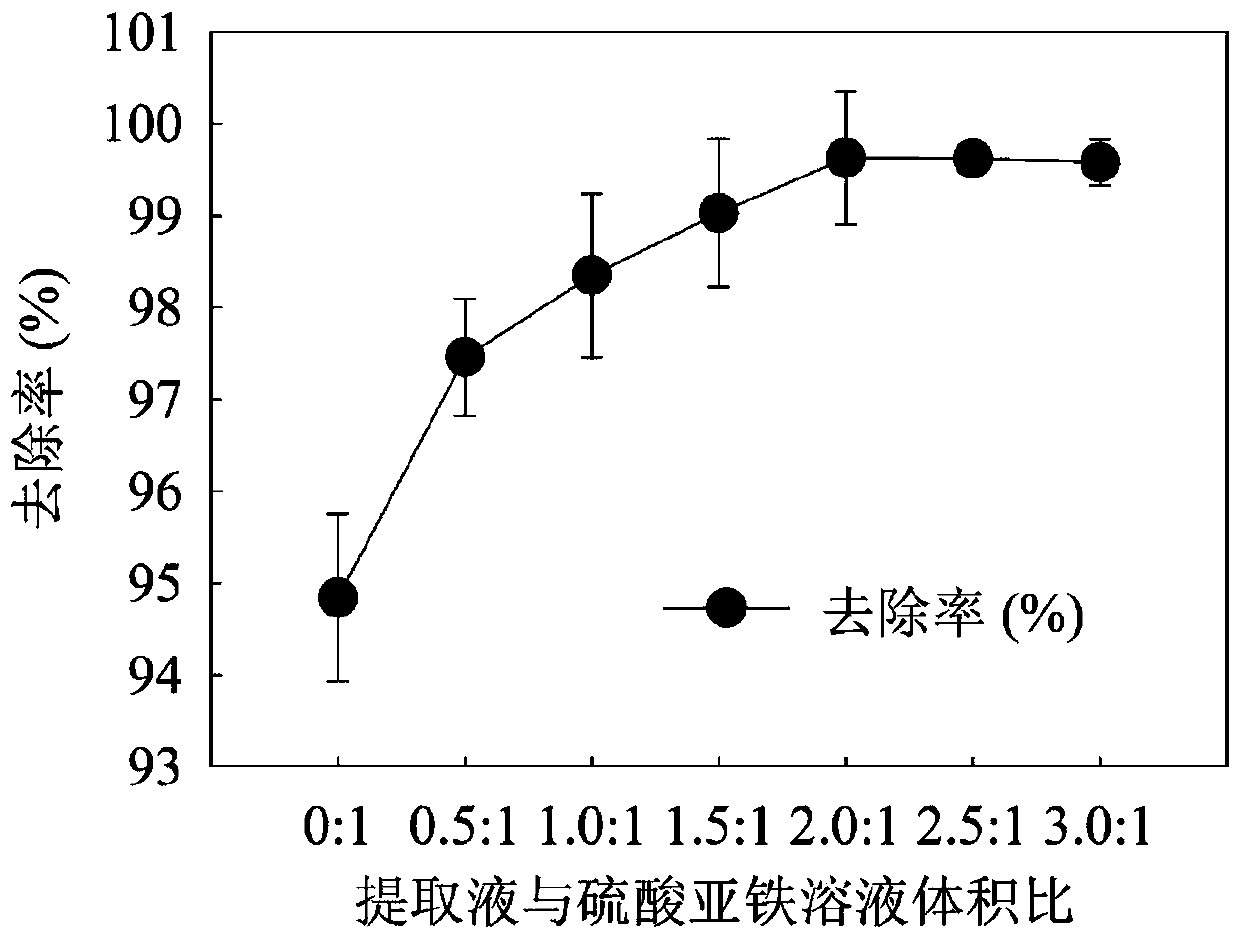

[0031] Pine bark was washed with deionized water and dried at 100 °C for 24 h. The dried pine bark was crushed and sieved, and the pine bark powder with a particle size below 300 μm was selected, soaked in anhydrous methanol at a ratio of 20 g / L, and ultrasonicated (60 W, 20 ° C) for 1 h. The pine bark powder methanol liquid is vacuum filtered through a 0.45 μm organic filter membrane, and the collected filtrate is the pine bark extract. The ferrous sulfate solution of pine bark extract and 20mL 11.1204g / L is mixed according to volume ratio 0:1, 0.5:1, 1.0:1, 1.5:1, 2.0:1, 2.5:1, 3.0:1 respectively ( The dosage of pine bark extract was 0, 10, 20, 30, 40, 50, 60mL respectively) to obtain the iron salt-pine bark extract mixture, which was shaken in a constant temperature water bath shaker for 5min (210rpm, 25°C). Then, 20 mL of 4.3152 g / L potassium borohydride solution was added dropwise to the mixture, and oscillated while adding. A black solid is formed in the system, and th...

