Gas protection welding wire and manufacturing method thereof

A technology of gas shielded welding wire and manufacturing method, which is applied to manufacturing tools, welding media, welding equipment, etc., can solve the problems of low smoke and dust, and achieve the effects of low smoke and dust, low spatter rate, and improved weld toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

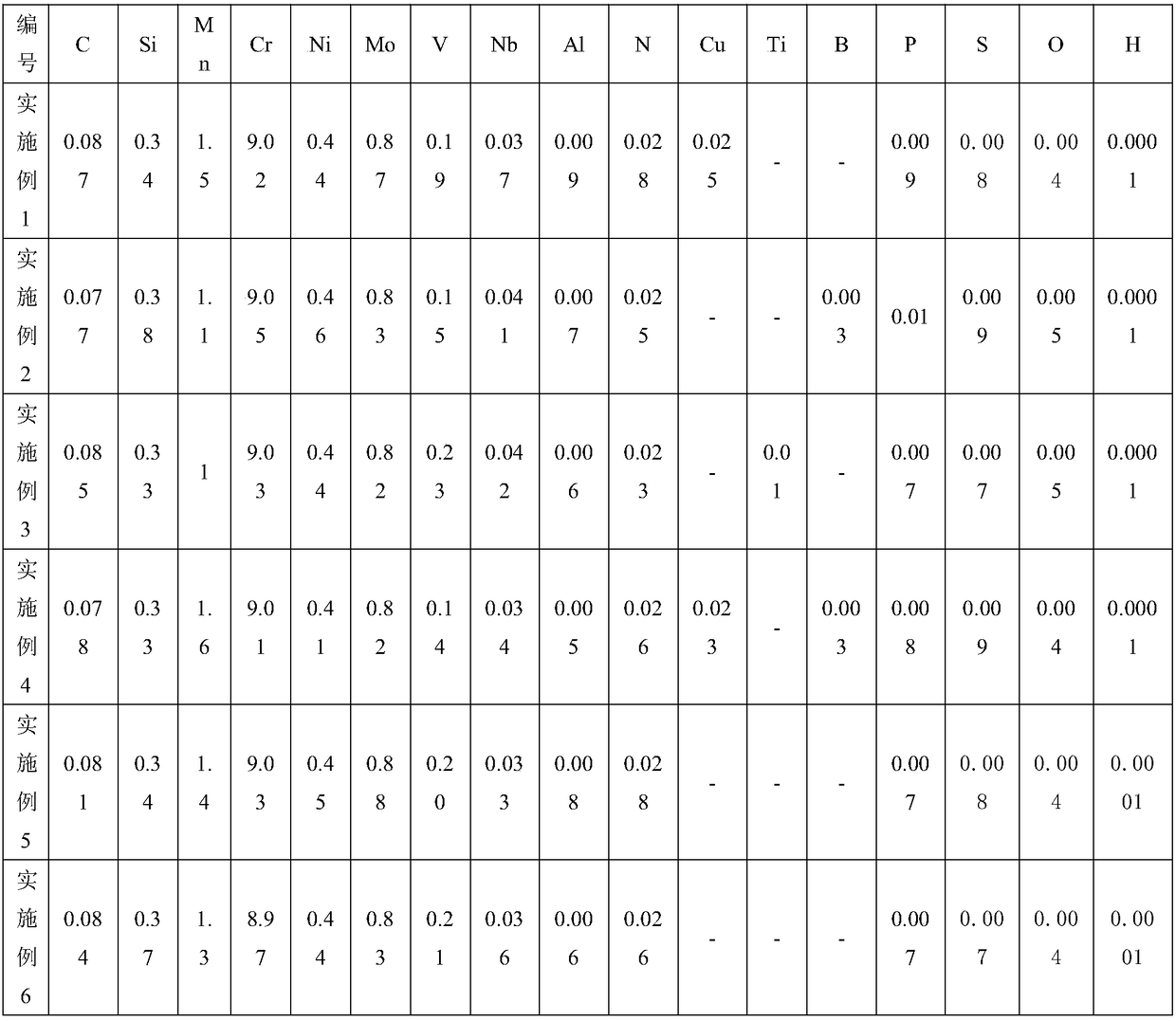

[0057] Table 1 lists the mass percentage of each chemical element in the gas shielded welding wire of Examples 1-6.

[0058] Table 1. (wt%, the balance is Fe and other unavoidable impurity elements except P, S, O, H)

[0059]

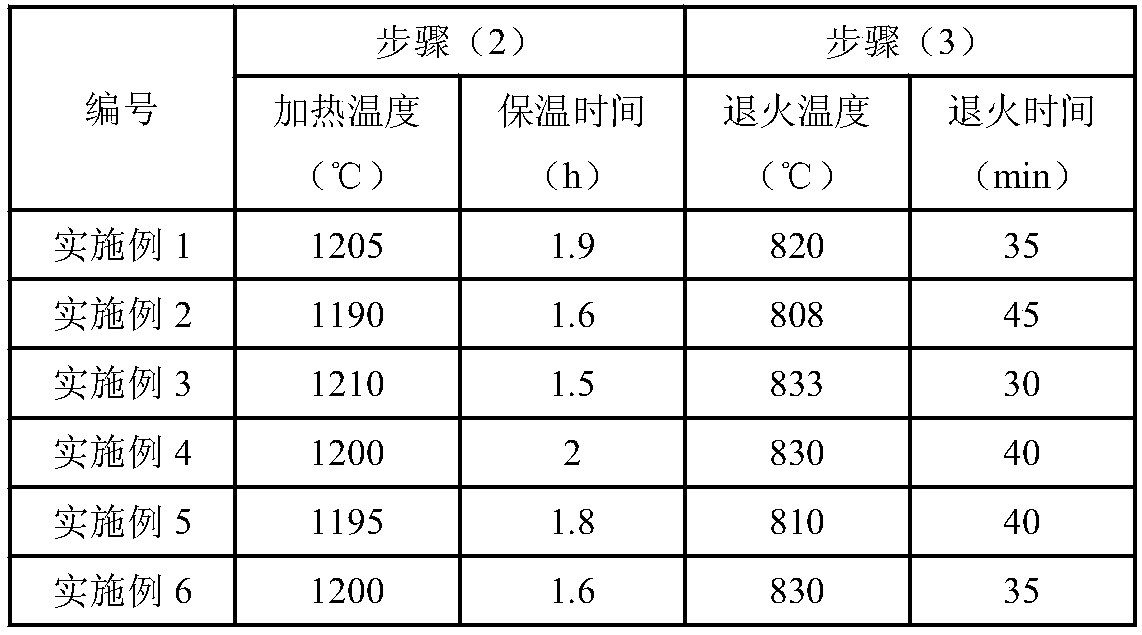

[0060] The manufacturing method of the gas shielded welding wire of embodiment 1-6 includes the following steps:

[0061] (1) Smelting and casting in accordance with the chemical element components listed in Table 1;

[0062] (2) First heat the cast billet in the range of 1190-1210°C for 1.5-2h, and then roll it to obtain a square billet, or heat the cast billet in the range of 1090-1110°C for 30-60min, and then forge it to obtain a square billet. Billet

[0063] (3) Rolling to obtain wire rod;

[0064] (4) Wire rod annealing: annealing temperature is 805-835℃, annealing time is 30-45min;

[0065] (5) Rolling or drawing to obtain gas shielded welding wire.

[0066] It should be noted that in the welding process, the shielding gas is used as the volume percentage of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com