High efficiency extracting method for sophora alopecuroide total alkaloid

An extraction method, the technology of Sophora sophora, applied in the direction of alkaloids, alkaloids, chemical instruments and methods, etc., can solve the problems that the extraction rate is less than 3%, only 1.5-2.5%, and the process is complicated, so as to improve the pressure of environmental treatment , High extraction yield of total alkali and strong process practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

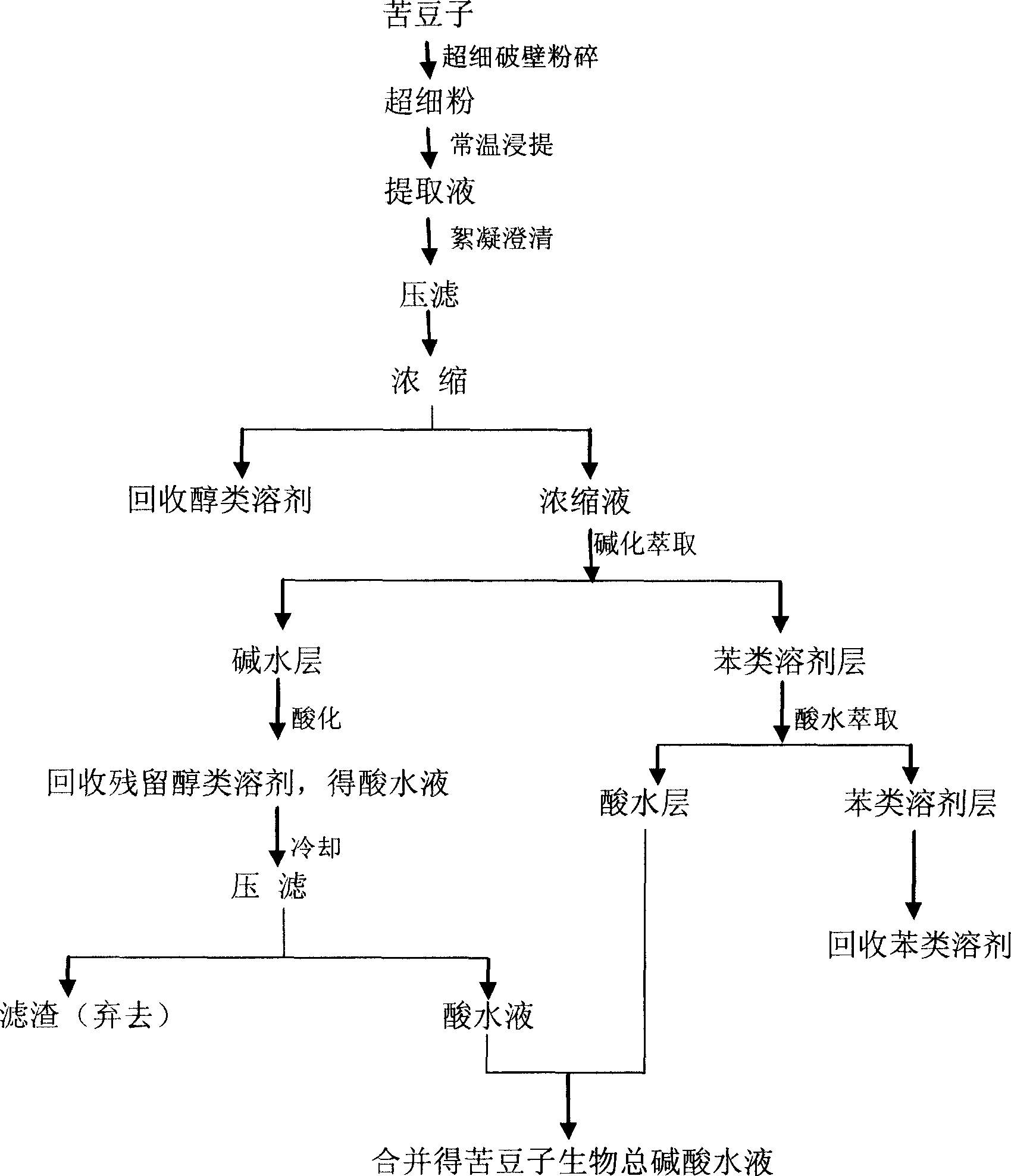

[0044] Such as figure 1 As shown, the specific extraction process steps are as follows:

[0045] (1) Ultra-micro-broken wall crushing: ultra-micro-broken wall-broken Sophora alopecuroides is crushed to 300 mesh ultra-fine wall-broken powder;

[0046] (2) Extraction at normal temperature: put the ultrafine broken wall powder of Sophora aphorae into the extraction tank, add a mixed solution of acidic water and methanol (containing 0.1% hydrochloric acid ), close the extraction tank, continuously stir and extract for 4 hours, draw this extract into a filter press for pressure filtration, and rinse the filter residue with methanol equivalent to 10% of the volume of the extraction solvent, and then draw the filtrate into a clarification tank;

[0047] (3) Flocculation and clarification: add 1% traditional Chinese medicine flocculation clarification agent (v / v) to the filtrate, stir continuously for 20 minutes and then let it stand for 4 hours, pump the supernatant into the concent...

Embodiment 2

[0054] The efficient method for the total alkaloids of Sophora sophora, the specific extraction process steps are as follows:

[0055] (1) Ultrafine broken wall crushing: the ultrafine broken wall of Sophora Sophorae is crushed to 400 mesh ultrafine broken wall powder;

[0056] (2) Normal temperature leaching: put the ultrafine broken wall powder of Sophora aphorae into the extraction tank, add the mixed solution of acidic water and ethanol (containing 0.1% acetic acid in the volume ratio of 2 times the mass of the ultrafine broken wall powder of Sophora sophora to the volume ratio of the extraction solvent) ), close the extraction tank, continue stirring and leaching for 6 hours, draw this extract into a filter press for pressure filtration, and wash the filter residue with 20% ethanol equivalent to the volume of the extraction solvent, and then draw the filtrate into the clarification tank;

[0057] (3) Flocculation and clarification: add 2% (v / v) fruit juice clarifier 101 t...

Embodiment 3

[0064] The efficient extraction method of total alkaloids of Sophora sophora, the specific extraction process steps are as follows:

[0065] (1) Ultra-micro-broken wall crushing: ultra-micro-broken wall-broken Sophora alopecuroides is crushed to 500 mesh ultra-fine wall-broken powder;

[0066] (2) Normal temperature leaching: put the ultrafine broken wall powder of Sophora aphorae into the extraction tank, add the mixed solution of acidic water and methanol (containing 0.1% sulfuric acid in the ratio of 3 times the mass of the ultrafine broken wall powder of Sophora sophora to the volume ratio of the extraction solvent) ), close the extraction tank, continue stirring and leaching for 6 hours, draw this extract into a filter press for pressure filtration, and rinse the filter residue with a small amount of methanol, then pump the filtrate into the clarification tank;

[0067] (3) Flocculation and clarification: add 2% (v / v) ZTC natural clarifier to the filtrate, stir continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com