High-speed wire production method capable of controlling same-circle mechanical property fluctuation of high-carbon steel wire rods

A production method and wire rod technology, applied in the field of steel rolling, can solve the problems of high investment and transformation costs, aggravating the performance fluctuation of the same ring, and controlling the narrow process window, so as to reduce the performance fluctuation of the same ring, improve the stability, and the process practicability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. This process is implemented in the production of 5.5mm cord steel 82A in Shougang High Line Plant, and the process steps are as follows

[0035] a. The fluctuation of the vibration value of the laying machine is controlled at 2mm / s, and the diameter of the laying ring is controlled at 9.5m to ensure the specification distribution of the coils on the air-cooled Stelmo roller table.

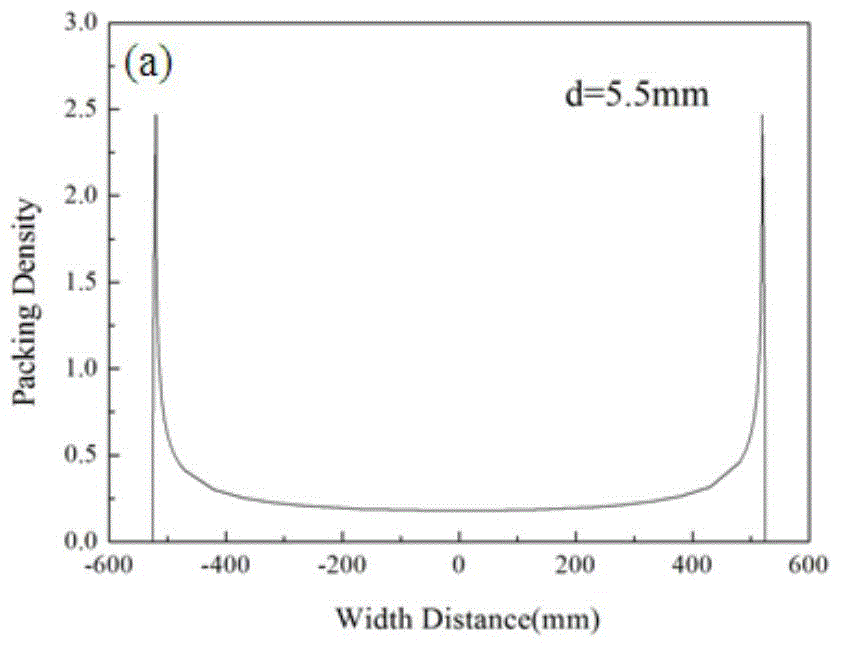

[0036] b. The starting speed of the roller table is controlled at 0.6m / s, and the density of the wire rods at the overlapping and non-lapping points is controlled.

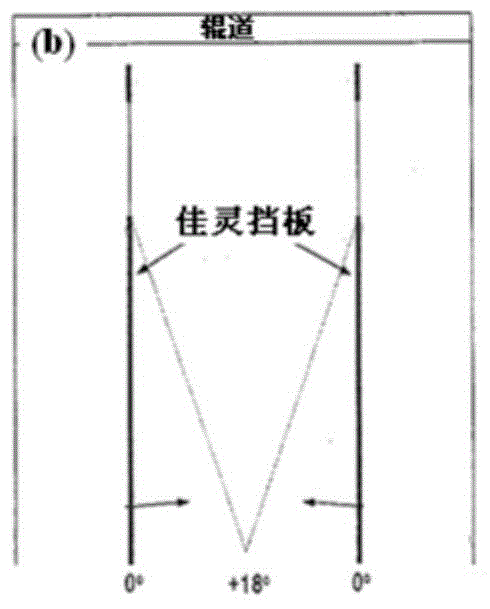

[0037] c. Adjust the Jialing baffle angle of the fan under the Stelmo air-cooled roller table according to the specifications of the wire rod: the angle of the 5.5mm wire rod Jialing baffle is controlled at 10°

[0038] d. The temperature at which the phase transition begins is controlled within 20°C.

Embodiment 2

[0040] This process is implemented in the production of 10mm hard wire steel in Shougang High Wire Plant, and the process steps are as follows

[0041] a. The fluctuation of the vibration value of the laying machine is controlled at 2.4mm / s, and the diameter of the laying ring is controlled at 1m to ensure the specification distribution of the coils on the air-cooled Stelmo roller table.

[0042]b. The starting speed of the roller table is controlled at 0.65m / s, and the density of the wire rods at the lap joints and non-lap joints is controlled.

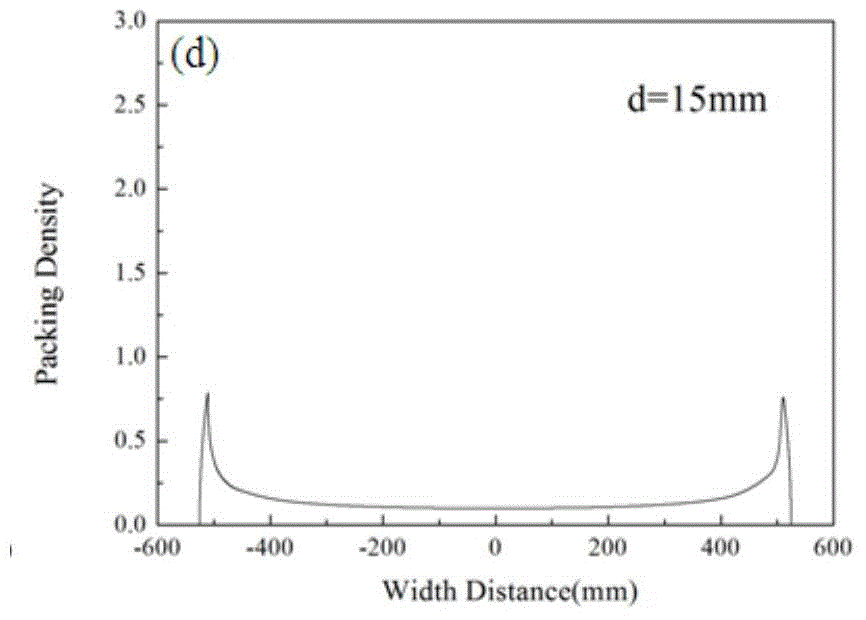

[0043] c. Adjust the angle of the Jialing baffle of the fan under the Stelmo air-cooled roller table according to the specifications of the wire rod: the angle of the Jialing baffle for the 10mm wire rod is controlled at 8°

[0044] d. The temperature at which the phase transition begins is controlled within 20°C.

Embodiment 3

[0046] This process is implemented in the production of 14mm82B in Shougang High Line Factory, and the process steps are as follows

[0047] a. The fluctuation of the vibration value of the laying machine is controlled at 3mm / s, and the diameter of the laying ring is controlled at 1.1m, so as to ensure the specification distribution of the coils on the air-cooled Stelmo roller table.

[0048] b. The starting speed of the roller table is controlled at 0.7m / s, and the density of the wire rods at the lap joints and non-lap joints is controlled.

[0049] c. Adjust the Jialing baffle angle of the fan under the Stelmo air-cooled roller table according to the specifications of the wire rod: the angle of the 14mm wire rod Jialing baffle is controlled at 5°

[0050] d. The temperature at which the phase transition begins is controlled within 30°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com