Preparation method of bromo-pyrrolecarbonitrile grafted block type acrylic acid self-polishing resin and environmentally-friendly marine antifouling composition

A technology of bromopyrrole nitrile and acrylic silicone resin, which is applied in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the problems that copper-containing antifouling agents affect human health and ecological safety, and achieve Good stability, uniform distribution, anti-fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] A kind of preparation method of bromopyrrole nitrile graft block type acrylic acid isobornyl resin, comprises the following steps:

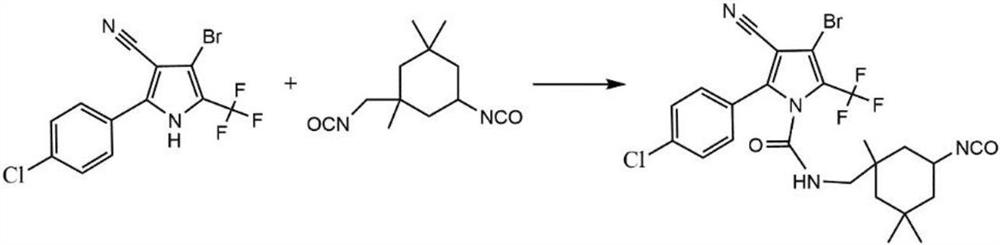

[0076] 1) Preparation of bromopyrrolenitrile-modified isocyanate: under the protection of inert gas, mix ethyl acetate and bromopyrrolenitrile evenly, then add dropwise to isophorone diisocyanate, heat up to 40-50°C for reaction, and Remove 40-60% of ethyl acetate under conditions, add xylene with a mass ratio of (40-60):(15-20) to the remaining ethyl acetate to obtain bromopyrrole nitrile-modified isocyanate. The mass ratio of ethyl acetate, bromopyrrole nitrile and isophorone diisocyanate is 100:(20-30):(15-20).

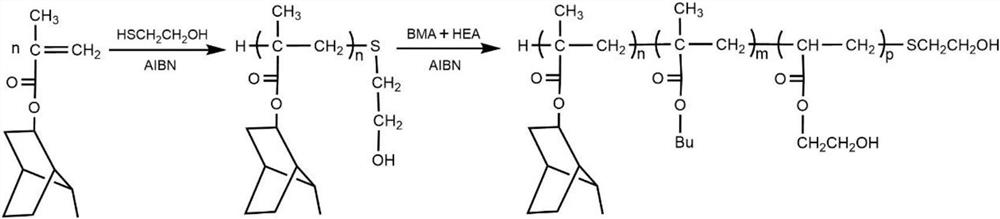

[0077] 2) Preparation of block-type isobornyl acrylate resin: Mix initiator, molecular weight modifier, isobornyl methacrylate and xylene under the protection of an inert gas, heat up to 65-75°C and react for 20-30 hours, then add formaldehyde The mixed solution of butyl acrylate, hydroxyethyl acrylate, xylene and initiator wa...

Embodiment 1

[0114] Embodiment 1: Preparation (A) of bromopyrrole nitrile modified isocyanate

[0115] Add 16.7g isophorone diisocyanate (IPDI), 100g dry ethyl acetate and 25g bromopyrrole nitrile homogeneous mixture in the four-necked flask equipped with high-purity argon protection, stirrer, reflux condenser and thermometer Add it dropwise into the system, raise the temperature to 45°C to continue the reaction, measure the content of NCO groups in the system by di-n-butylamine titration method, after reaching the theoretical value, remove 50g of ethyl acetate under vacuum conditions, add 18.3g of dry xylene to obtain bromopyrrole nitrile modified isocyanate (A).

[0116]

[0117] Preparation of Bromopyrrole Nitrile Modified Isocyanate (A)

Embodiment 2

[0118] Embodiment 2: the preparation of block type acrylic acid isobornyl resin (B1)

[0119] Add 0.6g of azobisisobutyronitrile (AIBN), 1.2g of mercaptoethanol, 45g of isobornyl methacrylate (IBOMA), and 51g of xylene in a 1L four-necked flask equipped with a stirrer, a reflux condenser, and nitrogen protection. After 24 hours of reaction, add 18g of butyl methacrylate (BMA), 27g of hydroxyethyl acrylate (HEA), 51g of xylene and 0.6g of AIBN, continue the reaction for 24 hours, cool to room temperature, and complete the reaction . The measured solid content was 47.2%. According to the GPC test, the number average molecular weight of the resin is 34287, the weight average molecular weight is 111775, and the dispersion degree is 3.26.

[0120]

[0121] Preparation of Block Type Acrylic Isobornyl Resin (B1)

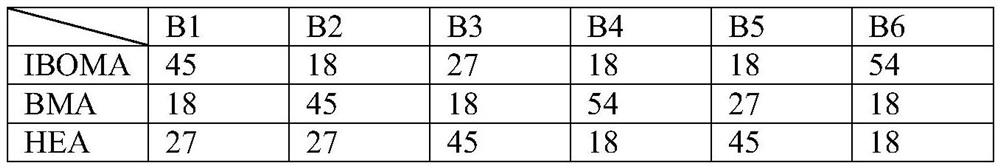

[0122] The batching weight (g) of the block type acrylic isobornyl resin of more different monomer ratios is as follows:

[0123]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com