Lithium titanate slurry of lithium battery and preparation method thereof

A technology for lithium titanate and lithium batteries, which is applied in the field of preparation of lithium titanate slurry for negative electrodes of lithium batteries. The effect of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] ① Add 52g of binder and 1932g of lithium titanate into the dry powder mixer and mix for 20-30min, stir and rotate at 15-25rpm to obtain a uniformly mixed mixture 1;

[0024] ②Add mixture 1 into a stirring pot with 1881g of solvent, mix and stir for 150-180min, the revolution of the mixer is 20-35rpm, and the rotation is 2000-3000rpm to obtain a uniform mixture 2;

[0025] ③ Add 390g of conductive agent into the mixture 2, mix and stir for 40-60min, the revolution of the mixer is 20-35rpm, and the stirring rotation is 2000-3000rpm to obtain a homogeneous mixture 3;

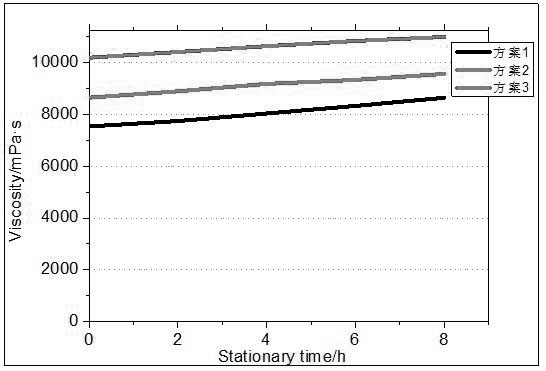

[0026] ④ Grind the mixture 3 with a sand mill equipped with 1.0-1.4mm zirconium beads on one side, and then add it to the mixer for stirring. The stirring time is 30-40min, the revolution of the mixer is 20-35rpm, and the vacuum degree is ≤ -0.08mPa to prepare 47%, lithium titanate slurry with a viscosity of 6000-12000mPa·s.

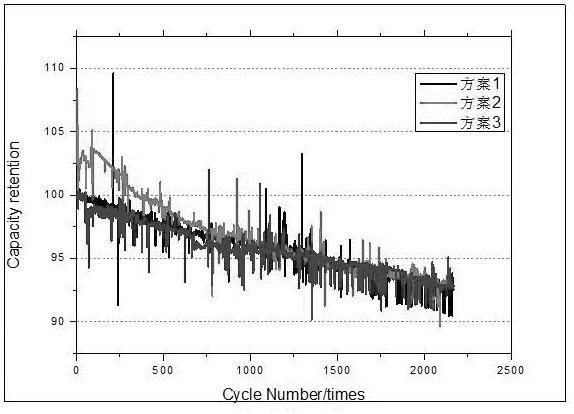

[0027] ⑤Lithium battery production process: sieving, coating, sheet production, w...

Embodiment 2

[0030] ① Add 54g of binder and 1928g of lithium titanate into the dry powder mixer and mix for 20-30min, stir and rotate at 15-25rpm to obtain a uniformly mixed mixture 1;

[0031] ②Add the mixture 1 into a stirring pot with 2087g of solvent, mix and stir for 150-180min, the revolution of the mixer is 20-35rpm, and the stirring rotation is 2000-3000rpm to obtain a uniform mixture 2;

[0032] ③Add 375g of conductive agent into the mixture 2, mix and stir for 40-60min, the revolution of the mixer is 20-35rpm, and the stirring rotation is 2000-3000rpm to obtain a homogeneous mixture 3;

[0033] ④ Grind the mixture 3 with a sand mill equipped with 1.0-1.4mm zirconium beads on one side, and then add it to the mixer for stirring. The stirring time is 30-40min, the revolution of the mixer is 20-35rpm, and the vacuum degree is ≤ -0.08mPa to prepare 45%, lithium titanate slurry with a viscosity of 6000-12000mPa·s.

[0034] ⑤Lithium battery production process: sieving, coating, sheet p...

Embodiment 3

[0037] ① Add 56g of binder and 1924g of lithium titanate into the dry powder mixer and mix for 20-30min, stir and rotate at 15-25rpm to obtain a uniformly mixed mixture 1;

[0038] ② Add mixture 1 into a stirring pot with 2181g of solvent, mix and stir for 150-180min, the revolution of the mixer is 20-35rpm, and the rotation is 2000-3000rpm to obtain a uniform mixture 2;

[0039] ③ Add 384g of conductive agent into the mixture 2, mix and stir for 40-60min, the revolution of the mixer is 20-35rpm, and the rotation of the mixer is 2000-3000rpm to obtain a homogeneous mixture 3;

[0040] ④ Grind the mixture 3 with a sand mill equipped with 1.0-1.4mm zirconium beads on one side, then add it to the mixer and stir for 30-40min, the mixer revolution is 20-35rpm, the vacuum degree is ≤-0.08mPa, and the solid content is prepared 44%, lithium titanate slurry with a viscosity of 6000-12000mPa·s.

[0041] ⑤Lithium battery production process: sieving, coating, sheet production, winding, l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com