Patents

Literature

34results about How to "Improve repair strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

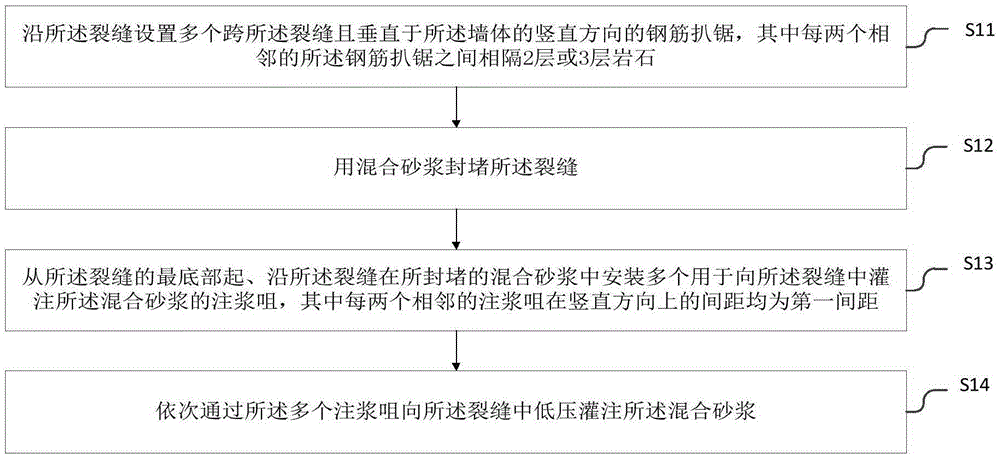

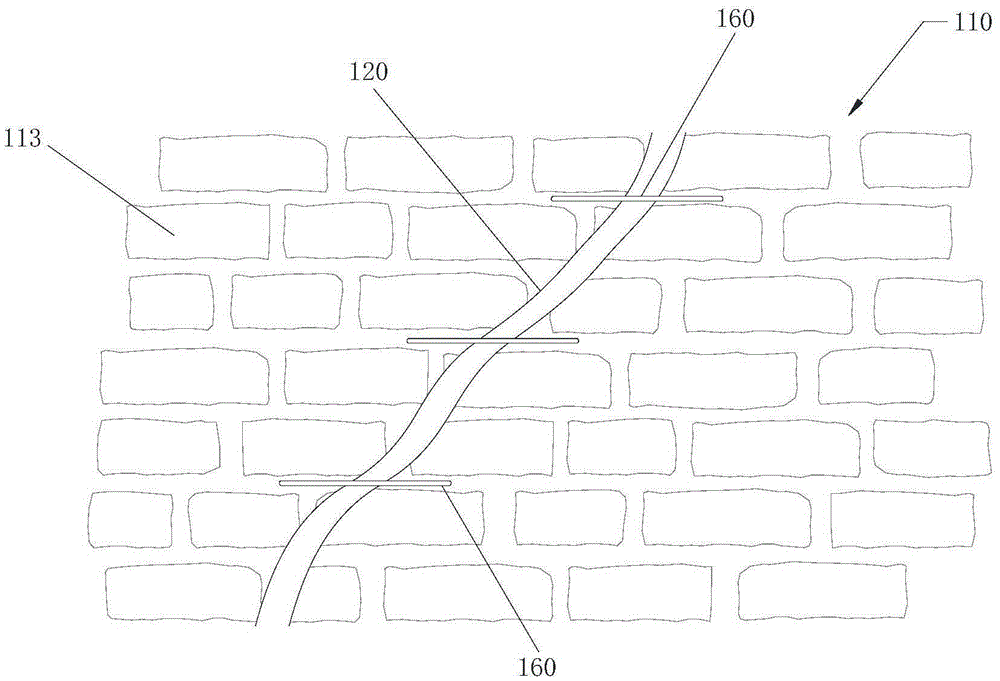

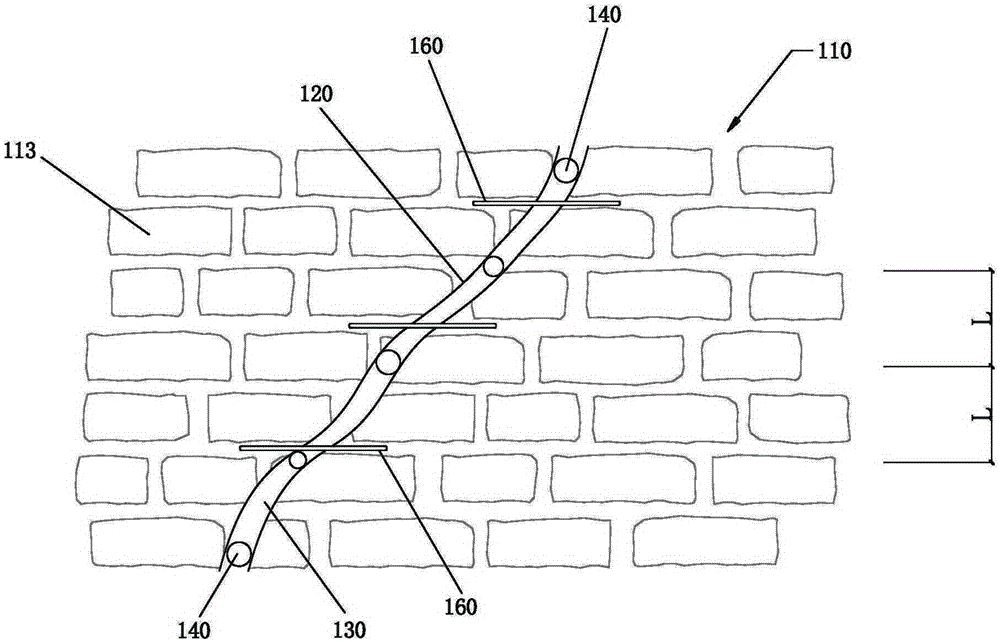

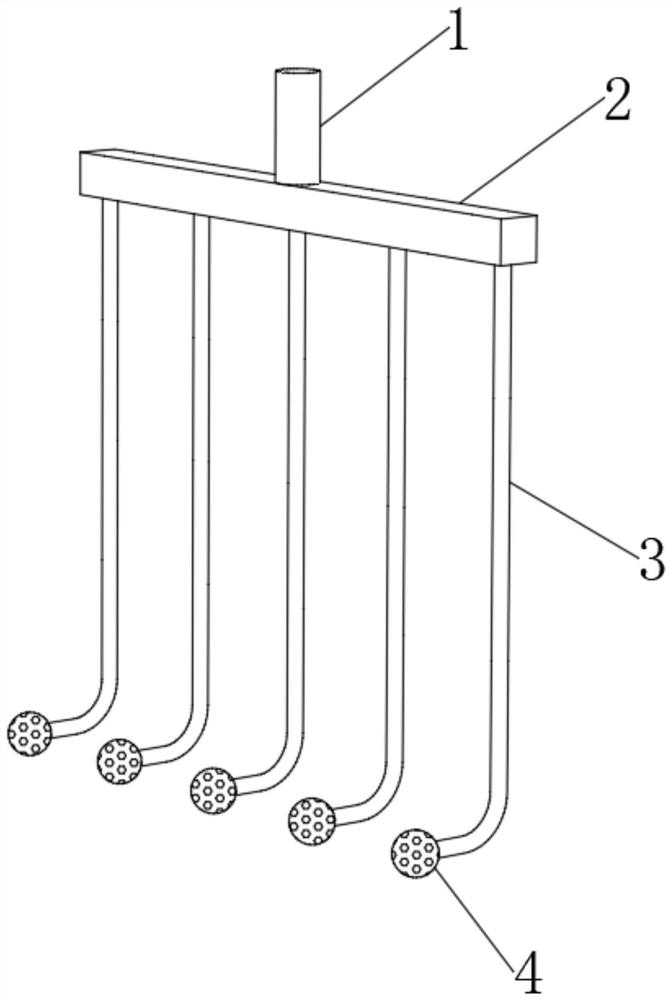

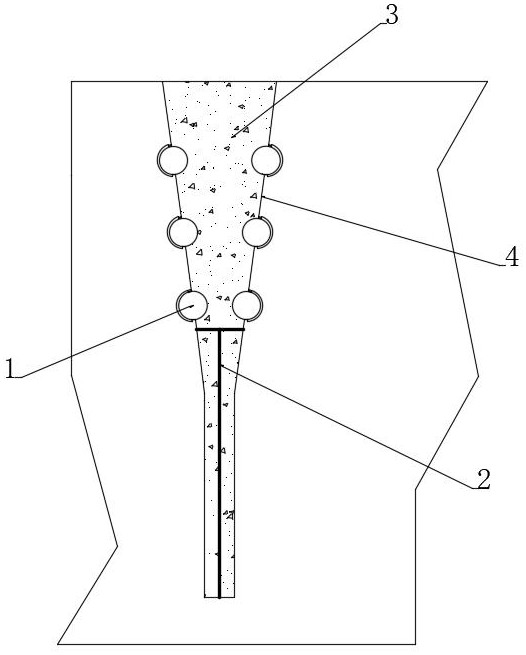

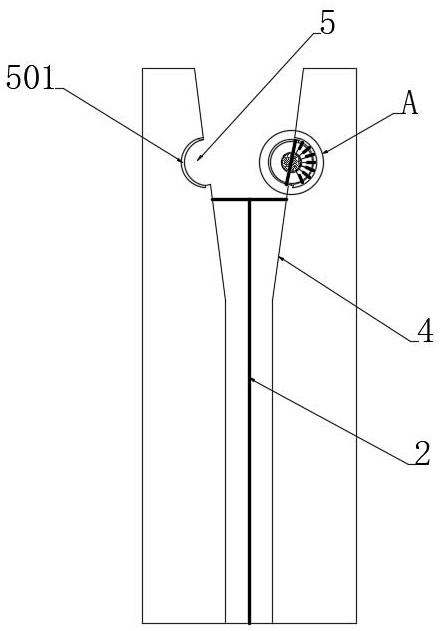

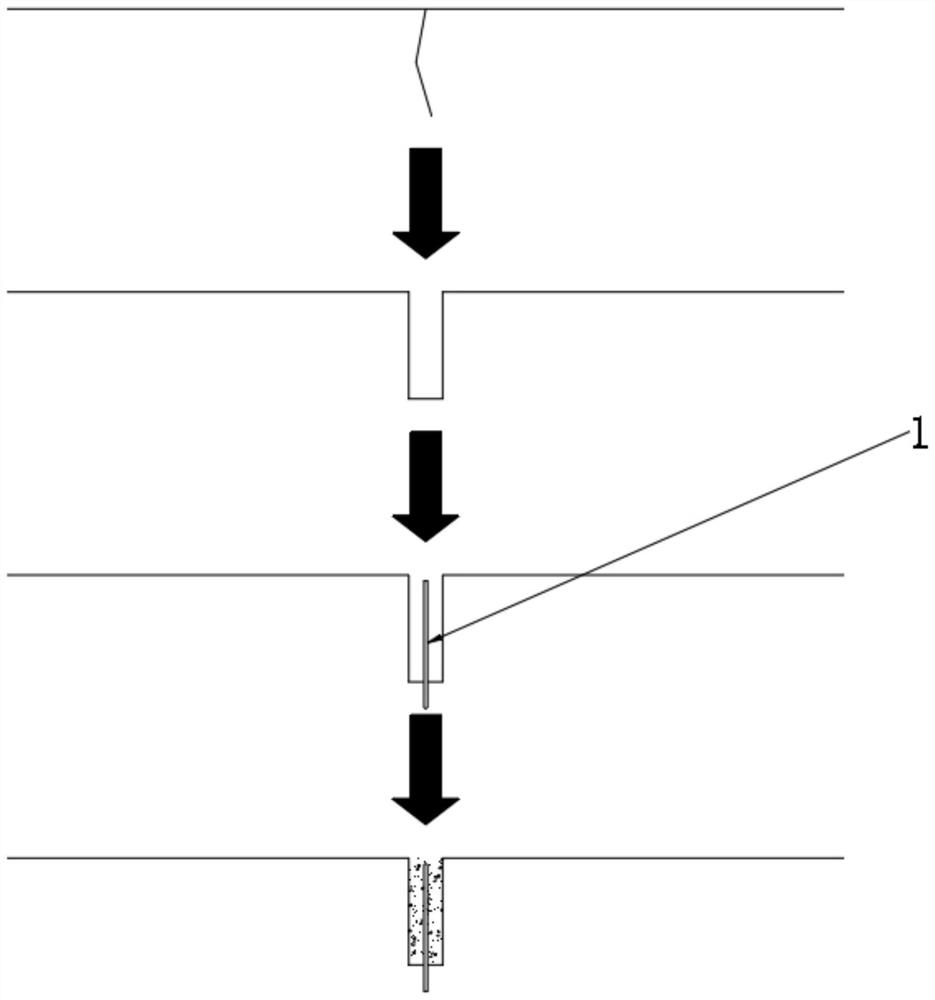

Method for repairing crack in historic building wall

The invention relates to the field of buildings, and particularly provides a method for repairing a crack in a historic building wall. The historic building wall is formed by piling of rock and is provided with the crack extending in the vertical direction, and the width of the crack is larger than 10 mm and smaller than or equal to 30 mm. The method comprises the steps of arranging a plurality of rebar digging saws which cross the crack and are perpendicular to the vertical direction of the wall along the crack, wherein two or three layers of rock exist between every two adjacent rebar digging saws; blocking the crack with composite mortar; installing a plurality of grouting nozzles used for pouring the composite mortar into the crack in the composite mortar used for blocking the crack along the crack from the bottom of the crack, wherein the distance, in the vertical direction, of every two adjacent grouting nozzles is first distance; conducting low-pressure injection of the composite mortar into the crack through the multiple grouting nozzles in sequence.

