Edge closing process for integrated woven covered stent

A covered stent, an integrated technology, is applied in the field of medical devices to achieve the effects of outstanding creativity and novelty, improved support performance and anti-slip performance, and strong process practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the present invention more obvious and understandable, the preferred embodiments are described in detail as follows in conjunction with the accompanying drawings:

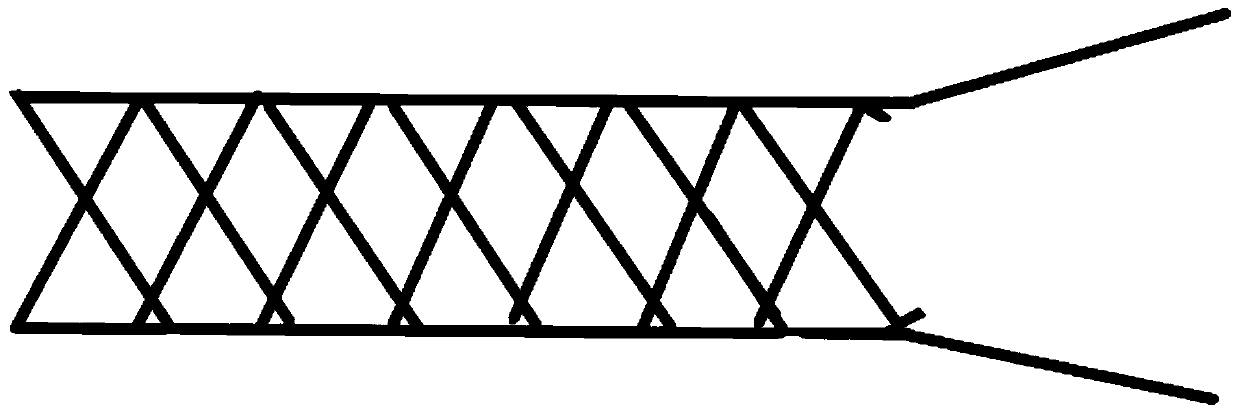

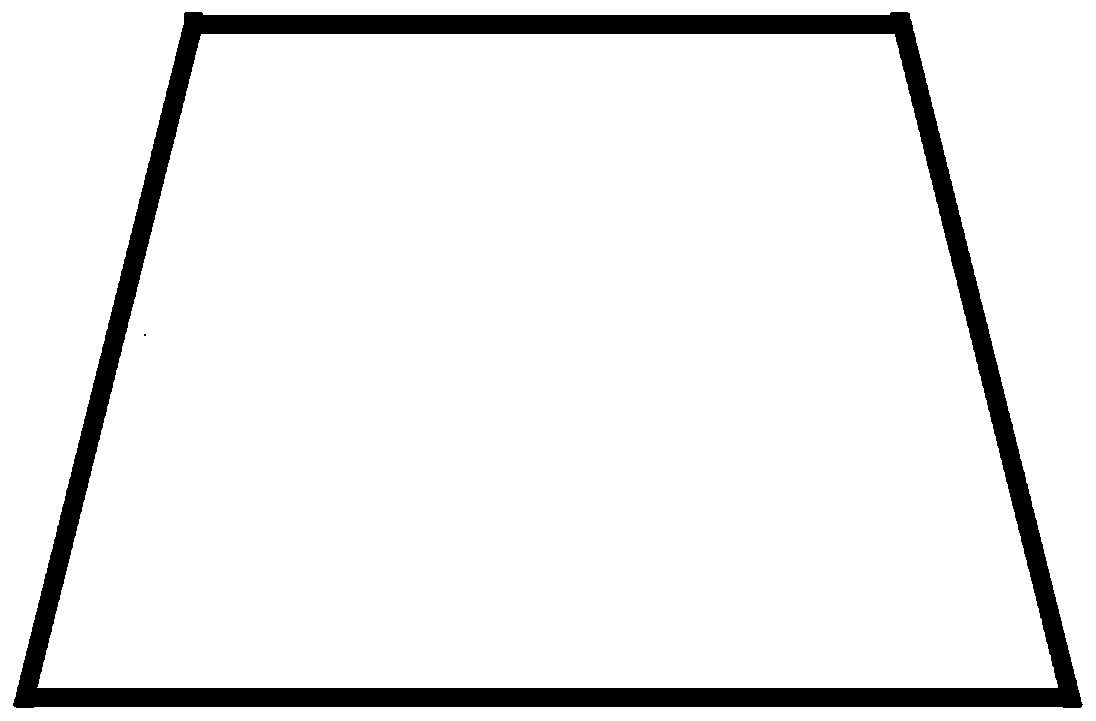

[0028] Such as Figure 1-2 As shown, the present invention provides an integrated braided film-covered stent edge trimming process, including the initial edge trimming process and the end end edge trimming process; including the following steps:

[0029] Step 1: Use a frustum-shaped braiding mold instead of a cylindrical mold at the initial stage of weaving, and only use metal fiber weaving at the initial stage of weaving to obtain the initial end bracket;

[0030] Step 2: When the stent is woven into the cylindrical part, the polymer fiber or yarn participates in the weaving;

[0031] Step 3: When the stent graft is woven to an effective length, the polymer fibers or yarns therein no longer participate in weaving, while the metal fibers therein continue to weave forward;

[0032] Step 4: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com