Fluoride-free low-nitrogen-sulfur ferro-molybdenum smelting raw material, ferro-molybdenum green smelting system and ferro-molybdenum green smelting method

A raw material, ferromolybdenum technology, applied in the green smelting system of ferromolybdenum and the field of green smelting of ferromolybdenum, can solve problems such as environmental pollution and nitrogen dioxide emission, and achieve the effect of reducing labor intensity and improving the working environment of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

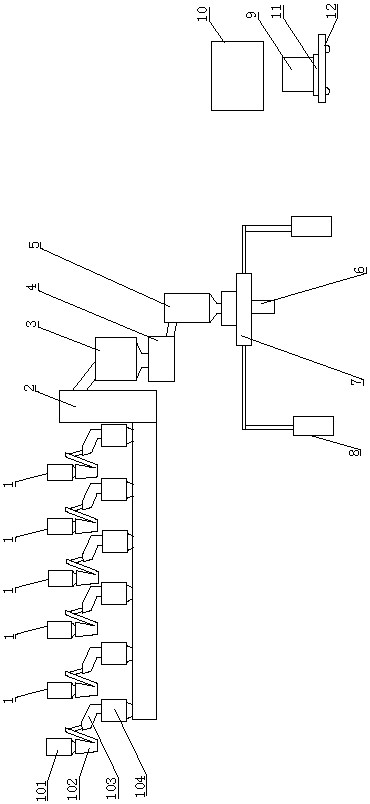

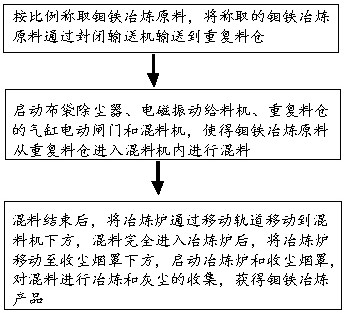

[0044] Preparation of sample one:

[0045] 101) The raw materials in each raw material bin are transported to the second electromagnetic vibrating feeder 103 by the screw conveyor 102 respectively, and each second electromagnetic vibrating feeder 103 transports each raw material to the corresponding weighing bin 104, each weighing After the heavy silo 104 accurately weighs the raw materials, the weighed raw materials are transported to the In the multiple silo 3, 4.5 tons of molybdenum oxide, 0.32 tons of raw stone, 1.58 tons of iron and phosphorus, 0.9 tons of metal silicon powder, 0.24 tons of aluminum particles, 0.9 tons of steel scrap and 200g of magnesium strips are put into the multiple silo After 3 minutes, enter the mixer 5 through the first electromagnetic vibrating feeder 4, and mix the materials for 15 minutes to obtain the mixture;

[0046] 102) Fix the smelting furnace 9 on the electronic double-drive rail flatbed truck 12 through the sand base plate 11, move the...

Embodiment 2

[0059] Preparation of sample two:

[0060] 201) The raw materials in each raw material bin are transported to the second electromagnetic vibrating feeder 103 through the screw conveyor 102, and each second electromagnetic vibrating feeder 103 transports each raw material to the corresponding weighing bin 104, each weighing After the heavy silo 104 accurately weighs the raw materials, the weighed raw materials are transported to the In the multiple silo 3, 4.0 tons of molybdenum oxide, 0.28 tons of quicklime, 1.54 tons of iron and phosphorus, 0.55 tons of metal silicon powder, 0.2 tons of aluminum particles, 0.9 tons of steel shavings and 170 g of magnesium strips are put into the multiple silo. After 3 minutes, enter the mixer 5 through the first electromagnetic vibrating feeder 4, and mix the materials for 20 minutes to obtain the mixture;

[0061] 202) Fix the smelting furnace 9 on the electronic double-drive track flatbed car 12 through the sand base plate 11, move the ele...

Embodiment 3

[0072] Preparation of sample three:

[0073] 301) The raw materials in each raw material bin are transported to the second electromagnetic vibrating feeder 103 through the screw conveyor 102, and each second electromagnetic vibrating feeder 103 transports each raw material to the corresponding weighing bin 104, each weighing After the heavy silo 104 accurately weighs the raw materials, the weighed raw materials are transported to the In the double silo 3, 4.0 tons of molybdenum oxide, 0.4 tons of quicklime, 2 tons of iron and phosphorus, 1.2 tons of metal silicon powder, 0.4 tons of aluminum particles, 0.9 tons of steel shavings and 250g of magnesium strips are put into the double silo. After 3 minutes, enter the mixer 5 through the first electromagnetic vibrating feeder 4, and mix the materials for 20 minutes to obtain the mixture;

[0074]302) Fix the smelting furnace 9 on the electronic double-drive rail flatbed car 12 through the sand base plate 11, move the electronic do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com