Patents

Literature

38results about How to "Strong process practicability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing all-polymer plane optical path

InactiveCN103592721ALow costSimple processOptical waveguide light guideMicro structurePolymer adhesive

The invention discloses a method for manufacturing an all-polymer plane optical path. The method comprises the steps of (1) obtaining an initial master mold by means of ultra-violet lithography and deep-etching technologies, duplicating a metallic nickel mold by means of electrochemical sedimentation, and manufacturing a polymer micro-structure part by means of mini molding; (2) conducting segment treatment on the part by means of the thermal annealing technology to reduce the roughness of the lateral wall and reduce scattering loss during optical wave transmission; (3) applying and filling polymer medium materials and obtaining the core structure of the plane optical path after the polymer medium materials are solidified; (4) combining a bondage layer of an element with an optical polymer substrate to achieve the manufacturing of the buried ridge type polymer plane optical path, wherein a polymer adhesive layer serves as the bondage layer of the element. Compared with a traditional method for manufacturing the polymer plane optical path, the method for manufacturing the all-polymer plane optical path has the advantages that cost is reduced and universality of technologies to materials is high.

Owner:SOUTH CHINA NORMAL UNIVERSITY

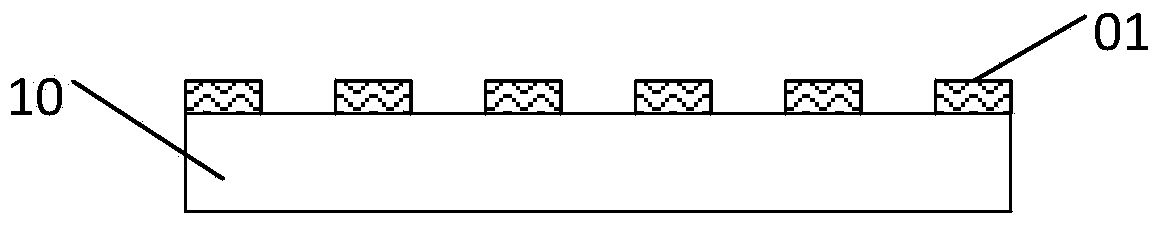

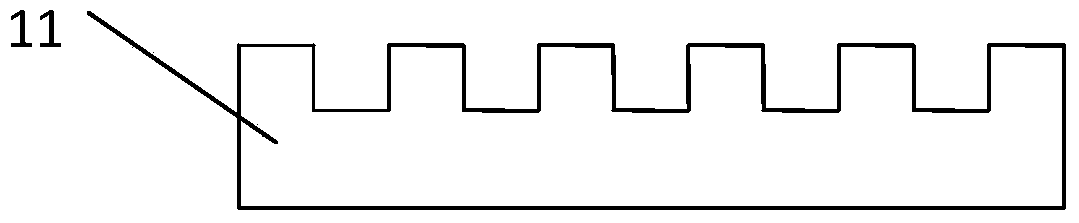

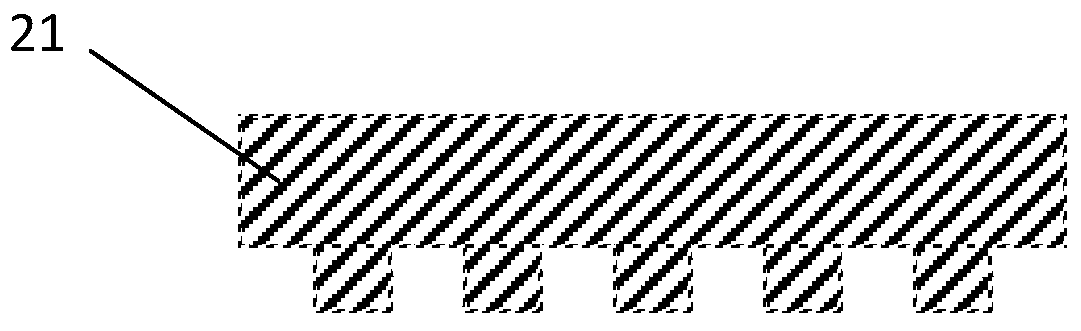

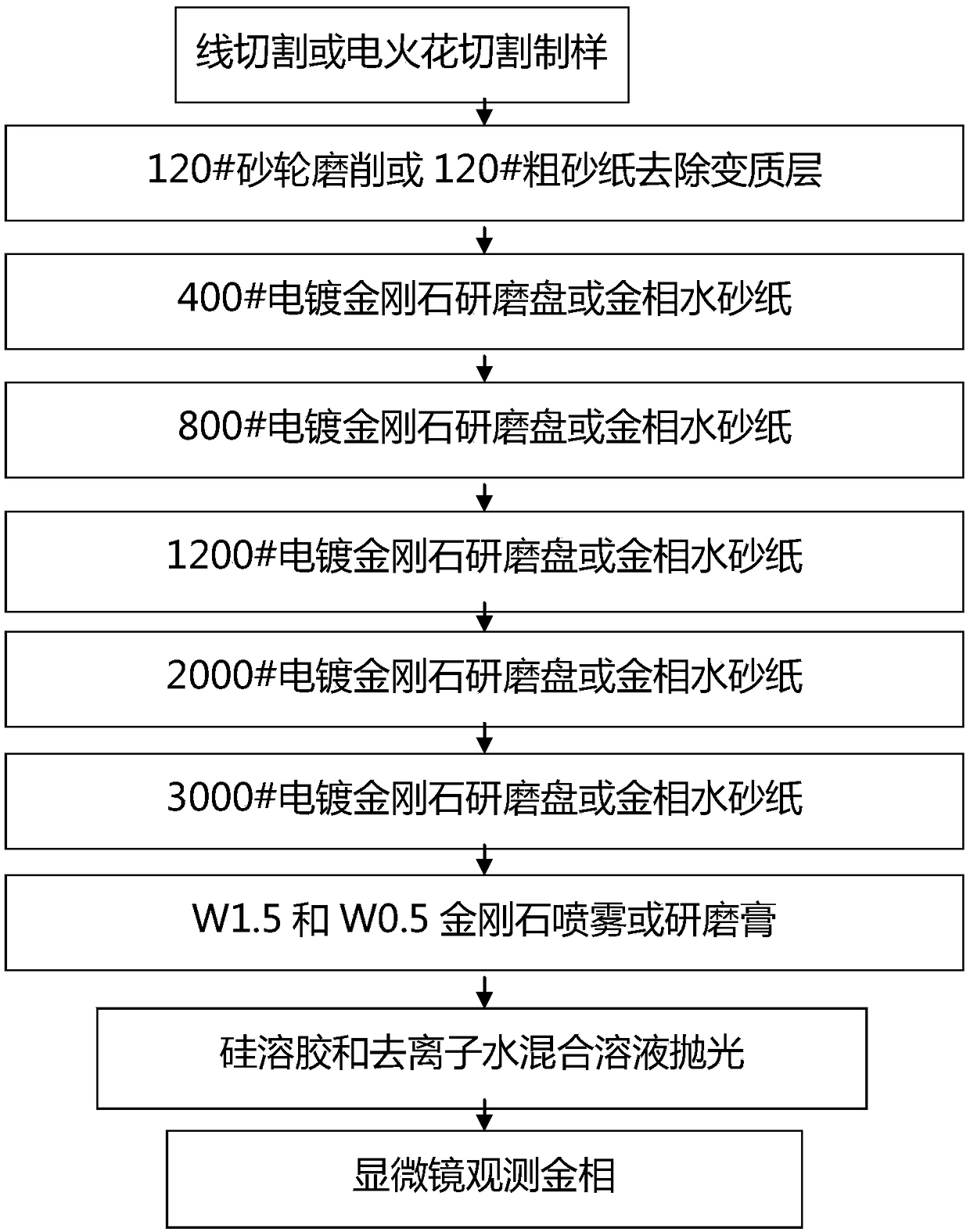

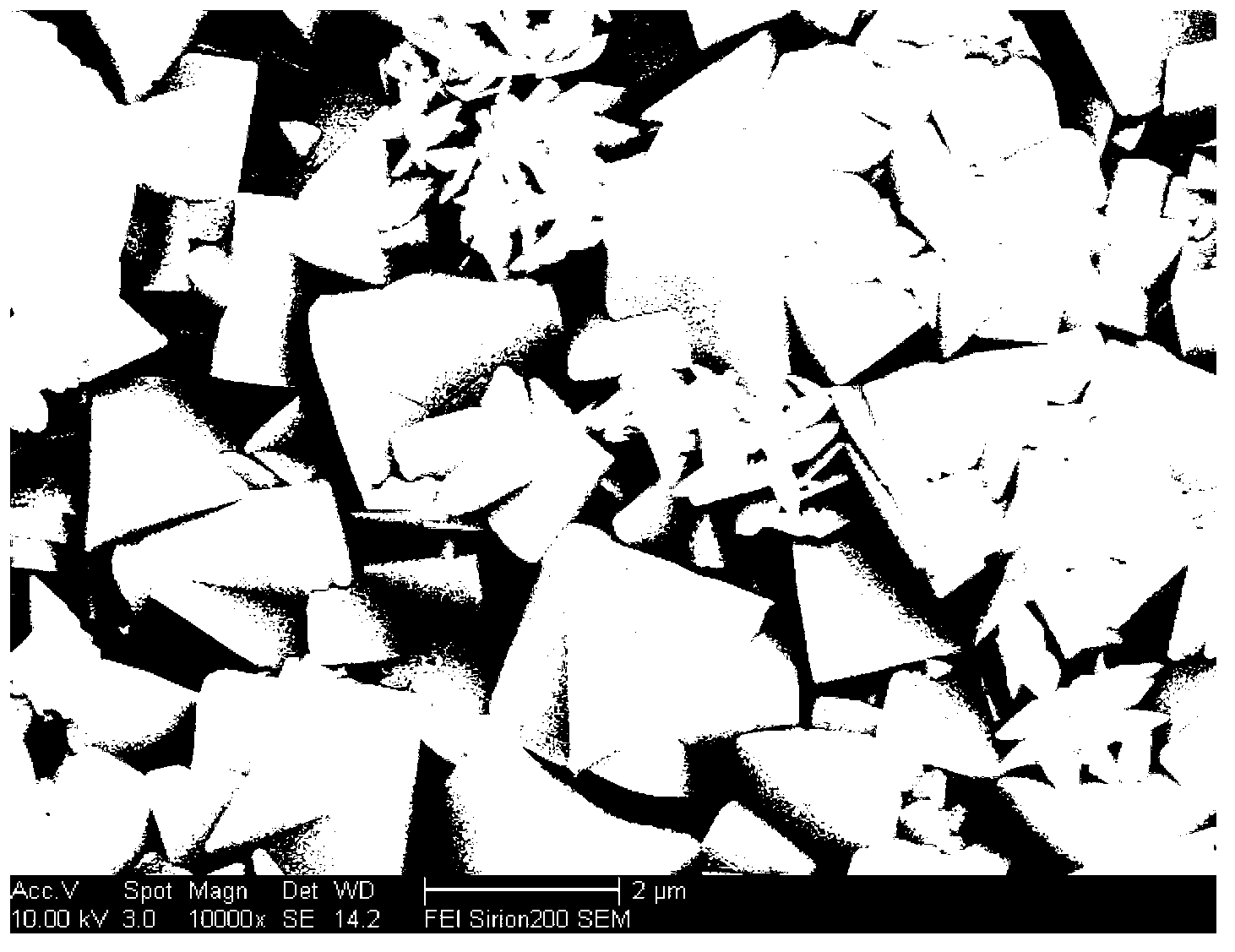

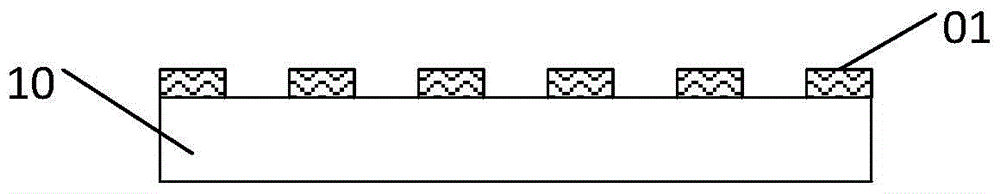

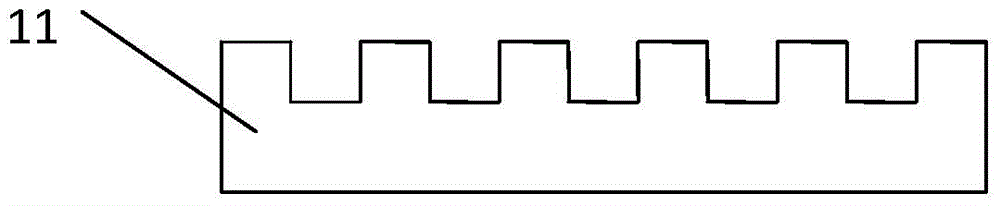

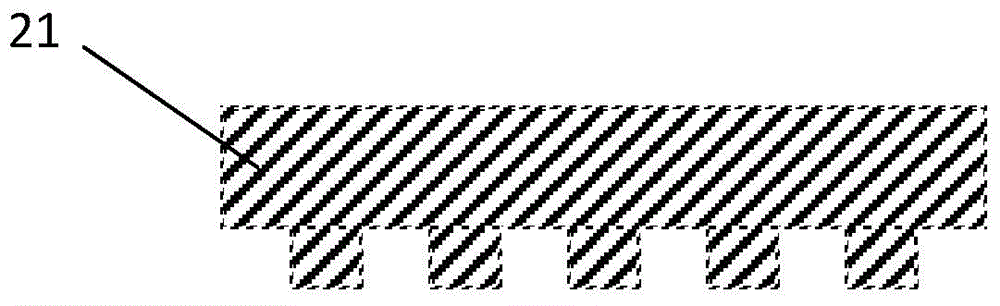

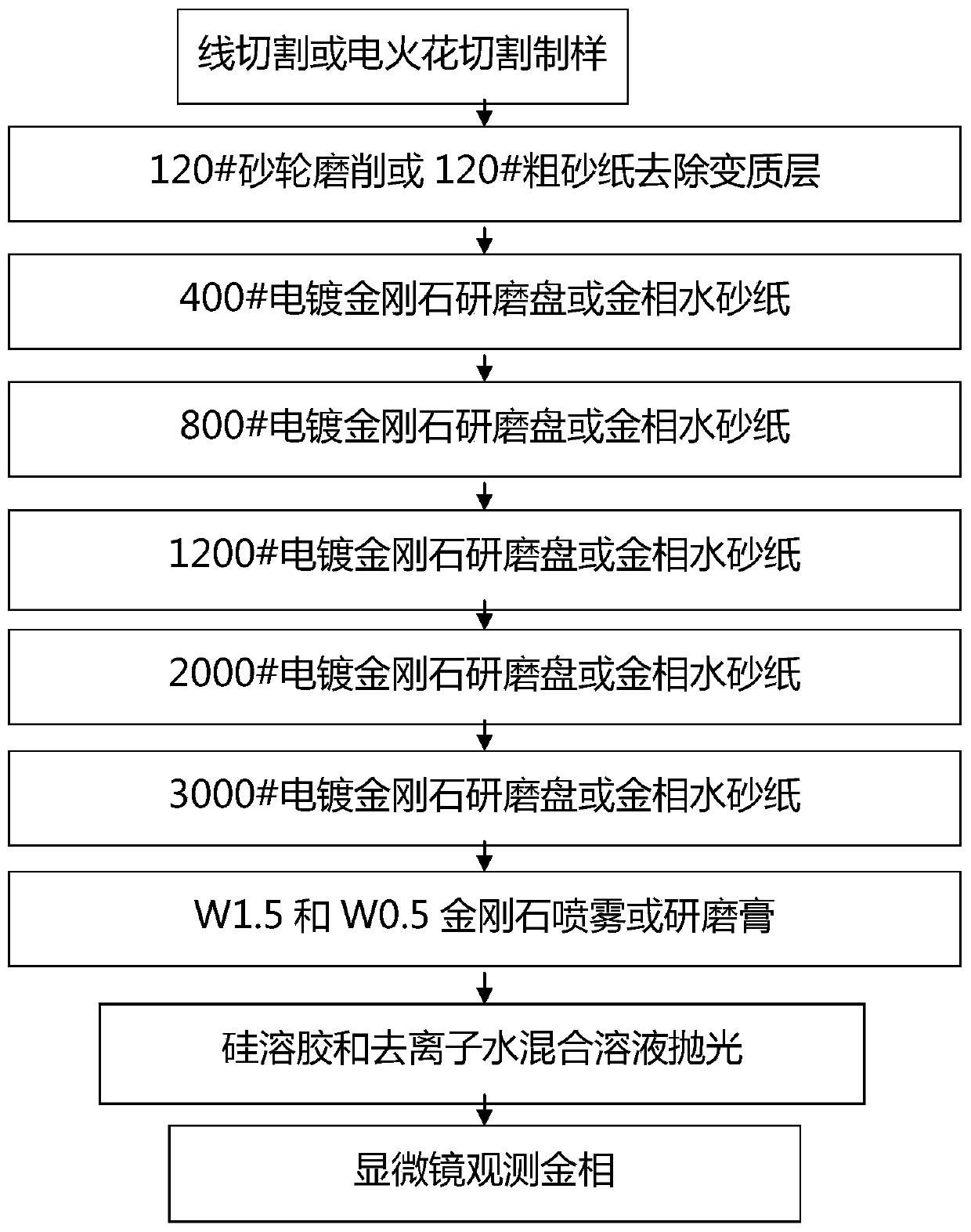

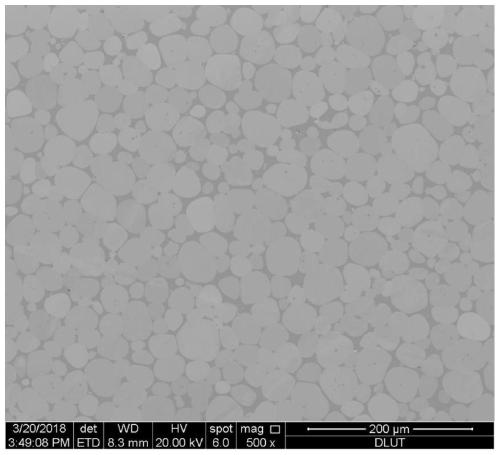

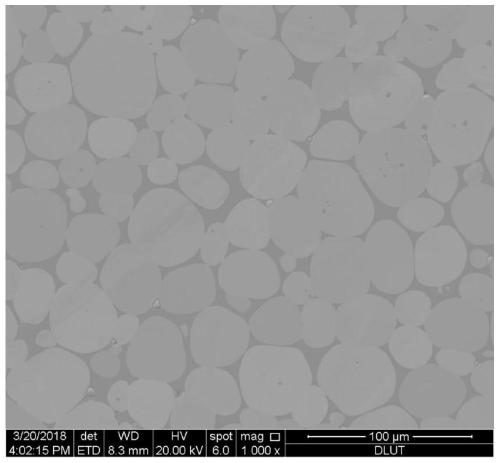

Preparation method of tungsten nickel iron alloy metallographic phase

ActiveCN108562470AAvoid it happening againNo pollution in the processPreparing sample for investigationEpoxyChemical corrosion

The invention relates to a preparation method of a tungsten nickel iron alloy metallographic phase, which belongs to the technical field of determination of a material surface structure. A machining method is mainly adopted to obtain a metallographic phase tissue structure of tungsten nickel iron alloy. The preparation method comprises a sample preparation step, a grinding step and a polishing step. In the sample preparation process, the tungsten alloy is cut into a sample piece, and after the cold mounting is performed on the sample, a remaining surface metamorphic layer in the electric sparkmachining is removed. In the grinding process, the tungsten alloy sample is inserted into an epoxy resin clamp, the surface of the sample is ground, after the grinding, the sample is ground by adopting diamond spray or diamond grinding paste, and finally the sample is ultrasonically cleaned. In the polishing process, after the sample is polished, the sample is ultrasonically cleaned and dried. According to the preparation method of the tungsten nickel iron alloy metallographic phase prepared in the invention, after the grinding and polishing, the metallographic phase observation can be performed without chemical corrosion, and the obtained metallographic phase is clear and complete in tissue structure and has no defects such as over-corrosion or corrosion pits; and the whole preparation process is safe and environmentally friendly, the operability is high, and the preparation process is simple and reliable.

