High-electric-conductivity phenolic-resin-based graphene-modified activated carbon, and preparation method and application thereof

A graphene modification and activated carbon technology, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems that the performance of activated carbon cannot meet the capacity, the pore size distribution is unreasonable, and the internal resistance of activated carbon is large. Migrating channels, reducing adverse effects, improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The invention provides a kind of preparation method of resin-based graphene modified activated carbon, comprising the following steps:

[0050] A) After the phenolic compound, the aldehyde compound and the graphene oxide undergo a hydrothermal reaction, a compound is obtained;

[0051] B) Under the condition of a protective atmosphere, after carbonizing the compound obtained in the above steps, a carbonized material is obtained;

[0052] C) after mixing the carbonized material obtained in the above steps with an activator, after activation under the condition of a protective atmosphere, the primary product of activated carbon is obtained;

[0053] D) The activated carbon primary product obtained in the above steps is subjected to heat treatment under the protection of reducing gas and / or protective atmosphere to obtain resin-based graphene-modified activated carbon.

[0054] In the present invention, firstly, the compound is obtained through hydrothermal reaction of ph...

Embodiment 1

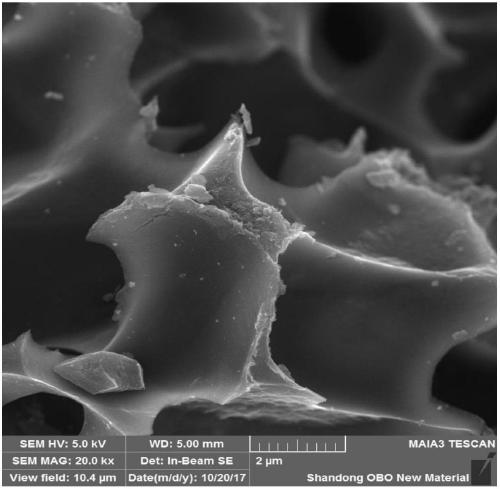

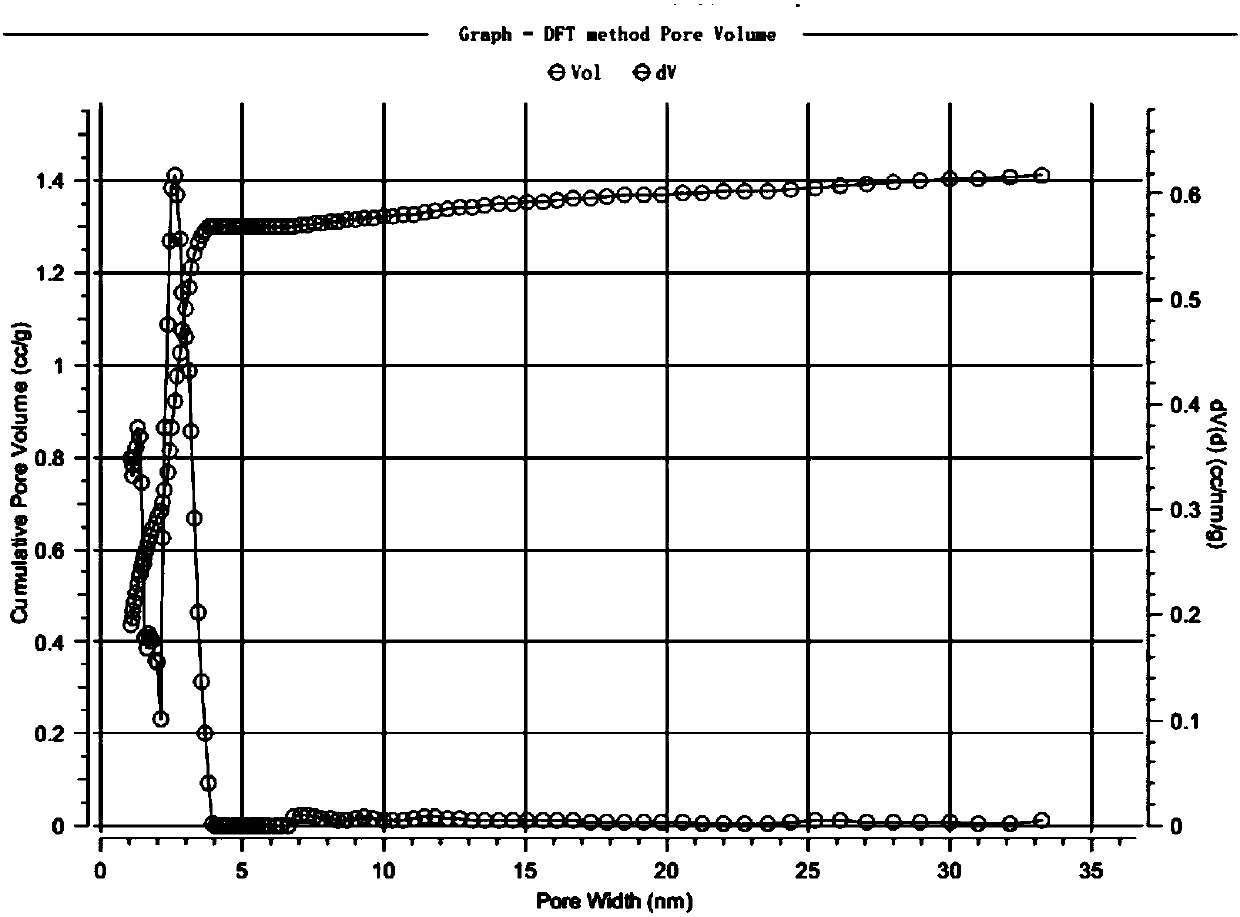

[0092] Take 37.6g of phenol, 97.4g of formaldehyde (37% aqueous solution), and 92ml of graphene oxide aqueous solution with a concentration of 8‰, add them to a 200ml hydrothermal kettle, and react at 180°C for 16h. After the reaction finishes, take out the resin / graphene (graphene oxide) composite.

