Solid-liquid synergistic saline-alkali soil conditioner and preparation method thereof

A saline-alkali soil and improver technology, which is applied in the fields of soil preparation methods, soil conditioning materials, and the preparation of organic fertilizers, to achieve the effect of low cost and easy large-scale promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The solid-liquid synergistic saline-alkali soil improver described in this embodiment includes a solid phase improver and a liquid phase improver;

[0034] The raw material components of the solid phase improver include charcoal manure decomposed matter, humic acid and acid residue with a mass ratio of 5:3:2;

[0035] The raw material components of the liquid phase improver include wood vinegar.

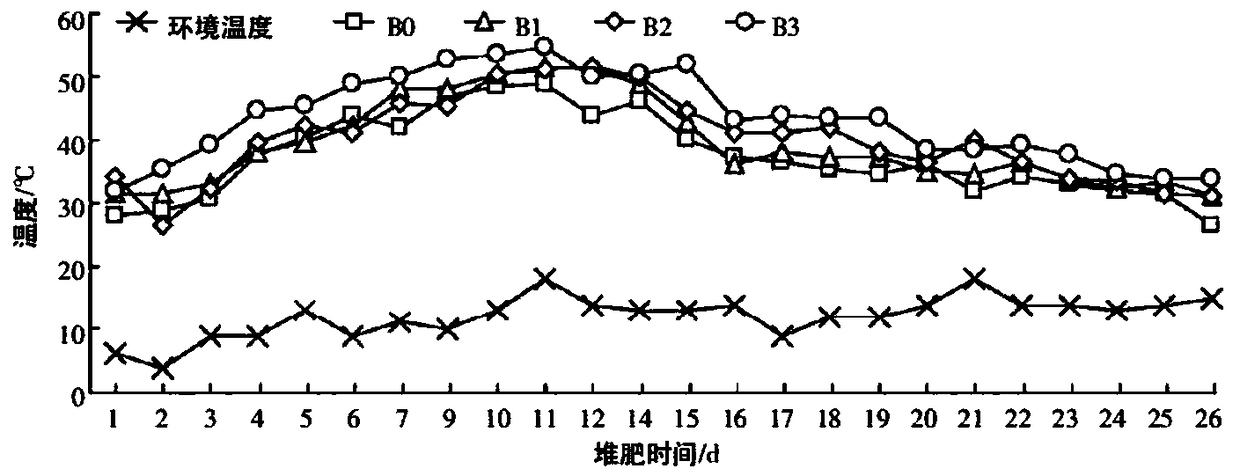

[0036] Wherein, the decomposed charcoal dung is obtained according to the following method: according to the mass ratio of 1:7, the biochar is mixed with fresh pig manure evenly, and naturally fermented by stacking for at least one month (the water content of the stack is controlled to be about 65%) , the temperature is around 40°C), and the decomposed product is obtained.

[0037] The humic acid is modified humic acid after ammonium bicarbonate ammonium treatment, and the specific modification steps include: adding 30 parts by weight of humic acid raw materials (humic acid c...

Embodiment 2

[0046] The solid-liquid synergistic saline-alkali soil improver described in this embodiment includes a solid phase improver and a liquid phase improver;

[0047] The raw material components of the solid phase improver include charcoal manure decomposed matter, humic acid and acid residue with a mass ratio of 4:4:1;

[0048] The raw material components of the liquid phase improver include wood vinegar.

[0049] Wherein, the decomposed charcoal dung is obtained according to the following method: according to the mass ratio of 1:10, the biochar is mixed with fresh pig manure evenly, and naturally fermented by stacking for at least one month (the water content of the stack is controlled to be about 65%) , the temperature is around 40°C), and the decomposed product is obtained.

[0050] Described humic acid is the modified humic acid after ammoniation treatment with ammonium bicarbonate, and the specific modification steps are the same as

[0051] Example 1.

[0052] The acid r...

Embodiment 3

[0060] The solid-liquid synergistic saline-alkali soil improver described in this embodiment includes a solid phase improver and a liquid phase improver;

[0061] The raw material components of the solid phase modifier include charcoal manure decomposed matter, humic acid and acid residue with a mass ratio of 6:2:3;

[0062] The raw material components of the liquid phase improver include wood vinegar.

[0063] Wherein, the decomposed charcoal manure is obtained according to the following method: according to the mass ratio of 1:20, the biochar is mixed with fresh pig manure evenly, and naturally fermented by stacking for at least one month (the water content of the stack is controlled to be about 65%) , the temperature is around 40°C), and the decomposed product is obtained.

[0064] Described humic acid is the modified humic acid after ammoniation treatment with ammonium bicarbonate, and the specific modification steps are the same as

[0065] Example 1.

[0066] The acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com