Compound of biological metal organic framework packaging corrosion inhibitor as well as preparation method and application of compound

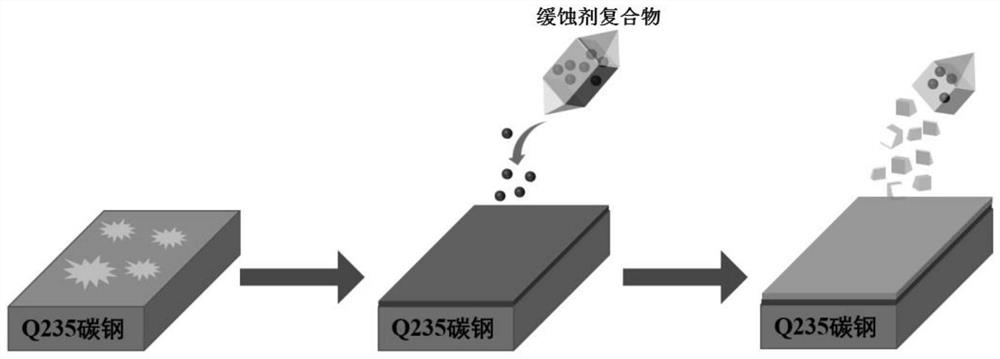

A metal-organic framework and organic framework technology are applied in the field of biological metal-organic framework-encapsulated corrosion inhibitor composites and the field of preparation thereof, which can solve the problems of lack of corrosion inhibitor function and inability to play dual corrosion inhibition, and achieve long-term performance. Effective anti-corrosion performance, efficient and easy to degrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

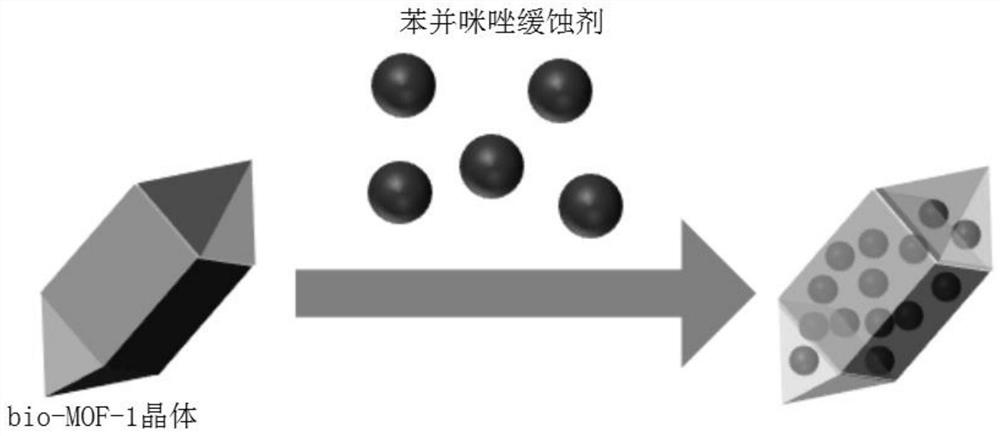

[0046] Example 1 Preparation of bio-MOF-1 encapsulated imidazole corrosion inhibitor complex

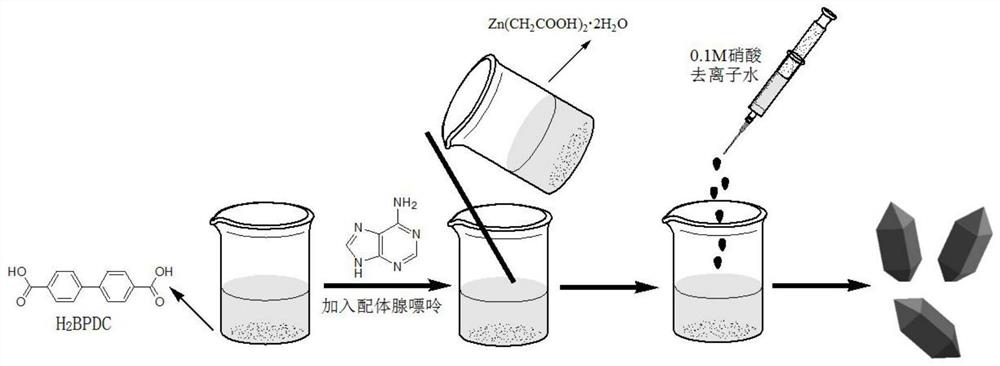

[0047] The synthetic route of bio-MOF-1 is as follows figure 1 Shown, its preparation method comprises the following steps:

[0048] 1. Preparation of bio-based metal-organic framework bio-MOF-1 carrier:

[0049] (1) 15.14mg (0.0625mmol) 4'4-biphenyl dicarboxylic acid (H 2 BPDC) was added to 10 mL of DMF solvent, heated and stirred at 50°C until completely dissolved, then 8.50 mg (0.0625 mmol) of adenine was added to the solution and stirred until dissolved to obtain ligand mixture A.

[0050] (2) Weigh 41.00mg (0.187mmol) of zinc acetate dihydrate (Zn(CH 2 COOH) 2 2H 2 0) added to 3.5mL DMF solvent, stirred for 5min to obtain solution B.

[0051] (3) Quickly add solution B to ligand mixture A (at this time, the molar ratio of zinc source, 4'4-biphenyldicarboxylic acid and adenine in the mixture is 3:1:1), and then pour into the mixture Add 0.5mL of 0.1M nitric acid and 0.5mL ...

Embodiment 2

[0057] Example 2 Preparation of bio-MOF-1 encapsulated imidazole corrosion inhibitor complex

[0058] 1. The preparation of the bio-based metal-organic framework bio-MOF-1 carrier is the same as in Example 1, the difference is that the amount of 4'4-biphenyl dicarboxylic acid (H2BPDC) is 30.30 mg (0.125 mmol), so that the mixed solution The molar ratio of zinc source, 4'4-biphenyldicarboxylic acid and adenine is 3:2:1.

[0059] 2. The preparation of the corrosion inhibitor composite is the same as that in Example 1. The loading amount of the benzimidazole corrosion inhibitor in bio-MOF-1 is 12.57wt%, and the loading efficiency is 90.62%.

Embodiment 3

[0060] Example 3 Preparation of bio-MOF-1 encapsulated imidazole corrosion inhibitor complex

[0061] 1. The preparation of the bio-based metal-organic framework bio-MOF-1 carrier is the same as in Example 1, the difference is that 4'4-biphenyl dicarboxylic acid (H 2 The usage amount of BPDC) is 45.42mg (0.188mmol), makes the mol ratio of zinc source, 4'4-biphenyl dicarboxylic acid and adenine in the mixed solution be 3:3:1.

[0062] 2. The preparation of the corrosion inhibitor composite is the same as that in Example 1. The loading amount of the benzimidazole corrosion inhibitor on bio-MOF-1 is 11.68wt%, and the loading efficiency is 89.21%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com