Owner:SICHUAN DAVID ARCHITECTURAL DESIGN CO LTD

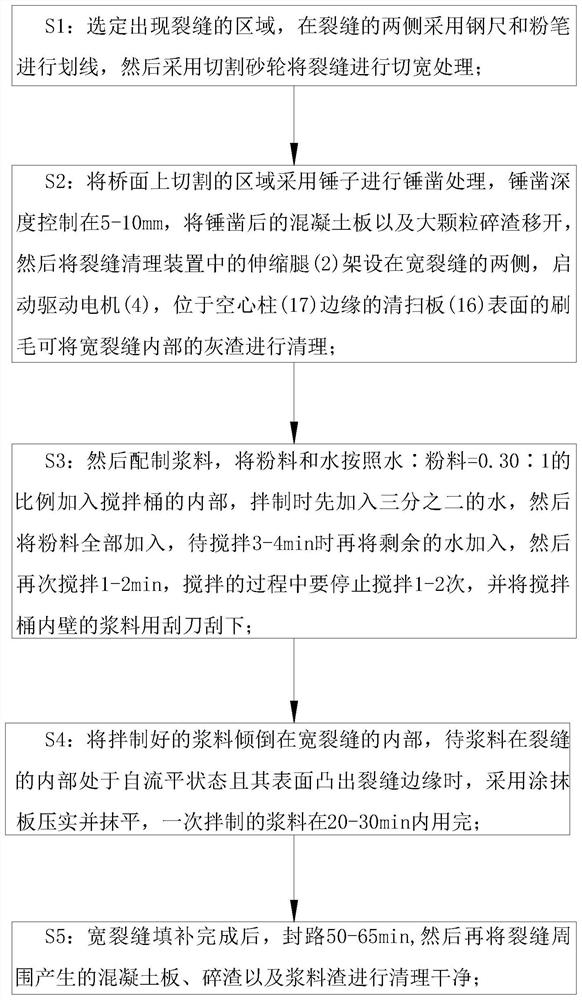

Bridge crack repairing method

InactiveCN111996928AWon't cause flyingEasy to operateBuilding repairsBridge erection/assemblySlagBridge deck

The invention belongs to the technical field of bridge crack repairing, and particularly relates to a bridge crack repairing method which comprises the following steps: S1, selecting an area with a crack, marking lines on two sides of the crack by adopting a steel ruler and chalk, and then carrying out width cutting treatment on the crack by adopting a cutting grinding wheel; and S2, hammering andchiseling an area cut on a bridge deck by adopting a hammer, controlling the hammering and chiseling depth to be 5-10mm, moving away a hammered and chiseled concrete slab and large-particle disintegrating slag, and erecting telescopic legs in a crack cleaning device on two sides of a wide crack. According to the invention, the crack cleaning device is arranged to clean ash and concrete residues in the crack; meanwhile, the crack cleaning device can be used for cleaning cracks with different depths and different widths, a hollow column and a cleaning plate push the cleaned ash to the moving direction of the crack cleaning device, then the ash can be collected through a dust suction pump, the whole process is convenient to operate, the labor is saved, and meanwhile, the dust flying cannot be caused.

Owner:侯小柱

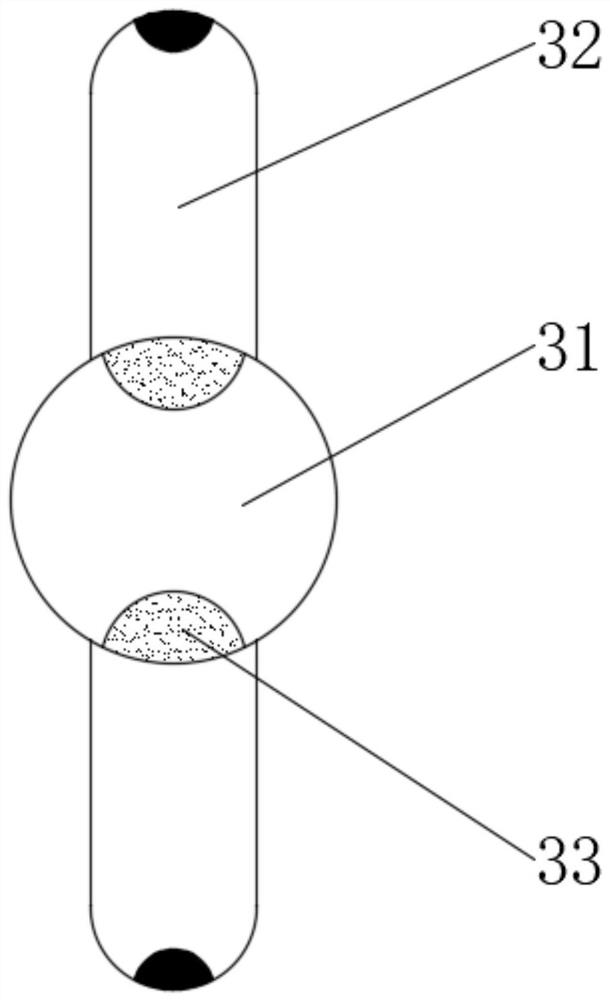

Corrosion-resistant aluminum alloy sectional material

ActiveCN111705290AHigh strengthAccelerated corrosionMolten spray coatingCeramic coatingAlloy substrate

The invention discloses a corrosion-resistant aluminum alloy sectional material and belongs to the technical field of metal material manufacturing. According to the corrosion-resistant aluminum alloysectional material, on the one hand, raw materials of an aluminum alloy substrate can be improved, proportioning and combination of different components are optimized, the strength and the corrosion resistance of the aluminum alloy substrate are enhanced in a whole, and the aluminum alloy substrate is further protected in a mode that a nano ceramic coating covers the surface of the aluminum alloysubstrate; and on the other hand, embedded repair rods are innovatively brought into the aluminum alloy substrate, part of internal stress can be eliminated while the strength of the aluminum alloy substrate is improved, moreover when the nano ceramic coating is corroded or damaged, repair actions of the embedded repair rods is triggered by means of a prone-to-corrosion part, repair magnetic ballsare actively attracted to a corroded position or a damaged position on the basis of a magnetic attraction function to perform repair, further corrosion or damage is avoided, the sectional material issuitable for self-repair under various corrosion conditions, the corrosion resistance of the aluminum alloy substrate is effectively improved, and the service life of the aluminum alloy substrate isprolonged.

Owner:上海芳桦建筑材料有限公司

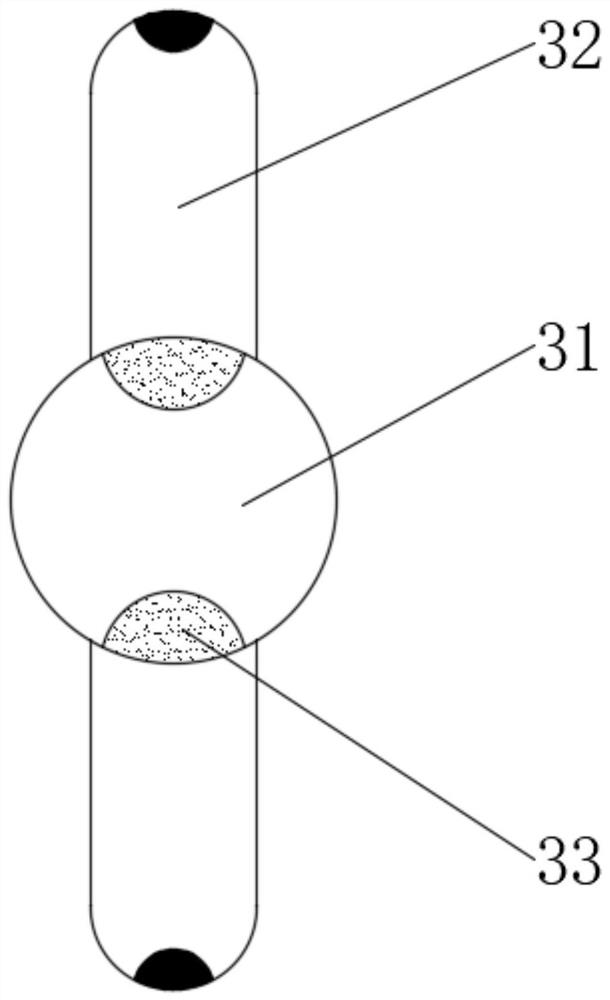

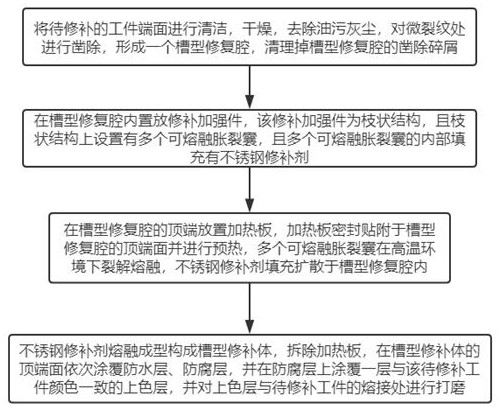

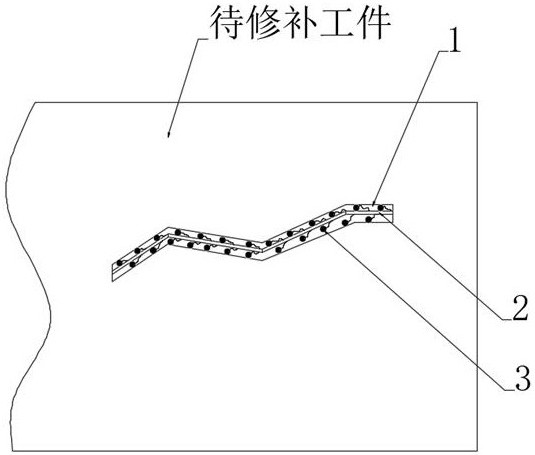

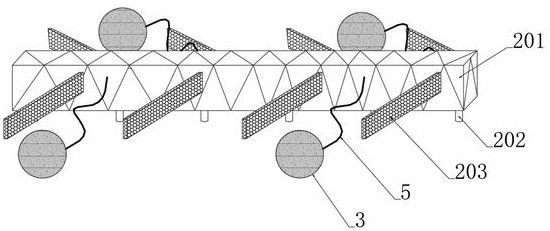

Melting repair method for repairing cracks of stainless steel workpiece

ActiveCN111843375ANot easy to fall offAvoid deformationSS - Stainless steelUltimate tensile strength

The invention discloses a melting repair method for repairing cracks of a stainless steel workpiece and belongs to the technical field of workpiece crack repair. The method comprises the following steps of chiseling away a crack to form a groove type repair cavity; placing a repair reinforcing part with a plurality of meltable cracking bags in the groove type repair cavity, wherein the meltable cracking bags are filled with a stainless steel repair agent; and covering the upper end surface of the groove type repair cavity hermetically by using a heating plate, wherein after heating, the meltable cracking bags in the groove type repair cavity are melted and cracked, the stainless steel repair agent in the meltable cracking bags overflow and fill the groove type repair cavity and form a groove type repair body with the repair reinforcing part, and the groove type repair body embedded with the repair reinforcing part improves the mechanical strength of the whole welding effectively. Meanwhile, by means of a hermetic welding filling method, it is favorable to join the stainless steel repair agent and the inner wall of the groove type repair cavity hermetically. The groove type repair body is unlikely to fall from a repaired part and is unlikely to deform and crack.

