Method for manufacturing all-polymer plane optical path

A manufacturing method and a technology for a planar optical circuit, which are applied in the field of manufacturing an all-polymer planar optical circuit, can solve the problems of unfavorable high-performance optical waveguide device preparation, increase device scattering loss, and limit the scope of use, and achieve a large and strong replication cost advantage. Compatibility, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

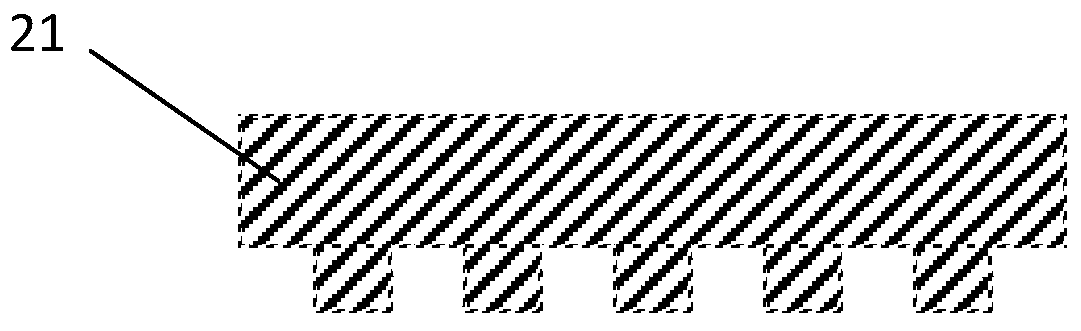

[0052] Such as Figures 1 to 7 As shown, a method for fabricating an all-polymer planar optical path, wherein, Figure 7 It is a flow chart of this embodiment, and the specific steps are as follows:

[0053] Step (1), testing the optical properties of the polymer materials 31, 41, 51, using the waveguide theory of Maxwell's equations to conduct mode analysis and device propagation characteristic simulation. Obtain the device structure in the light wave single-mode or multi-mode transmission state. Then, according to the simulation parameters of the device, use computer-aided design tools to draw the mask layout of the device, mark the distribution of the planned device, and process and manufacture the mask plate for lithography.

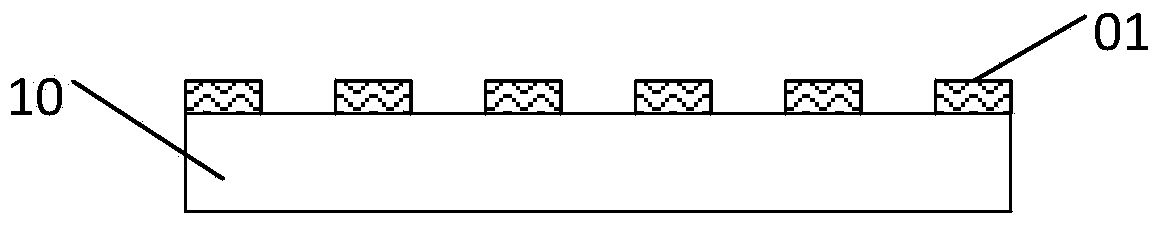

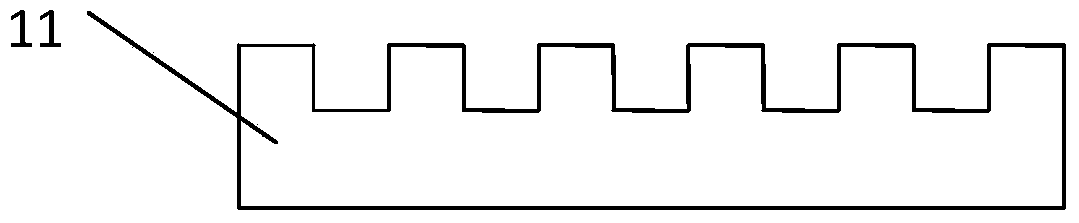

[0054] Step (2), spin-coat AZ5214 photoresist 01 on the conductive silicon wafer 10, use Suss MA6 equipped with a broadband light source for photolithography, first select the exposure mode, edit the exposure time, and then perform contact exposure...

Embodiment 2

[0062] The fabrication method of the all-polymer planar optical path of this embodiment still adopts Figure 1 to Figure 7 As an illustration, the specific steps are as follows:

[0063] Step (1), the test obtained cycloolefin material E48R (polymer material 31) has a refractive index of 1.518 at 1550nm, and the polysiloxane material OE-6550 (polymer material 41) has a refractive index of 1.532 at a wavelength of 1550nm . E48R is selected as the cover layer 51, and OE-6550 is used as the optical transmission medium. After simulation calculation, the structural size of single-mode transmission is W=H=5um, that is, when OE-6550 is used as the dielectric to transmit electromagnetic waves with a wavelength of 1550nm, the width and height of the core cross-sectional size of the single-mode transmission are both 5um.

[0064] Step (2), spin coating AZ5214 photoresist 01 on the silicon wafer 10, the spin coating speed is 4000rpm, the time is 30s, the pre-baking temperature is 95 de...

Embodiment 3

[0072] Step (1), test the refractive index of polymethacrylate PMMA (polymer material 31) at 1550nm is 1.479, the refractive index of polysiloxane material OE-6550 (polymer material 41) at 1550nm wavelength 1.532. PMMA is selected as the upper reflection layer 51, and OE-6550 is used as the light wave transmission medium. After simulation calculation, the structural size of single-mode transmission is W=H=3um.

[0073] Step (2), spin-coat AZ5214 photoresist 01 on the silicon wafer 10, the spin-coating speed is 4000rpm, the time is 30s, the pre-baking temperature is 95 degrees, the time is 90s, the exposure time is 6.8s, and after developing for 45s, no The cross-linked photoresist is removed in the developer, and finally the pattern structure of the mask is obtained on the photoresist 01.

[0074] Step (3), harden the film at a temperature of 110 degrees for 90 seconds, put it into the deep silicon etching equipment of STS for dry etching, and then use acetone to ultrasonica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com