A bainitic type x100 grade seamless line pipe and its manufacturing method

A technology of seamless line pipe and bainitic type, which is applied in the field of high-strength seamless line pipe and its manufacturing, which can solve the problems of performance degradation and achieve the effect of low welding crack sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

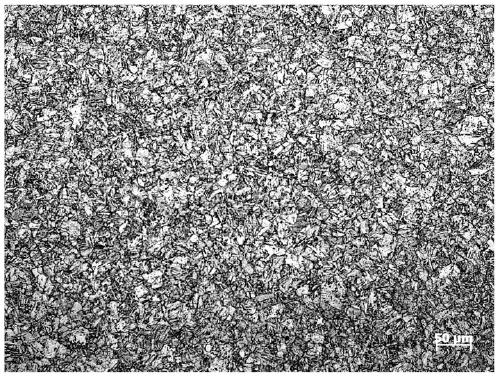

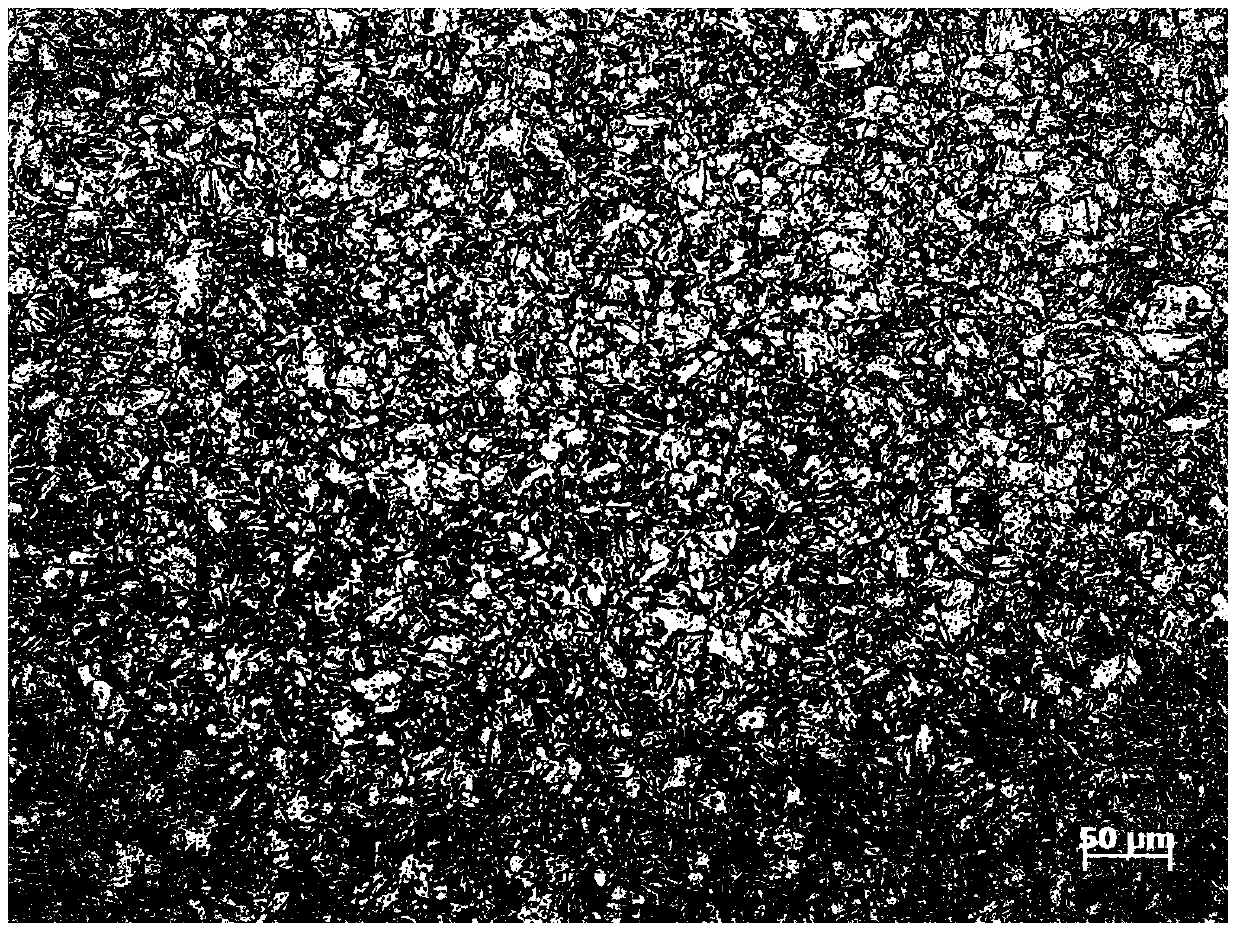

Image

Examples

Embodiment A1-A6 and comparative example B1-B4

[0051] The bainitic grade X100 seamless line pipes of the above-mentioned Examples A1-A6 and the seamless line pipes of Comparative Examples B1-B4 were prepared by the following steps:

