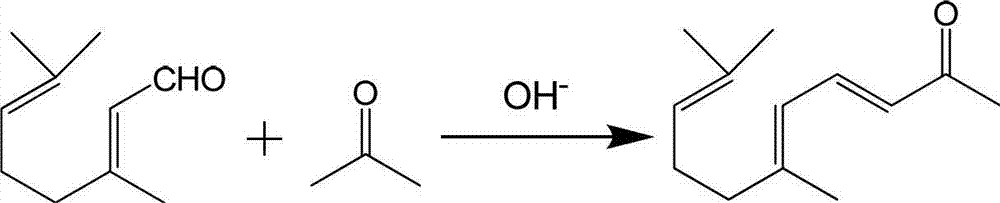

Method for continuously preparing pseudo ionone of vitamin A intermediate

A technology for pseudo-ionone and vitamin, which is applied in the field of continuous preparation of vitamin A intermediate pseudo-ionone, can solve problems such as high requirements on equipment corrosion and solid waste pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

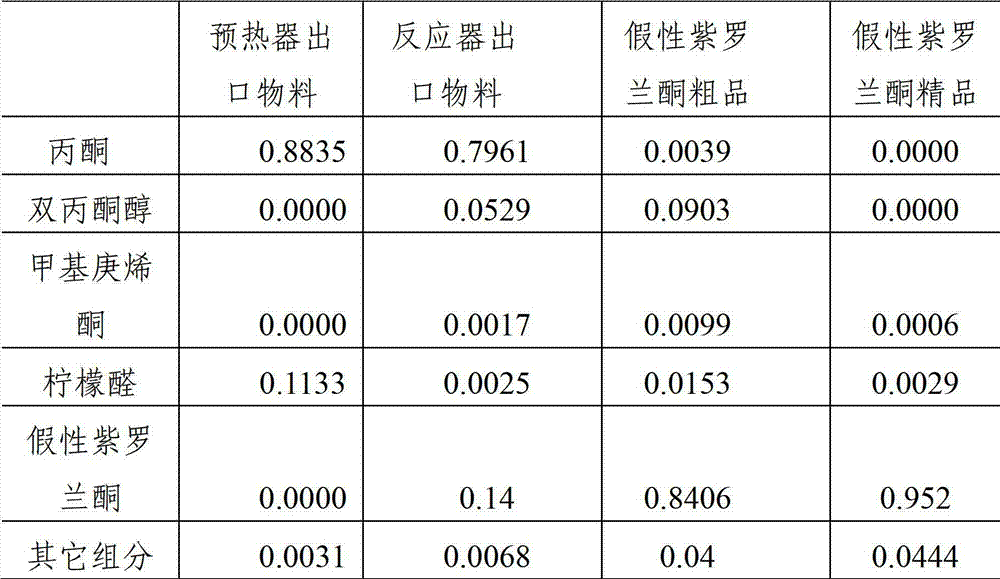

Embodiment 1

[0034] Citral 145g / h (content 97.3%, obtained by high vacuum fractionation and purification of litsea cubeba oil) and acetone 1200g / h with a water content of 10% are mixed evenly, pressurized to 8MPa by a pump, and heated to 100 in a preheater ℃, and then mixed with 0.4% NaOH aqueous solution 100g / h pressurized to the same pressure through a static mixer, and then entered a tubular reactor for condensation reaction. The reaction residence time is 10 minutes, and the reaction liquid is analyzed by gas chromatography. The reaction liquid is decompressed to normal pressure and enters the flash tower, and the recovered acetone with a water content of 8% is obtained from the top of the tower. The oil layer was recovered under reduced pressure to obtain 202.6g / h of pseudo-ionone crude product, which was tested and analyzed by gas chromatography, and the crude product was further separated by high-vacuum rectification to separate unreacted light components, citral and pseudo-ionone fi...

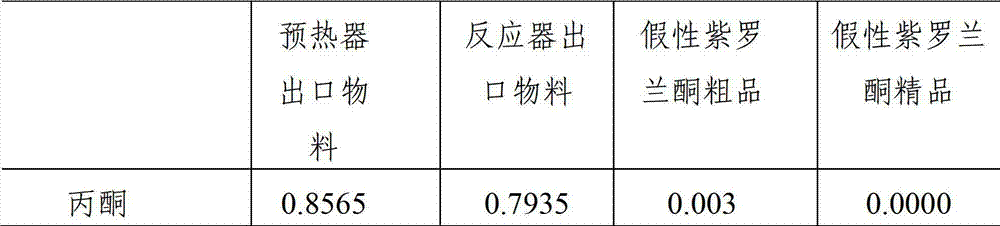

Embodiment 2

[0038] According to the method of Example 1, the difference is that citral is mixed uniformly with 150g / h (content 97.3%) and acetone 1000g / h with a water content of 15% (the mol ratio of acetone to citral is 15:1), and other conditions are not changed. Change. 177.3g / h of the pseudo-ionone fine product was obtained, the content was 94.9% (the sum of the contents of the two isomers), the conversion rate of citral was 96.41%, and the selectivity was 98.9%, which was relative to the yield of citral pseudo-ionone It is 91.23%.

Embodiment 3

[0040] According to the method of Example 1, the difference is that citral is mixed uniformly with 120g / h (content 97.3%) and acetone 1500g / h with a water content of 10% (the molar ratio of acetone to citral is 30:1), and other conditions are not changed. Change. 142.2g / h of pseudo-ionone was obtained, with a content of 95.5% (the sum of the contents of the two isomers), and a yield of 91.44% relative to that of citral pseudo-ionone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com