Owner:中山市方威金属科技有限公司

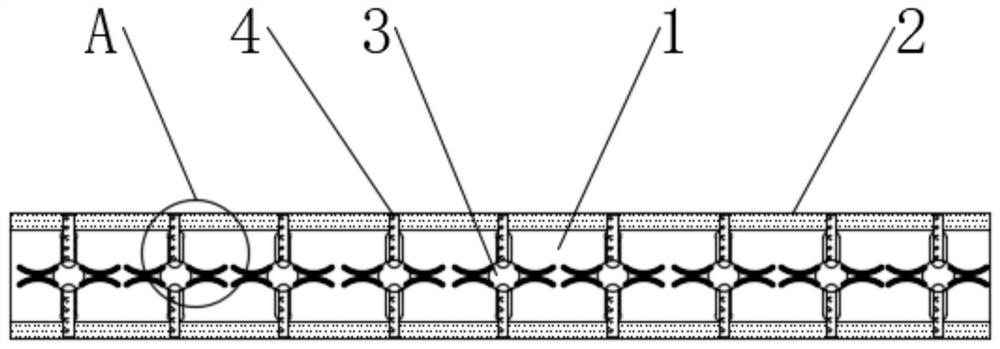

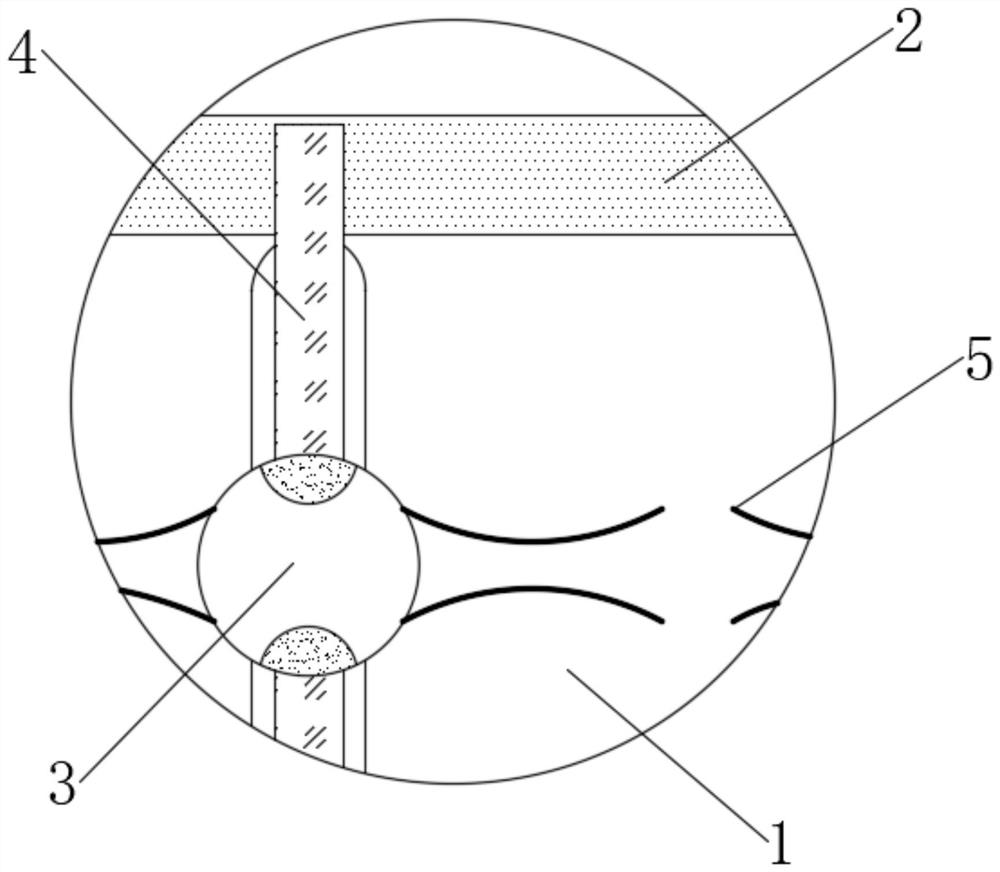

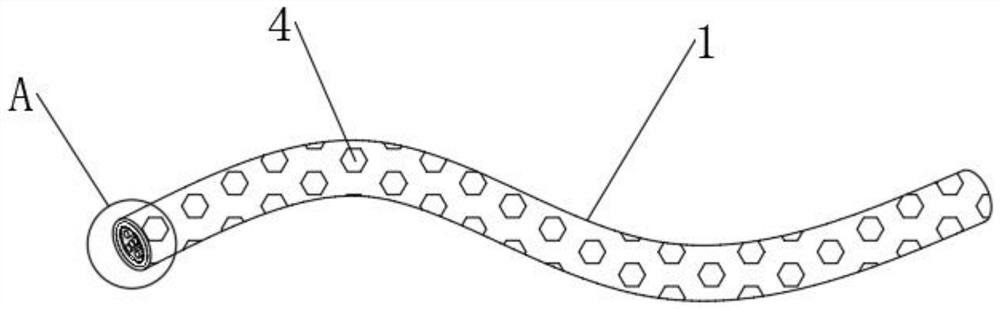

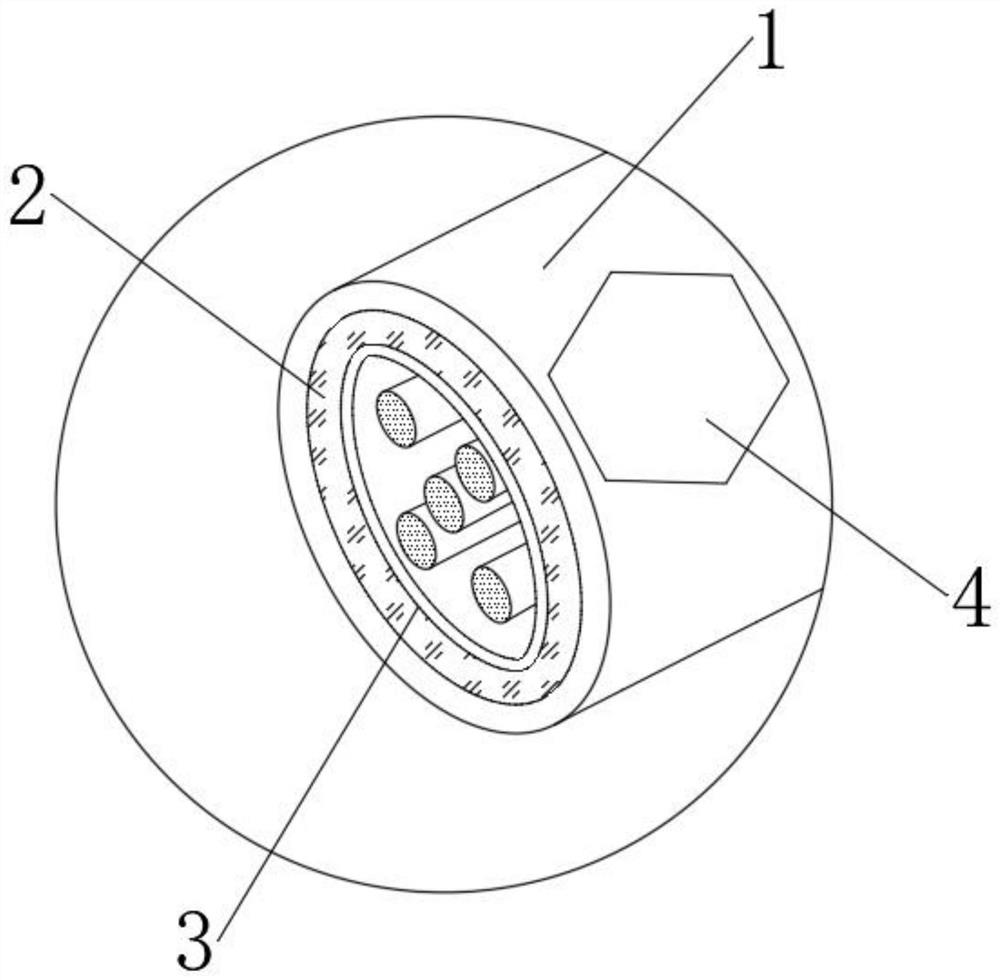

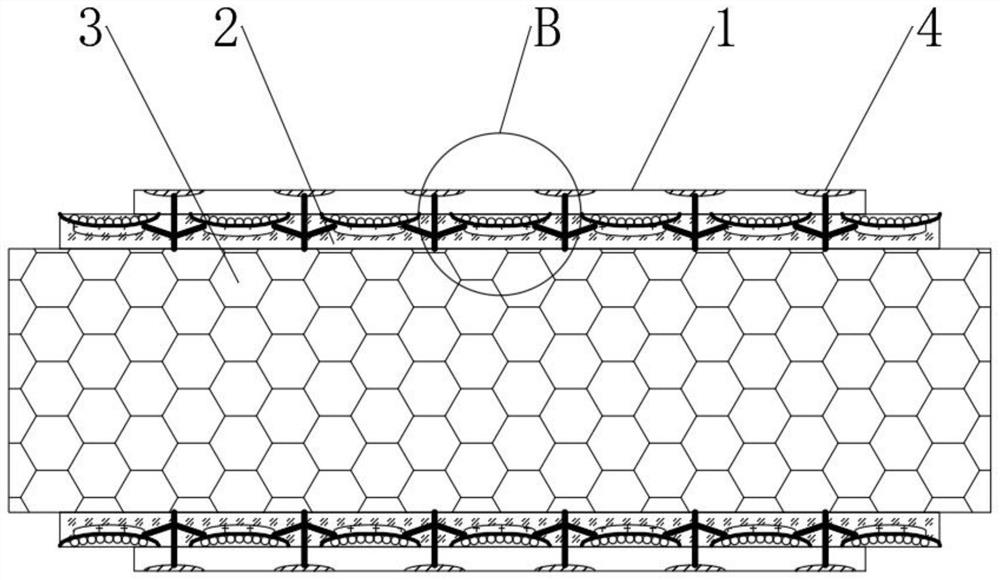

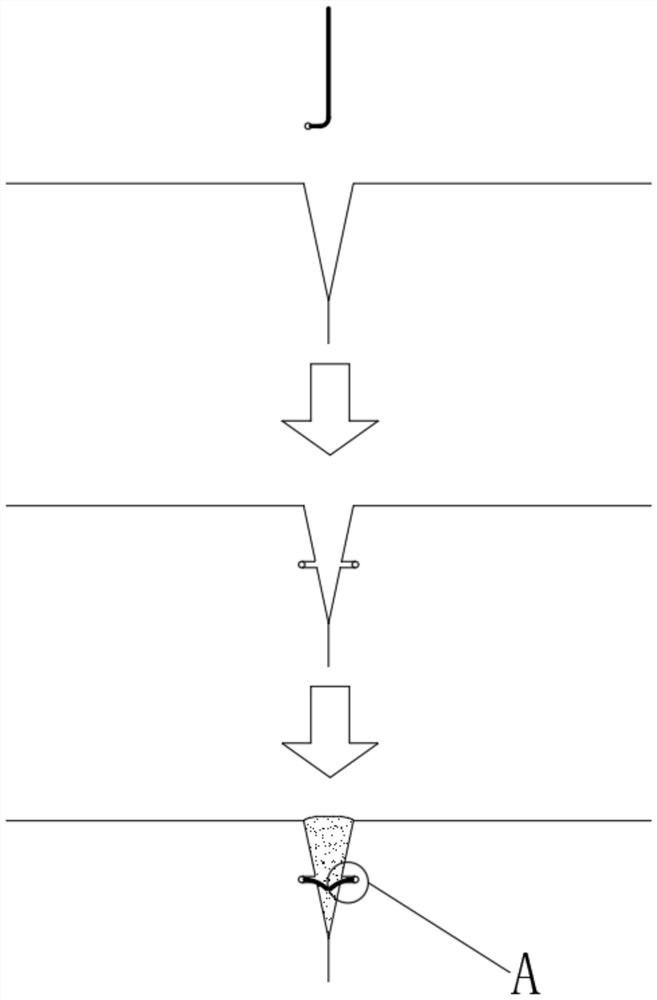

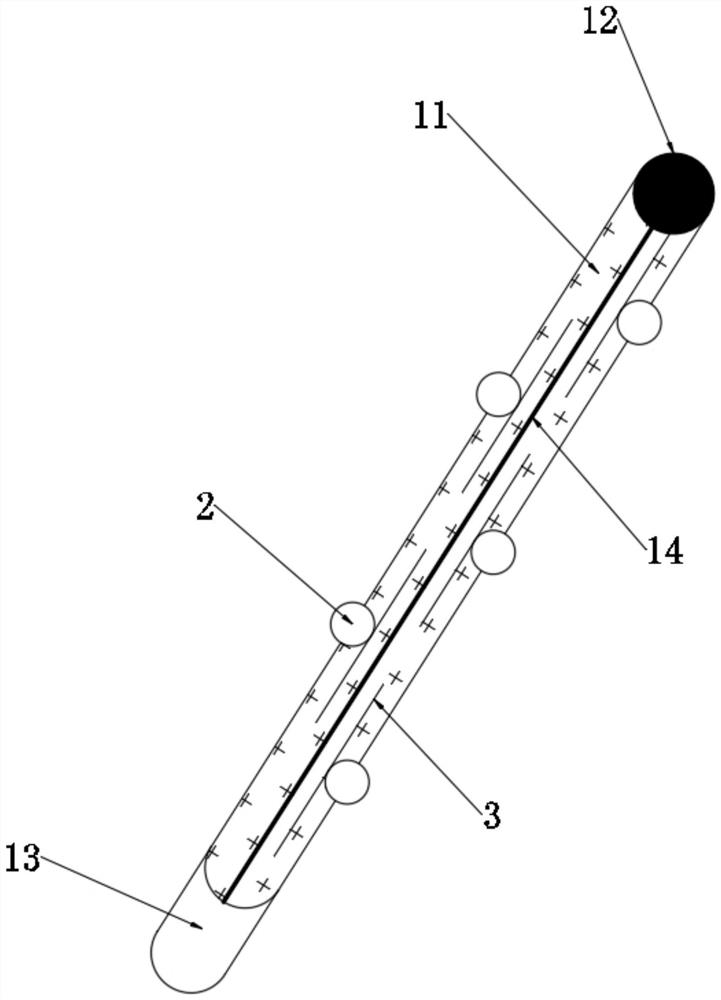

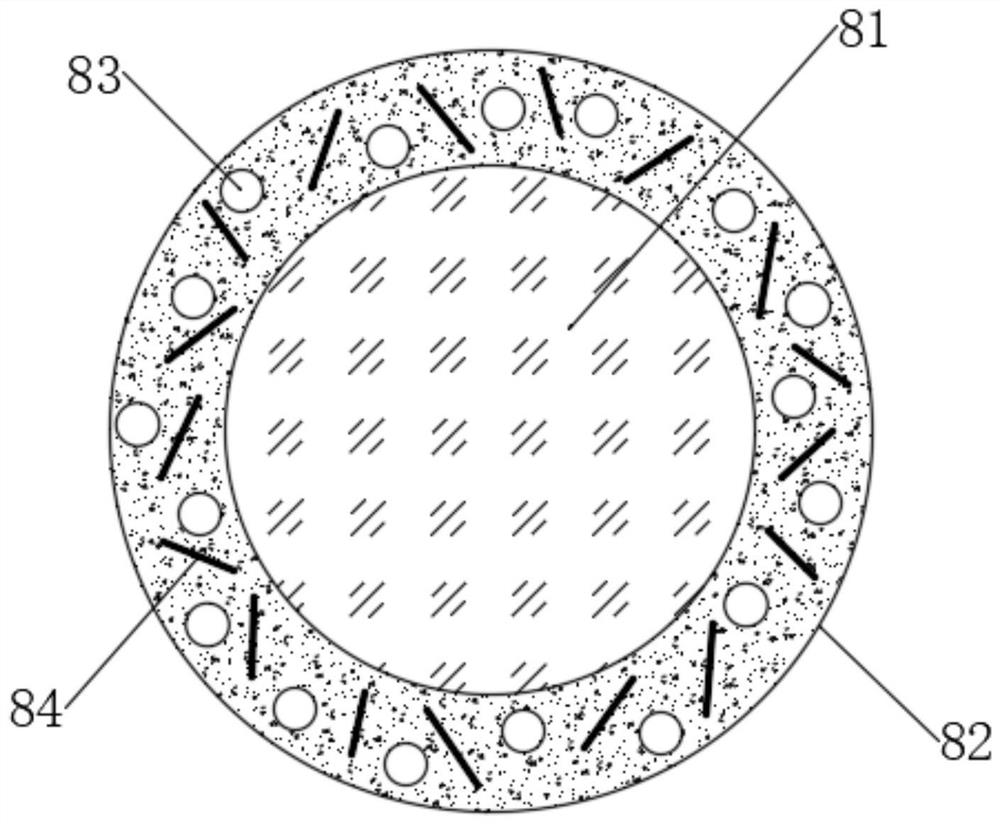

Self-crack-repairing type low-failure-rate optical cable for network engineering construction

InactiveCN111929784AImprove repair strengthAvoid secondary crackingFibre mechanical structuresAdhesiveEngineering

The invention discloses a self-crack-repairing type low-failure-rate optical cable for network engineering construction. The invention belongs to the technical field of network engineering. Accordingto the invention, after a protective coat is cracked, external air quickly enters along a crack and is in contact with a crack repairing ball preset in a crack repairing layer; the crack repairing action of the crack repairing ball is triggered; the crack sealing ball firstly automatically heats to enter the crack; an opening film is punctured based on the characteristic that a memory crack sealing wire absorbs heat and begins to deform; at the moment, a two-component thermosetting adhesive is extruded and released and is converged and fused in the crack; the protective coat in the crack areastarts to be plasticized due to heat; the memory crack sealing wire can smoothly penetrate into the protective coat, the memory crack sealing wire firstly restores the shape of the fishhook along withthe gradual cooling of the crack sealing ball, the crack area is cured and bonded together under the action of the adhesive, the action similar to needle and thread crack sealing is achieved, the repairing strength of the crack can be remarkably improved, and the secondary cracking phenomenon is prevented.

Owner:徐州迪沃通讯工程有限公司

Tire inflation leak-repairing agent

InactiveCN103374329AImprove repair abilityMature repair abilityMonocarboxylic acid ester polymer adhesivesOther chemical processesWater basedAlcohol

The invention relates to a tire inflation leak-repairing agent which adopts a water-based acrylate adhesive as the main leak-repairing agent, and tetrafluoroethane and hexafluoropropane as a main air inflation agent. The tire inflation leak-repairing agent comprise a liquid component (1) and a gas component (2) by mass percentage, wherein the liquid component (1) comprises 17%-63% of the water-based acrylate adhesive, 2%-23% of C1-C5 alcohol, 1%-28% of glycol ether, 1%-9% of a nonionic surfactant, 0.02%-0.1% of nipalgin, and the balance of water; the gas component (2) can be a mixture of the following constituents: 15%-100% of the tetrafluoroethane, 0%-80% of the hexafluoropropane, and 0%-30% of propane, butane or propane and butane. According to the invention, an aerosol cans is adopted to pack a product, and the mass ratio of the liquid component to the gas component is 1 to 1-3.

