Medium simulation fluid and method of selecting steel for hydraulic support based on pitting resistance

A technology of hydraulic support and simulating liquid, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of cumbersome sample production, long experimental period, high experimental cost, and achieve fast and convenient judgment and short period. , the effect of simple experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Implementation example 1

[0022] The method for selecting steel for hydraulic supports based on the pitting resistance performance provided in this example, the specific operation steps are as follows:

[0023] The specific operation steps are as follows:

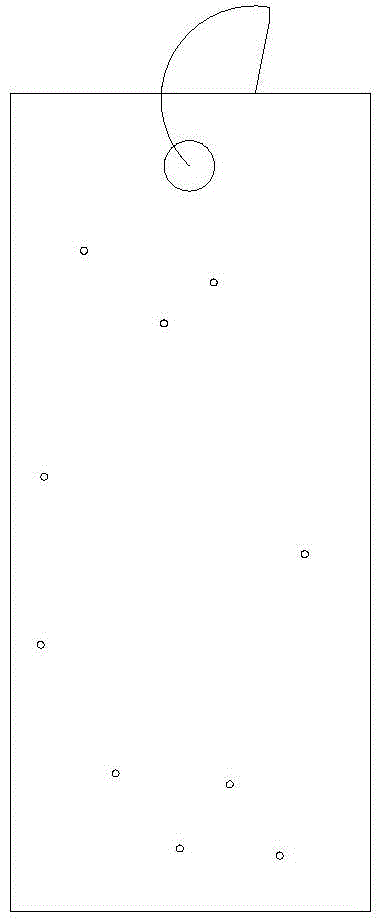

[0024] 1) Sample production: DBT steel and contrast steel 30CrMnSi used for the coal mine mechanical hydraulic support were sampled along the rolling direction, processed into a test piece of 30mm×15mm×2mm, and a suspension hole with a diameter of 2mm was drilled on the test piece, such as figure 1 shown.

[0025] 2) Preparation of medium simulation liquid: emulsifier for coal mine mechanical hydraulic support with a mass fraction of 5%, NaCl with a mass fraction of 1%, and deionized water with a conductivity of less than 2 μs / cm for the rest. The pH of the simulated corrosion solution is controlled as 8 to 12.

[0026] 3) The coal mine machinery hydraulic support steel test piece and the reference steel test pie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com