Owner:DALIAN UNIV OF TECH

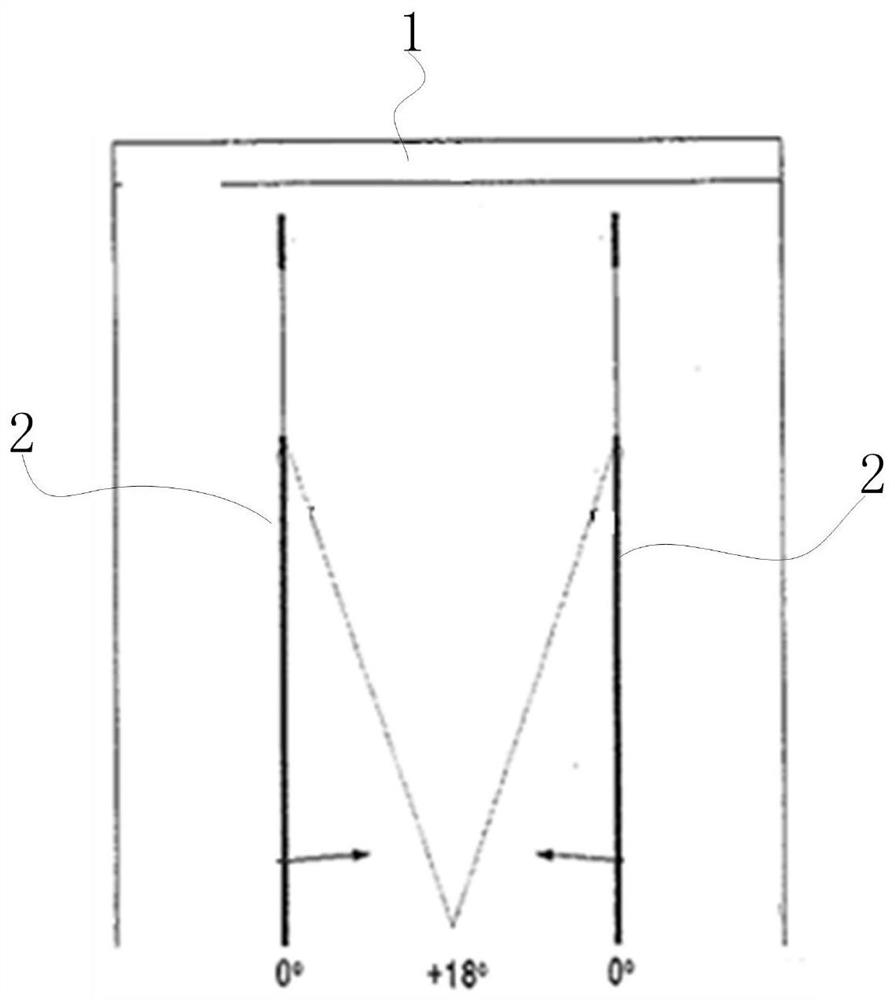

Slot-less rolling technique of rolling section

InactiveCN1833790AResolve twistHighlight substantive featuresRoll mill control devicesMetal rolling arrangementsMaterials scienceRolling mill

A fluteless rolling technology for rolling steel section includes sequentially determining 14 technological parameters including total cross-section shrinkage ratio of the workpiece to be rolled, the pressing down size of each pass, total number of passes, 5 correcting coefficients, etc, and rolling by fluteless rolling mill while regulating the clamp to the workpieces.

Owner:XINJIANG BAYI IRON & STEEL

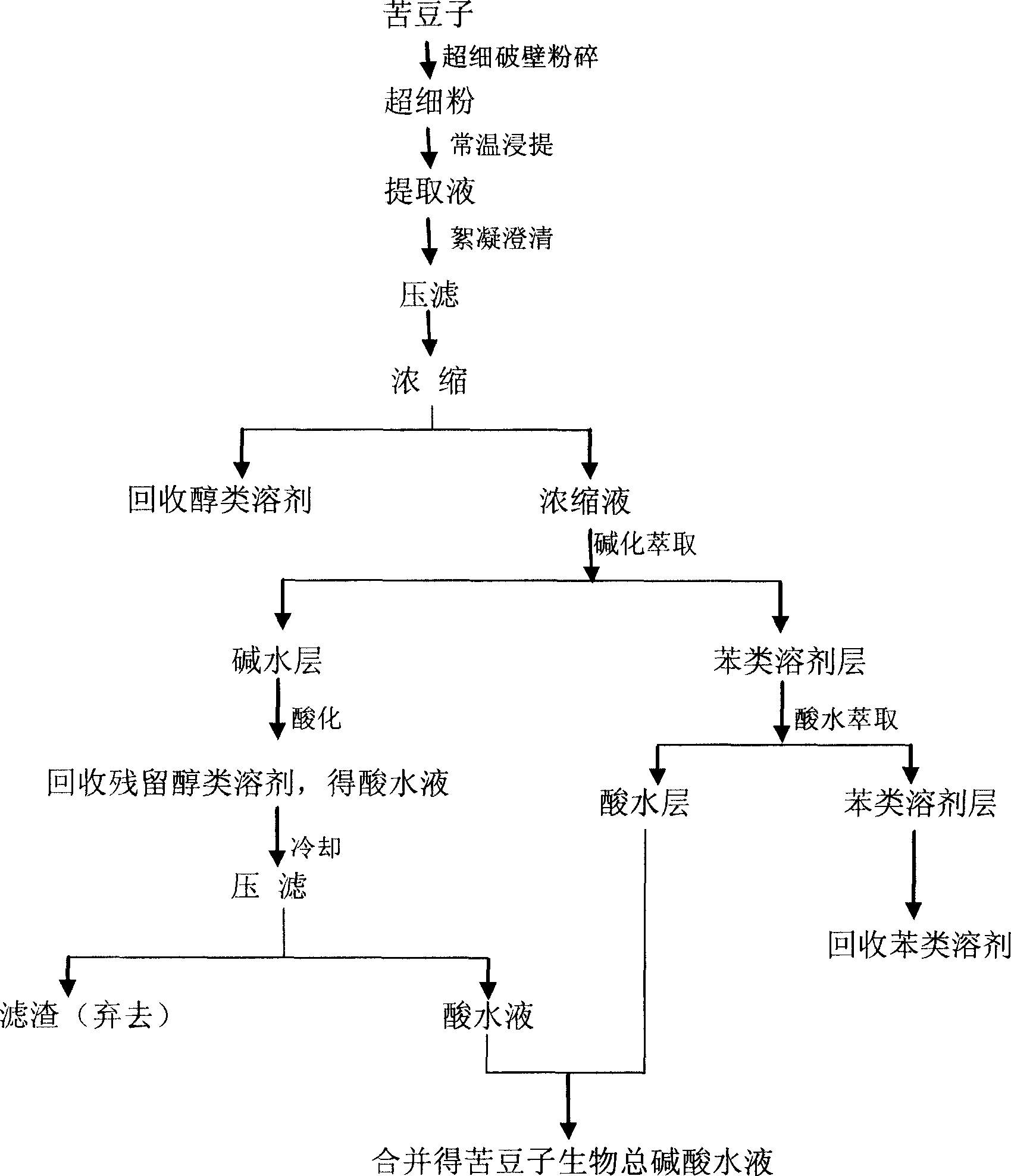

High efficiency extracting method for sophora alopecuroide total alkaloid

InactiveCN1899364AGood for free releaseNo emissionsAntibacterial agentsAlkaloids chemistryFlocculationUltra fine

The high efficiency process of extracting total alkaloid of Sophora alopecuroide includes the steps of: ultra-fine wall breaking and crushing, normal temperature leaching, flocculation to clarify, concentrating, alkaline extraction, acid extraction, acid filtering, etc. The extracting process is reasonable, simple, short in flow, high in total alkaloid yield, environment friendly and suitable for industrial production.

Owner:淮安市农业科学研究院

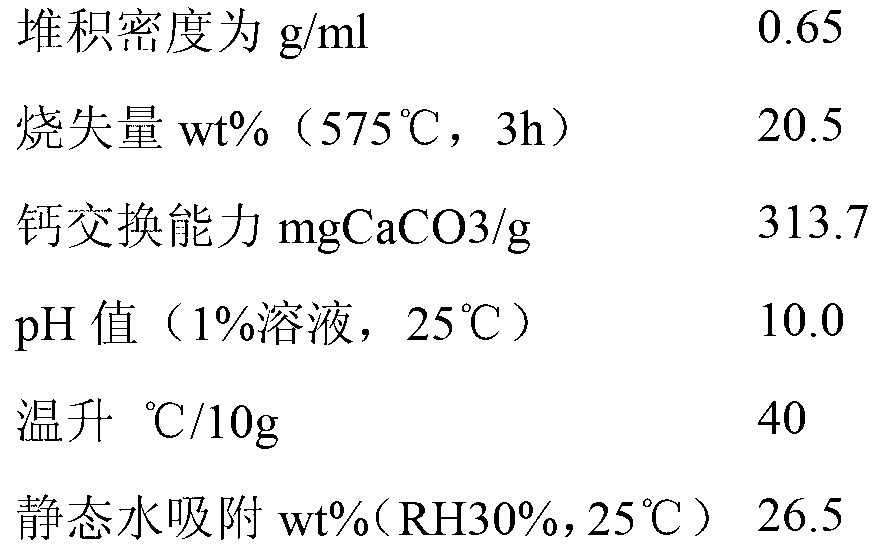

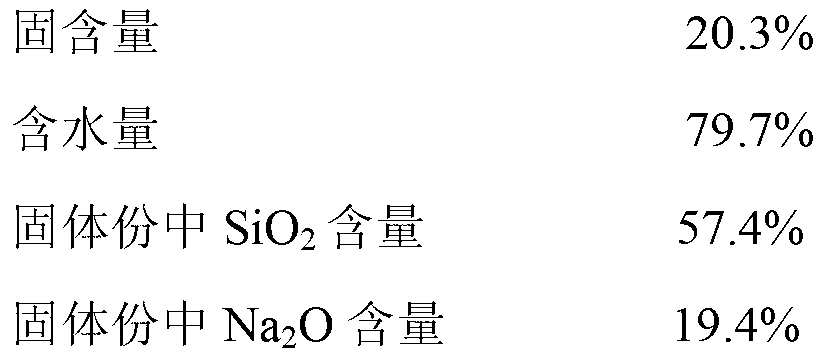

Method for recycling waste silicon slag discharged in production of zirconyl chloride

ActiveCN103303974AEnvironmental benefits win-winLess investmentZirconium compoundsSlagZirconium oxychloride

The invention relates to a method for recycling waste silicon slag discharged in production of zirconyl chloride and belongs to a method for recycling waste slag discharged in the preparation process of a zirconium compound. The method is characterized by comprising the following steps of: firstly, converting waste silicon slag into an aqueous solution of sodium silicate, filtering, and then using the residue filtered out directly as a raw material for preparing the zirconyl chloride product; performing crystallization treatment on the filtrate, filtering the crystallized product, drying the obtained filter cake, and preparing all of the filter cake into a 4A molecular sieve product; and then realizing complete recycling of the waste silicon slag. The method for recycling waste silicon slag discharged in the production of zirconyl chloride provided by the invention is low in equipment investment and simple and convenient in operation steps. As a result, the environmental pollution of the waste silicon slag discharged in the production of zirconyl chloride in the prior art on soil, water and atmosphere is avoided. The production cost of the zirconyl chloride is obviously reduced, the economic benefit of a zirconyl chloride production enterprise is improved and the development of the zirconyl chloride industry is promoted.