Owner:李雪松

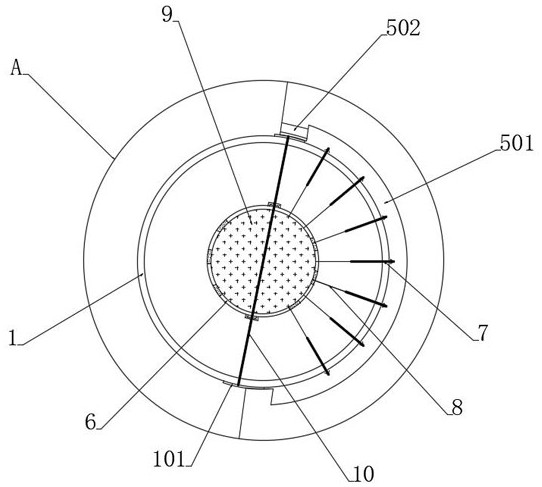

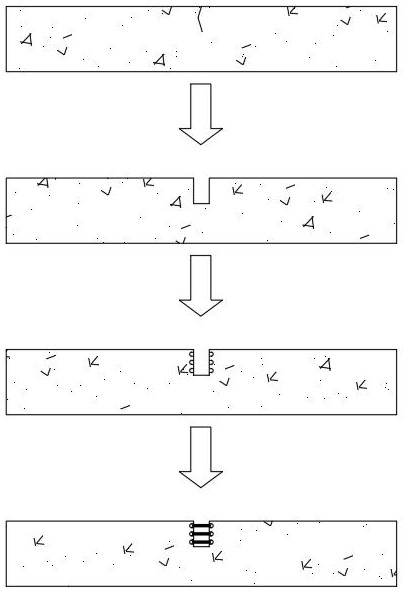

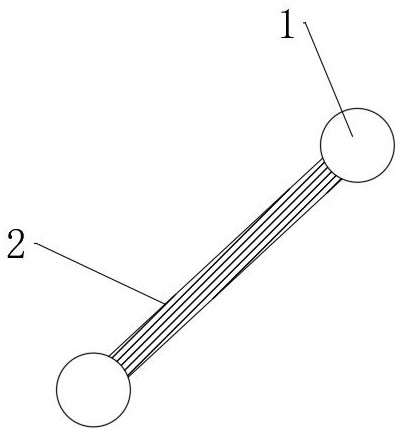

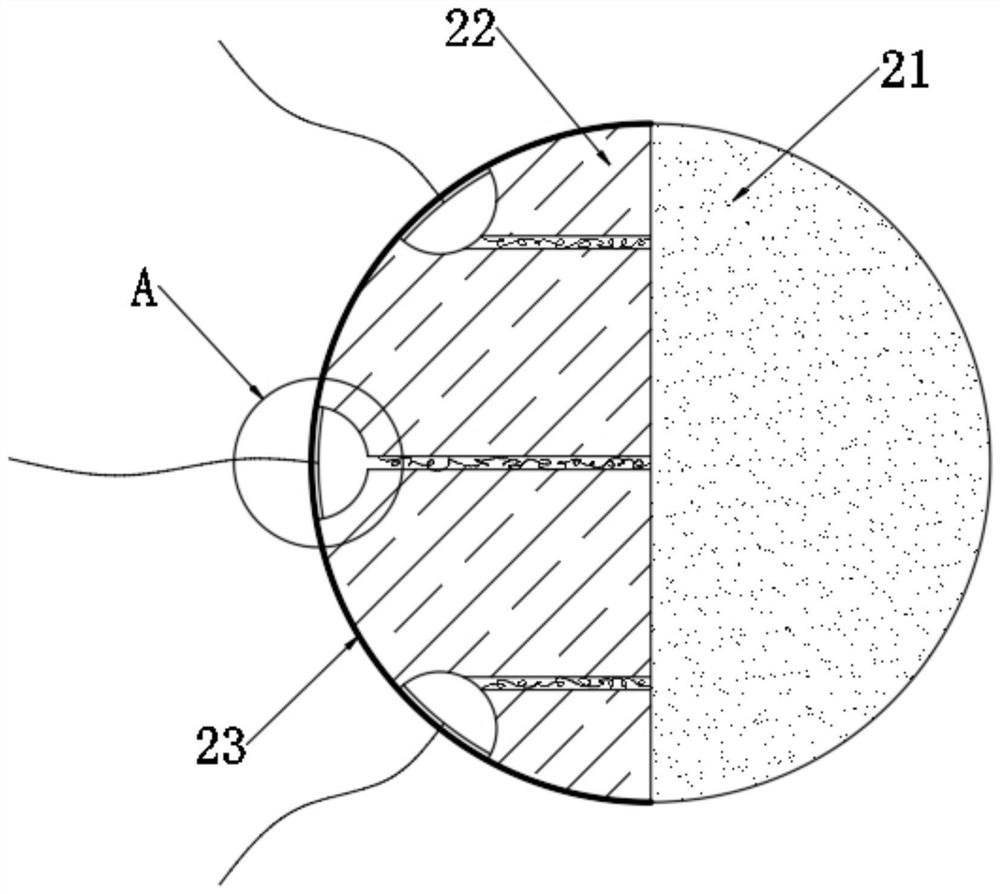

Asphalt pavement crack embedded repairing method

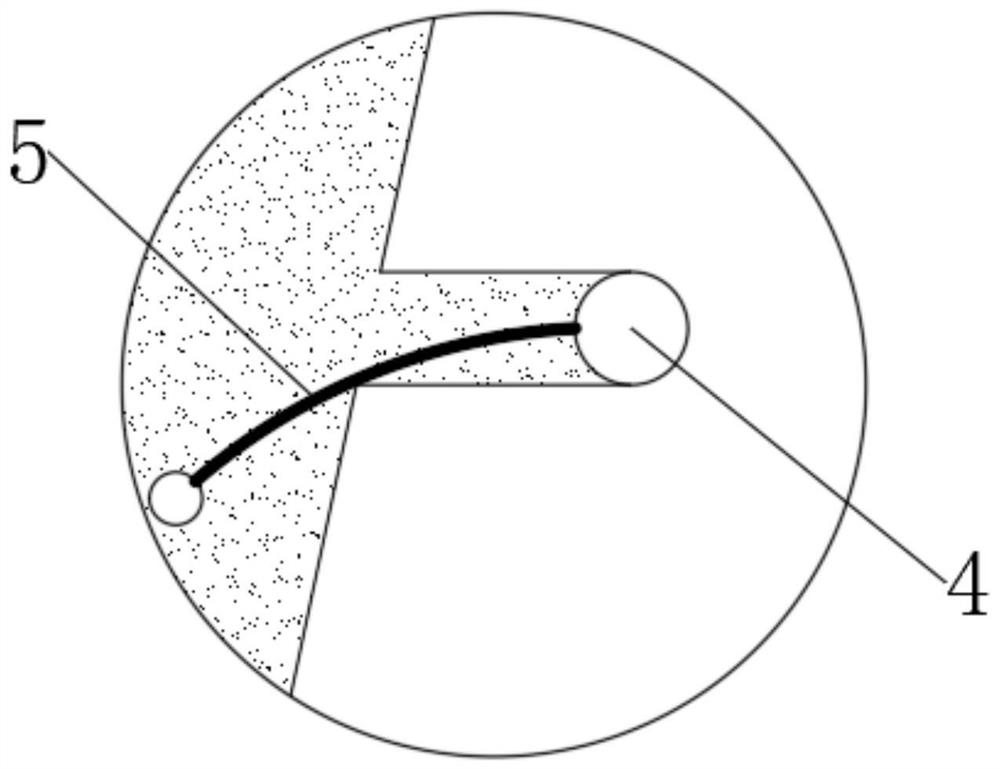

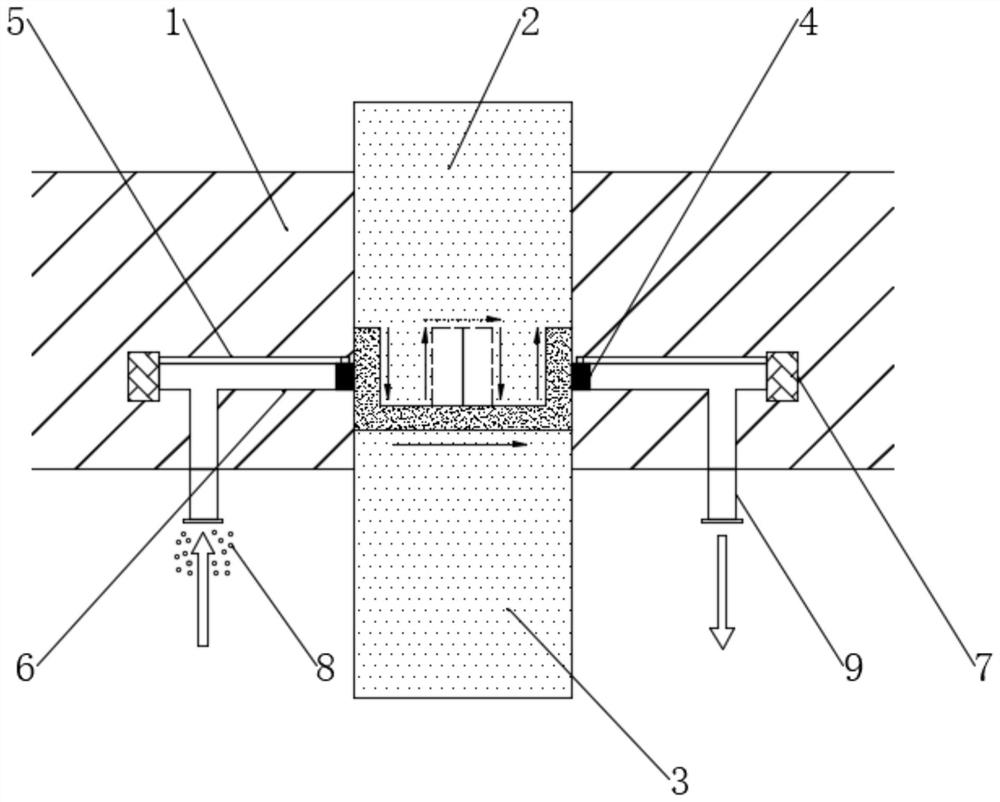

PendingCN112342859AImprove repair strengthAvoid secondary crackingIn situ pavingsRoads maintainenceStructural engineeringAsphalt pavement

The invention discloses an asphalt pavement crack embedded repairing method, and belongs to the technical field of asphalt pavement construction. The method comprises the following steps of: after expanding a crack, uniformly digging a plurality of fusion embedding holes in two side walls in the crack through molten asphalt by using a hole embedding tool, and reserving pre-embedded magnetic ballsin the fusion embedding holes; then preparing a joint sealing material on site, mixing a proper number of chemical force soft rods to be injected into the cracks after being mixed to be uniform, forcing the chemical force soft rods to partially enter the fusion embedding holes to be combined with the pre-embedded magnetic attraction balls through the magnetic attraction effect of the pre-embeddedmagnetic attraction balls on the chemical force soft rods, and foring high-strength combination of the cracks and an original asphalt pavement after the joint sealing material is cured; when the crackis extruded, the downward pressure of the chemical force soft rod is converted into the extrusion of the pavement on the two sides of the crack to the center, so that the pressure can be effectivelycounteracted, secondary cracking at the crack can be prevented, and the crack repairing strength is greatly improved.

Owner:福州市天伟达电子科技有限公司

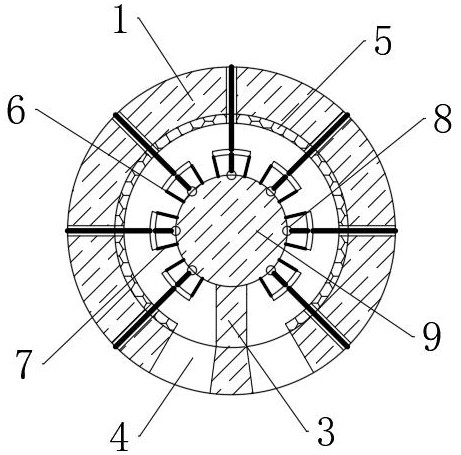

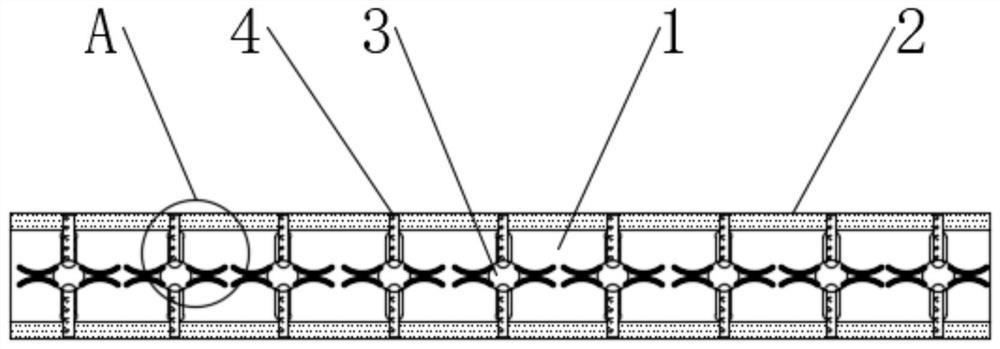

Anchoring type concrete crack repairing method

InactiveCN112343107ANot easy to secondary crackingImprove anchoring abilityFoundation repairBulkheads/pilesRepair materialStructural engineering

The invention discloses an anchoring type concrete crack repairing method, and belongs to the technical field of concrete crack repairing. The method comprises the following steps that a plurality ofanchoring balls are anchored on the inner wall of a crack position dug into a Y-shaped groove, a T-shaped anchoring nail is inserted at the bottom in the Y-shaped groove, a repairing material with a certain temperature is injected into the Y-shaped groove, the repairing material is fused and bonded with the T-shaped anchoring nail and the plurality of anchoring balls, after the anchoring balls areheated, a binder in the anchoring balls overflows, the binder is a molten resin material with cohesiveness, the repairing material is guided into the anchoring groove and fused with the binder, and the binder is used as a bonding material for anchoring between the repairing material and the anchoring balls and anchoring holes. The anchoring effect of the anchoring balls on the inner sides of theanchoring holes is effectively improved, the repairing material can be fully bonded and fixed to the anchoring balls under the matching effect of the binder, the repairing strength of the repairing material and the Y-shaped groove repairing interface is effectively improved to a certain degree, and secondary cracking of the crack is not likely to happen.

Owner:福州盛世凌云环保科技有限公司

Bridge deck crack high-strength repairing method

PendingCN112160259AAvoid the phenomenon of secondary crackingImprove repair strengthBridge erection/assemblyRoads maintainencePunchingChemical reaction

The invention discloses a high-strength bridge deck crack repairing method, which belongs to the technical field of bridge deck construction. The method comprises the following steps: reasonably expanding a crack, uniformly punching holes in the side wall of the crack, injecting magnetic concrete, bridging two adjacent holes in a self-connecting piece put into the crack on the basis of a magneticattraction effect, triggering self-anchoring ball on the self-connecting piece to make a gap, a chemical reaction being controlled to be generated and stopped, then the propelling effect of gas beingcontrolled. High-frequency impact is formed in a hole through the punching column to achieve punching, finally, after punching is finished, the bonding action is triggered, and the punching column isforced to be in multi-point deep connection with the hole wall permanently. Then repairing concrete is injected into the cracks, on one hand, the repairing concrete enters the self-connecting piece tobe reinforced and shaped, on the other hand, the cracks are filled, the connecting effect on the bridge floor on the two sides of the cracks is formed after forming, a tensile force is given all thetime, the secondary cracking phenomenon is avoided, and the repairing strength is greatly improved.

