A method for safely synthesizing propylene oxide and coproducing adipic acid

A technology of propylene oxide and adipic acid, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., can solve the problems of waste of resources, complicated preparation, pollution, etc., and achieve less VOC emissions and resources. The effect of rational utilization and process intrinsic safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

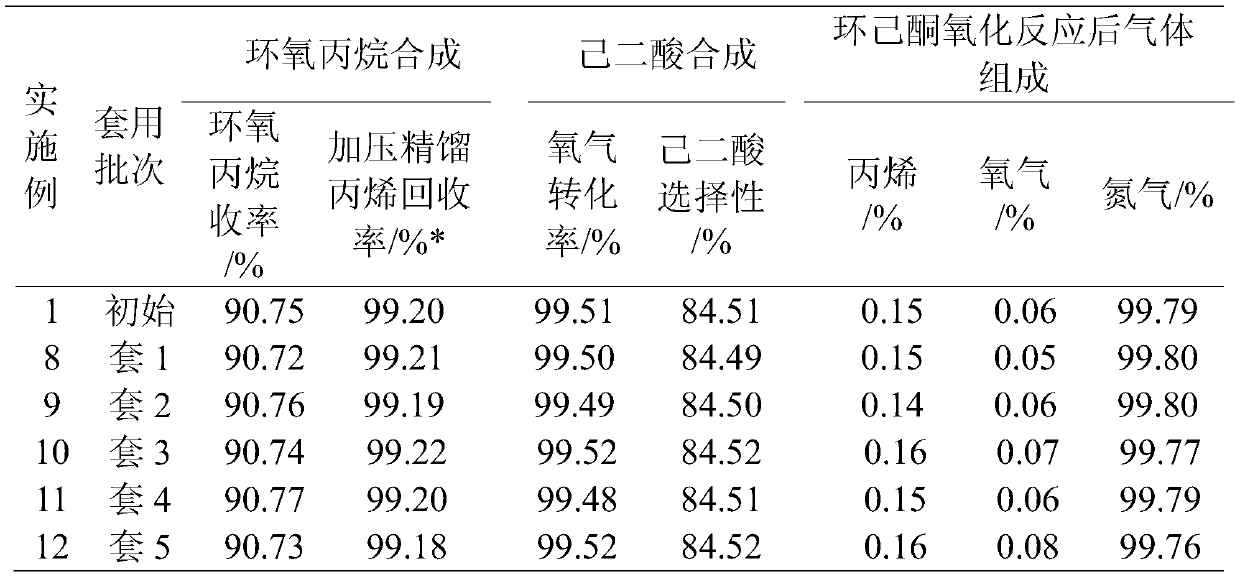

Embodiment 1

[0037] Put 1000g of toluene and 20g of phosphotungstic acid catalyst into the propylene oxide synthesis reactor, fill it with 500g of propylene and 300g of hydrogen peroxide with a mass fraction of 35%, feed nitrogen to control the reaction pressure to 4MPa, and react at 80°C for 2 hours , the yield of propylene oxide was 90.75%. During the reaction process, the gas phase components are continuously separated, and the gas phase components pass through a pressurized rectification tower to separate and recover propylene. The volume fraction of oxygen in the noncondensable gas produced at the top of the tower is 9.94%, the gas fraction of nitrogen is 89.93%, and the volume fraction of propylene is 0.13%, and the recovery rate of propylene in the pressurized rectification stage is 99.20%.

[0038] Add 1000g cyclohexanone, 20g cobalt acetate and 1000g acetic acid solvent into the cyclohexanone oxidation reactor, pass through the non-condensable gas extracted from the top of the pre...

Embodiment 2

[0040] Add 1000g of acetonitrile and 50g of phosphomolybdic acid catalyst into a propylene oxide synthesis reactor, fill with 420g of propylene and 70g of hydrogen peroxide with a mass fraction of 50%, feed nitrogen to control the reaction pressure to 4MPa, and react at 60°C for 6 hours , the yield of propylene oxide was 93.01%. During the reaction process, the gas phase components are separated, and the gas phase components pass through the pressurized rectification tower to separate and recover propylene. The volume fraction of oxygen in the non-condensable gas extracted from the top of the tower is 7.44%, the gas volume fraction of nitrogen is 92.22%, and the volume fraction of propylene is 0.34% %, the recovery rate of propylene in the pressurized rectification stage is 99.32%.

[0041] Put 1000g cyclohexanone, 5g manganese acetate and 1000g methyl ethyl ketone solvent into the cyclohexanone oxidation reactor, feed the non-condensable gas extracted from the top of the pres...

Embodiment 3

[0043] Add 1000g of dichloroethane and 50g of phosphovanadic acid catalyst into a propylene oxide synthesis reactor, fill with 210g of propylene and 500g of hydrogen peroxide with a mass fraction of 34%, and feed in nitrogen to control the reaction pressure to 3MPa at 40°C After 18 hours of reaction, the yield of propylene oxide was 90.50%. During the reaction process, the gas phase components are separated, and the gas phase components pass through the pressurized rectification tower to separate and recover propylene. The volume fraction of oxygen in the non-condensable gas produced at the top of the tower is 11.28%, the gas volume fraction of nitrogen is 88.50%, and the volume fraction of propylene is 0.22%. , The recovery rate of propylene in the pressurized rectification stage is 99.45%.

[0044] Add 1000g cyclohexanone, 10g iron porphyrin and 5000g isobutanol solvent into the cyclohexanone oxidation reactor, feed the non-condensable gas extracted from the top of the press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com