Environment-friendly soybean oil-based moisture-cured polyurethane wood adhesive

A soybean oil-based, epoxidized soybean oil technology, applied in the field of polyurethane adhesives, can solve problems such as not meeting the requirements of product environmental protection, and achieve the effects of reducing energy consumption costs, high bonding strength, and simplifying processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

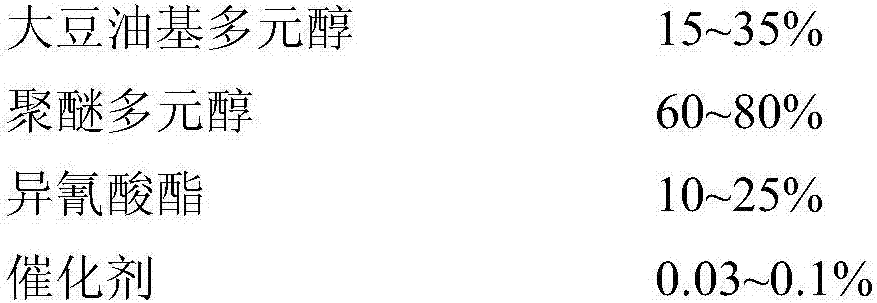

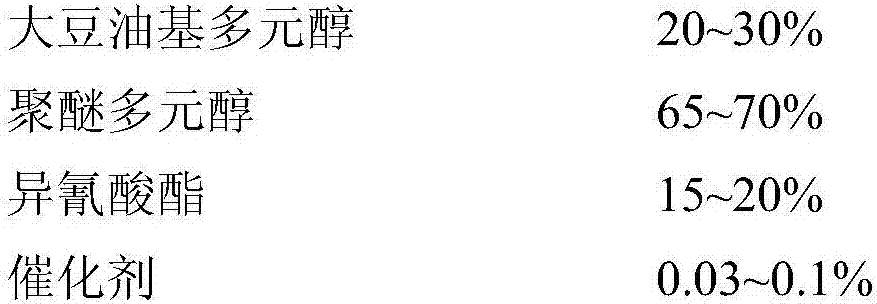

Method used

Image

Examples

Embodiment 1

[0021] The dehydration treatment of embodiment 1 soybean oil polyol and polyether polyol

[0022] Put a 250mL four-necked bottle in an oven at 120°C and dry it. Add 20g of soybean oil-based polyol and 80g of PPG2000 into the four-necked bottle. g, viscosity (45°C) is 913mPa·s. Install mechanical stirring, thermometer and nitrogen bladder. Turn on the stirring and oil pump, evacuate to a vacuum degree of about -0.098MPa, heat with a heating mantle, slowly raise the temperature to 120°C, dehydrate for 1.5h, until no bubbles escape, stop heating, wait until the temperature cools down to the temperature required for feeding , stop stirring, turn off the oil pump, and then blow in nitrogen to release the vacuum. In the following examples, soybean oil-based polyols and polyether polyols were mixed with this method for dehydration.

Embodiment 2

[0024] Add 64.6g of MDI after heating and melting into the soybean oil-based polyol and polyether diol mixture dehydrated according to the method in Example 1, control the temperature at 75°C, react for 1h, stop stirring, lower the system temperature, add 243uL prepared 2g / 10ml dibutyltin dilaurate and 153uL bismorpholine diethyl ether, after reacting for 30min, stop stirring, vacuumize again for 10min, get rid of the air bubbles in the reaction solution, and discharge the material to obtain 165g large Soybean oil-based polyurethane adhesive, stored in a desiccator airtight. The adhesive is heated to 85°C, the viscosity is 3500mPa·s, and the adhesive is used to bond wood with a moisture content of 8% by brushing. The glue amount is 125g / ㎡, and the pressure is 1.5MPa, pressurized for 12 hours, tested after 72 hours, the dry compressive shear strength of the product reached 10.84MPa, and the wet compressive shear strength after soaking at (60±5)°C for 3 hours was 5.82MPa.

Embodiment 3

[0026] Take by weighing 25g soybean oil-based polyol and 75g propylene oxide polyether glycol, join in the four-neck bottle after drying, carry out dehydration treatment according to the method in embodiment 1, add the 69.81g MDI after heating and melting In the mixed solution of soybean oil-based polyol and polyether diol, control the temperature at 75°C, react for 1h, stop stirring, lower the system temperature, add 252uL prepared 2g / 10ml dibutyltin dilaurate and 80uL bismorpholine di Ethyl ether, after reacting for 30 minutes, stop stirring, vacuumize again for 10 minutes, remove the air bubbles in the reaction solution, and discharge the material to obtain 169.81 g of soybean oil-based polyurethane adhesive for wood, which is placed in a desiccator for airtight storage. The adhesive is heated to 85°C, the viscosity is 2980mPa·s, and the adhesive is used to bond wood with a moisture content of 8% by brushing. The glue amount is 125g / ㎡, and the pressure is 1.5MPa, the pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com