Pipelined cocoon harvesting process for industrialized silkworm rearing work

An in-operation, factory-like technology, applied in animal husbandry and other directions, can solve the problems of high probability of failure, time-consuming and labor-intensive, small scale, etc., and achieve the effect of saving labor costs, improving sorting efficiency, and improving cocoon harvesting rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

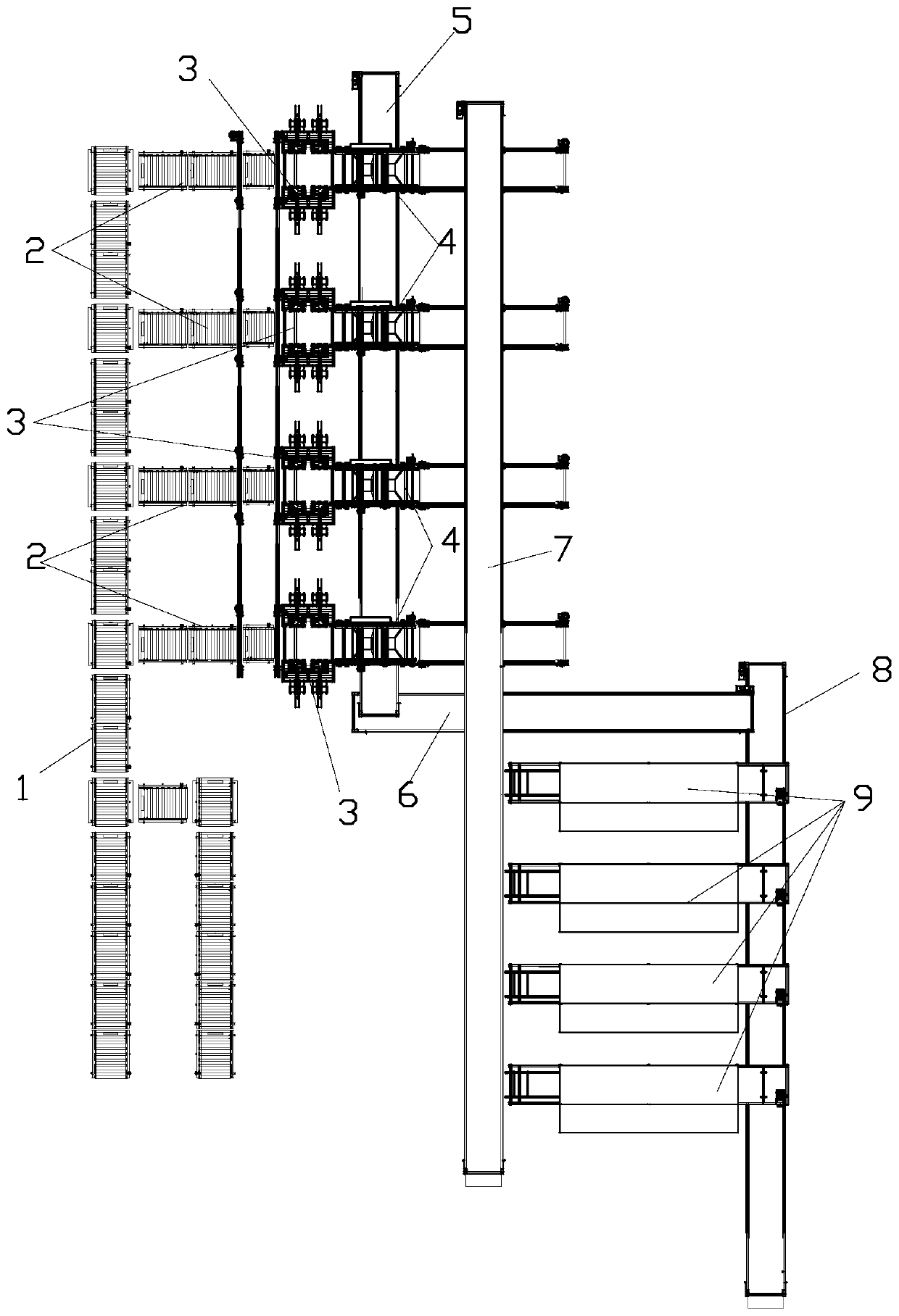

[0041] Such as Figure 1 to Figure 12 As shown, the assembly line cocoon picking process in the factory sericulture operation includes the following steps:

