Lithium battery lithium titanate slurry and preparation method thereof

A technology of lithium titanate and lithium battery, which is applied in the field of preparation of lithium titanate slurry for lithium battery negative electrode, can solve the problems of agglomeration, coating with particles, difficulty in sieving, etc., and achieves improved consistency, easy coating, overcoming Difficulty dispersing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] ① Add 52g of binder and 1932g of lithium titanate into the dry powder mixer for 20-30min, stir and revolve for 15-25rpm, and obtain a well-mixed mixture 1;

[0024] ② Add mixture 1 into a stirring pot containing 1881g of solvent, carry out mixing and stirring for 150-180min, rotate the mixer at 20-35rpm, and stir and rotate at 2000-3000rpm to obtain uniform mixture 2;

[0025] ③ Add 390g of conductive agent into the mixture 2, carry out mixing and stirring for 40-60min, rotate the mixer at 20-35rpm, and stir and rotate at 2000-3000rpm to obtain a uniform mixture 3;

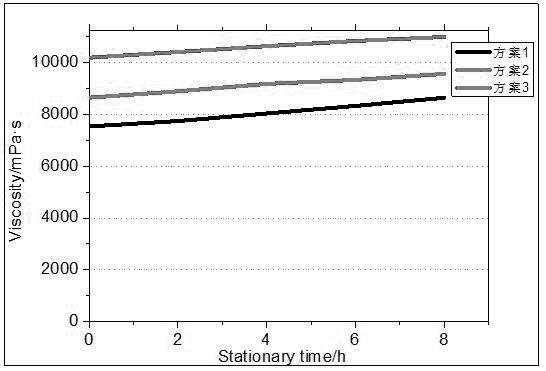

[0026] ④ Sand the mixture 3 with a sand mill equipped with 1.0-1.4mm zirconium beads, then add it to the mixer and stir, the stirring time is 30-40min, the mixer rotates at 20-35rpm, the vacuum degree is ≤-0.08mPa, and the solid content is prepared. 47% lithium titanate slurry with a viscosity of 6000-12000 mPa·s.

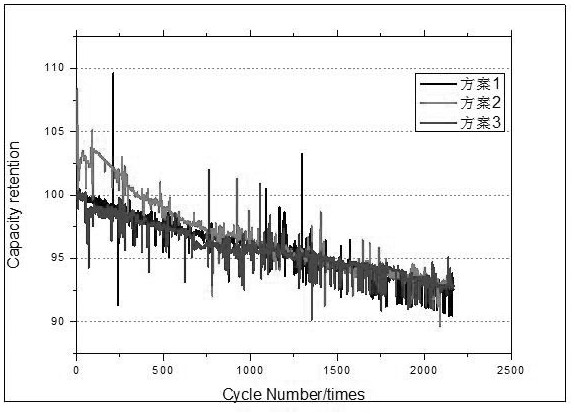

[0027] ⑤ Lithium battery production process: conventional processes such as sieving, coatin...

Embodiment 2

[0030] ① Add 54g of binder and 1928g of lithium titanate into the dry powder mixer for 20-30min, stir and revolve for 15-25rpm, to obtain a well-mixed mixture 1;

[0031] ② Add mixture 1 into a stirring pot containing 2087g of solvent, carry out mixing and stirring for 150-180min, rotate the mixer at 20-35rpm, and stir and rotate at 2000-3000rpm to obtain uniform mixture 2;

[0032] ③ Add 375g of conductive agent into the mixture 2, mix and stir for 40-60min, rotate the mixer at 20-35rpm, and stir and rotate at 2000-3000rpm to obtain a uniform mixture 3;

[0033] ④ Sand the mixture 3 with a sand mill equipped with 1.0-1.4mm zirconium beads, then add it to the mixer and stir, the stirring time is 30-40min, the mixer rotates at 20-35rpm, the vacuum degree is ≤-0.08mPa, and the solid content is prepared. 45% lithium titanate slurry with a viscosity of 6000-12000 mPa·s.

[0034] ⑤ Lithium battery production process: conventional processes such as sieving, coating, filming, windin...

Embodiment 3

[0037] ① Add 56g of binder and 1924g of lithium titanate into the dry powder mixer and mix for 20-30min, stir and revolve for 15-25rpm, to obtain a well-mixed mixture 1;

[0038] ② Add mixture 1 into a stirring pot containing 2181g of solvent, carry out mixing and stirring for 150-180min, rotate the mixer at 20-35rpm, and stir and rotate at 2000-3000rpm to obtain uniform mixture 2;

[0039] ③ Add 384g of conductive agent into the mixture 2, carry out mixing and stirring for 40-60min, the mixer rotates at 20-35rpm, and stirs and rotates at 2000-3000rpm to obtain a uniform mixture 3;

[0040] ④ Sand the mixture 3 with a sand mill equipped with 1.0-1.4mm zirconium beads, then add it to the mixer and stir, the stirring time is 30-40min, the mixer rotates at 20-35rpm, the vacuum degree is ≤-0.08mPa, and the solid content is prepared. 44% lithium titanate slurry with a viscosity of 6000-12000 mPa·s.

[0041] ⑤ Lithium battery production process: conventional processes such as sievi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com