Fabricated beam-column joint connecting device and application thereof

A technology for connecting devices and beam-column joints, applied in the field of structural engineering and construction, can solve the problems of single modular building unit combination form, difficulty in ensuring joint strength and safety, and unfavorable building maintenance and repair component replacement, etc., to improve the overall rigidity. , Good auxiliary positioning effect, the effect of speeding up the assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

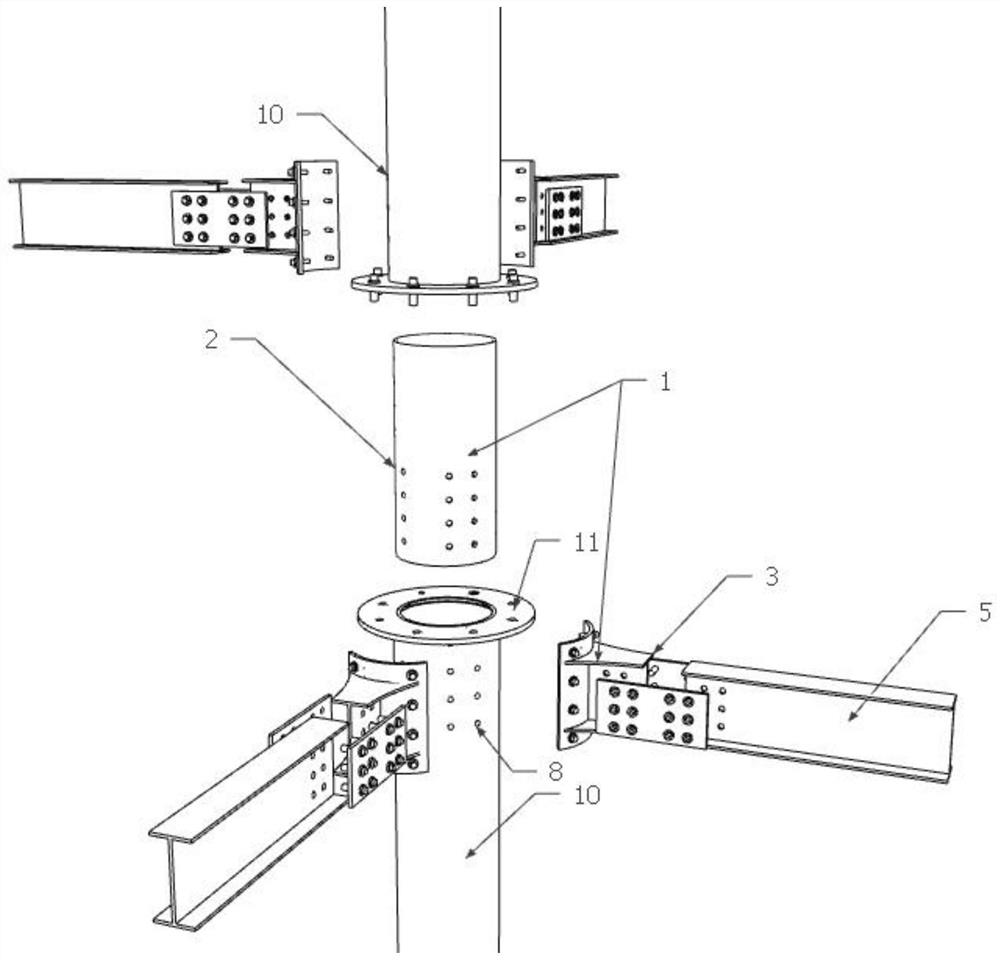

[0046] Embodiment 1: A beam-column node connection device

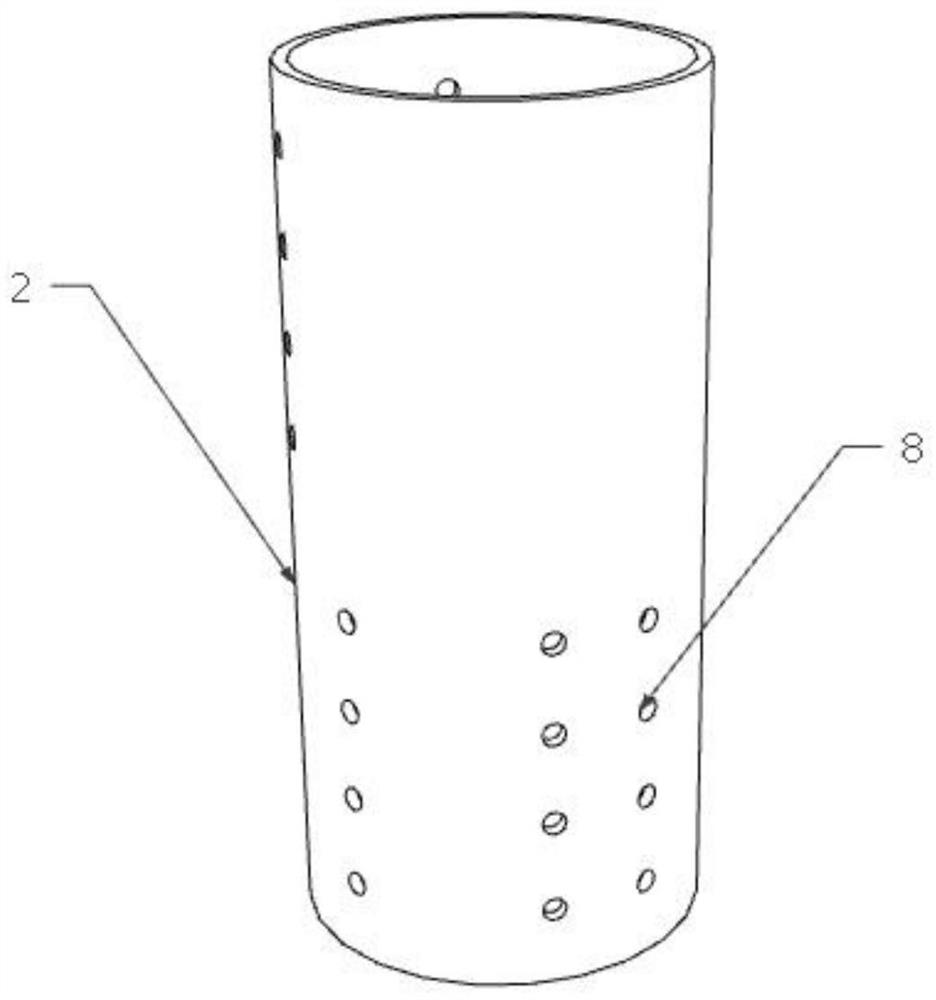

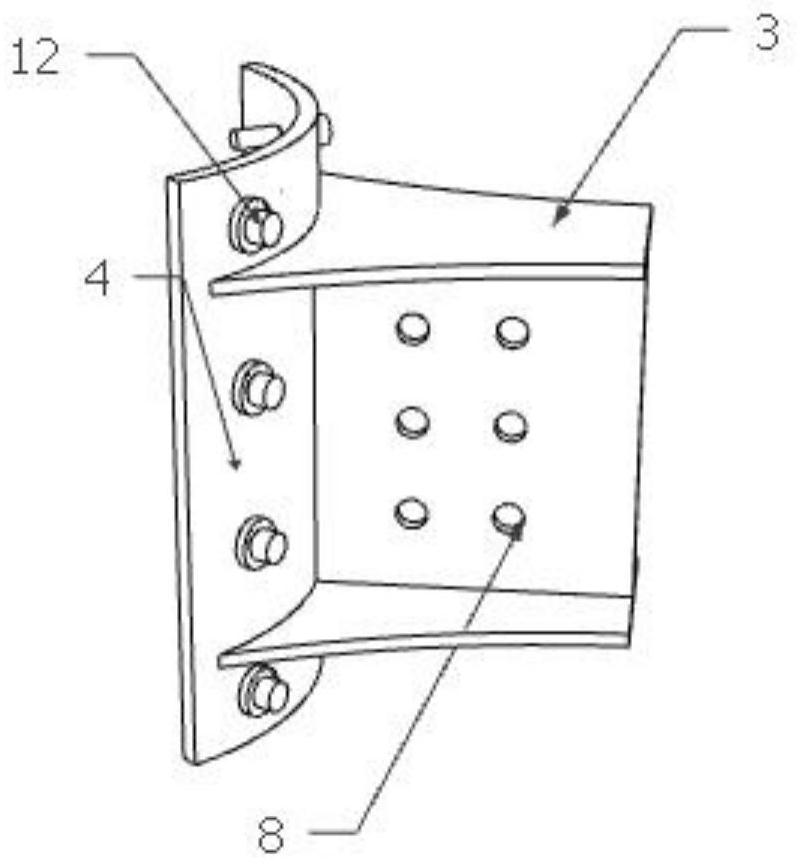

[0047] Such as Figure 1-3 The beam-to-column connection device 1 includes an inner sleeve 2 and a connector 3, the connector 3 includes a curved steel plate 4, an H-shaped steel 5, a first connecting steel plate 6 and a second connecting steel plate 7, and the H-shaped steel 5 and The protruding sides of the arc-shaped steel plates 4 are connected, and the inner sleeve 2, the arc-shaped steel plates 4, the web of the H-shaped steel 5, the first connecting steel plates 6 and the second connecting steel plates 7 are provided with some reserved parts. hole 8.