Owner:山东广通新材料有限公司

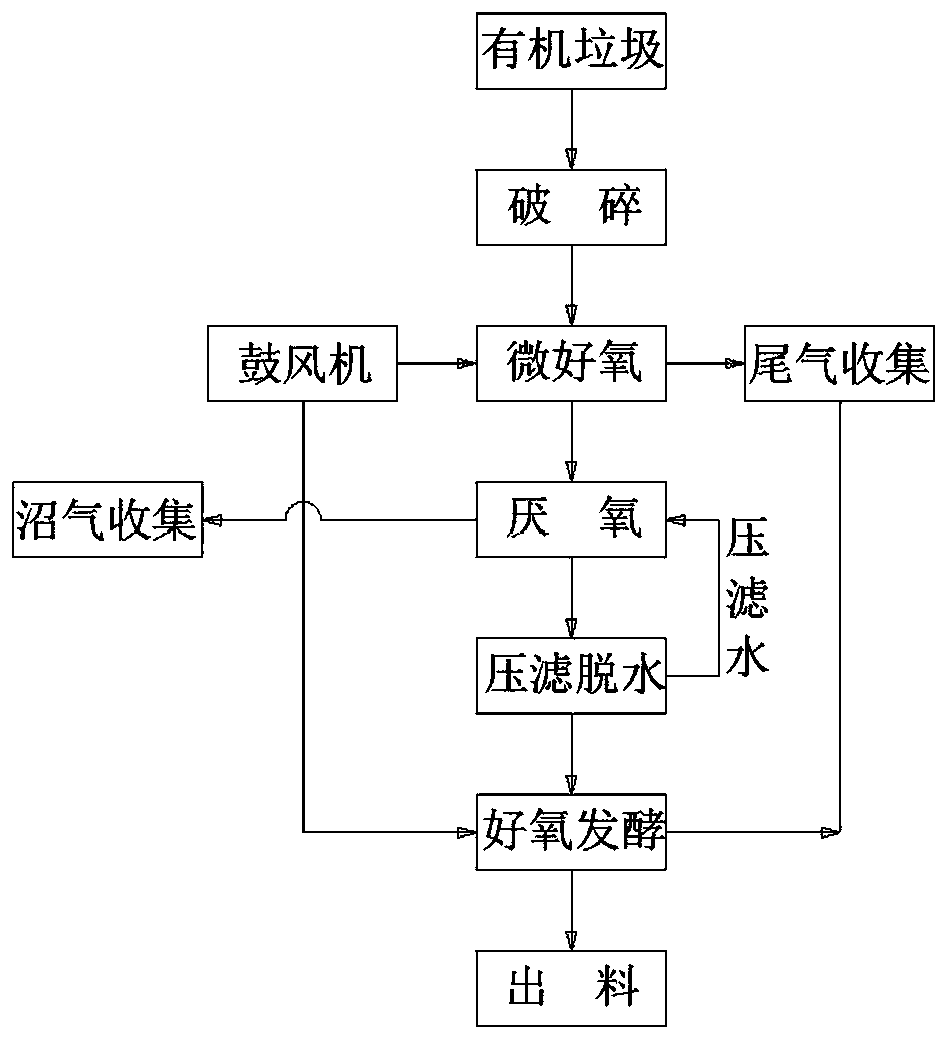

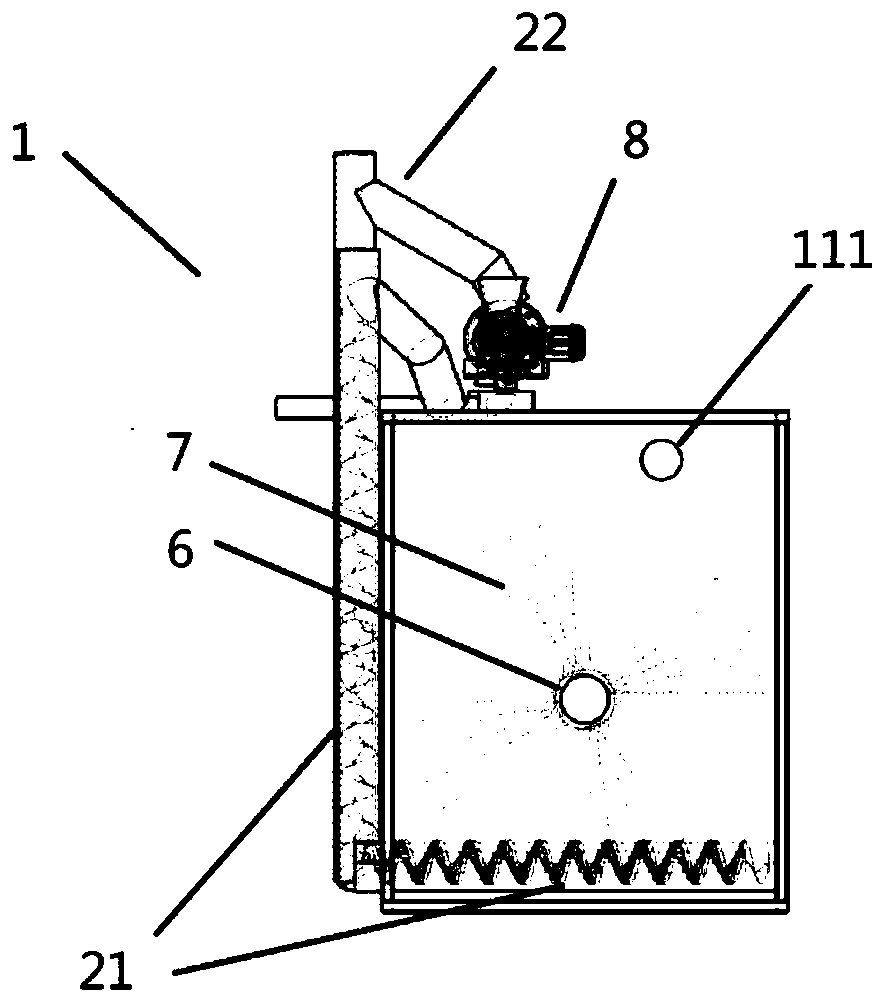

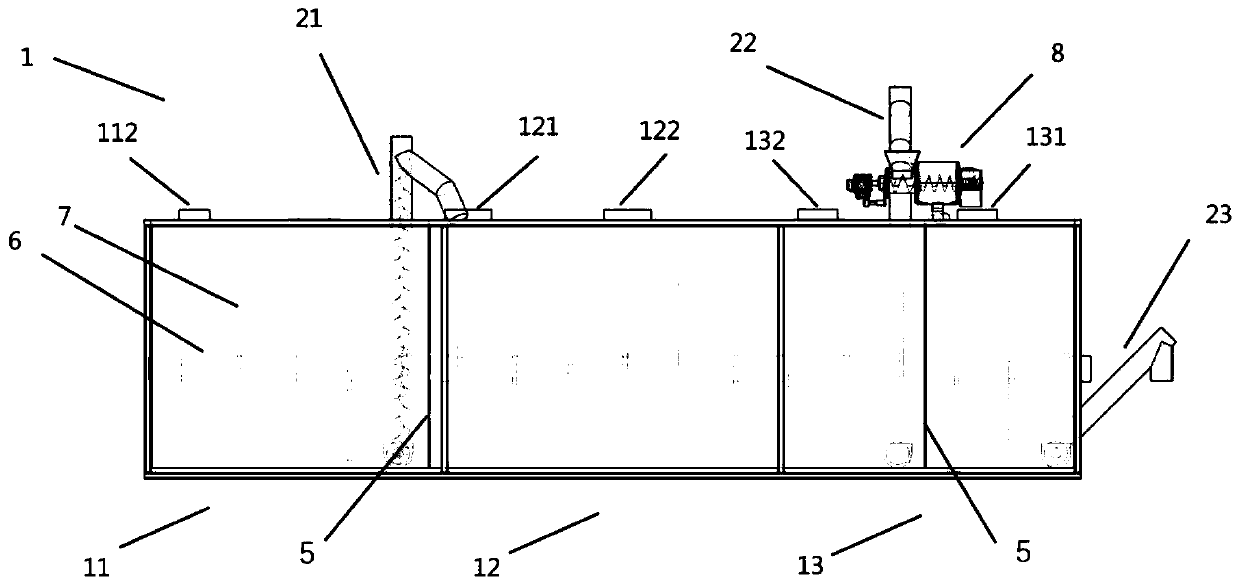

Three-stage integrated treatment system and method for organic biomass garbage

InactiveCN111215432AOvercome mobilityOvercome the clogging problemSolid waste disposalTransportation and packagingProcess engineeringEnvironmental engineering

The invention discloses a three-stage integrated treatment system for organic biomass garbage and a treatment method for the organic biomass garbage. The treatment system involves a three-stage fermentation reactor, a spiral feeding and discharging device, an external circulating coil and a deodorization device. According to the system, the kitchen garbage is subjected to micro-aerobic pretreatment by integrating a micro-aerobic process, an anaerobic process and an aerobic process, so that the problem of unstable operation caused by acidification in the anaerobic process is avoided; secondly,a horizontal plug flow mode and an integrated slow stirring mode are adopted, so that the mass transfer efficiency and the heat transfer efficiency in the anaerobic process are improved; and thirdly,the materials are conveyed on line in the micro-aerobic, anaerobic and aerobic processes in a multi-stage spiral conveying mode, and the problems of poor flowability and blockage of the material floware solved. The process is high in practicability, continuous and efficient, well solves the environmental problem caused by the urban kitchen garbage, comprehensively utilizes the wastes in a recycling manner, and is suitable for environment-friendly treatment of easily biodegradable organic wastes.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

