Rapid evaluation method for electrochemical performance of silicon negative electrode material

An evaluation method, electrochemical technology, applied in nanotechnology for materials and surface science, analysis of materials, material analysis using wave/particle radiation, etc., can solve problems such as strong surface activity, small particles, and large specific surface area , to achieve the effects of short time-consuming, strong process practicability, and reduced floating phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

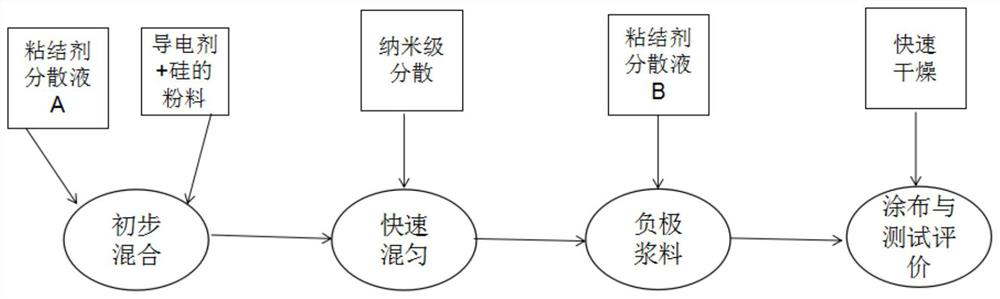

[0030] The rapid evaluation method of the electrochemical performance of the silicon negative electrode material of the present embodiment, such as figure 1 shown, including the following steps:

[0031] 1. First, add nano-silica powder, acetylene black and carbon nanotube conductive paste to the dispersion of sodium carboxymethyl cellulose, and after preliminary mixing, transfer to the machine with the function of airflow shear force generated by speed difference In the dispersing equipment, the rotating speed is 30 m / s, and the time is 30 seconds, and rapid mixing is carried out to realize nano-scale dispersion, and slurry A is obtained;

[0032] 2. Then add the SBR dispersion liquid rich in carboxyl groups on the surface to slurry A, and mix at a speed of 560 rpm for about 30 minutes to obtain slurry B;

[0033] 3. Then apply the slurry B on the copper current collector, and dry it quickly through an infrared heater and a blast oven;

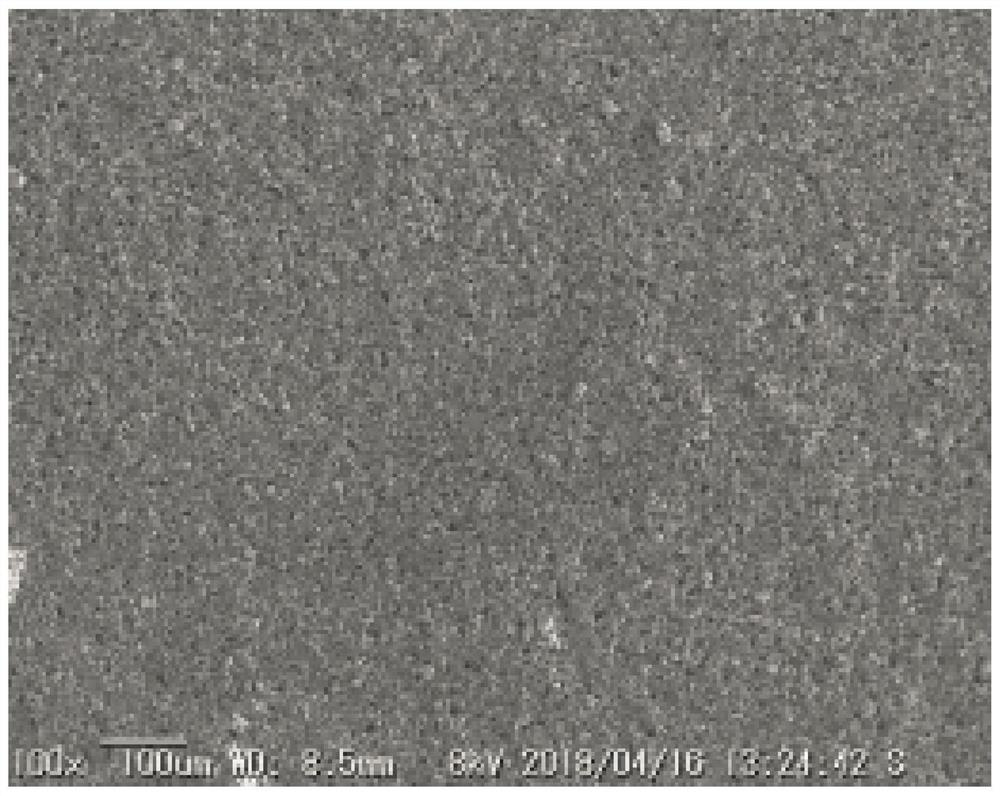

[0034] 4. After the pole piece is pu...

Embodiment 2

[0040] The rapid evaluation method of the electrochemical performance of the silicon negative electrode material of the present embodiment, such as figure 1 shown, including the following steps:

[0041] 1. First, add nano-silica powder and graphene conductive paste to the dispersion of carboxymethyl cellulose lithium. After preliminary mixing, transfer it to the beater equipment with ultrasonic dispersion function. The time is more than 1h. Mix to achieve nanoscale dispersion to obtain slurry A;

[0042] 2. Then add the PAA dispersion liquid rich in carboxyl groups on the surface to slurry A, and mix at a speed of 560 rpm for about 30 minutes to obtain slurry B;

[0043] 3. Then apply the slurry B on the copper current collector, and dry it quickly through an infrared heater and a blast oven;

[0044] 4. After the pole piece is punched into a pole piece with a certain diameter and processed, the CR series button battery is assembled for testing and evaluation.

[0045] Eac...

Embodiment 3

[0050] The rapid evaluation method of the electrochemical performance of the silicon negative electrode material of the present embodiment, such as figure 1 shown, including the following steps:

[0051]1. First, add silicon powder, silicon oxide, and carbon black conductive paste to the dispersion of carboxymethyl cellulose. After preliminary mixing, transfer to the ball milling equipment with ultra-small particle size ball milling beads. Time For more than 3h, mixing is carried out to realize nanoscale dispersion, and slurry A is obtained;

[0052] 2. Then add the sodium alginate binder into the slurry A, and mix at a speed of 560rpm for about 30 minutes to obtain the slurry B;

[0053] 3. Then apply the slurry B on the copper current collector, and dry it quickly through a blast oven;

[0054] 4. After the pole piece is punched into a pole piece with a certain diameter and processed, the CR series button battery is assembled for testing and evaluation.

[0055] Each raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com