[0093] Vacuum drying at 120° C. for 24 hours to remove excess water to obtain a dried resin / graphene (graphene oxide) block, which was crushed to 25-30 μm.

[0094] The composite was added into a nitrogen-protected tube furnace, and carbonized at 500°C for 3 hours to obtain a carbonized product. The carbonized product is ground into a powder of 10-12 μm.

[0095] Take 30g of carbide and 120g of potassium hydroxide powder and mix them evenly, add them into a pure nickel crucible, heat up to 800°C at a rate of 5°C / min under nitrogen protection for 1h, cool down naturally, wash until neutral, and use 3% 60 It was acid-washed with HCl at ℃ for 2 hours, washed with water again until...

Embodiment 2

[0104] Take 18.8g of phenol, 48.7g of formaldehyde (37% aqueous solution), and 92ml of graphene oxide aqueous solution with a concentration of 8‰, add them to a 200ml hydrothermal kettle, and react at 180°C for 12h. After the reaction finishes, take out the resin / graphene (graphene oxide) composite.

[0105] Vacuum drying at 120° C. for 24 hours to remove excess water to obtain a dried resin / graphene (graphene oxide) block, which was pulverized to a size of 26-28 μm.

[0106] The composite was added to a nitrogen-protected tube furnace and carbonized at 550°C for 2 hours to obtain a carbonized product. The carbonized product is ground into a powder of 8-10 μm.

[0107] Take 30g of carbide and 150g of potassium hydroxide powder and mix them evenly, add them into a pure nickel crucible, heat up to 900°C at a rate of 5°C / min under nitrogen protection for 1h, cool down naturally, wash until neutral, and use 3% 60 It was acid-washed with HCl at ℃ for 2 hours, washed with water ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com