[0048] Preferably, the center line of the arc-shaped steel plate 4 is perpendicular to the upper flange plate and the lower flange plate of the H-shaped steel 5 .

[0049] As preferably, the width of the upper flange plate and the lower flange plate of the H-shaped steel 5 decreases gradually as the distance between it and the arc-shaped steel plate 4 gradually...

Embodiment 2

[0052] Embodiment 2: A method of connecting beams and columns

[0053] Such as Figure 4-5 , the beam 9 is an H-shaped steel beam, the web of the beam 9 is provided with a number of reserved holes 8; the column 10 is a round steel column, and the upper end and / or lower end of the column 10 is connected with a ring-shaped steel plate 11, and, the column 10 and the annular steel plate 11 are provided with a number of reserved holes 8; the method is to use the above-mentioned node connection device 1, and set the upper and lower adjacent columns 10 on the inner sleeve 2, so that The inner sleeve 2 is located inside the two adjacent columns 10 up and down and at the junction of the two adjacent columns 10 up and down, and the ring-shaped steel plates of the two adjacent columns 10 are connected by the reserved holes 8 and fasteners 12 11 connection, connect the inner sleeve 2, the column 10 and the curved steel plate 4 through the reserved hole 8 and the fastener 12, connect the ...

Embodiment 3

[0057] Embodiment 3: a kind of beam column

[0058] The construction method of beam and column sees embodiment 2, wherein:

[0059] Beam and column size: the cross-sectional size of the round steel pipe column is A300mm×10mm; the cross-sectional size of the inner sleeve is A280mm×10mm, and the height is 800mm; the outer diameter of the circular steel plate at the end of the column is A 外 500mm, inner diameter A 内 is 300mm, and the thickness is 20mm; the cross-sectional size of the H-shaped steel beam is 300mm×150mm×8mm×15mm.

[0060] Connector size: curved steel plate shape is a quarter circle, height 400mm, thickness 10mm, inner diameter A 内 The width of the upper and lower flanges of the H-shaped steel is smoothly transitioned from 200mm to 150mm. The end with a width of 200mm is welded with the arc-shaped steel plate, and the end with a width of 150mm is connected with the H-shaped steel beam. The thickness is 15mm, and the cross-sectional size of the web is 8mm. ×270mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com