Owner:高双兵

Repair method of blast furnace cold wall

InactiveCN104928422AThere is no problem of water leakageImprove repair strengthCooling devicesCopperUltimate tensile strength

The invention discloses a repair method of a blast furnace cold wall. The repair method comprises the following steps: (1) a copper corrugated pipe smaller than a raw water pipe in inner diameter is inserted in a damaged cooling wall water pipe; (2) the two ends of the copper corrugated pipe are respectively connected with cooling water to form a new cooling channel; and (3) a high-heat conductivity carbon grouting material is filled between the copper corrugated pipe and the raw water pipe. The repair method has the beneficial effects of no existence of leakage problem after the repair and high repair intensity.

Owner:王春博

Concrete bridge deck crack repairing method for bridge

ActiveCN113005925AImprove repair strengthImprove liquidityBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses a method for repairing cracks on a concrete bridge floor of a bridge, and belongs to the technical field of bridges, and the method comprises the following steps: reasonably expanding the cracks, drilling an embedded hole, inserting a defoaming rod into the embedded hole, injecting concrete for repairing, and filling oxygen to exhaust air in the embedded hole, wherein the defoaming rod in the embedded hole can react with oxygen in the concrete to release heat, and then the defoaming rod is softened to deform; a magnetic field is applied above the crack to force the defoaming rods to swing in the concrete, on one hand, the concrete can be assisted to be densely filled, and the fluidity is improved; on the other hand, bubbles in the concrete can be eliminated, oxygen can be absorbed for reaction, the defoaming effect can be improved, oxygen is not prone to remaining, the defoaming rod is gradually cooled and hardened after oxygen is consumed up, the strength can be improved by reserving the defoaming rod in the concrete, and therefore the crack repairing strength is remarkably improved, and the phenomenon of secondary cracking is not prone to occurring.

Owner:中铁一局集团厦门建设工程有限公司 +1

Repairing agent for subway shield segments and preparation method of repairing agent

InactiveCN111995349AGuaranteed crack resistanceImprove compactnessSolid waste managementAluminateCellulose

The invention discloses a repairing agent for subway shield segments and a preparation method of the repairing agent. The repairing agent is prepared from the following raw materials in parts by mass:200 to 300 parts of ordinary Portland cement; 150-200 parts of white cement; 100 to 250 parts of sulphoaluminate cement; 20-50 parts of microbeads; 50 to 100 parts of silica fume (silica powder); 150to 250 parts of active glass powder; 1 to 10 parts of excitant; 50 to 100 parts of concrete expanding agent; 0.1 to 0.4 part of plastic expanding agent; 1 to 5 parts of water reducing agent; 0.1 to 0.4 part of defoaming agent; 0 to 0.5 part of cellulose; 15 to 35 parts of redispersible latex powder; and A parts of water. The sum of the dosages of the components excepting water, namely the sum ofthe parts of the components excepting water is B, and the water-material ratio, namely the ratio of A to B, is 0.15-0.20: 1. The invention further provides a preparation method of the repairing agent.Through the synergistic effect of all the components, the repairing agent is high in early and later compressive strength, good in wear resistance and small in color difference with old concrete repairing, has the characteristics of good bonding performance and crack resistance, and is convenient to apply and popularize.

Owner:刘翠芬

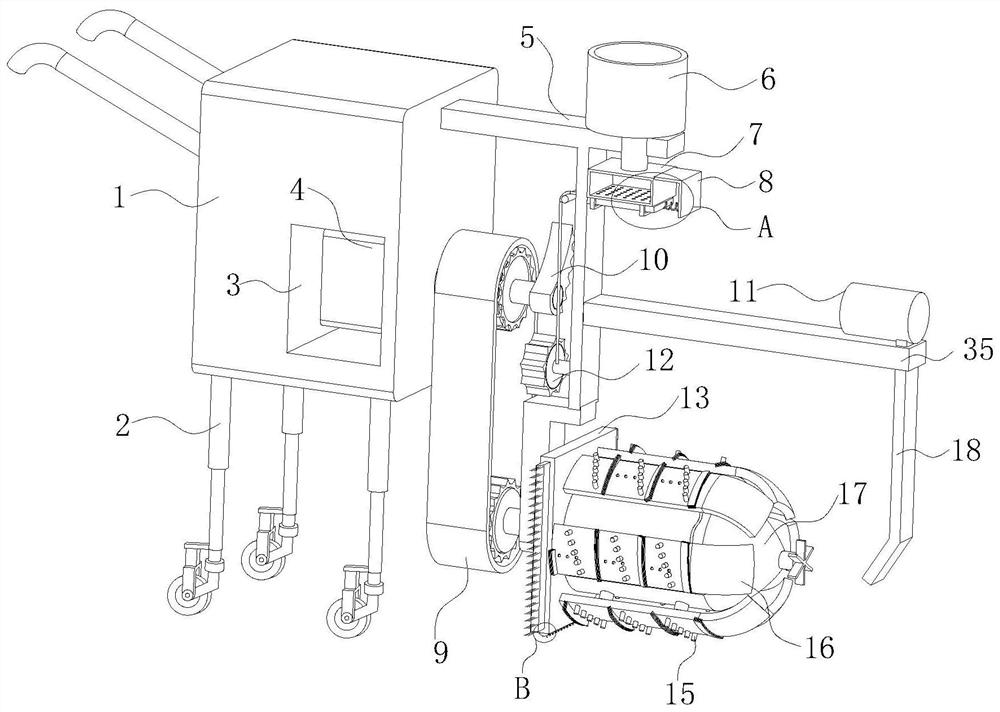

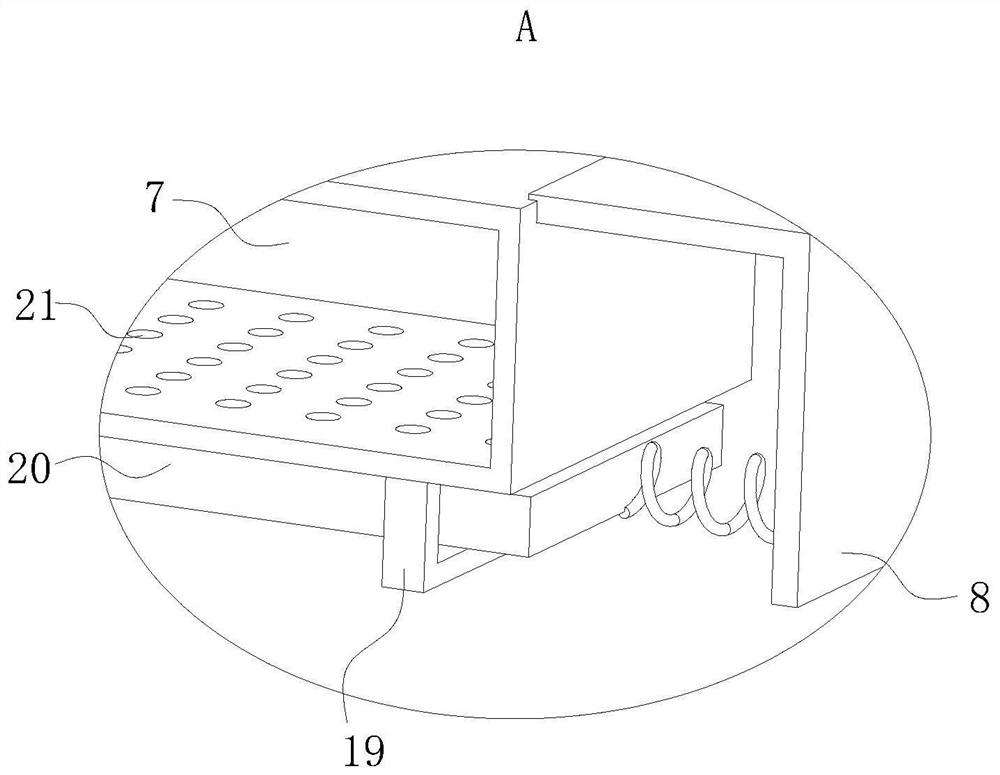

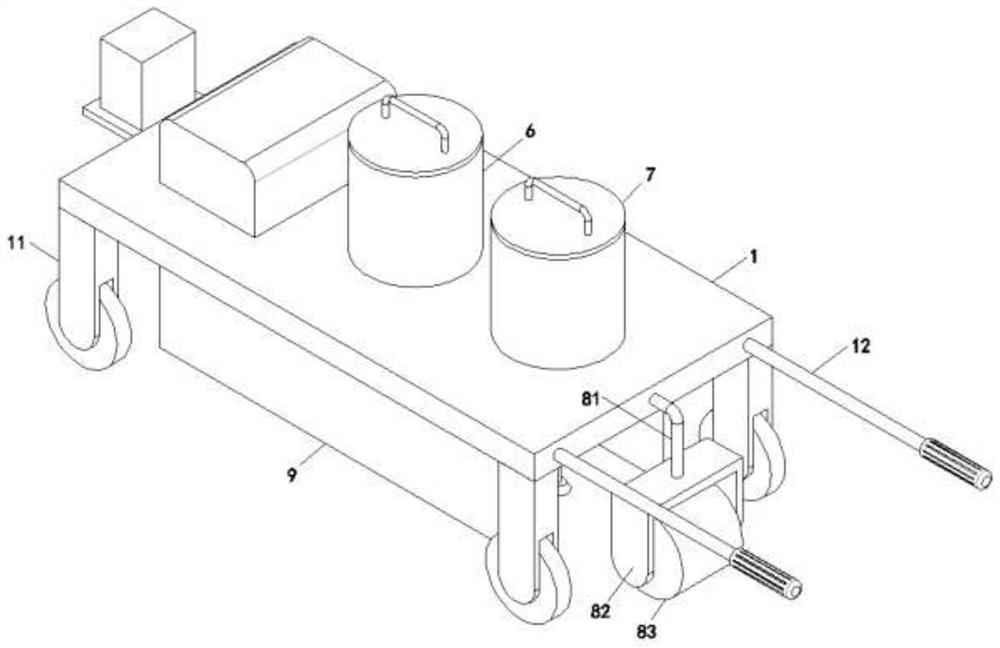

Crack repairing device with cleaning function for highway construction

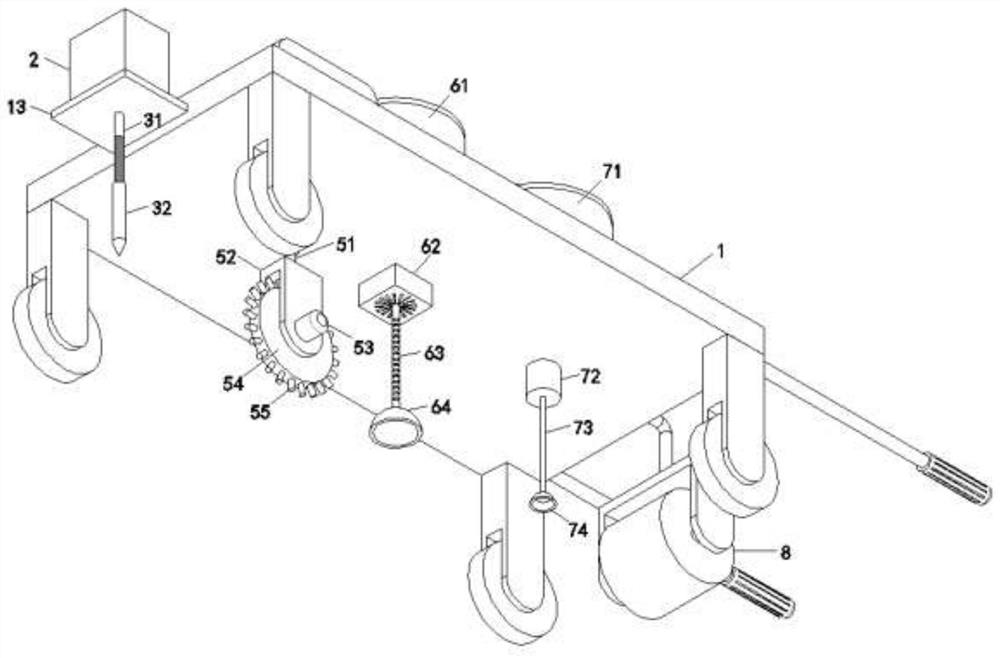

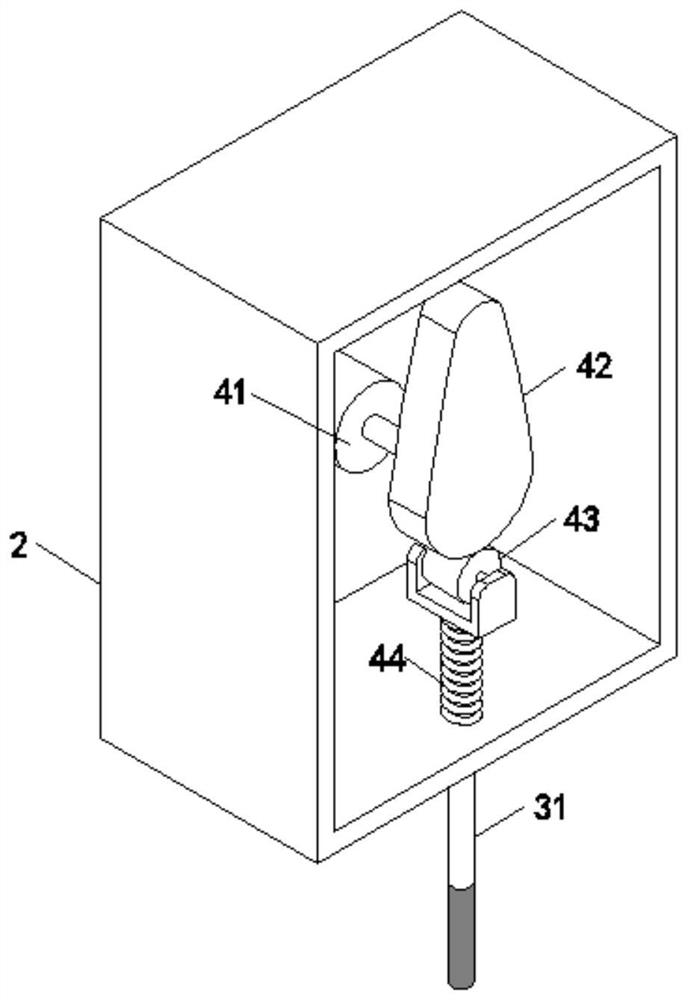

InactiveCN113605200AImprove repair strengthImprove work efficiencyRoads maintainenceStructural engineeringMechanical engineering

The invention relates to the technical field of road maintenance, in particular to a crack repairing device with a cleaning function for road construction. The crack repairing device with the cleaning function for road construction comprises a vehicle body, a cleaning mechanism, a sweeping mechanism, a dust collection mechanism and a repairing mechanism; wheels are fixedly installed at the four corners of the bottom of the vehicle body; a push handle is fixedly installed on the side wall of the vehicle body; a supporting plate is fixedly installed on the side wall of the vehicle body; a box body is fixedly installed at the top of the supporting plate; the cleaning mechanism is installed at the bottom of the box body; the driving mechanism is further installed in the box body; the sweeping mechanism is installed at the bottom of the vehicle body; the dust collection mechanism is installed at the bottom of the vehicle body; and the repairing mechanism is installed at the bottom of the vehicle body. The crack repairing device with the cleaning function for road construction has the advantages that road gaps can be cleaned, so that asphalt can more uniformly flow into the gaps to repair a road.

