One-piece braided film-covered stent edge finishing process

A covered stent, an integrated technology, is applied in the field of medical devices to achieve the effects of outstanding creativity and novelty, strong technological practicability, and improved support performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the present invention more obvious and understandable, the preferred embodiments are described in detail as follows in conjunction with the accompanying drawings:

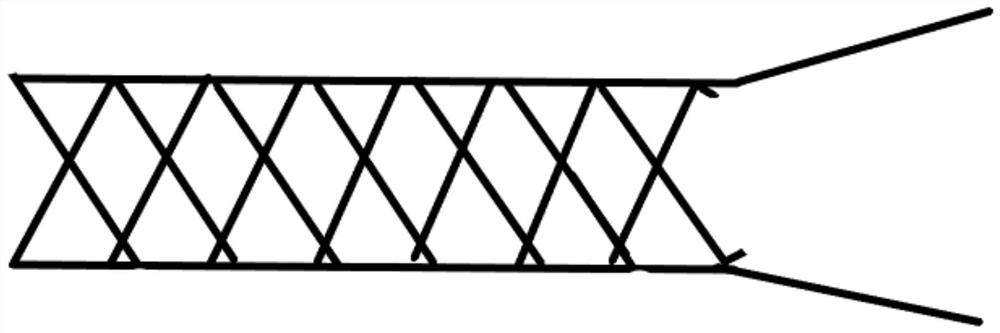

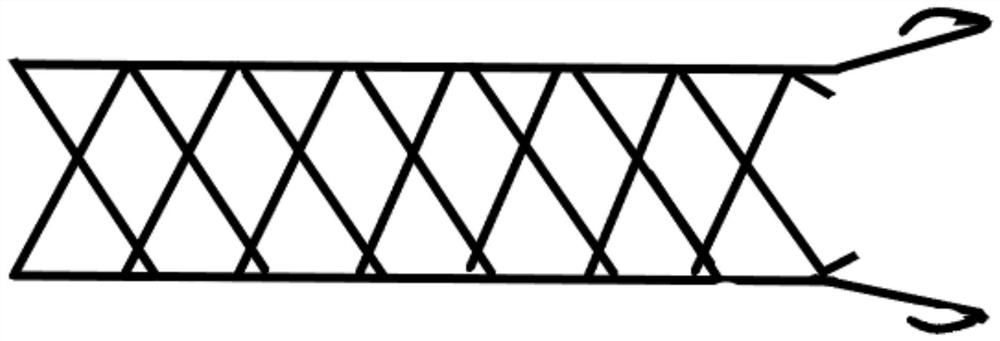

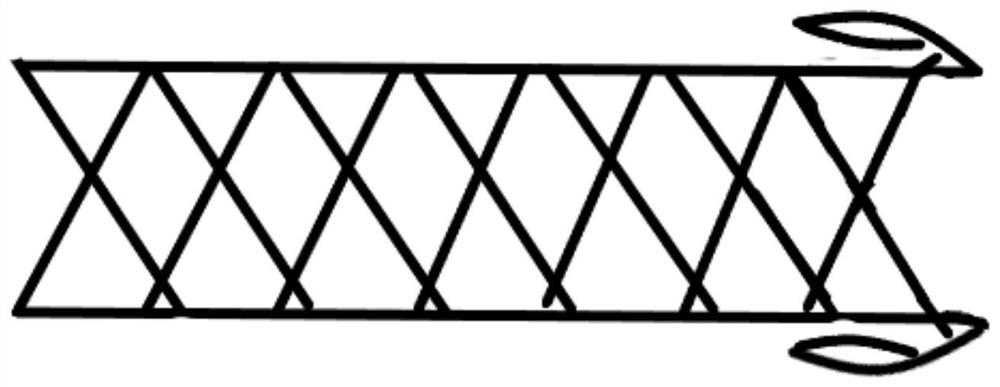

[0037] Such as Figure 1-4 As shown, the present invention provides an integrated braided film-covered stent edge trimming process, including the initial edge trimming process and the end end edge trimming process; including the following steps:

[0038] Step 1: In the initial stage of weaving, a frustum-shaped weaving mold is used instead of a cylindrical mold. In the initial stage of weaving, only polymer yarn is used to weave to obtain a coating;

[0039] Step 2: When the film is woven to the cylindrical part, the wire participates in the weaving;

[0040] Step 3: When the stent graft is woven to the effective length, the metal wire in it will not continue to participate in weaving, and the polymer yarn in it will continue to weave forward to obtain the stent graft;

[0041] Step 4: Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com