Process system for producing crude phenol by decomposing net sodium phenolate by using heating furnace flue gas

A technology of heating furnace and sodium phenolate, which is applied in the field of coking, can solve the problems of small coal tar processing equipment system capacity, affecting the normal production and development of enterprises, and unable to produce crude phenol products, etc., to meet the national environmental protection requirements and practicality Strong, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

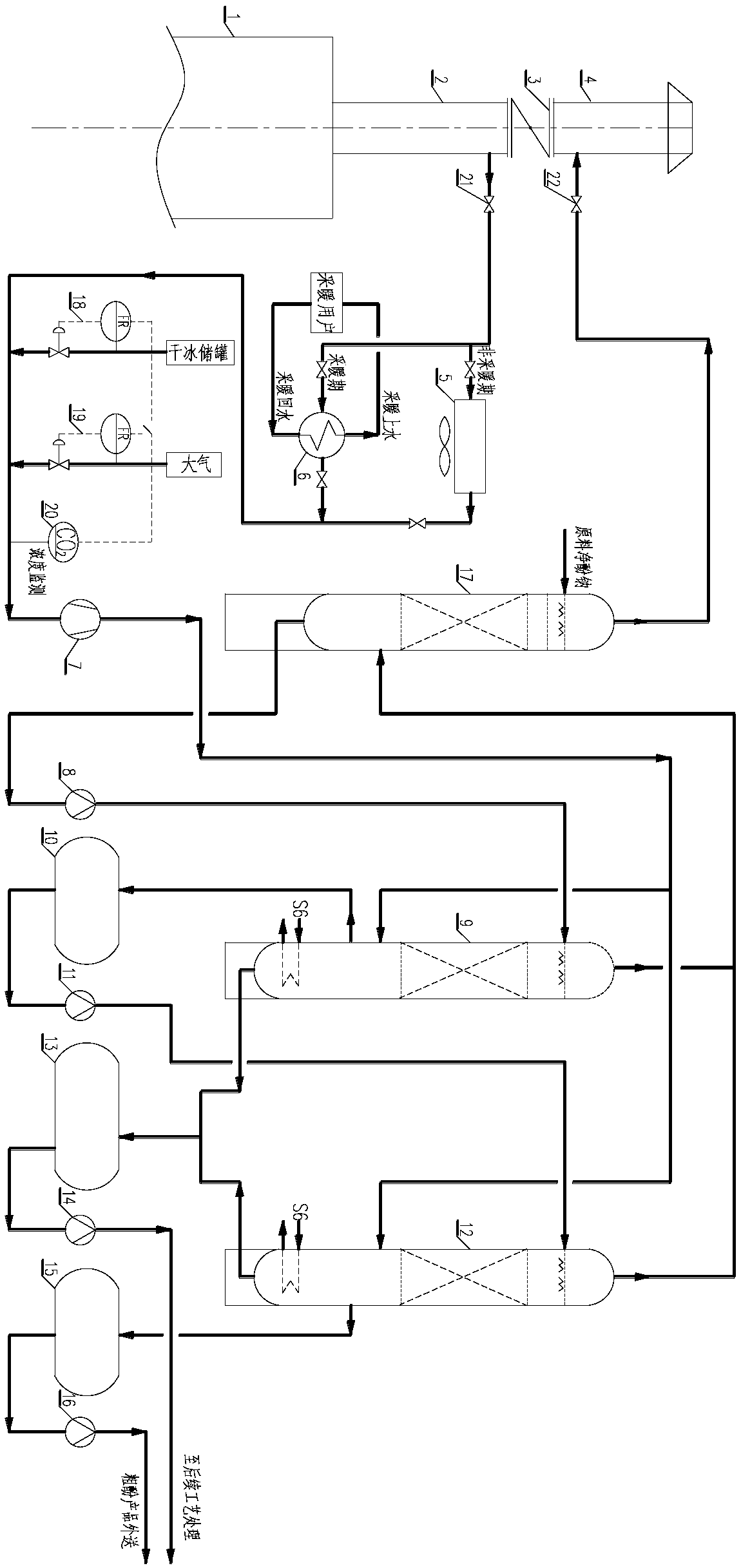

[0032] See figure 1 As shown, the present invention relates to a process system for producing crude phenol by utilizing heating furnace flue gas to decompose net sodium phenate, comprising a traffic valve 3, a flue gas cooling system, a flue gas concentration regulating pressurization system and a phenoxide decomposition system, the traffic The valve 3 is arranged on the chimney of the heating furnace 1 to divide the chimney into an upper section 4 of the chimney and a lower section 2 of the chimney, the top of the lower section 2 of the chimney is provided with a flue gas outlet, and the bottom of the upper section 4 of the chimney is provided with a flue gas inlet;

[0033] The flue gas cooling system is composed of a flue gas air cooler 5 and a flue gas / heating water heat exchanger 6, wherein the flue gas air cooler 5 and the flue gas / heating w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com