Owner:高亚楠

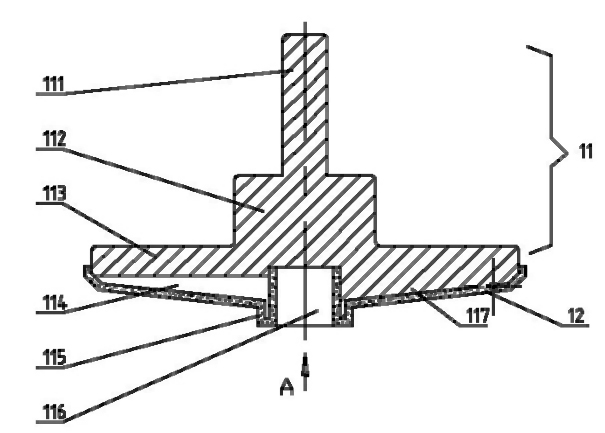

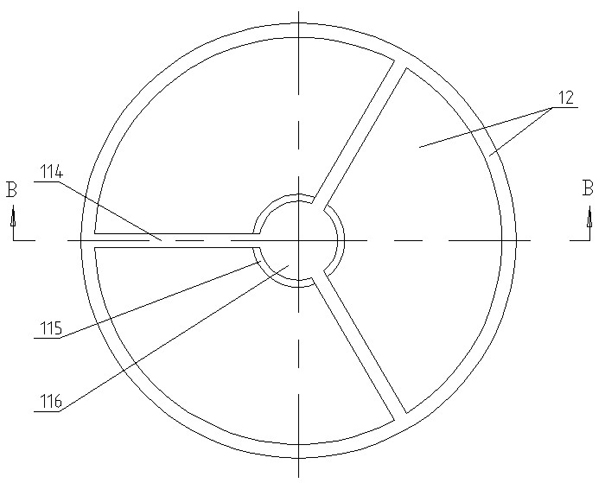

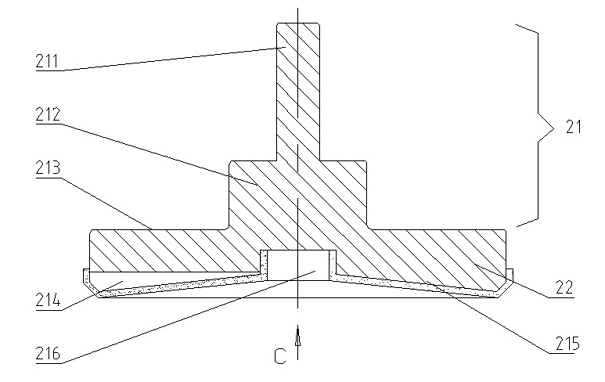

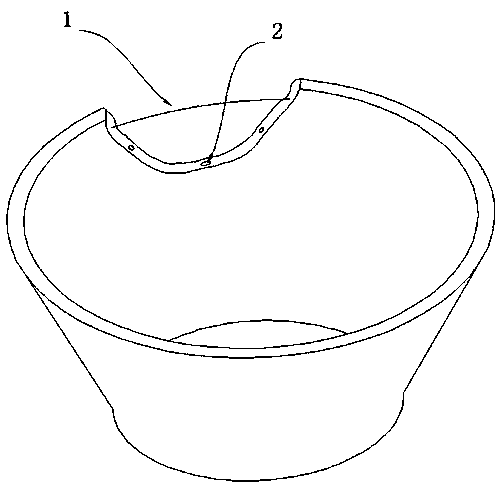

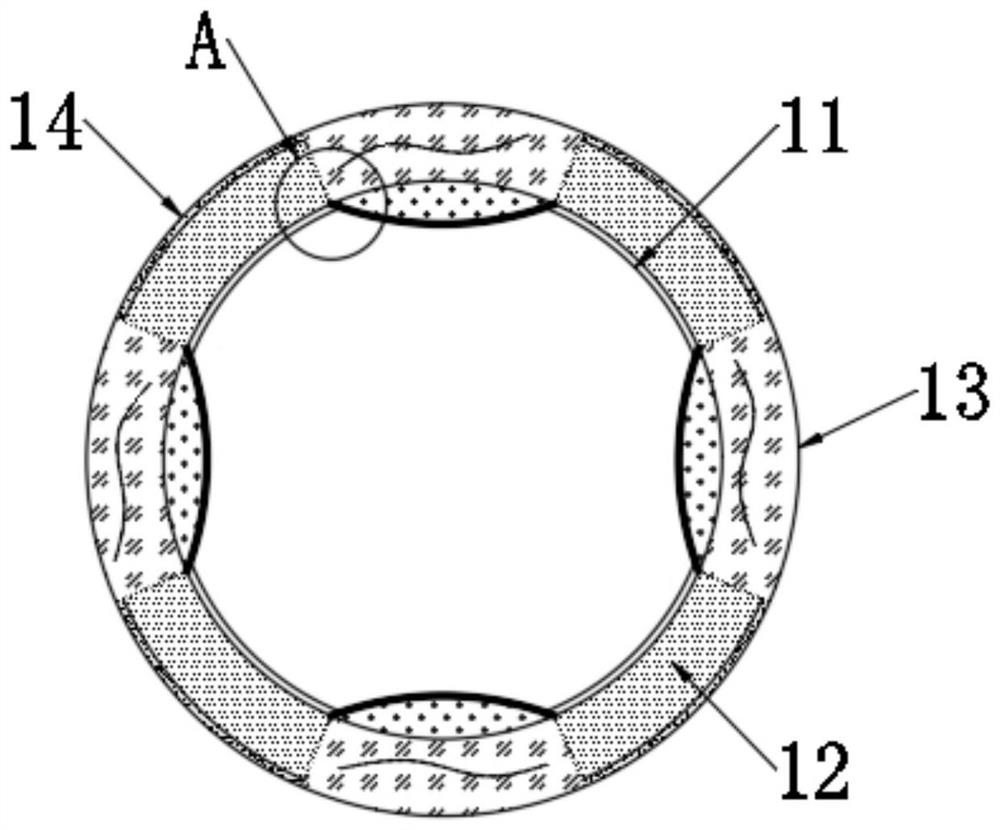

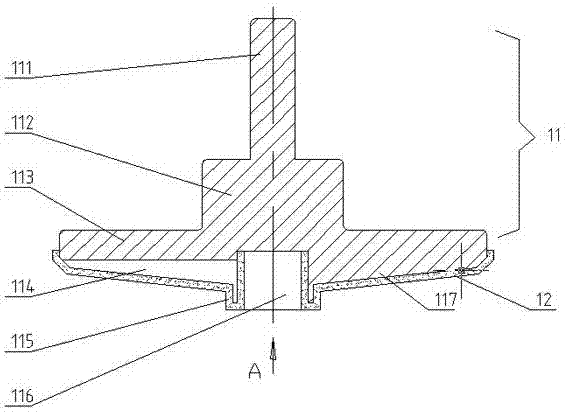

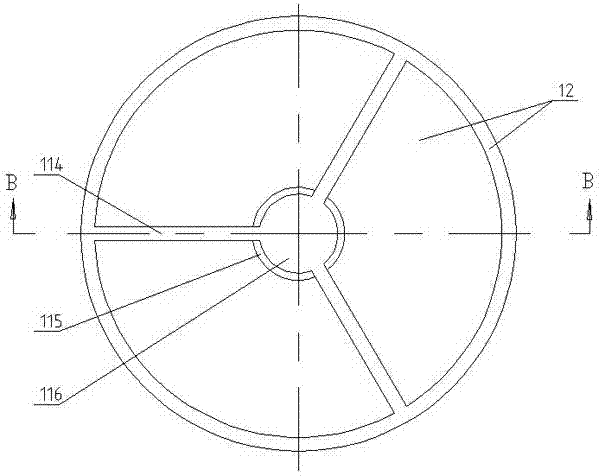

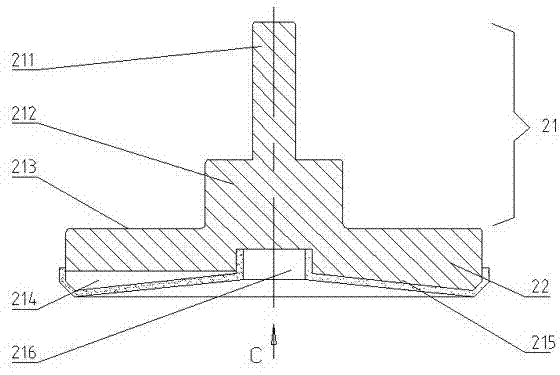

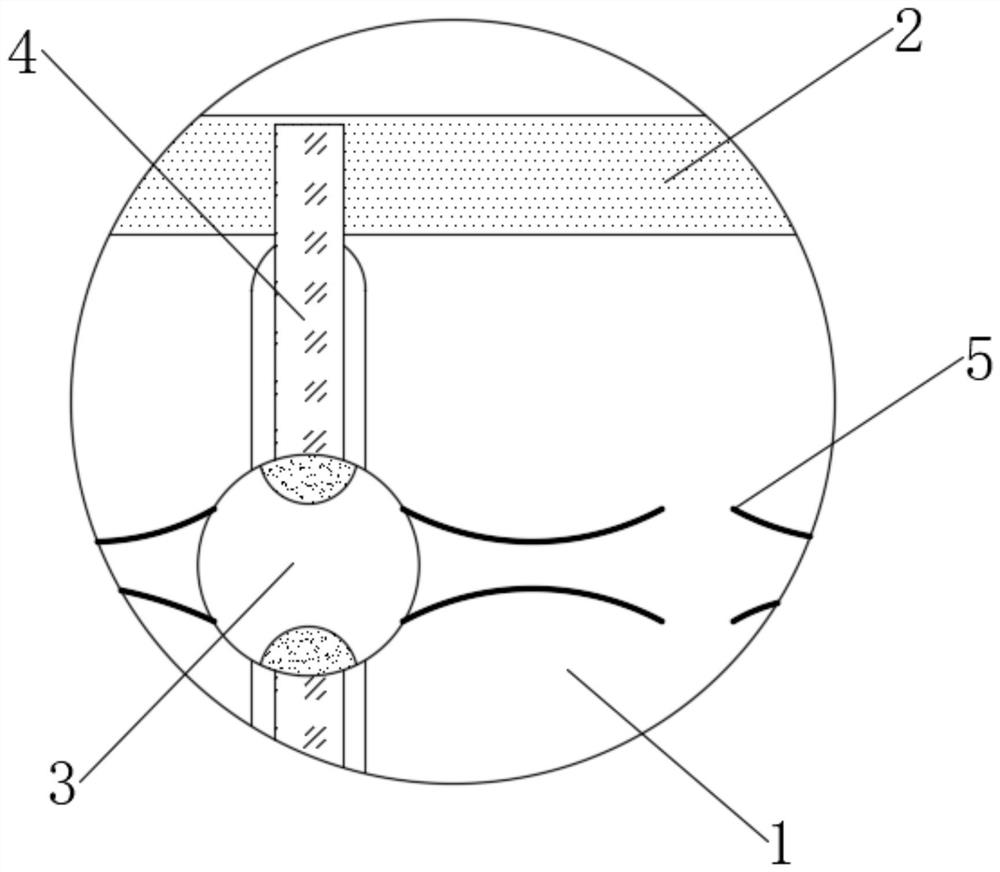

Tool and method for repairing composite laminated sheet structural member

The invention relates to a tool for repairing a composite laminated sheet structural member. The tool for repairing the composite laminated sheet structural member comprises a pair of male grinding wheel and a female grinding wheel which have the same overall dimension and are matched with each other, wherein the male grinding wheel consists of a cam body and a convex surface diamond particle plated layer; a cylindrical boss and three first elongated slots are formed on an outer convex surface cone of the cam body; the three first elongated slots are distributed radially and uniformly; the female grinding wheel consists of a concave wheel body and a concave surface diamond particle plated layer; a second central bottom hole and three second elongated slots are formed on an inner concave surface cone of the concave wheel body; the three second elongated slots are distributed radially and uniformly; and the outer diameter of the cylindrical boss of the male grinding wheel is equal to the inner diameter of the second central bottom hole of the female grinding wheel. A repairing method comprises the following steps of: processing inner concave surface conical holes in the damaged holes, needing to be repaired, of the male grinding wheel which is arranged into an electric drill; cutting outer convex surface conical solidified patches by using the female grinding wheel which is arranged into the electric drill; placing the outer convex surface conical solidified patches on the inner concave surface conical holes which are covered by glue films; and heating, pressurizing and solidifying an assembled glue-jointed composite member. In the tool and the method, the traditional hand grinding mode is replaced by a machining mode, so the grinding quality and the work efficiency are improved and labor intensity is reduced.

Owner:JIANGXI HONGDU AVIATION IND GRP

Matching repair technique for porcelain

InactiveCN108640710AImprove connection strengthGuaranteed to be effective for a long timeReinforced concreteTissue material

The invention relates to the field of porcelain repair, in particular to a matching repair technique for porcelain. The technique comprises the following steps: 1) a blind hole is formed in a green body of a porcelain wound, and a fixing rod is mounted by punching a hole; 2) a metal mesh in a shape of the porcelain wound is clipped and winds around the fixing rod, and a relatively fixed bracket isformed; 3) molding is performed on one side of the porcelain surface by a shaping material, and a shaping mold is formed to serve as a liner; 4) the fixed bracket is wrapped with a tissue material, and then scraping is performed to repair the porcelain wound; 5) after scraping, the shaping mold is taken down, and a repair part is polished to be smooth after the tissue material is hardened completely. Combination of the bracket and the tissue material is like the structure of reinforced concrete, repair strength is improved greatly, the tissue material has high hardness and stability after being hardened, a plurality of structures similar to tenon and mortise can be formed after the tissue material in the blind hole is hardened, so that connecting strength is improved greatly, and damage to the green body is quite small by the form of the blind hole.

Owner:俞敏

Color landscape pavement maintenance material and preparation method thereof

InactiveCN110128089ASolving Pavement Crack Repair ProblemsSolve the problem of retaining the original road surface appearancePavement maintenanceMaterials science

The invention relates to the field of pavement maintenance, in particular to a color landscape pavement maintenance material and a preparation method thereof. The curing material is prepared by mixingdecolored emulsified asphalt, hydraulic inorganic cementing material and inorganic colored coloring pigment. An emulsifying agent should be added when the maintenance material works in a constructionenvironment at the temperature of lower than 5 DEG C. The color landscape pavement maintenance material has the same color repairing effect, and meanwhile, the problems of pavement crack repairing and original pavement appearance retaining are solved. The hydraulic material in the material has certain rigidity after being coagulated, and the emulsified asphalt has certain flexibility after beingdemulsified, so that the repair strength of the material is higher than that of the emulsified asphalt and a slurry sealing layer.