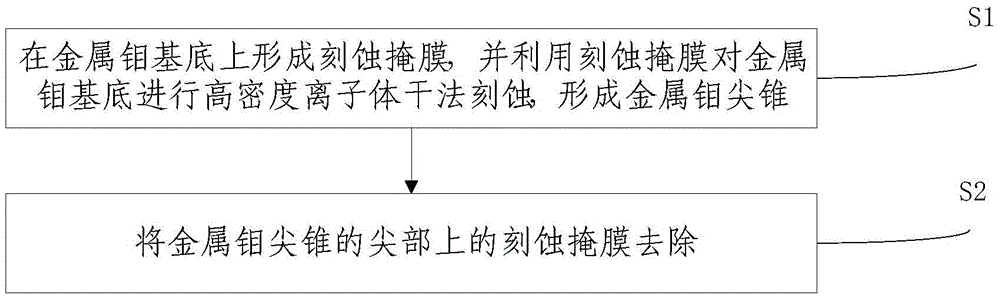

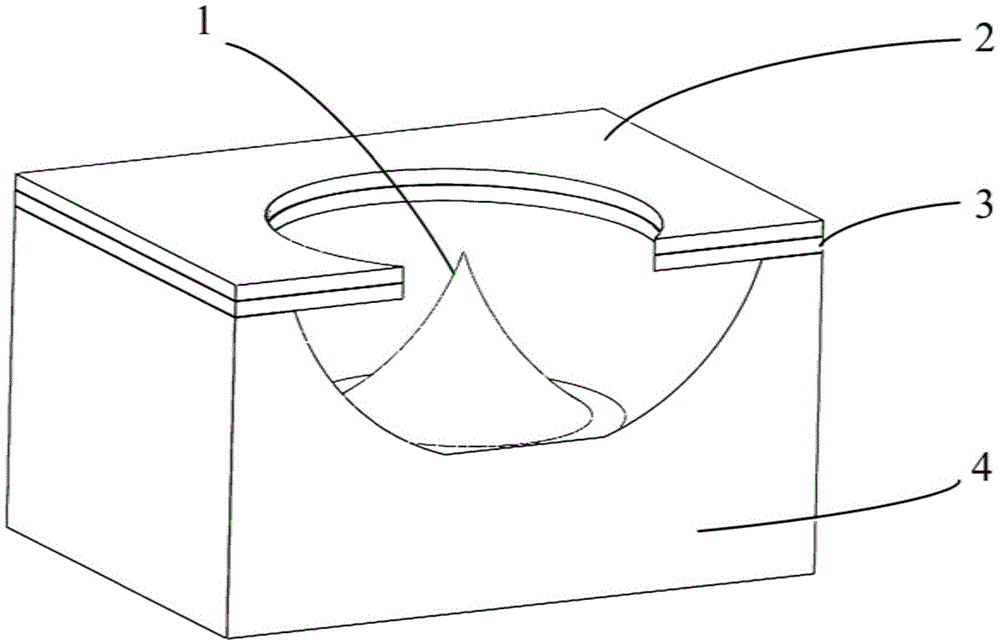

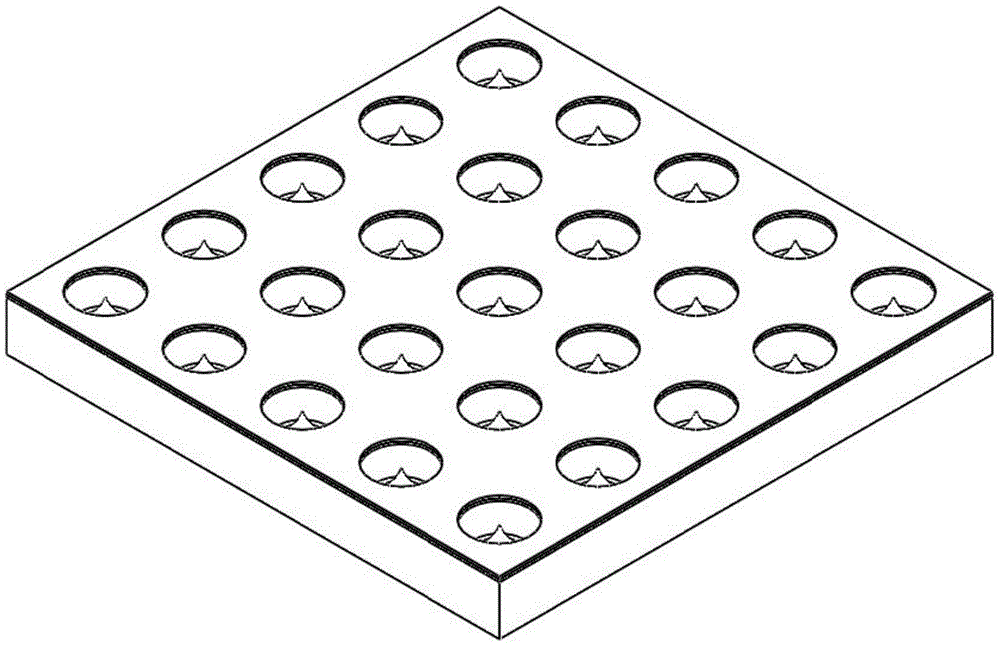

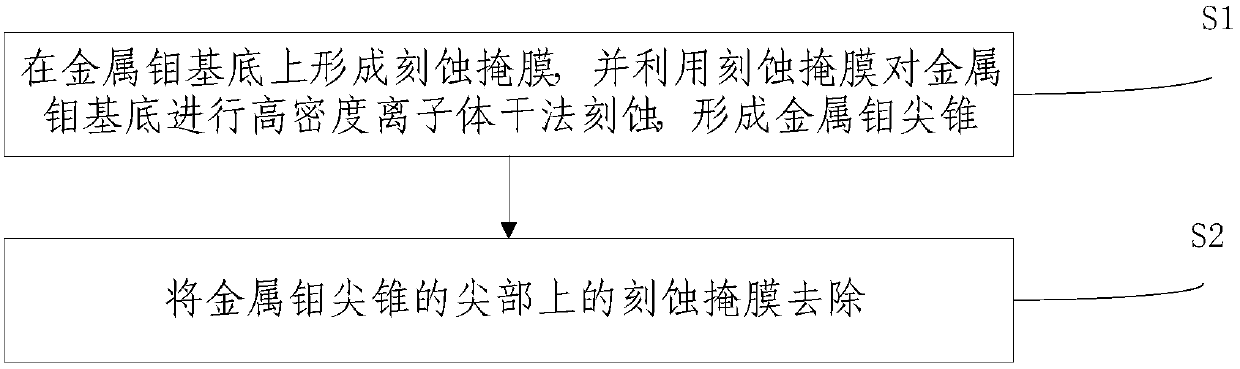

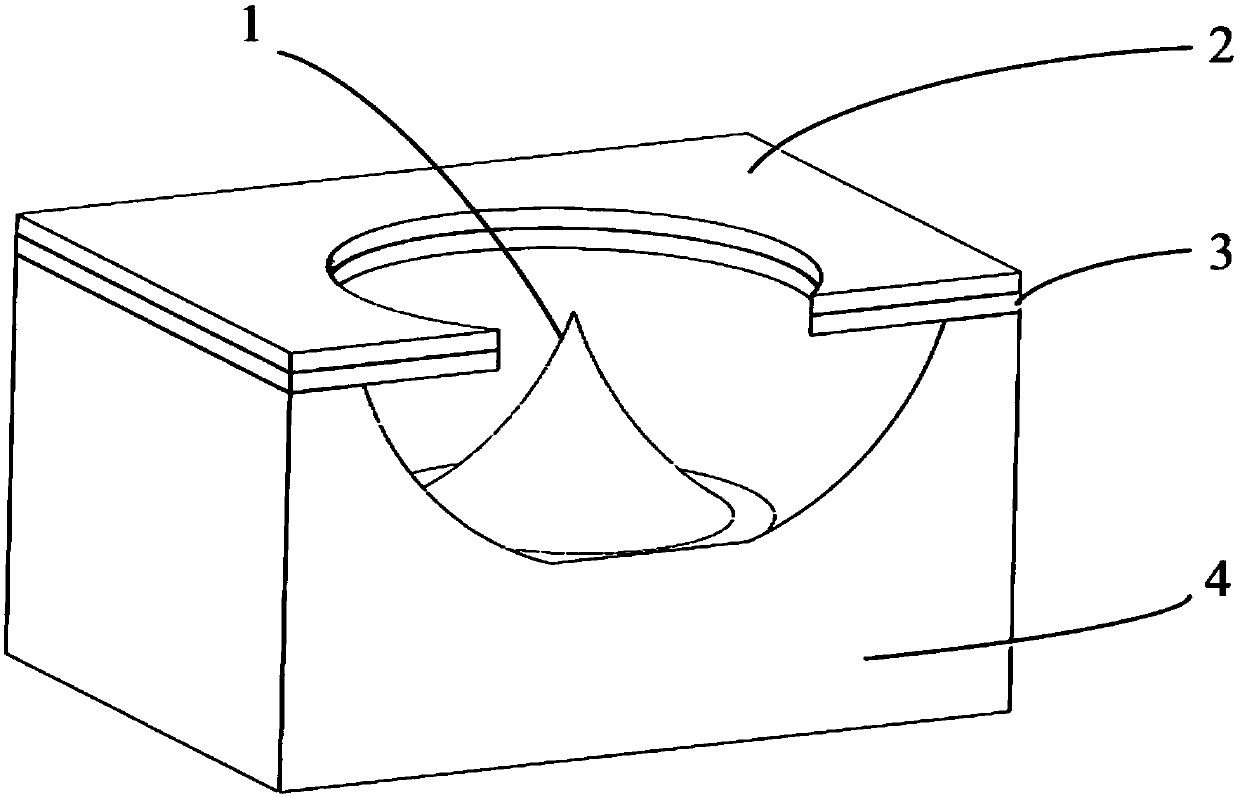

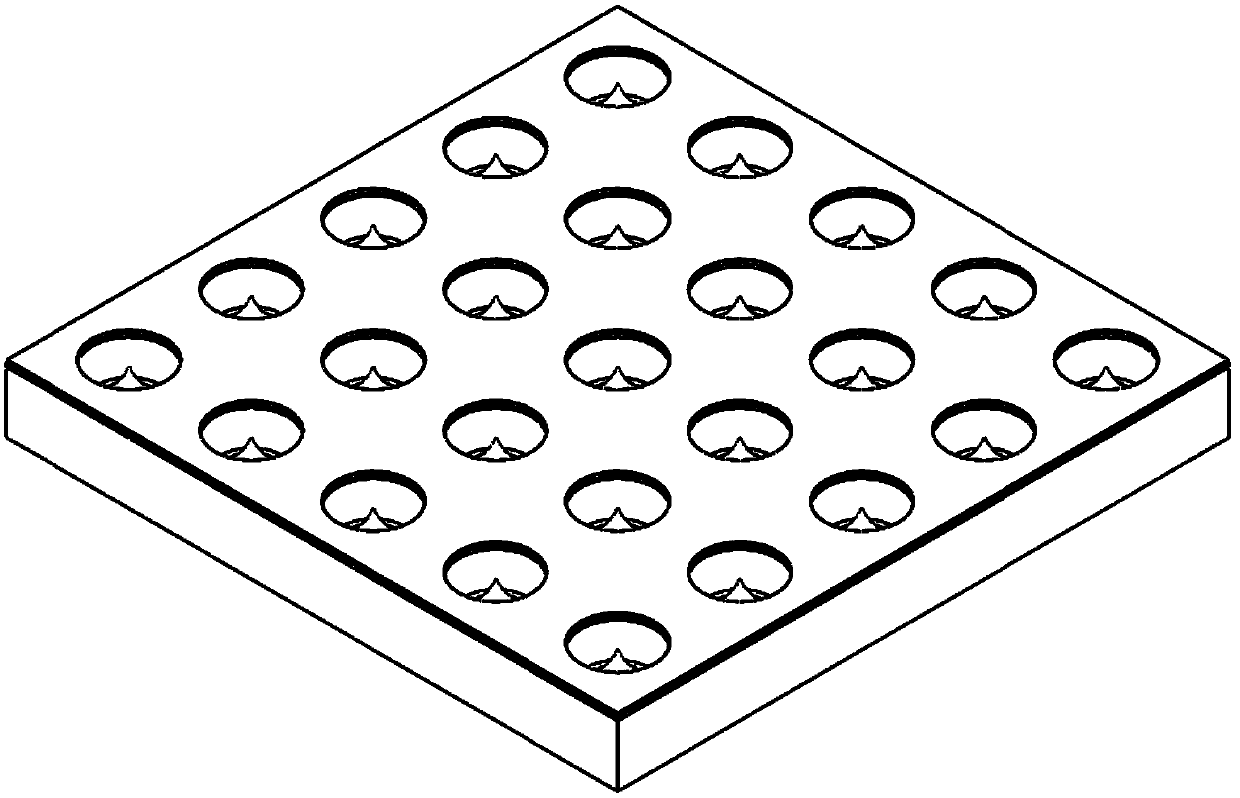

Field electron emission cathode array based on molybdenum substrate and preparation method thereof

ActiveCN105551910AGood lookingImprove adhesionDischarge tube/lamp detailsCold cathode manufactureHigh rateField electron emission

The invention discloses a field electron emission cathode array based on a molybdenum substrate and a preparation method thereof. According to the invention, an etching mask is firstly formed on a molybdenum substrate; then high density plasma dry etching is carried out to the molybdenum substrate to form molybdenum pointed cones. The molybdenum pointed cones are directly formed on the substrate; the problem of poor adhesion with underlay is thoroughly solved; heavy current and strong electric field can be borne; high rate isotropic etching is carried out to the molybdenum body material through the high density plasma dry etching method; therefore large area appearance accordant molybdenum pointed cone arrays can be obtained at the same time; large area even emission can be realized; only primary etching is contained in the manufacturing process of the field electron emission cathode array; the pointed cone centers and gate hole centers are automatically aligned without deflection; compared with the prior art, the technical solution of the invention is featured by few procedures, high efficiency, simplicity and low cost and is applicable to large scale preparation.

Owner:PEKING UNIV

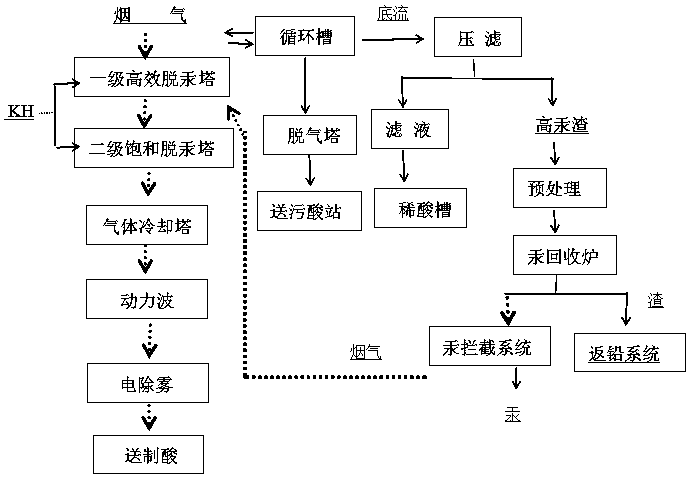

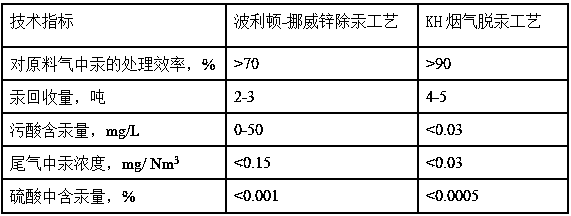

Process for deep purification and recovery of mercury in lead-zinc smelting flue gas

ActiveCN110433630ARealize production recoveryGuarantee up-to-standard dischargeGas treatmentDispersed particle separationCooling towerFlue gas

The present invention discloses a process for deep purification and recovery of mercury in lead-zinc smelting flue gas. According to the process, a macromolecule nanometer material demercuration agentKH is adopted and added to a first-class high-efficiency washing demercuration tower and a second-class deep washing demercuration tower, certain process conditions are controlled to realize deep purification of mercury and wash down dust and other heavy metals in flue gas, and then a gas cooling tower, a power wave and an electric demister are used to deeply purify the flue gas. After the flue gas is treated, the Hg content in the flue gas is less than 0.03 mg / Nm<3>, the mercury content in sulfuric acid produced by flue gas is less than 0.0005%. The process meets the requirements of mercuryemission in flue gas, and the recovery rate of mercury in flue gas is 90% or more, and the process has good environmental benefits.

Owner:湖南株冶环保科技有限公司

Brush plating technology of aluminium alloy

The invention discloses a brush plating technology of aluminum alloy. The technology comprises the following steps: polishing the surface, which will be subjected to brush plating, of an aluminum alloy by abrasive paper to remove the oxide scales; then carrying out cathode electrolysis under a voltage of 10-15 V for 10 to 20 seconds to remove the oil, washing the aluminum alloy by water; performing anode activation by using an activating liquid under a voltage of 12-16 V for 8 to 12 seconds to turn the surface of aluminum alloy into a dark grey color, washing the aluminum alloy by water, wiping the surface to be plated by an alkaline cooper plating solution in the absence of electricity; carrying out copper pre-plating through brush plating under a voltage of 8-10 V for 1 to 2 minutes, washing the aluminum alloy by water; carrying out tin plating through brush plating under a voltage of 8-12 V for 0.5 to 3 minutes, and washing the aluminum alloy by water to finish the brush plating. The technology has the advantages of simple steps and easy operation and control. The voltage and time of brush plating can be reasonably controlled to guarantee the quality of brush plating, the combination between the coating and the substrate is good, bubbling is not easy to happen, thus the corrosion on aluminum alloy is effectively prevented, and the technology is very practical.

