Preparation method of tungsten nickel iron alloy metallographic phase

A technology of tungsten-nickel-iron alloy and tungsten alloy, which is applied in the field of material surface structure measurement, can solve problems such as difficulty in precise control of corrosive agent concentration and corrosion time parameters, harm to human health and the environment, and complicated corrosion process, so as to improve grinding efficiency and solve Difficult to recover, clear and complete metallographic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

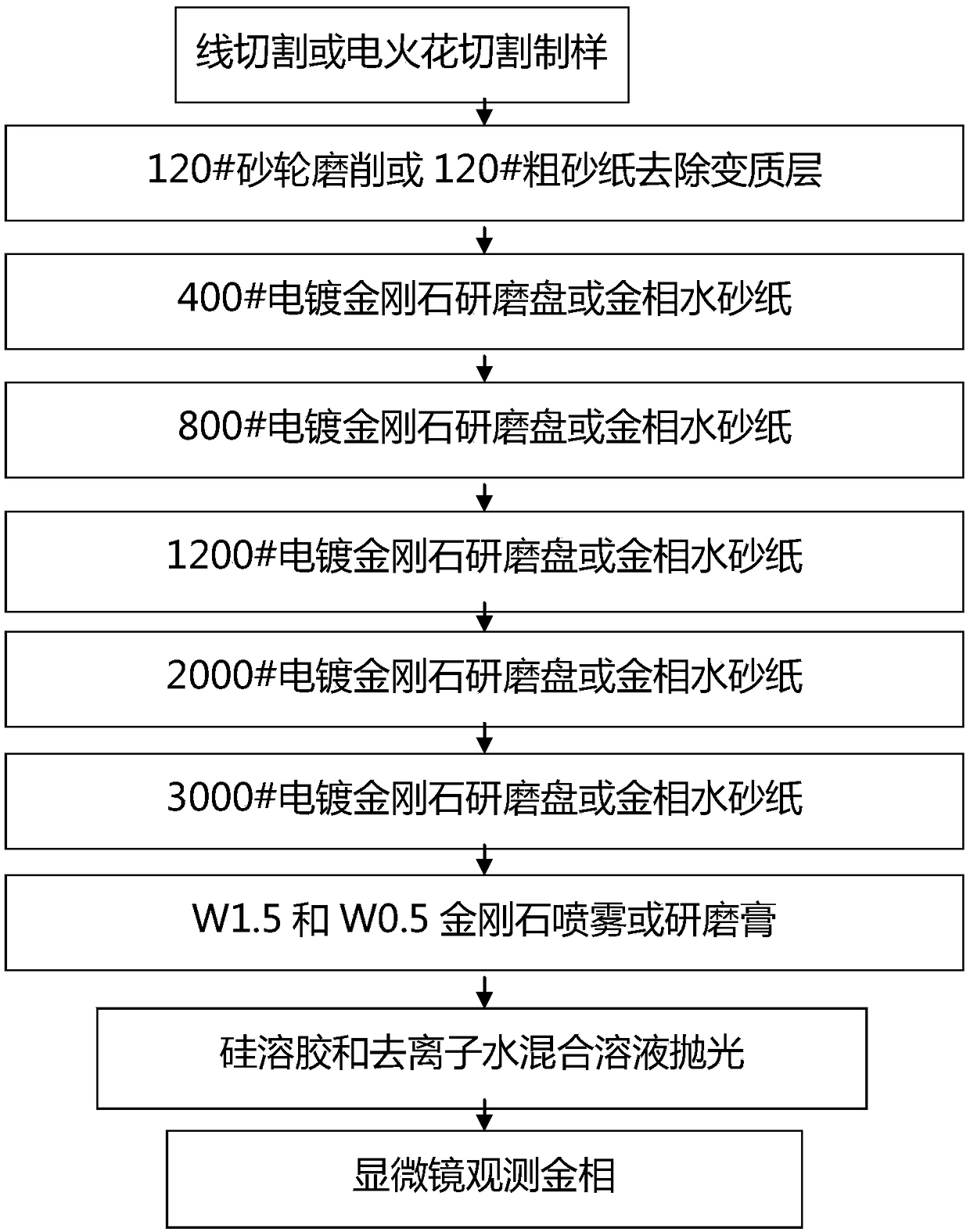

[0021] Such as figure 1 Shown, a kind of tungsten-nickel-iron alloy metallographic preparation method of the present invention, raw material is 95W-3.5Ni-1.5Fe, comprises the following steps:

[0022] The raw material is cut into a sample with a diameter of Φ10×thickness of 7mm by EDM, and the surface metamorphic layer is quickly removed by grinding with a 120# diamond grinding wheel, and the removal depth is 0.3mm.

[0023] Set the sample in an epoxy resin fixture with a diameter of 30mm and a height of 20mm, and use 400#, 800#, and 1200# metallographic water sandpaper to roughly grind the surface of the sample in turn on the grinding and polishing machine, and the grinding line speed is 3.6m / s. The grinding pressure is 15kPa, and the effective grinding time of sandpaper of each particle size is 8min; then, the metallographic water sandpaper of 2000#, 3000#, 5000# is used to finely grind the surface of the sample in turn, the grinding line speed is 1.5m / s, and the grinding pr...

Embodiment 2

[0026] Such as figure 1 Shown, a kind of tungsten-nickel-iron alloy metallographic preparation method of the present invention, raw material is 95W-3.5Ni-1.5Fe, comprises the following steps:

[0027] The raw material is cut into a sample with a diameter of Φ15×thickness 10mm by EDM, and the surface metamorphic layer is quickly removed by milling to a depth of 1mm.

[0028] Set the sample in an epoxy resin fixture with a diameter of 30mm and a height of 20mm, and then use 400#, 800#, 1200#, 2000#, 3000# electroplated diamond grinding discs to grind the sample on a polishing machine. The pressure is 11kPa, the grinding speed is 1.5m / s, and the effective grinding time of each particle size of electroplated diamond grinding disc is 15min. After grinding, the sample is ground with W1.5, W0.5 diamond spray or diamond grinding paste respectively. The linear speed is 3m / s, the grinding pressure is 20kPa, and when the particle size of the abrasive is changed during the grinding proce...

Embodiment 3

[0031] Such as figure 1 Shown, a kind of tungsten-nickel-iron alloy metallographic preparation method of the present invention, raw material is 95W-3.5Ni-1.5Fe, comprises the following steps:

[0032]The raw material is cut into a sample with a diameter of Φ15×thickness of 7mm by electric discharge, and the surface metamorphic layer is quickly removed by a 120# diamond grinding wheel, and the removal depth is 0.5mm.

[0033] Set the sample in an epoxy resin fixture with a diameter of 30mm and a height of 20mm, and then use 400#, 800#, 1200#, 2000#, 3000# electroplated diamond grinding discs to grind the sample on a polishing machine. The pressure is 15kPa, the grinding speed is 2.1m / s, and the effective grinding time of each particle size of electroplated diamond grinding disc is 15min to ensure that the surface of each sample is ground flat. After grinding, use W1.5 and W0.5 diamond spray to control the sample Rough polishing is performed on the workpiece, the polishing line...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com