Owner:SHANXI ZHONGRUN LUKE TECH CO LTD

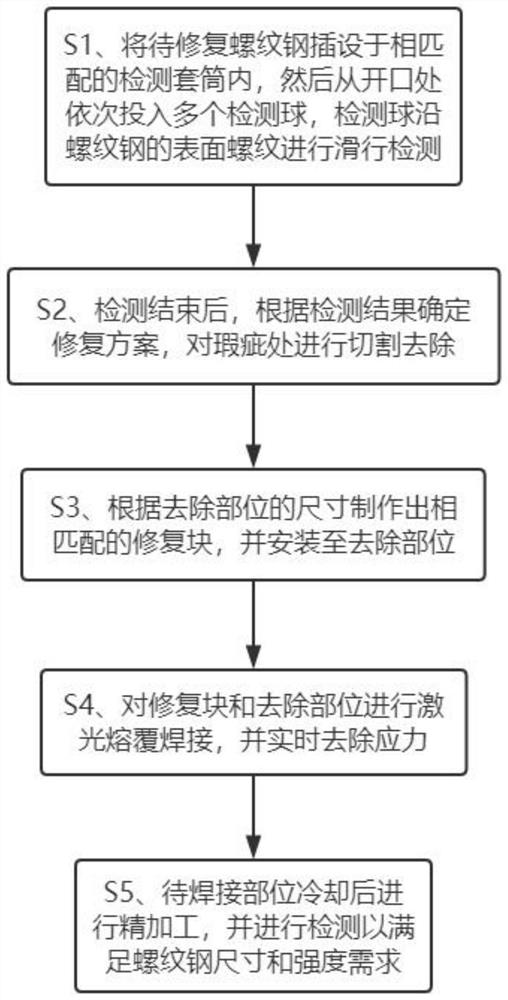

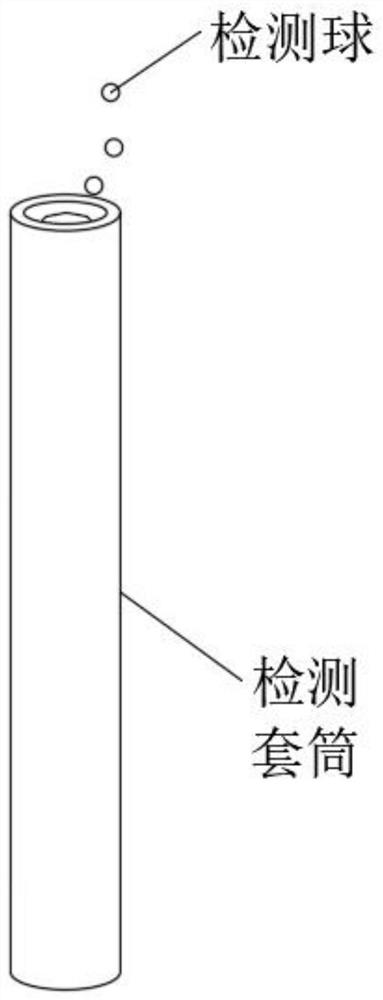

Deformed steel bar surface flaw repairing process

ActiveCN113478166AImprove detection and repair efficiencyImprove detection efficiencyMetallic material coating processesSS - Stainless steelSteel bar

The invention discloses a deformed steel bar surface flaw repairing process, and belongs to the technical field of stainless steel. A deformed steel bar can be detected by innovatively introducing a detection sleeve and detection balls. The deformed steel bar is only required to be inserted into the detection sleeve, and then a plurality of detection balls are sequentially put from an opening. The detection balls can automatically slide down along a thread on the surface of the deformed steel bar and detect flaws on the thread in the sliding-down process. Once the thread has a notch or deforms, the detection balls can adapt to the notch or the deformation so as to trigger the extrusion action on internal elastic oil absorption blocks, and marking liquid is released to mark the flaws. Meanwhile, the multiple detection balls are used for simultaneous detection, so that the detection efficiency and precision can be improved, and meanwhile the situation that the detection is broken due to the clamping condition can be avoided. The deformed steel bar is taken out after detection is finished, flaws can be repaired according to the marked position. The repair strength is improved through a laser cladding technology, and thus the detection and repair efficiency of the deformed steel bar is greatly improved.

Owner:北京天润恒远工贸有限公司

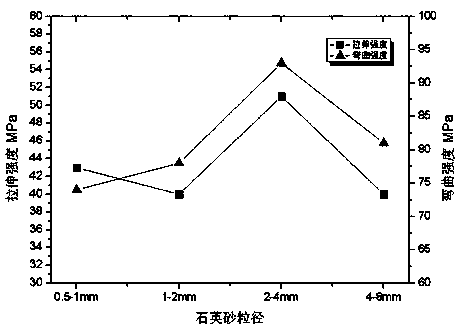

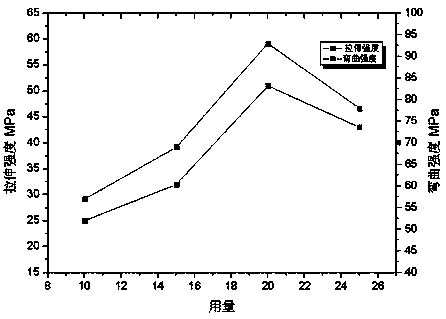

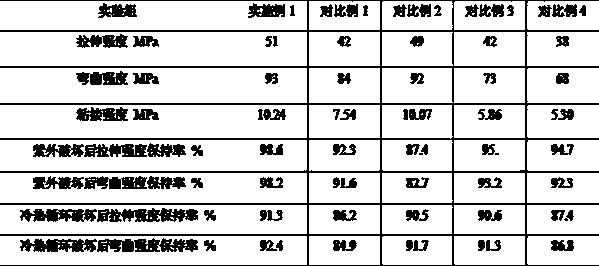

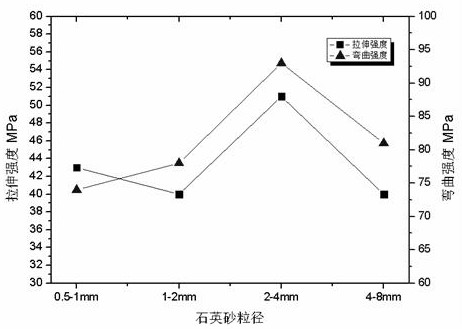

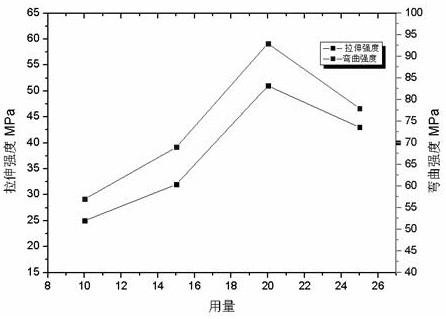

Concrete repairing material and preparation method thereof

The invention discloses a concrete repairing material which comprises the following raw materials in parts by weight: 30-35 parts of sulfate aluminum cement, 8-10 parts of quartz sand, 6-8 parts of river sand, 20-25 parts of epoxy-polyurethane composite material, 2-4 parts of heat releasing material, 2-3 parts of thermal changing material, 2-3 parts of water reducer, 0.5-0.6 part of anionic surfactant and 1-2 parts of retarder. After the concrete repairing material is added into a crack in initial stage, the thermal changing material shrinks after being heated, a sufficient space is leaved forother polymer materials and base stocks to flow into a gap, and more base stocks and polymers are accommodated in the gap. After heat dissipation, the thermal changing material swells, so that the crack is filled with base stocks and polymers and higher repairing strength can be achieved.

Owner:上海知碳电力工程有限公司

A kind of concrete repair material and preparation method thereof

Owner:上海知碳电力工程有限公司

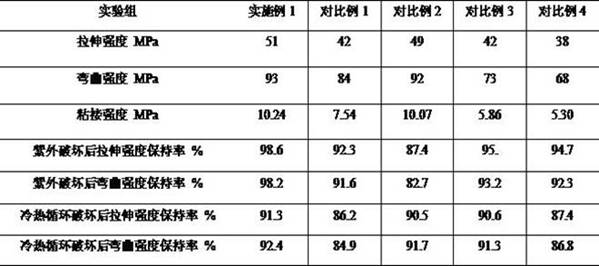

Method and device for repairing concrete after fire, and storage medium

InactiveCN108918583AImprove durabilityImprove repair strengthAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial heat developmentUltimate tensile strengthMaterials science

Owner:GUANGDONG UNIV OF TECH

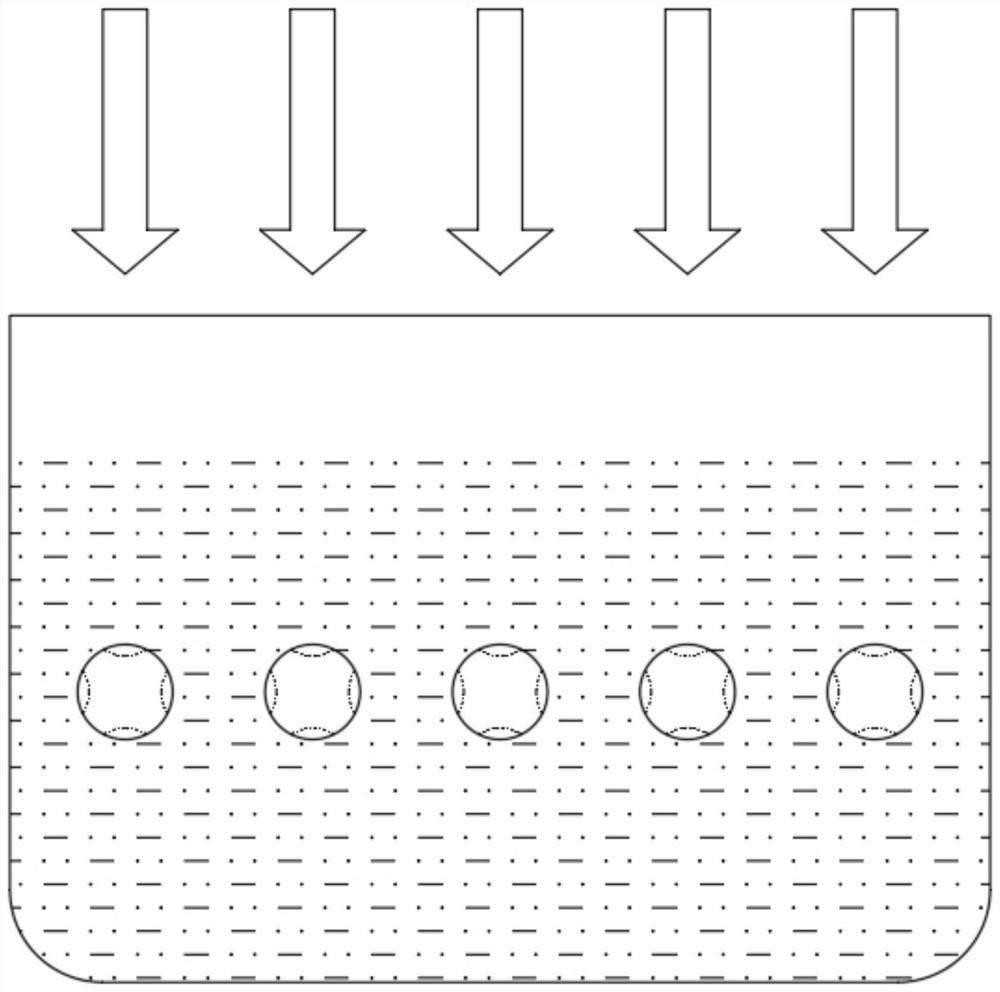

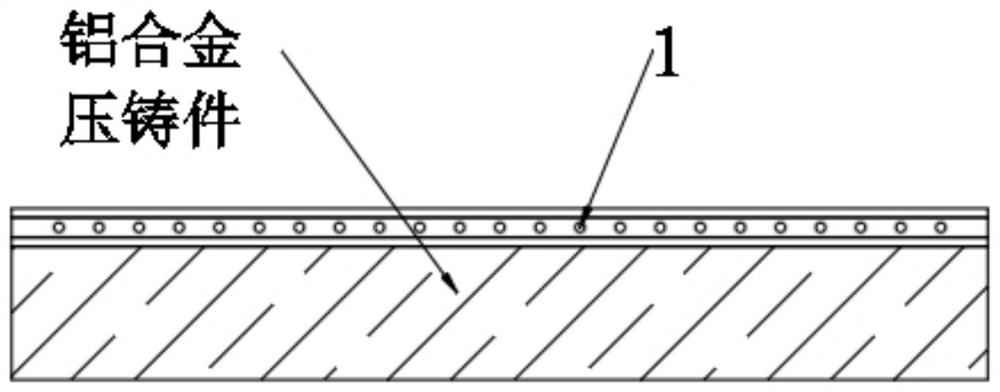

Light-weight aluminum alloy die casting surface treatment method

ActiveCN113070466AHigh strengthImprove seismic performanceAnti-corrosive paintsDie castingGas bubble

The invention discloses a light-weight aluminum alloy die casting surface treatment method, and belongs to the technical field of aluminum alloy die casting. A plurality of evenly-distributed repairing capsules are pre-embedded in a preservative layer of an interlayer; then a chemical foaming reaction is triggered in a forming process; bubbles are formed in the preservative and decomposed in the heating process to generate a large amount of gas, so that a continuous porous structure is formed; meanwhile, the repairing capsules serve as aggregate to support and reinforce the porous structure; meanwhile, the strength and shock resistance of the preservative layer are improved; and after the surface of a aluminum alloy die casting is damaged, under the porous structure characteristic of the preservative layer, external air makes contact with the repairing capsules; then the repairing capsules replace the aluminum alloy die casting to generate an oxidation reaction; heat is generated to trigger a healing action; damage to the surface of the aluminum alloy die casting is repaired; direct contact with the external environment is avoided; and therefore, the anti-corrosion performance of the aluminum alloy die casting is guaranteed.