Owner:QINGDAO SHOUSHENG IND

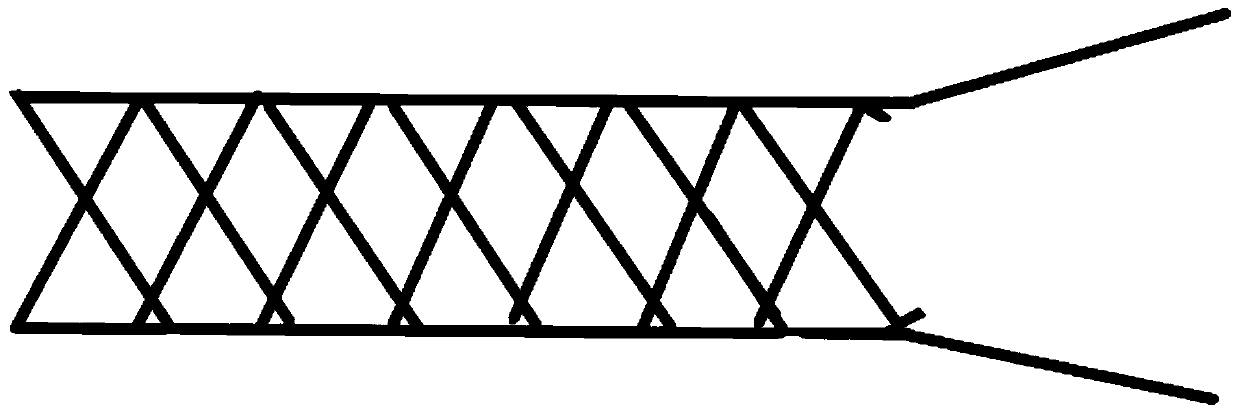

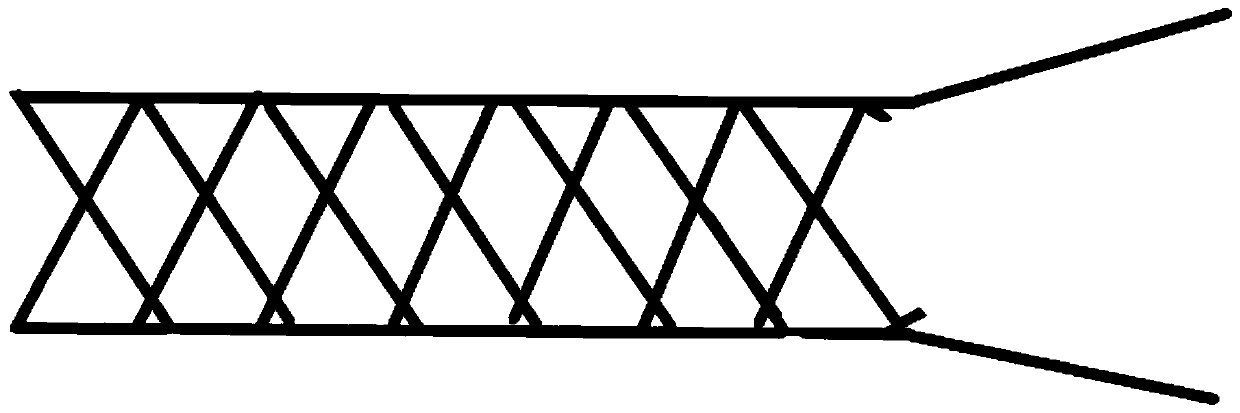

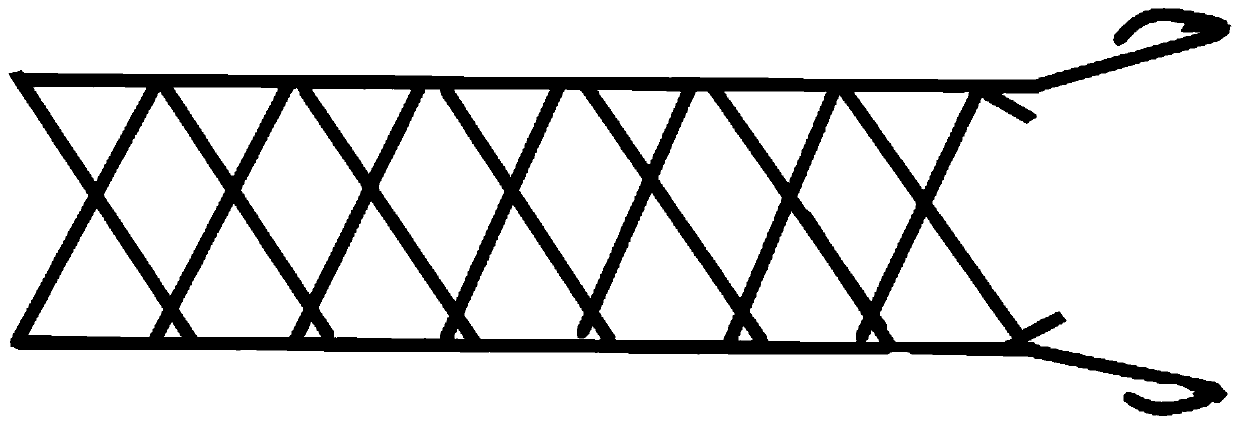

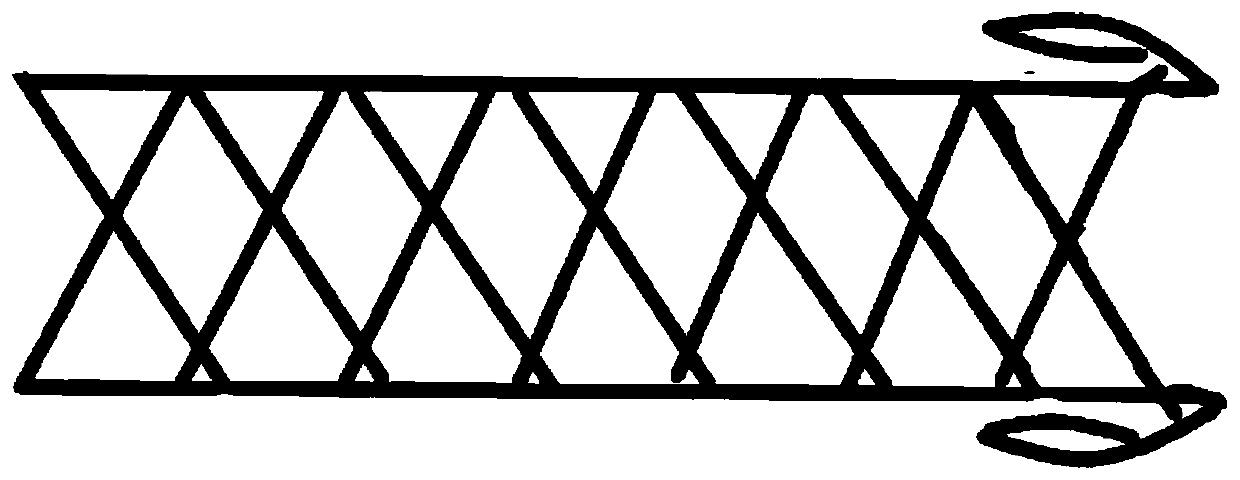

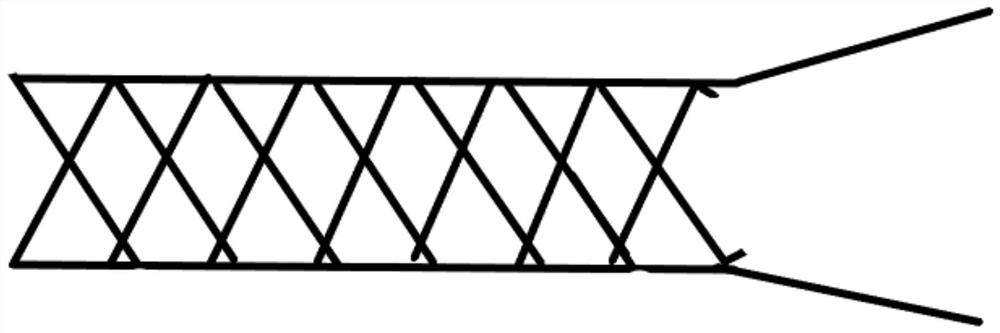

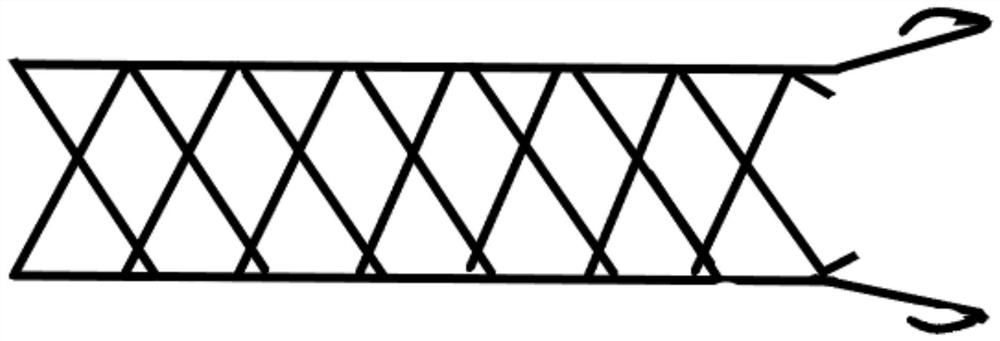

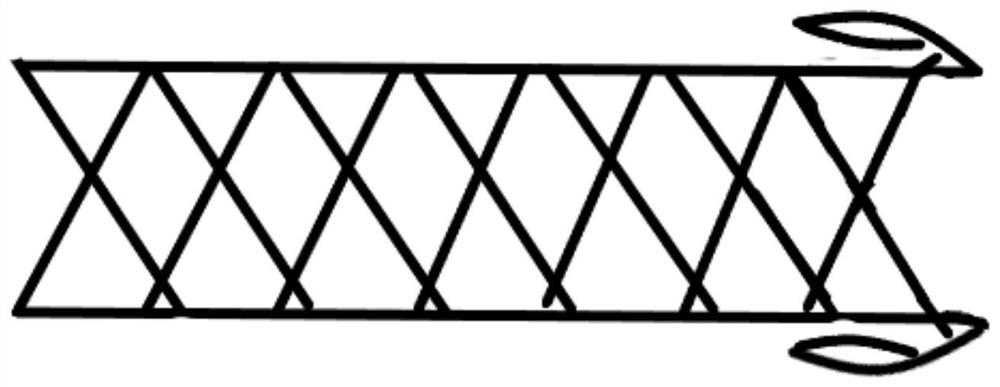

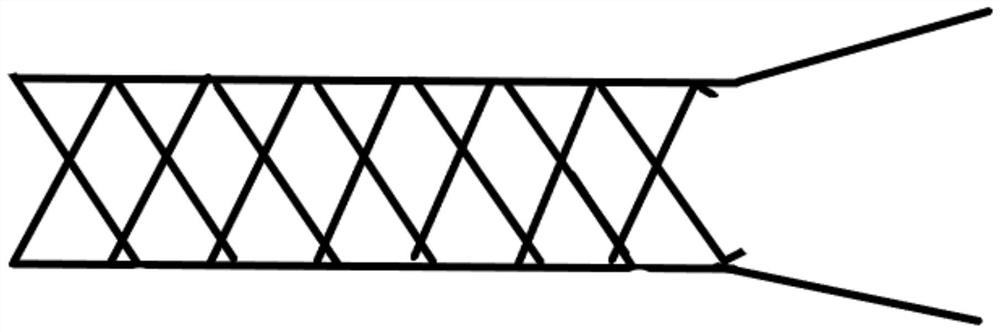

Edge closing process for integrated woven covered stent

The invention relates to an edge closing process for an integrated woven covered stent, and belongs to the technical field of medical instruments. The edge closing process comprises a starting end edge closing process and an ending end edge closing process. A two-step ending method is adopted to close the edge of the integrated woven covered stent formed by weaving metal and polymer fiber materials in a mixed mode. By means of the edge closing process based on the two-step ending method, smooth edge closing can be conducted on the end of the integrated woven covered stent, and the supporting performance of the covered stent is improved to a certain extent. The process is simple, high in practicability and outstanding in creativity. The application of the process is beneficial to promotingthe industrialization of a binary hybrid integrated covered stent.

Owner:DONGHUA UNIV +1

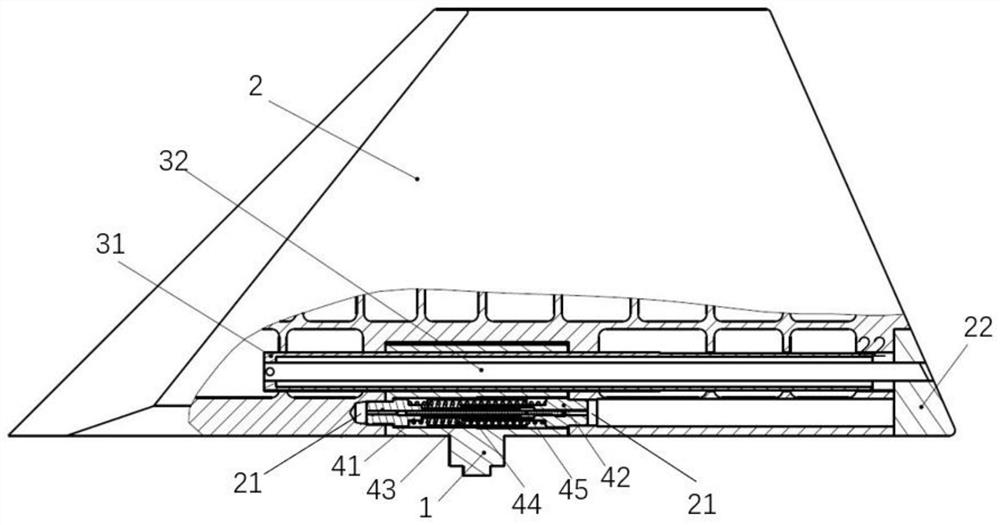

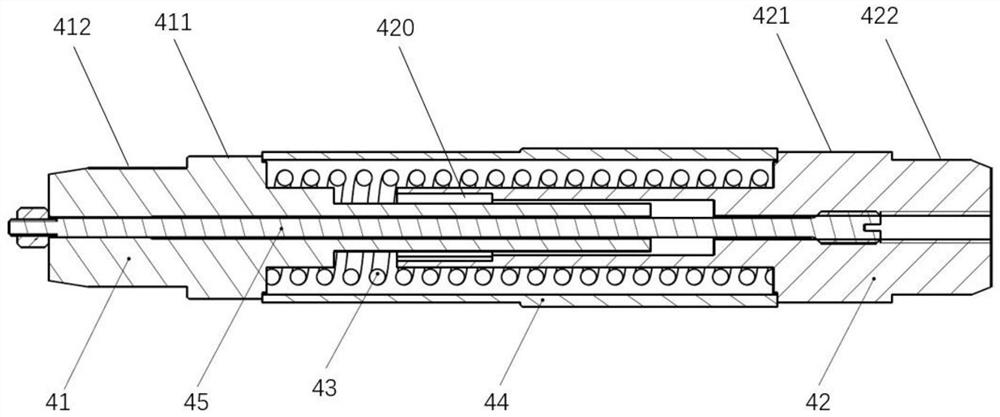

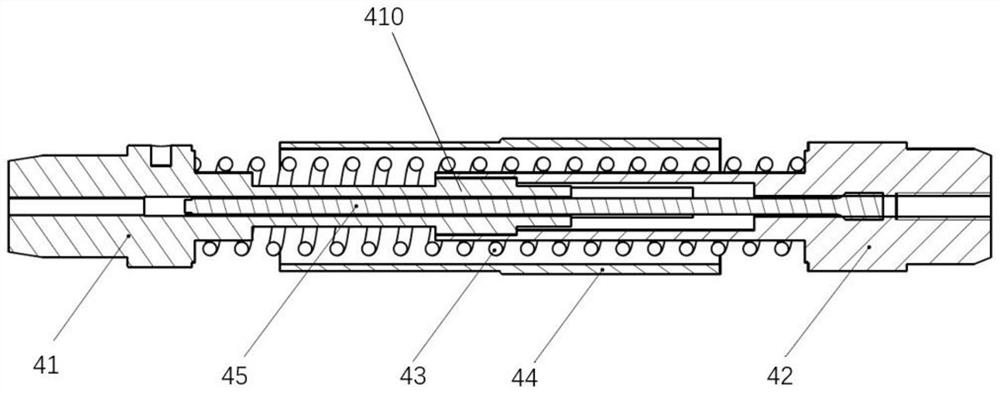

Missile folding rudder self-locking system

PendingCN114199083ASimple structureStrong process practicabilityProjectilesControl theoryTorsion spring

The invention relates to a missile folding rudder self-locking system in the technical field of missile equipment. The missile folding rudder self-locking system comprises an inner rudder, an outer rudder, a driving mechanism and a lock pin mechanism. The outer rudder is provided with a lock hole, the lock pin mechanism comprises a first lock rod, a second lock rod, a torsional spring and a lock pin sleeve, the lock pin sleeve is fixed on the inner rudder, the torsional spring is sleeved in the lock pin sleeve, and the first lock rod and the second lock rod are respectively inserted from two ends of the torsional spring and pre-press the torsional spring; the inner rudder and the outer rudder are in driving connection through the driving mechanism, in the process that the driving mechanism drives the outer rudder to be unfolded relative to the inner rudder, the torsion spring pushes the first locking rod and the second locking rod to be axially separated, and after the outer rudder and the inner rudder are unfolded in place, the end of the first locking rod and the end of the second locking rod are embedded into the locking holes correspondingly. The end of the first locking rod and the end of the second locking rod are used for preventing the inner rudder and the outer rudder from rotating in the radial direction. The missile folding rudder is simple in structure, high in process practicability, short in machining period and suitable for working in a high-temperature environment for a long time.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

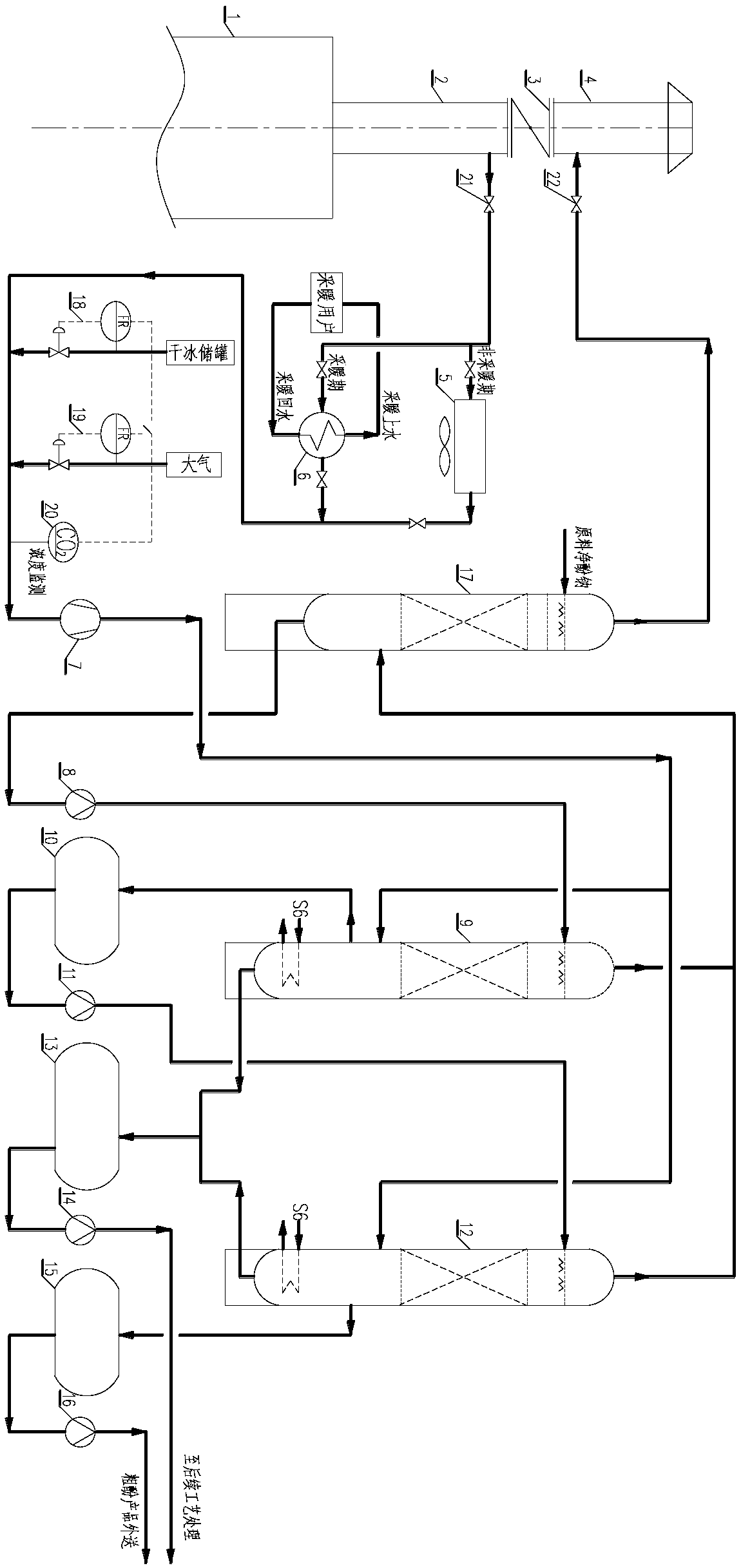

Process system for producing crude phenol by decomposing net sodium phenolate by using heating furnace flue gas

PendingCN109456148APracticalSimple processOrganic chemistryOrganic compound preparationSodium carbonateProcess systems