Embodiment 2

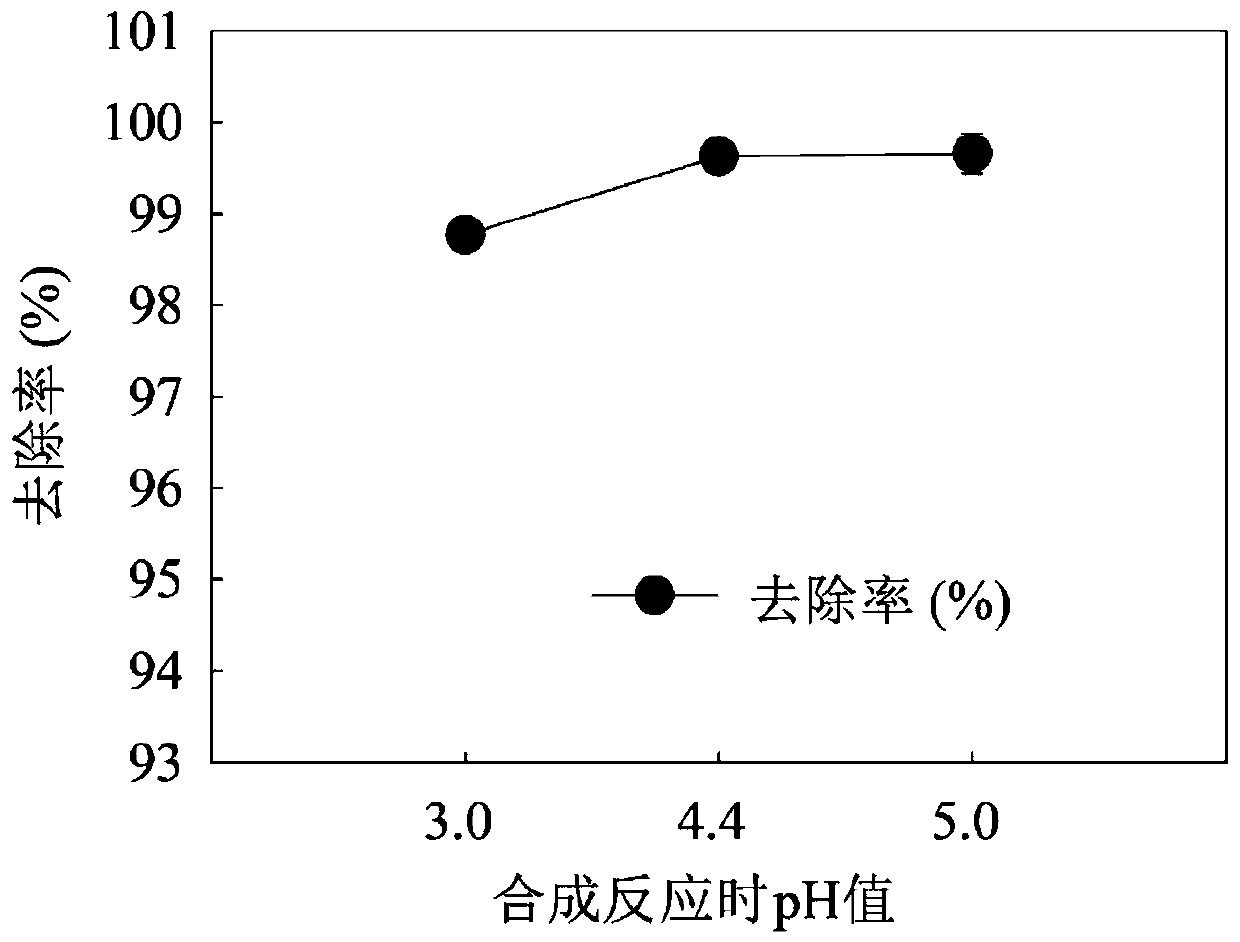

[0035] Pine bark was washed with deionized water and dried at 100 °C for 24 h. The dried pine bark was crushed and sieved, and the pine bark powder with a particle size below 300 μm was selected, soaked in anhydrous methanol at a ratio of 30 g / L, and ultrasonicated (70 W, 25 ° C) for 1 h. The pine bark powder methanol liquid is vacuum filtered through a 0.45 μm organic filter membrane, and the collected filtrate is the pine bark extract. The pine bark extract is mixed with 20mL 33.3612g / L ferrous sulfate solution according to the volume ratio of 2.5:1 (the amount of pine bark extract is 50mL) to obtain the iron salt-pine bark extract mixed solution, which is placed in a constant temperature water bath shaker Shake for 5 min (220 rpm, 25°C). After adjusting the pH value of the mixed solution to 3.0, 4.4 (without adjusting the pH value), 5.0, 7.0, 9.0, and 11.0, add 20 mL of 16.1820 g / L potassium borohydride solution dropwise to the mixed solution, and oscillate while adding ....