[0042] (1) The breeding frame group is fed into:

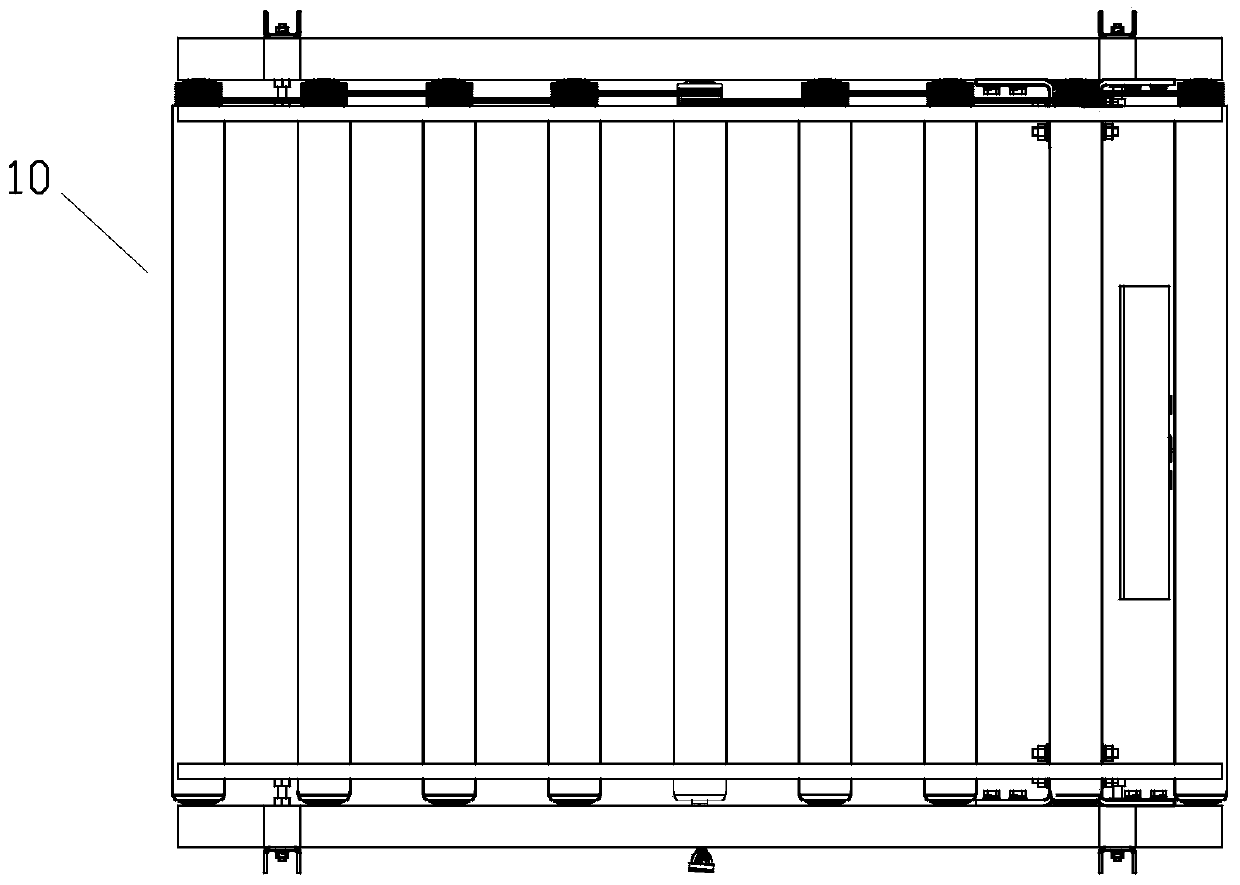

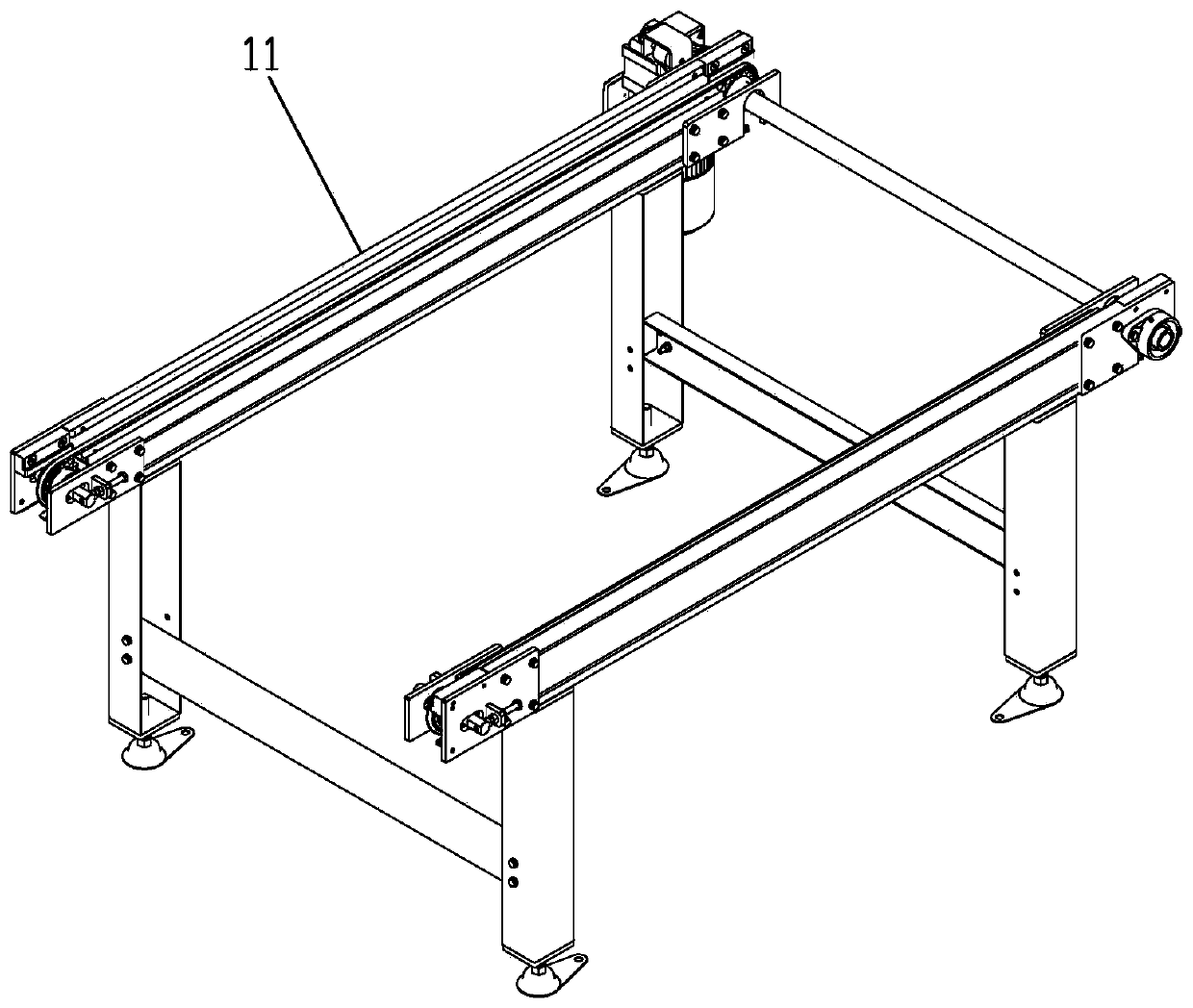

[0043] Before the culture frame is sent to the culture frame dismantling machine, the culture frame is first stacked into a culture frame group. Generally, each group of culture frame stacks has 12-20 culture frames; the culture frame group is placed on the horizontal track by a truck On the conveyor line 1, when placing, it should be pre-positioned, the placement position should be controlled, and the pallet stacker can be pulled out after placement. The transverse track conveyor line 1 is composed of a plurality of track conveyors 10 . The culture frame is transferred from the horizontal track conveying line 1 to the vertical track conveying line 2 by the track rotating platform 12, and one side of the transverse track conveying line 1 is arranged with 4-6 parallel lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com