The invention relates to a process system for producing crude phenol by decomposing net sodium phenolate by using heating furnace flue gas. The process system comprises a traffic valve, a flue gas cooling system, a flue gas concentration regulating pressurization system and a phenate decomposition system. By improving the structure of a heating furnace chimney, the heating furnace flue gas containing CO2 is cooled, collected, thickened and pressurized and sent to the phenate decomposition system to react with the net sodium phenolate to form the crude phenol and a sodium carbonate solution, the problem that the crude phenol can further be produced without direct supply of a CO2 concentration gas source required for the decomposition of the phenate, the process flow is simple, the operationis convenient, the investment is saved, the operation cost is low, no pollution is caused, and the national environmental protection requirements are met.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

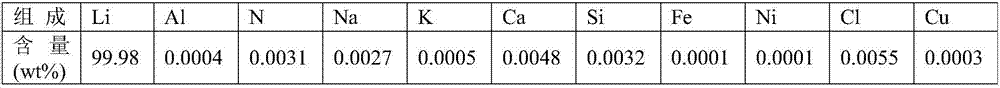

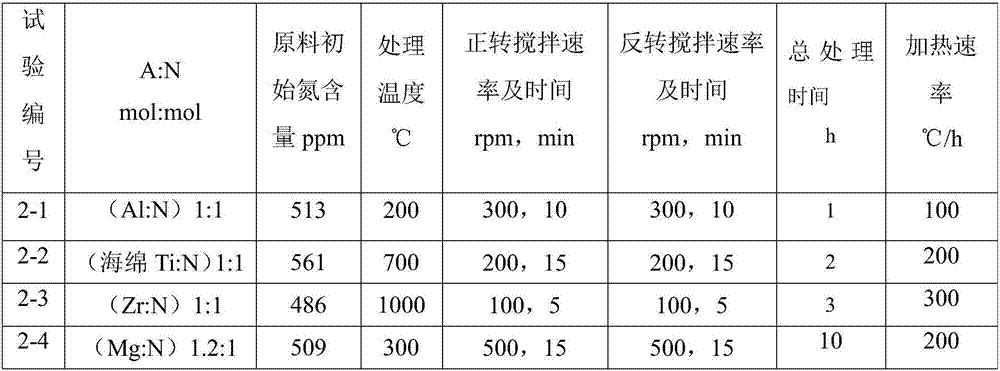

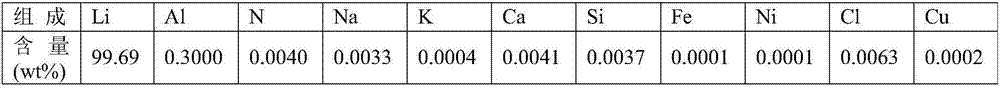

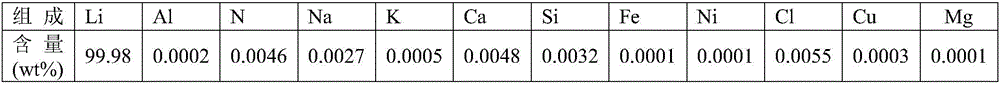

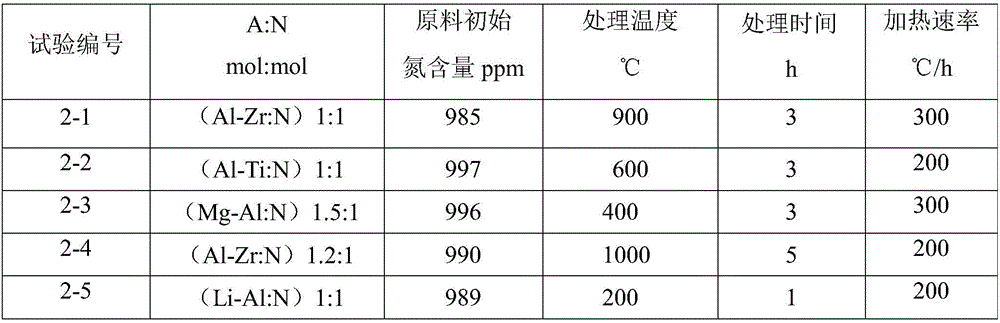

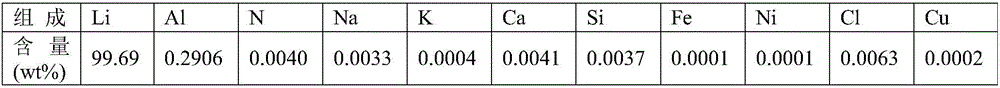

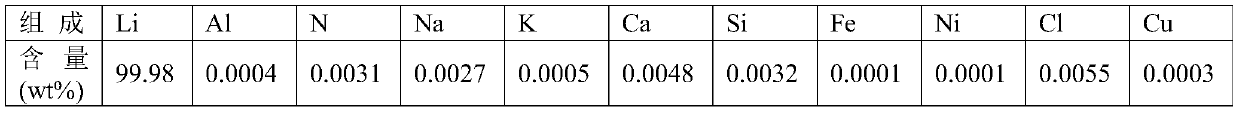

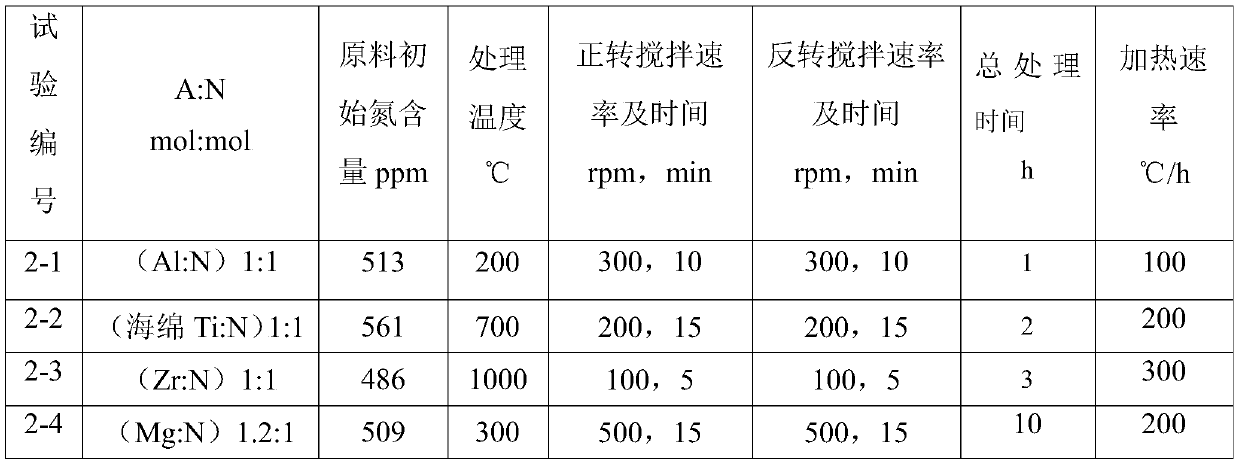

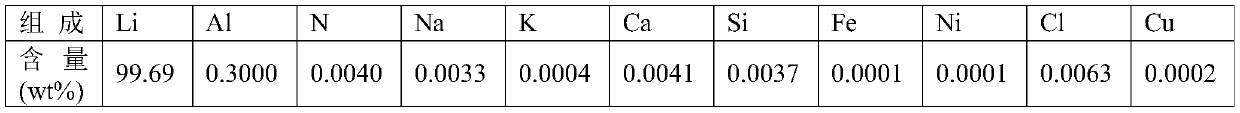

Method for reducing and removing nitride in lithium metal or lithium alloy

The invention relates to a method for reducing and removing nitride in lithium metal or a lithium alloy, and belongs to the technical field of lithium metal. According to the technical aim to be achieved, the method for reducing and removing the nitride in the lithium metal or the lithium alloy is provided. The method comprises the steps that under the vacuum or inert gas shielding atmosphere, the lithium metal or the lithium alloy is molten and stirred, then a nitrogen removing source A is added for reacting, the reacting temperature is controlled to range from 180 DEG C to 1,000 DEG C, reacting is carried out under a specific stirring method, settling and filtering are carried out after reacting is completed, and filter liquor is the lithium metal or the lithium alloy after nitrogen removing. The method is high in practicality, low in cost, short in reacting time, easy and convenient to operate and easy to achieve. The recovery rate of the lithium metal or the lithium alloy treated through the method is 98% or above, meanwhile, the active metal residual quantity is small, and the purity of the treated lithium metal or lithium alloy is not influenced; and the nitrogen content in the lithium metal or the lithium alloy can be reduced to 50 ppm or below and is far below the standard value 300 ppm in the national standard.

Owner:TIANQI LITHIUM CORP

Method for forming patterns on polyester/silk cloth surface through magnetron sputtering technology

InactiveCN107558271AHigh fastnessStrong process practicabilityVacuum evaporation coatingSputtering coatingSilk clothPolyester

The invention discloses a method for forming patterns on a polyester / silk cloth surface through a magnetron sputtering technology. The method comprises: 1) respectively carrying out coating finishingand laser etching on the surface of a fabric; and 2) coating the fabric surface being subjected to coating finishing and laser etching with a metal plating layer by using magnetron sputtering. According to the present invention, by combining magnetron sputtering, coating finishing and laser etching, the problem that the pattern is formed on the metal fabric is effectively solved, the original appearance characteristics of the fabric are changed, and the formed pattern is clear and distortion-free, and has good fastness; and the process has advantages of strong practicality and high productionefficiency, and the plated film layer has advantages of uniformity, compactness, and strong adhesion.

Owner:信成(亚洲)有限公司

Edge closing process for integrated woven covered stent

ActiveCN111544169ASolve the problem of edge closingAchieve smooth edgesStentsMedical devicesFiberStructural engineering

The invention relates to an edge closing process for an integrated woven covered stent, and belongs to the technical field of medical instruments. The process comprises a starting end edge closing process and an ending end edge closing process. A two-step ending method is adopted to close the edge of the integrated woven covered stent formed by weaving metal and polymer fiber materials in a mixedmode. By means of the edge closing process of the two-step end method, smooth edge closing can be conducted on the end of the integrated woven covered stent, and the supporting performance of the covered stent is improved to a certain extent. The process is simple, high in practicability and outstanding in creativity; and the application is beneficial to promoting the industrialization of the binary mixed-weaving integrated tectorial membrane stent.

Owner:DONGHUA UNIV +1

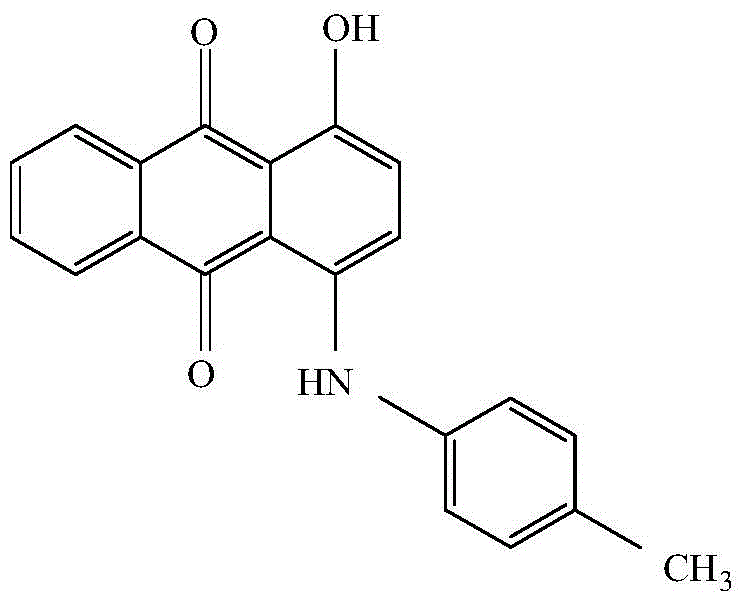

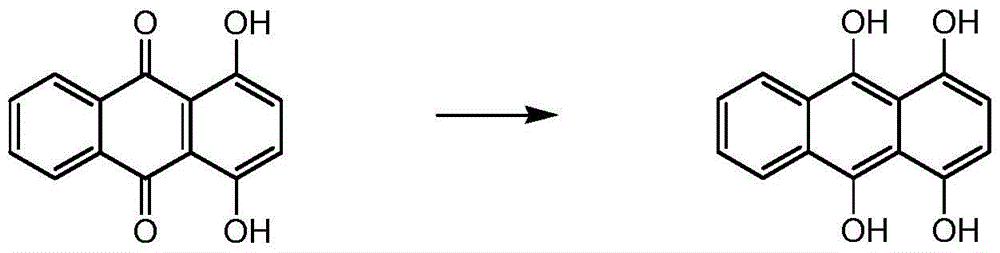

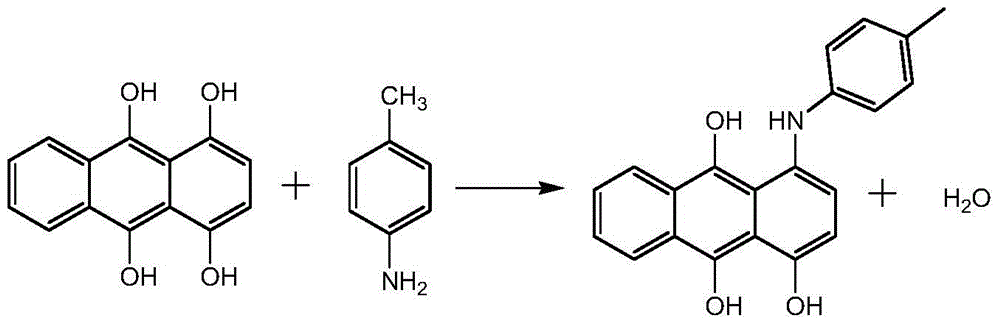

A kind of synthetic method of solvent violet 13

ActiveCN105237417BReduced post-processingSave manpower and material resourcesOrganic chemistryOrganic compound preparationToluidineMaterial resources

The invention discloses a synthetic method for solvent violet 13, and develops a new route for synthesizing violet 13 by employing a one-pot process. The method comprises successively adding methanol, 1,4-dihydroxyanthraquinone, 4-nitrotoluene, iron powder and boric acid into a pressure container, sealing the container and performing nitrogen displacement, then heating with stirring, introducing hydrogen for hydrogenation reduction, after the reaction system stops absorbing hydrogen, performing warm-keeping reaction, heating after the reaction is finished, performing condensation reaction, cooling after the reaction is finished, releasing the pressure, introducing air and performing oxidation reaction, and finally adding hydrochloric acid for beating, filtering, washing and drying, so as to obtain violet 13. According to the method, the initial raw material p-toluidine is replaced by 4-nitrotoluene, direct usage of the highly-toxic raw material p-toluidine is avoided, and the synthetic technology is low in toxicity and friendly to environment. By pouring all of the raw materials into the container, the postprocessing process of the intermediate step is saved, and a large amount of manpower and material resource is saved.

Owner:JIANGSU DAOBO CHEM

One-piece braided film-covered stent edge finishing process

ActiveCN111544169BSolve the problem of edge closingAchieve smooth edgesStentsMedical devicesFiberPolymer science

The invention relates to an integrated braided film-covered stent edge trimming process, which belongs to the technical field of medical devices; it includes a starting edge trimming process and an end end edge trimming process; a "two-step finishing method" is used to mix metal and polymer fiber materials The one-piece braided stent graft has been trimmed. Through the "two-step finishing method" edge trimming process, the end of the integrated braided stent graft can be trimmed smoothly, and the supporting performance of the stent graft can be improved to a certain extent. The technology is simple, practical, and creative; its application will be conducive to promoting the industrialization of binary mixed-weaving integrated stent grafts.

Owner:DONGHUA UNIV +1

Method for reducing and removing nitride in metal lithium or lithium alloy

The invention relates to a method for reducing and removing nitride in metal lithium or lithium alloy, and belongs to the technical field of lithium metal. The method achieves the technical effect of reducing and removing nitride in metal lithium or lithium alloy. The method comprises the steps that in the vacuum or inert gas shielding atmosphere, metal lithium or lithium alloy is molten and stirred, a nitride removal source A is added for a reaction, the reaction temperature is controlled to be 180-1000 DEG C, the reaction time is 0.1-10 h, sedimentation and filtration are carried out after the reaction is finished, and the filtrate is nitride-removed metal lithium or lithium alloy. The active metal alloy is adopted as the nitride removal source, practicability is high, the cost is low, reaction time is short, and operation is simple and easy to implement. The recovery rate of the metal lithium or lithium alloy treated by the method is 98% or above, meanwhile, the active metal alloy residual quantity is low, the purity of the treated metal lithium or lithium alloy is not affected, and the nitrogen content in the metal lithium or lithium alloy can be reduced to be 50 ppm or below and is far lower than the standard value 300 ppm or below in the national standard.