[0052] (1) smelt and forge the ingot into a round tube billet of φ 300mm according to the chemical composition ratios listed in Table 1;

[0053] (2) Forging to obtain a tube blank with a specification of 219mm*14.5mm

[0054] (3) Heat and keep warm the tube blank, and obtain the blank tube through piercing, continuous rolling, tension reduction or sizing, wherein the heating temperature of the blank tube is 1150-1300°C, and the holding time is 1-4h.

[0055] (4) Quenching: Heat the blank pipe to 920-1000°C, keep it warm for 0.3-1h, then rapidly cool it to below 180°C at a cooling rate of 15-80°C / s, and use oil quenching or water quenching for quenching.

[0056] (5) Tempering: the tempering temperature is 500°C to 700°C.

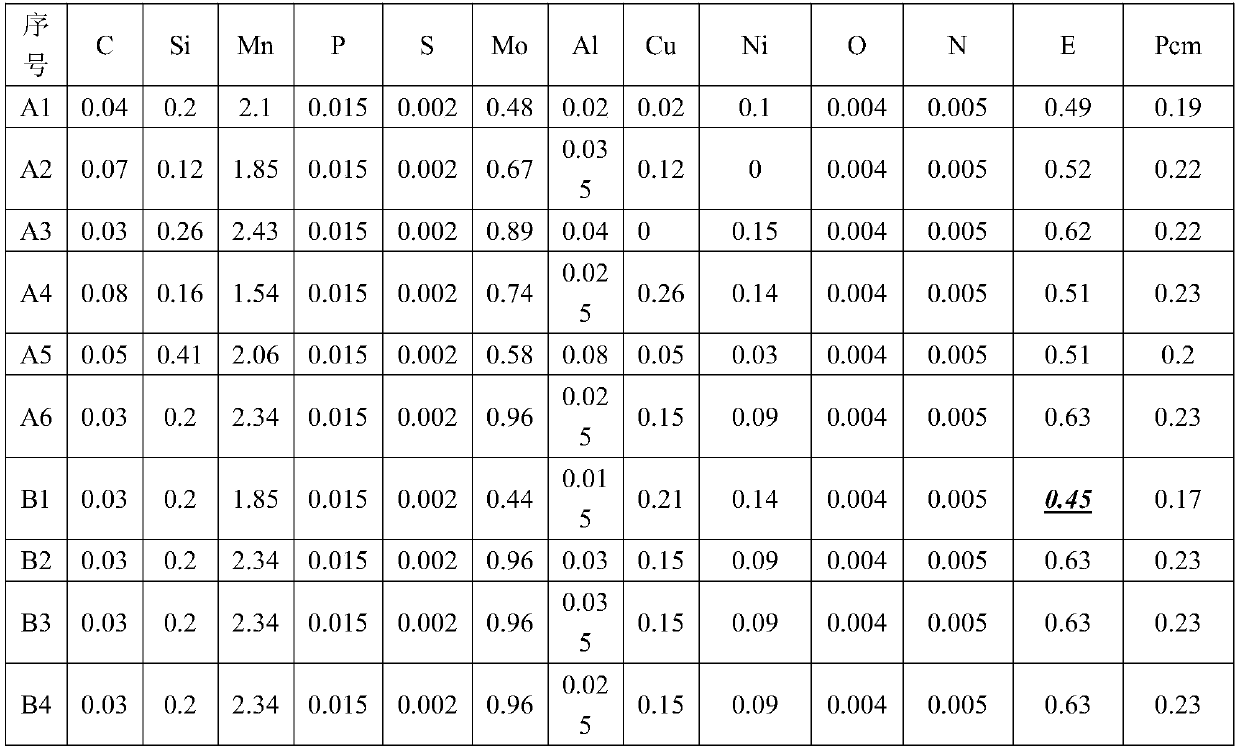

[0057] Table 1 lists the mass percentage distribution of chemical el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com