Steel specially for agricultural cultivator wear part and production technology thereof

A production process and farming machine technology, which is applied in the field of alloy steel, can solve problems such as unsatisfactory, pollute the environment, and damage the health of employees, and achieve the effects of simplified heat treatment process, scientific composition ratio, and superior hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

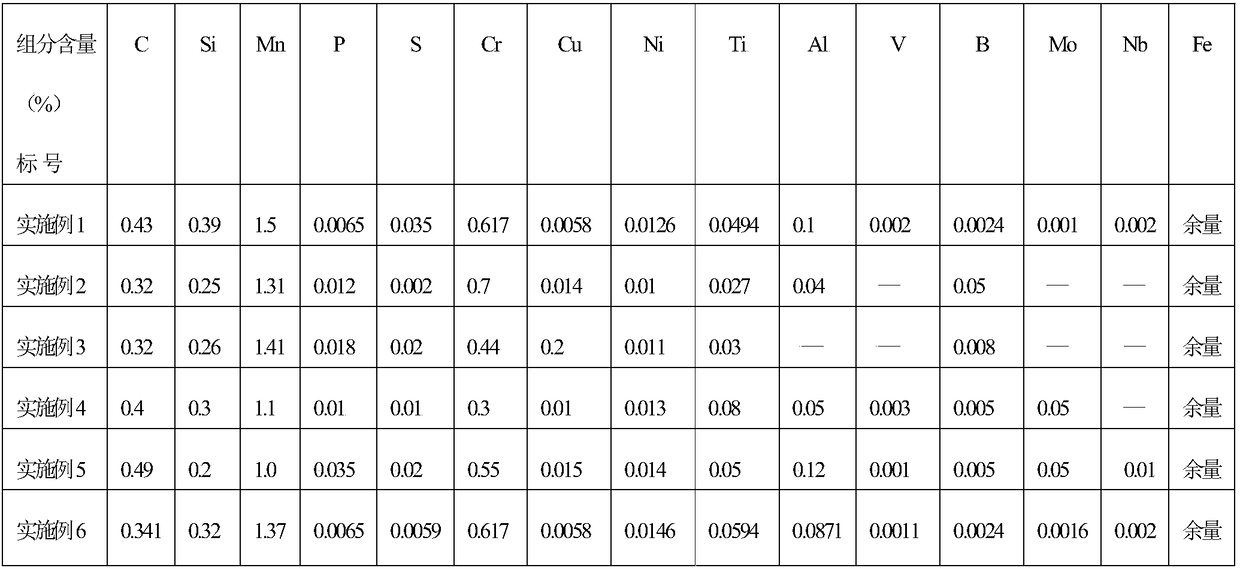

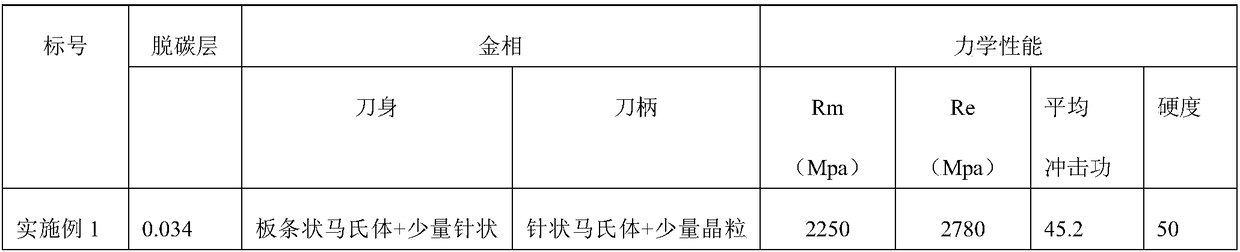

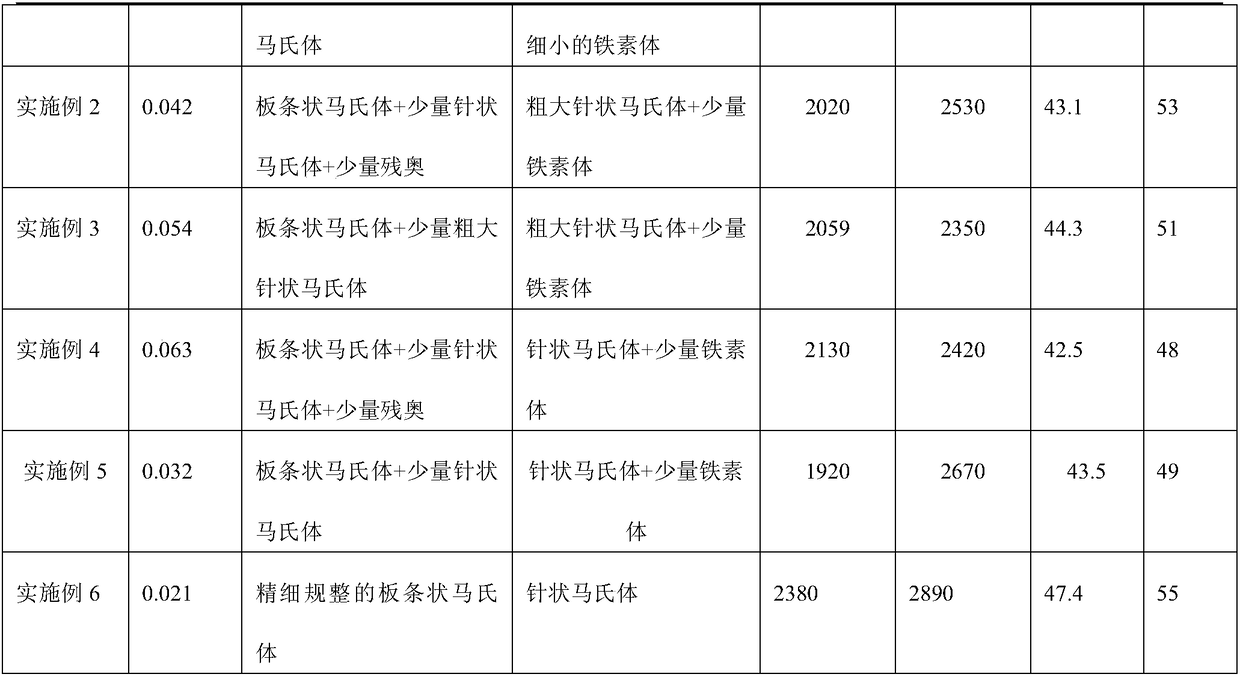

Embodiment 1

[0022] A special steel for agricultural machine wear parts, comprising the following components by mass percentage: C 0.43%, Si0.39%, Mn 1.5%, P 0.0065%, S 0.0035%, Cr 0.617%, Cu 0.0058%, Ni 0.0126 %, Ti0.0494%, Al 0.10%, V 0.0020%, B 0.0024%, Mo 0.001%, Nb 0.002%, and the balance is Fe. When preparing, firstly add each component according to the above ratio, then heat and shape it into a 10*10*80mm flat steel, heat at 870°C, keep the temperature for 15 minutes, put it into tap water for quenching, and finally shape it into a rotary tiller.

Embodiment 2

[0024] A special steel for agricultural machine wear parts, comprising the following components by mass percentage: C 0.32%, Si0.25%, Mn 1.31%, P 0.012%, S 0.002%, Cr 0.7%, Cu 0.014%, Ni 0.010 %, Ti0.027%, Al 0.04%, B 0.05%, and the balance is Fe. First add the components according to the above ratio, then heat and shape it into a 10*10*80mm flat steel, heat it at 870°C, keep the temperature for 15 minutes, put it in tap water to quench, and finally shape it into a rotary tiller.

Embodiment 3

[0026] A special steel for agricultural machinery wear parts, comprising the following components by mass percentage: C 0.32%, Si0.26%, Mn 1.41%, P 0.018%, S 0.02%, Cr 0.44%, Cu 0.2%, Ni 0.011 %, Ti 0.030%, B 0.008%, and the balance is Fe. First add the components according to the above ratio, then heat and shape it into a 10*10*80mm flat steel, heat it at 870°C, keep the temperature for 15 minutes, put it in tap water for quenching, and finally shape it into a rotary tiller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com