Owner:TIANQI LITHIUM CORP

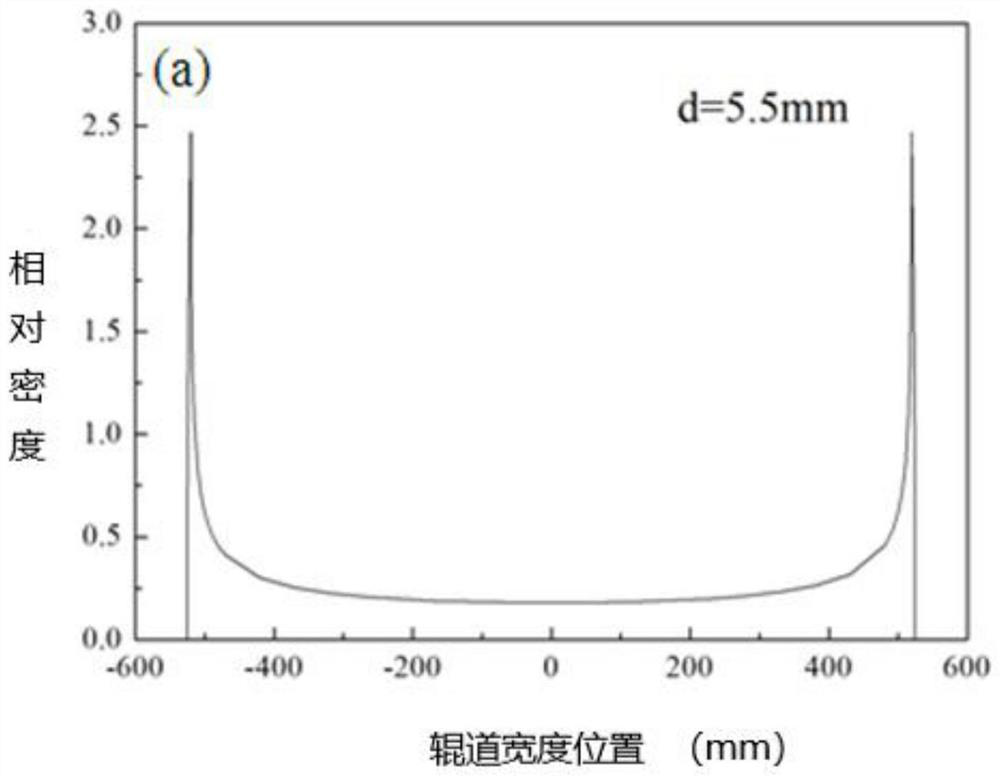

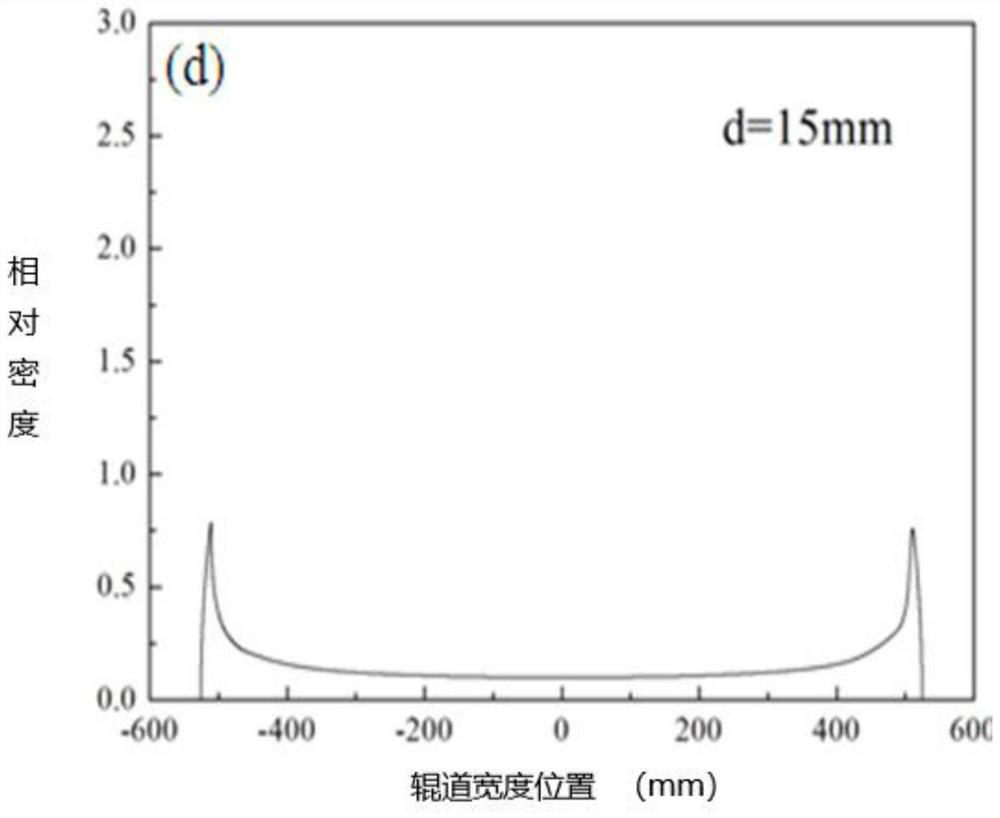

High-speed wire production method for controlling same-circle mechanical property fluctuation of high-carbon steel wire rod

InactiveCN111940501AReduce performance fluctuations in the same circleImprove pull performanceFlexible work arrangmentsMetal rolling arrangementsWire rodTemperature control

The invention provides a high-speed wire production method for controlling the same-circle mechanical property fluctuation of a high-carbon steel wire rod. The high-speed wire production method comprises the following steps that the vibration value fluctuation of a laying head is controlled to be 2-3 mm / s, the laying circle diameter is controlled to be 9.5-1.1 m, and the specification distributionof a coil on an air-cooled Stelmor roller way is ensured; the starting speed of the roller way is controlled to be 0.6-0.7 m / s, and the density degree of steel wire rods of lap joints and non-lap joints is controlled; according to the specification of the steel wire rod, the angle of a Jiaoling baffle of a fan under the Stelmor air cooling roller way is adjusted, specifically, the angle of the Jiaoling baffle of the 5.5-8 mm steel wire rod is controlled to be 10 degrees, the angle of the Jiaoling baffle of the 8-12 mm steel wire rod is controlled to be 8 degrees, and the angle of the Jiaolingbaffle of the 12-16 mm steel wire rod is controlled to be 5 degrees; and the phase change starting temperature is controlled within 20-30 DEG C. The method has the advantages that the same-circle performance fluctuation of the steel wire rod is effectively reduced, the drawing capacity of the steel wire rod and the stability of steel wire performance are improved, the process practicability is high, and the method is suitable for improving the quality of high-carbon steel wire rods in high-speed wire factories.