Embodiment 3

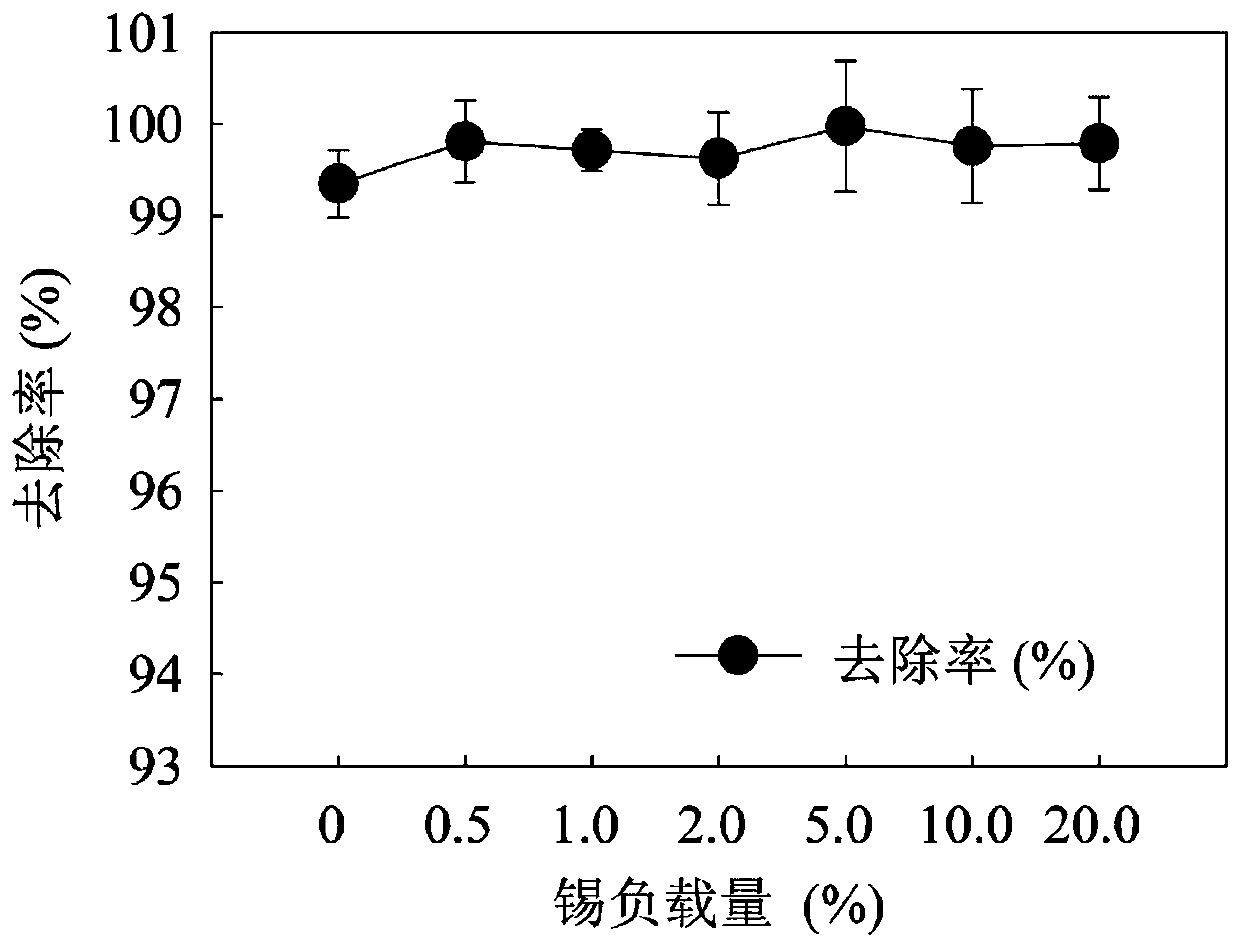

[0039] Pine bark was washed with deionized water and dried at 100 °C for 24 h. The dried pine bark was crushed and sieved, and the pine bark powder with a particle size below 300 μm was selected, soaked in anhydrous methanol at a ratio of 40 g / L, and ultrasonicated (80 W, 30 ° C) for 1 h. The pine bark powder methanol liquid is vacuum filtered through a 0.45 μm organic filter membrane, and the collected filtrate is the pine bark extract. Mix the pine bark extract with 20mL 55.6020g / L ferrous sulfate solution according to the volume ratio of 2.5:1 (the amount of pine bark extract is 50mL) to obtain the iron salt-pine bark extract mixture, which is placed in a constant temperature water bath shaker Shake for 5 min (230 rpm, 25°C). Add 20mL of 32.3640g / L potassium borohydride solution dropwise to the mixed solution with an initial pH value of 4.4 (without adjusting the pH value), and vibrate while adding, a black solid is formed in the system, and bubbles are constantly bubbling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com