Owner:QINGDAO SPECIAL STEEL CO LTD

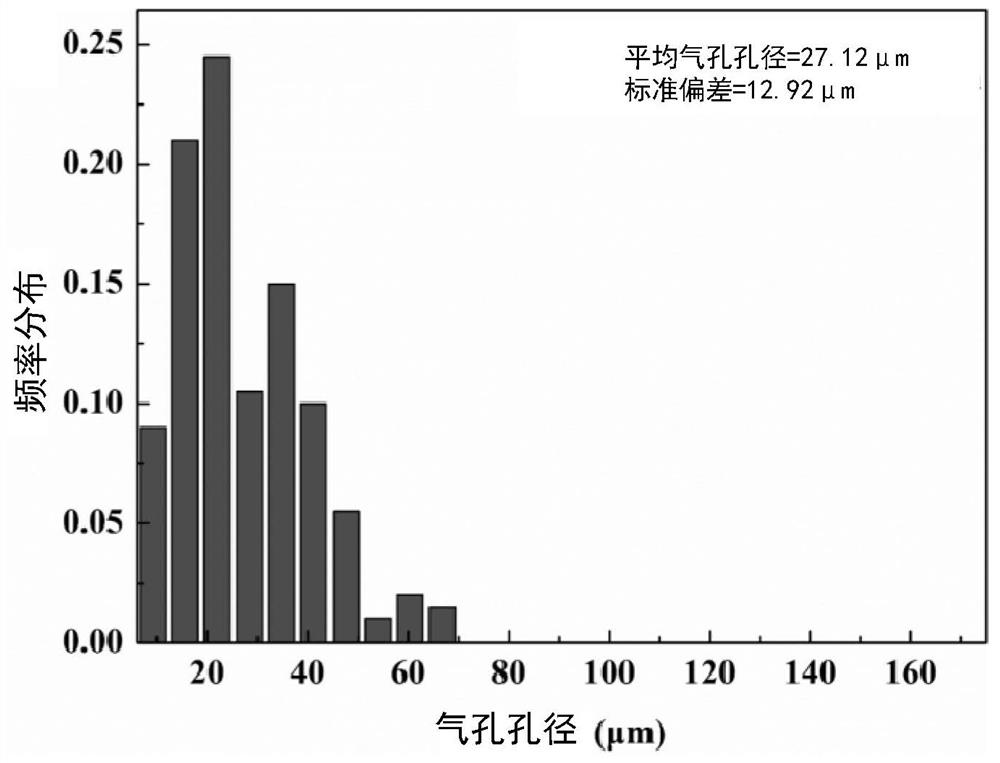

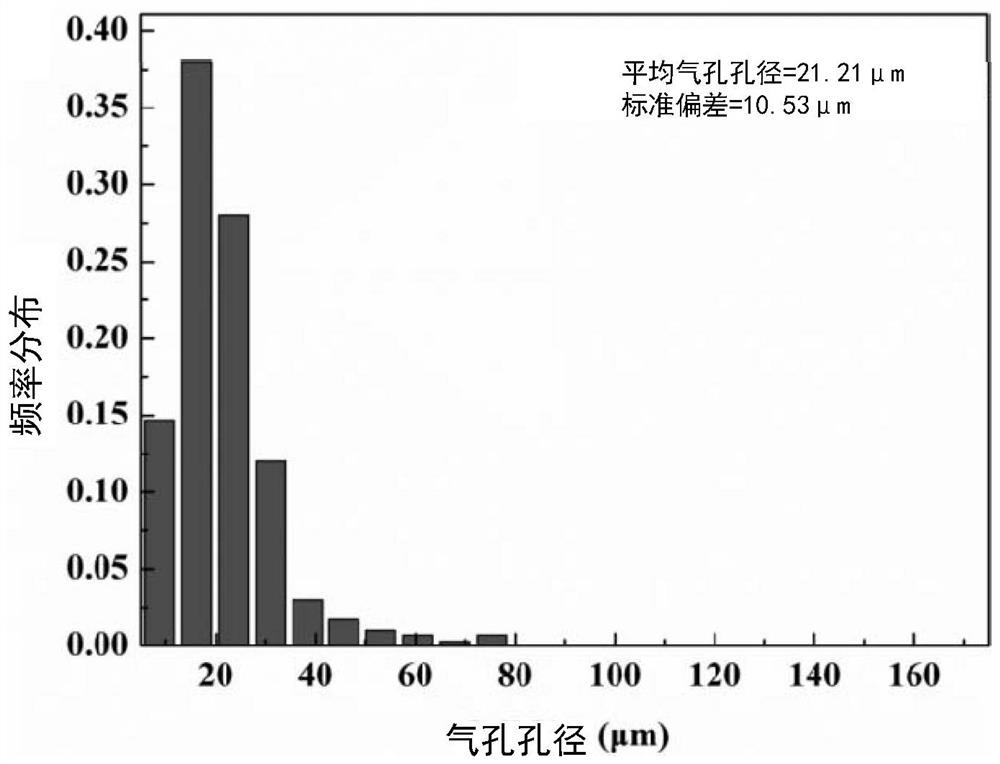

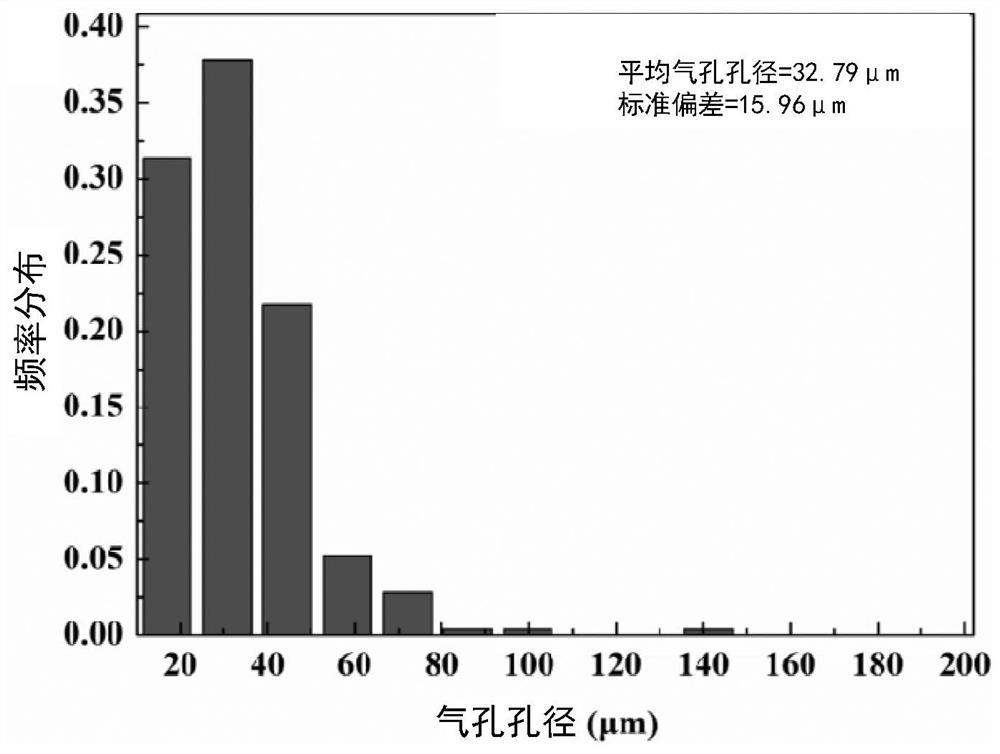

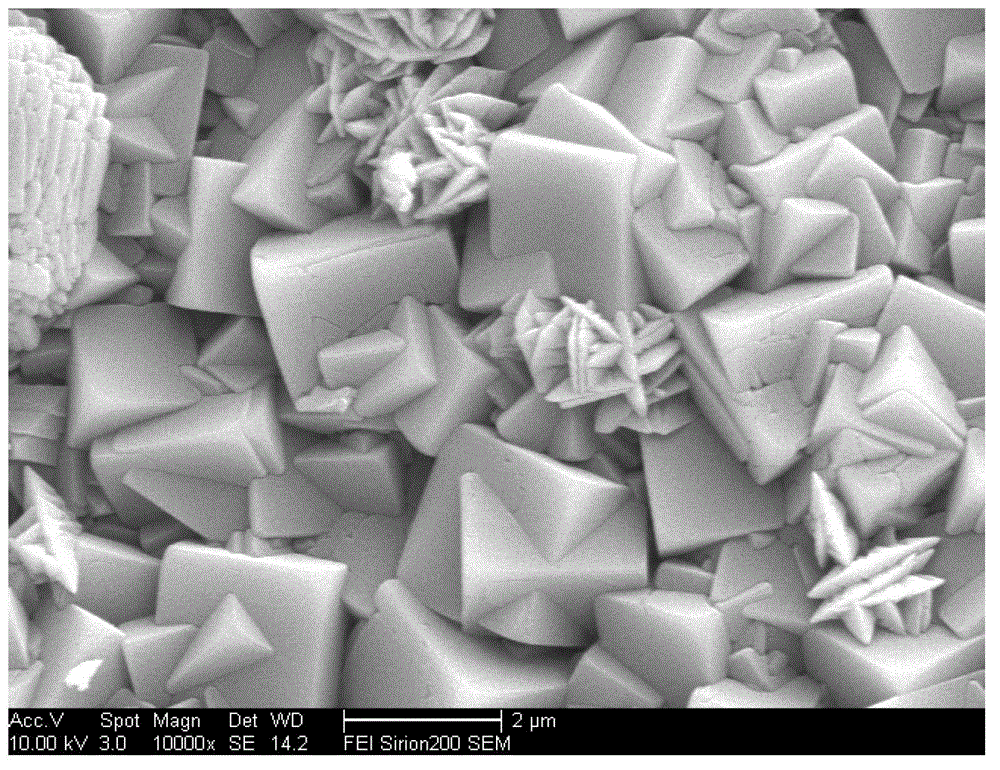

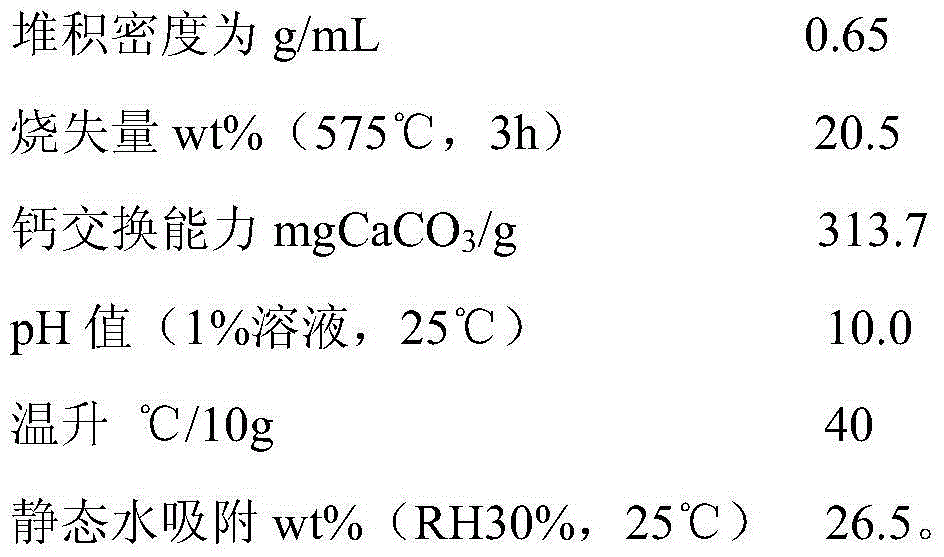

A kind of low dielectric porous mullite wave-transparent material and preparation method thereof

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for recycling waste silicon slag discharged in production of zirconyl chloride

Owner:山东广通新材料有限公司

Method for reducing and removing nitrides in lithium metal or lithium alloy

The invention relates to a method for reducing and removing nitride in lithium metal or a lithium alloy, and belongs to the technical field of lithium metal. According to the technical aim to be achieved, the method for reducing and removing the nitride in the lithium metal or the lithium alloy is provided. The method comprises the steps that under the vacuum or inert gas shielding atmosphere, the lithium metal or the lithium alloy is molten and stirred, then a nitrogen removing source A is added for reacting, the reacting temperature is controlled to range from 180 DEG C to 1,000 DEG C, reacting is carried out under a specific stirring method, settling and filtering are carried out after reacting is completed, and filter liquor is the lithium metal or the lithium alloy after nitrogen removing. The method is high in practicality, low in cost, short in reacting time, easy and convenient to operate and easy to achieve. The recovery rate of the lithium metal or the lithium alloy treated through the method is 98% or above, meanwhile, the active metal residual quantity is small, and the purity of the treated lithium metal or lithium alloy is not influenced; and the nitrogen content in the lithium metal or the lithium alloy can be reduced to 50 ppm or below and is far below the standard value 300 ppm in the national standard.

Owner:TIANQI LITHIUM CORP

An integrated braided film-covered stent trimming process

ActiveCN111544168BSolve the problem of edge closingAchieve smooth edgesStentsPolymer scienceEngineering

The invention relates to an integrated braided film-covered stent edge trimming process, which belongs to the technical field of medical devices; it includes a starting edge trimming process and an end end edge trimming process; a "two-step finishing method" is used to mix metal and polymer fiber materials The one-piece braided stent graft has been trimmed. Through the "two-step finishing method" edge trimming process, the end of the integrated braided stent graft can be trimmed smoothly, and the supporting performance of the stent graft can be improved to a certain extent. The technique is simple, the practicability is strong, and the creativity is outstanding; the application of the present invention will be beneficial to promote the industrialization of the binary mixed braided integrated stent graft.

Owner:DONGHUA UNIV +1

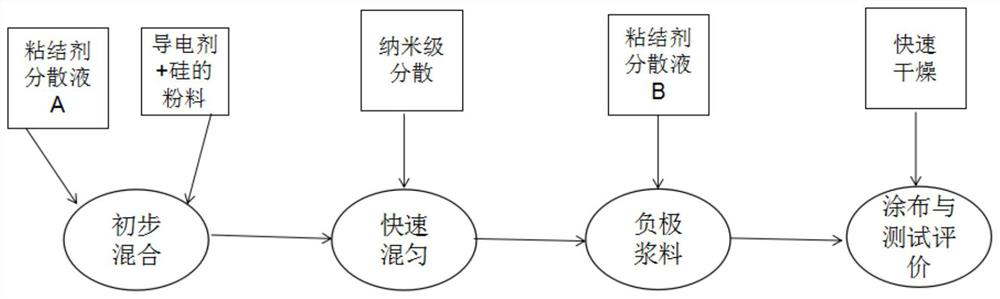

Rapid evaluation method for electrochemical performance of silicon negative electrode material

PendingCN111948542AFast analysis and evaluationAccurate and fast analytical evaluationMaterial nanotechnologyMaterial analysis using wave/particle radiationButton batteryPole piece

The invention discloses a method for quickly evaluating the electrochemical performance of a silicon negative electrode material, which comprises the following steps: adding silicon powder and a conductive agent into a binder A, and carrying out nanoscale dispersion to obtain slurry A; adding a surface functionalized binder B into the slurry A, and uniformly mixing to obtain slurry B; coating theslurry B on the surface of a copper current collector, performing drying, and performing punching to obtain a pole piece; and assembling the pole pieces into a CR series button cell, and carrying outevaluation test. Compared with the prior art, the method provided by the invention has the beneficial effects that the electrochemical performance of the silicon negative electrode material is accurately and quickly analyzed and evaluated mainly through the design of a nano-dispersion process of silicon particles, the matching of a surface functionalized binder, the quick drying of a pole piece and other process designs.

Owner:BAOSHAN IRON & STEEL CO LTD

Slot-less rolling technique of rolling section

InactiveCN100369680CResolve twistHighlight substantive featuresRoll mill control devicesMetal rolling arrangementsMaterials scienceRolling mill

Owner:XINJIANG BAYI IRON & STEEL

Potassium glycyrrhetate and its preparing process and use

InactiveCN1109044CStrong process practicabilitySuitable for industrial mass productionMetabolism disorderSteroidsWhite powderPotassium

A potassium glycyrrhetate (C30H45O4K) is prepared from glycyrrhizic acid through hydrolysis to generate glycyrrhetic acid, and reaction with potassium hydroxide. It is a white powder with medical function of reducing blood fat and treating inflammation, hypersensitivity, virus, cough, asthma, etc.

Owner:NINGXIA UNIVERSITY

A method of manufacturing an all-polymer planar light path

InactiveCN103592721BLow costSimple processOptical waveguide light guidePolymer scienceLithographic artist

The invention discloses a method for manufacturing an all-polymer planar optical path, which includes the following steps: (1) using ultraviolet lithography and deep etching technology to obtain an initial original mold, then duplicating a metal nickel mold by electrochemical deposition, and then using a micro mold Plastic method to make polymer microstructure parts; (2) Use thermal annealing process to process the parts in sections to reduce the roughness of the side wall and reduce the scattering loss in light wave transmission; (3) Coating and filling polymer dielectric materials , to form the core structure of the planar optical path after curing; (4) Use the polymer glue layer as the binding layer of the component, and then combine the binding layer with the optical polymer substrate to realize the preparation of the buried ridge type polymer planar optical path. Compared with the preparation method of the traditional polymer plane optical path, the invention reduces the cost, and the technique has strong versatility for materials.

Owner:SOUTH CHINA NORMAL UNIVERSITY

A kind of metallographic preparation method of tungsten-nickel-iron alloy

ActiveCN108562470BAvoid it happening againNo pollution in the processPreparing sample for investigationEpoxyChemical corrosion

Owner:DALIAN UNIV OF TECH

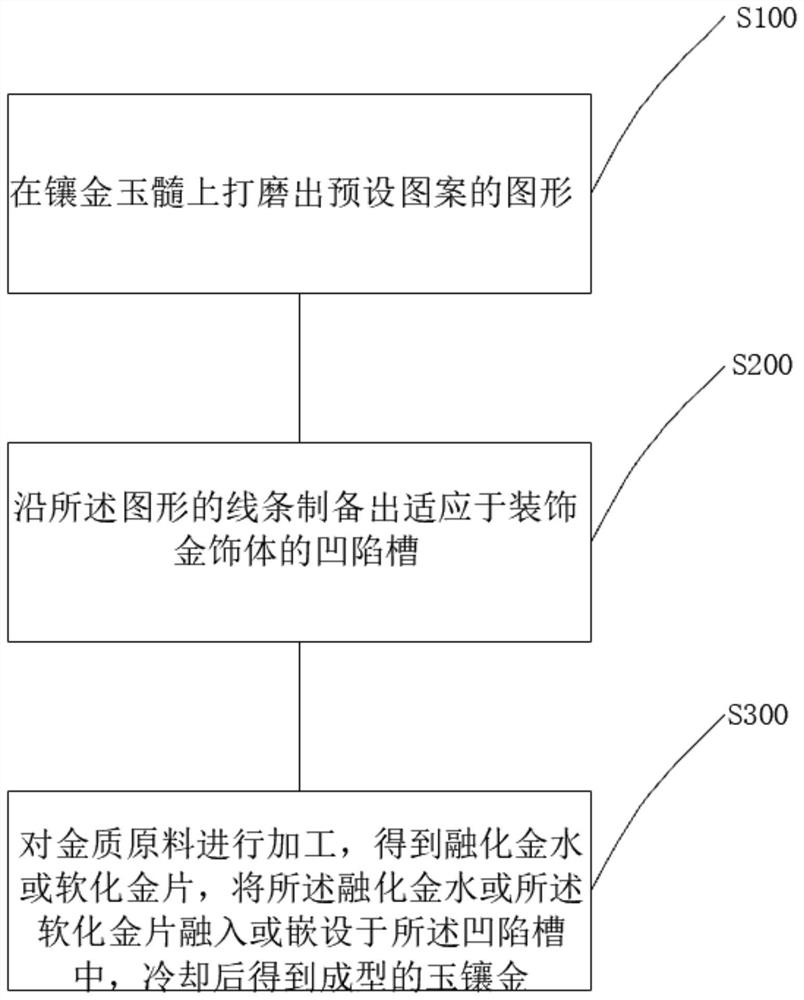

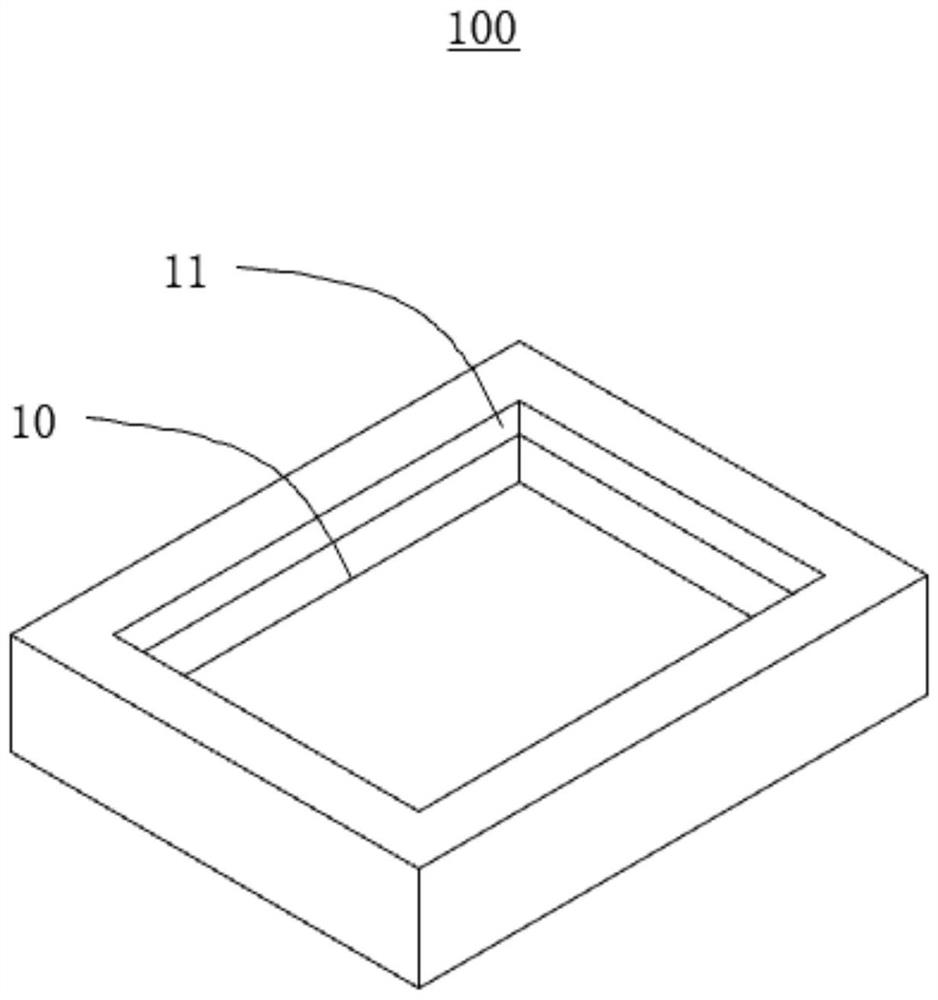

Preparation process of jade inlaid with gold

PendingCN113370703AImprove stabilityAvoid separationDecorative surface effectsJewelleryMetallurgyMaterials science

The invention provides a preparation process of a jade inlaid with gold, and relates to the technical field of gold inlaid. The process comprises the following steps of S1, polishing a pattern with a preset pattern on gold inlaid jade marrow; S2, preparing a concave groove suitable for decorating a gold ornament along the line of the pattern; and S3, machining a gold raw material, obtaining molten gold water or softened gold pieces, enabling the molten gold water or the softened gold pieces to be fused or embedded into the concave groove, and obtaining the formed jade inlaid gold after cooling. According to the preparation process of the jade inlaid with the gold, the concave groove is machined, so that molten gold or the softened gold pieces can be smoothly fused into or embedded into the concave groove, the stability of the formed gold jade is improved, the phenomenon that the gold and the jade is separated is avoided, and the process is high in practicability and beneficial to popularization.

Owner:申友元

Electron Emission Cathode Array Based on Metal Molybdenum Substrate and Its Fabrication Method

ActiveCN105551910BGood lookingImprove adhesionDischarge tube/lamp detailsCold cathode manufactureHigh rateField electron emission

The invention discloses a field electron emission cathode array based on a molybdenum substrate and a preparation method thereof. According to the invention, an etching mask is firstly formed on a molybdenum substrate; then high density plasma dry etching is carried out to the molybdenum substrate to form molybdenum pointed cones. The molybdenum pointed cones are directly formed on the substrate; the problem of poor adhesion with underlay is thoroughly solved; heavy current and strong electric field can be borne; high rate isotropic etching is carried out to the molybdenum body material through the high density plasma dry etching method; therefore large area appearance accordant molybdenum pointed cone arrays can be obtained at the same time; large area even emission can be realized; only primary etching is contained in the manufacturing process of the field electron emission cathode array; the pointed cone centers and gate hole centers are automatically aligned without deflection; compared with the prior art, the technical solution of the invention is featured by few procedures, high efficiency, simplicity and low cost and is applicable to large scale preparation.

Owner:PEKING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com