Owner:江苏竣昌科技有限公司

Tool and method for repairing composite laminated sheet structural member

Owner:JIANGXI HONGDU AVIATION IND GRP

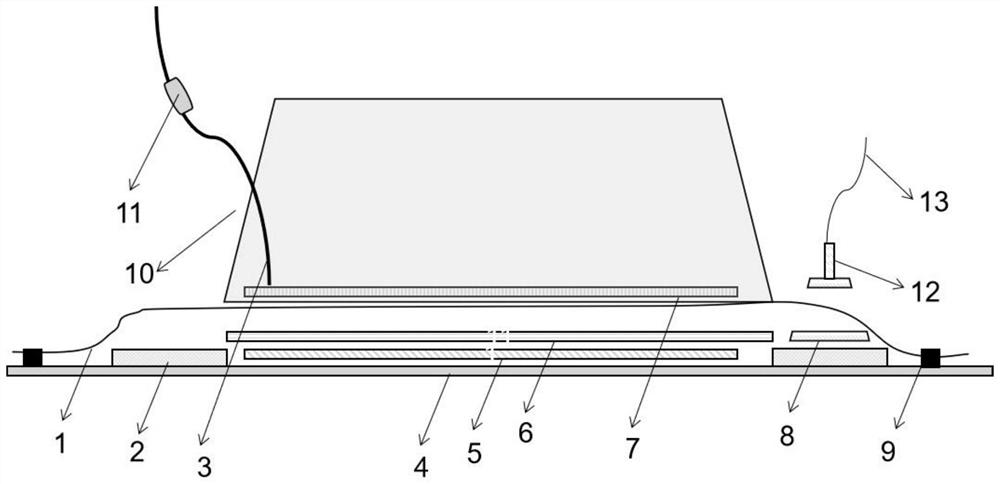

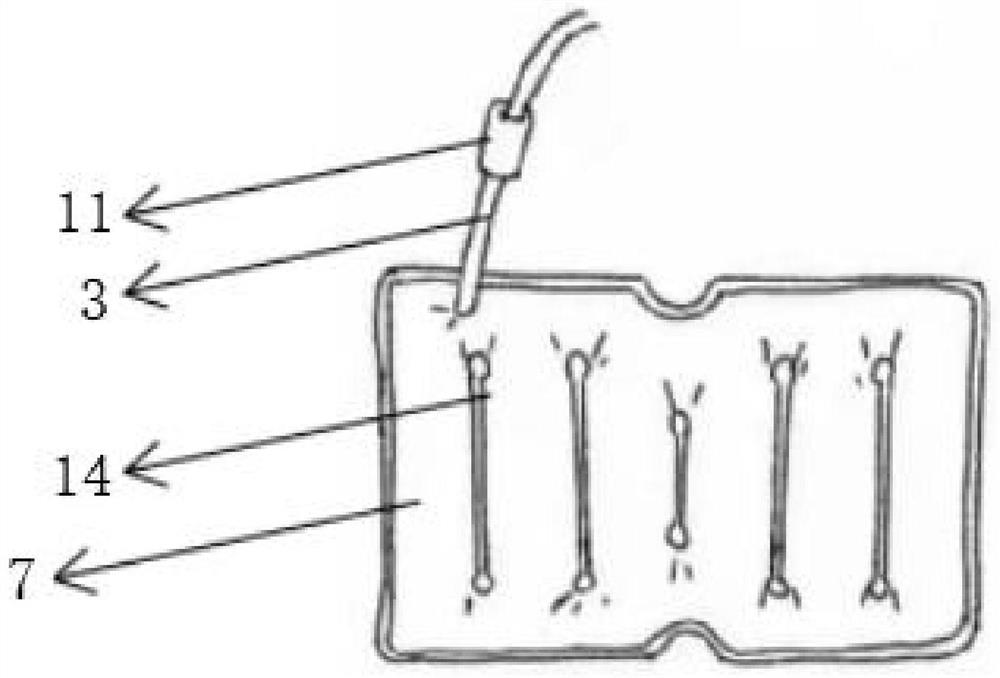

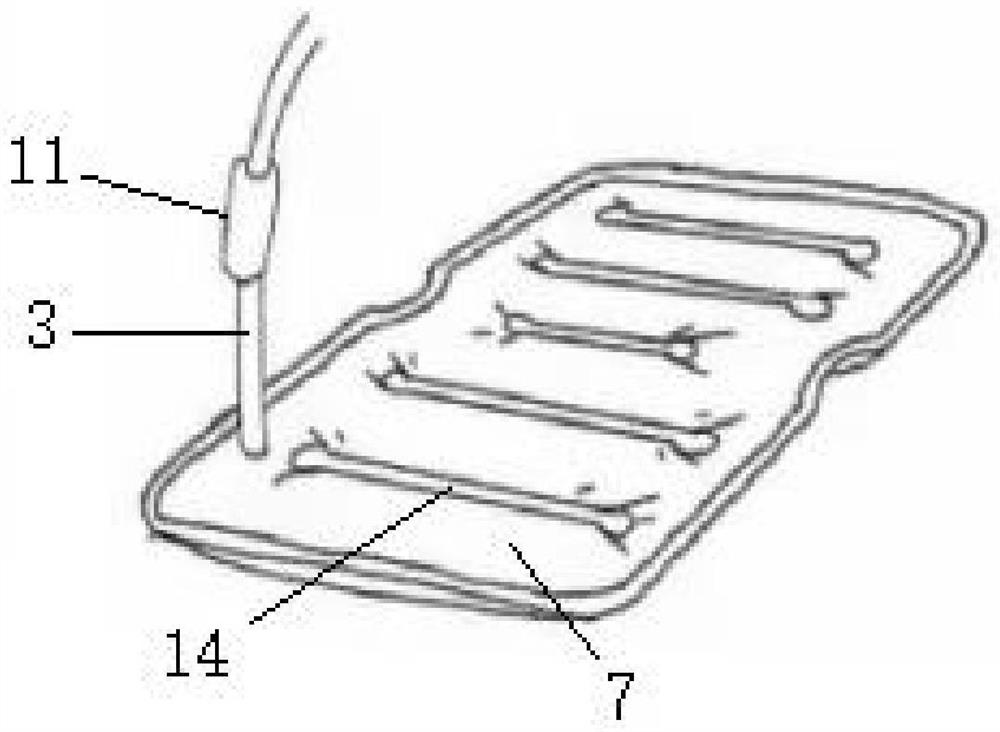

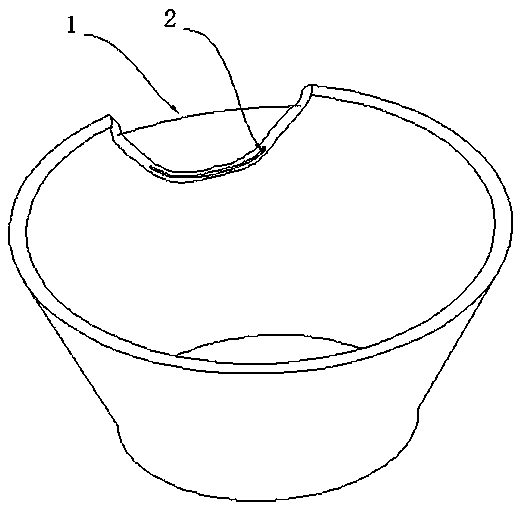

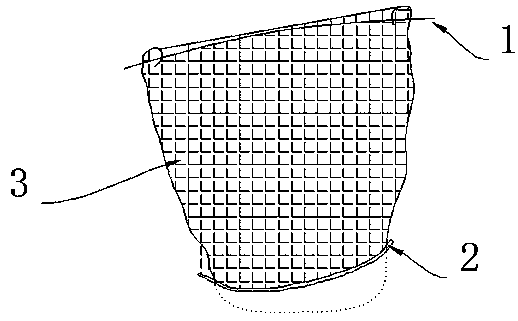

Self-adaptive portable microwave heating repair bag, manufacturing process and using method

The invention relates to the technical field of aviation equipment body structure microwave curing repair, in particular to a self-adaptive portable microwave heating repair bag, a manufacturing process and a using method, the repair bag comprises a to-be-repaired piece, and further comprises a vacuum bag film connected to the to-be-repaired piece through a sealing rubber strip; demolding cloth and an isolating membrane; the self-adaptive portable wave absorbing bag is arranged above the vacuum bag film; a portable microwave radiator cavity; and packaging the assembly. According to the invention, the self-adaptive portable microwave heating repair bag is manufactured by selecting the wave absorbing liquid, selecting the material of the wave absorbing bag and analyzing and selecting the packaging process, so that the curing speed is accelerated, the matrix is uniformly heated, the repair strength is improved, the self-adaptive portable microwave heating repair bag is not influenced by the attribute of the repair material, and the service life of the repair bag is prolonged. The application range of the microwave curing technology is expanded while the strength of the repair area is further improved; in addition, the mode of absorbing waves through liquid and transmitting waves through the outer bag is adopted, and on the premise that rapid heating is achieved, it is effectively guaranteed that the temperature in the bag is uniform.

Owner:国营芜湖机械厂

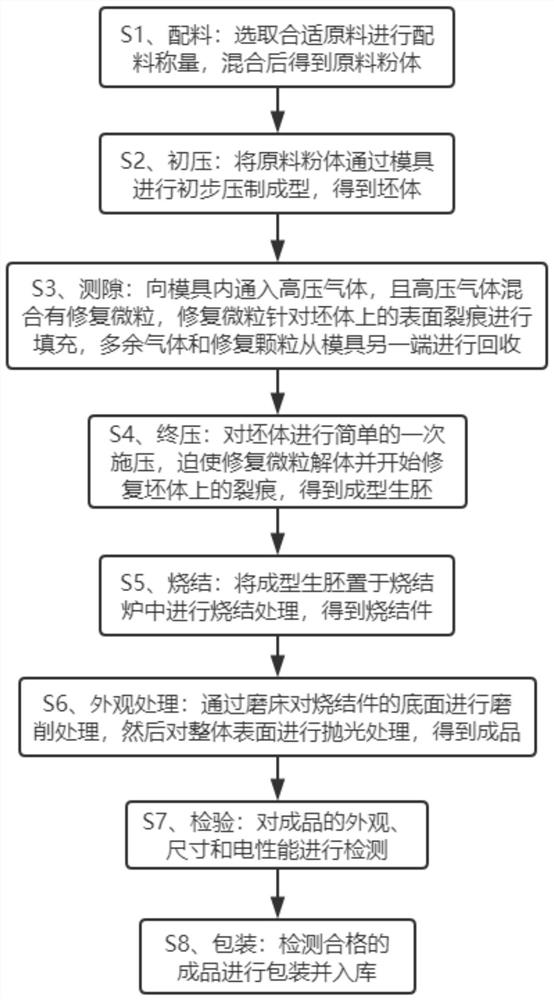

A method for forming a flat and ultra-thin power transformer magnetic core

ActiveCN111584225BImprove reliabilityImprove pass rateInductances/transformers/magnets manufactureTransformerEngineering

The invention discloses a method for forming a magnetic core of a flat and ultra-thin power transformer, which belongs to the field of soft ferrite materials, and can be realized by improving the material selection and pressing molding process, and selecting raw material powder with suitable particle size and loose specific gravity. After mixing, the method of secondary pressing is adopted. The raw material powder is preliminarily shaped by the initial pressure to obtain a green body, and then the high-pressure gas mixed with repair particles is introduced into the mold to force the high-pressure gas to carry the repair particles through the surface of the green body, and Fill the cracks of the green body. In the subsequent final pressing process, not only the green body is fully formed, but also the disintegration of the repair particles is pressed to trigger the repair action, and the high-strength integrated repair is realized along the crack, which reduces the deformation and cracking of the product. The qualification rate of the finished magnetic core is greatly improved. The magnetic core formed by the invention is suitable for use in various flat power transformers due to its low structure, thin wall, easy heat dissipation, high reliability, easy assembly and serialization.

Owner:NANTONG HUAXING MAGNETIC MATERIAL

A corrosion-resistant aluminum alloy profile

ActiveCN111705290BHigh strengthAccelerated corrosionMolten spray coatingManufacturing technologyCeramic coating

The invention discloses a corrosion-resistant aluminum alloy profile, which belongs to the technical field of metal material manufacturing. A corrosion-resistant aluminum alloy profile can improve the raw materials of the aluminum alloy matrix on the one hand, and optimize the ratio and combination of different components. , enhance the strength and corrosion resistance of the aluminum alloy matrix as a whole, and further protect the aluminum alloy matrix by covering the surface of the aluminum alloy matrix with a nano-ceramic coating. The embedded repair rod can improve the strength of the aluminum alloy matrix and eliminate part of the internal stress, and when the nano-ceramic coating is corroded or damaged, the repair action of the embedded repair rod is triggered by the set easy-to-corrosion parts, based on the magnetic attraction. The repair magnetic ball is actively adsorbed to the corrosion or damage to repair, avoid further corrosion or damage, and is suitable for self-repair under various corrosion conditions, effectively improving the corrosion resistance of the aluminum alloy substrate and prolonging its service life.

Owner:上海芳桦建筑材料有限公司

Porcelain repair technology

InactiveCN108748695AHigh hardnessUnbreakableCeramic shaping apparatusStone-like material working toolsReinforced concreteRebar

The invention relates to the field of porcelain repair, and particularly relates to a porcelain repair technology. The porcelain repair technology comprises the following steps: (1) cleaning a porcelain wound; (2) grooving the green body of the porcelain wound, and drilling and installing a fixed rod; (3) scissoring a metal mesh sheet with the shape of the porcelain wound, and inserting one end ofthe metal mesh sheet into the groove and winding the fixed rod with the other end of the metal mesh sheet to form a fixed support; (4) carrying out die taking at one side of the surface of porcelainby virtue of a shaping material to form a shaping die as a liner; (5) wrapping the fixed support by virtue of a structure material, and then scraping to repair the porcelain wound; and (6) after the scraping is finished, taking down the shaping die, and grinding the repair part smooth after the structure material is completely hardened. According to the porcelain repair technology, the combinationof the fixed support and the structure material is similar to the structure of reinforced concrete, so that the repair strength is greatly increased; and meanwhile, the used structure material formsa structure similar to a male tenon and a female tenon while entering the groove, so that the connection strength of the repair part and the green body is ensured.

Owner:俞敏

Cement-based polymer cementing material for duct piece repairing and duct piece repairing method

InactiveCN111574150AFlexible adjustment ratioRepair method is simpleUnderground chambersTunnel liningCellulosePolymer science

The invention provides a cement-based polymer cementing material for duct piece repairing and a duct piece repairing method. The material is prepared from the following components in percentage by weight: 55.5 to 58.8 percent of tailing slag; 30 to 35 percent of ordinary Portland cement; 8 to 10 percent of white cement; 0.9 to 1.2 percent of redispersible rubber powder; and 0.3 percent of cellulose ether. The duct piece repairing method comprises the following steps of: S1, estimating the total weight of a required cement-based polymer cementing material, and pouring the material into a container; S2, adding water into the container, the ratio of the cement-based polymer cementing material to the water being 1: 2.5, and stirring an obtained mixture until the mixture is fully wetted and uniform; S3, smearing / filling a to-be-repaired area with the mixture so as to complete the repairing of a duct piece. The material is high in setting and hardening speed and repairing strength; and the repairing method is simple and convenient and can shorten the waiting time of a repaired duct piece and increase the delivery speed of the duct piece.

Owner:西安中铁工程装备有限公司

Honeycomb sandwich structure part repairing method for reducing structure loss

The invention provides a honeycomb sandwich structure part repairing method for reducing the structure loss. For the defective area abandoning laying layer gradient grinding link, a through hole withsmaller diameter is directly drilled in the defect center, and then a defective area honeycomb core is subjected to full-depth cutting and breaking treatment by using an L-shaped rotating cutting device; it is ensured that the defective area honeycomb core is cut and broken and then pouring sealant injection / stirring is carried out by using the through hole and an injection device, it is ensured that a defect area cavity is fully filled with the pouring sealant, and then a curing process is executed. Due to the fact that the original surface is restored by curing and polishing, the defective area can be fully filled under the condition that an original structural laying layer is damaged to a small degree, and the repairing target is achieved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

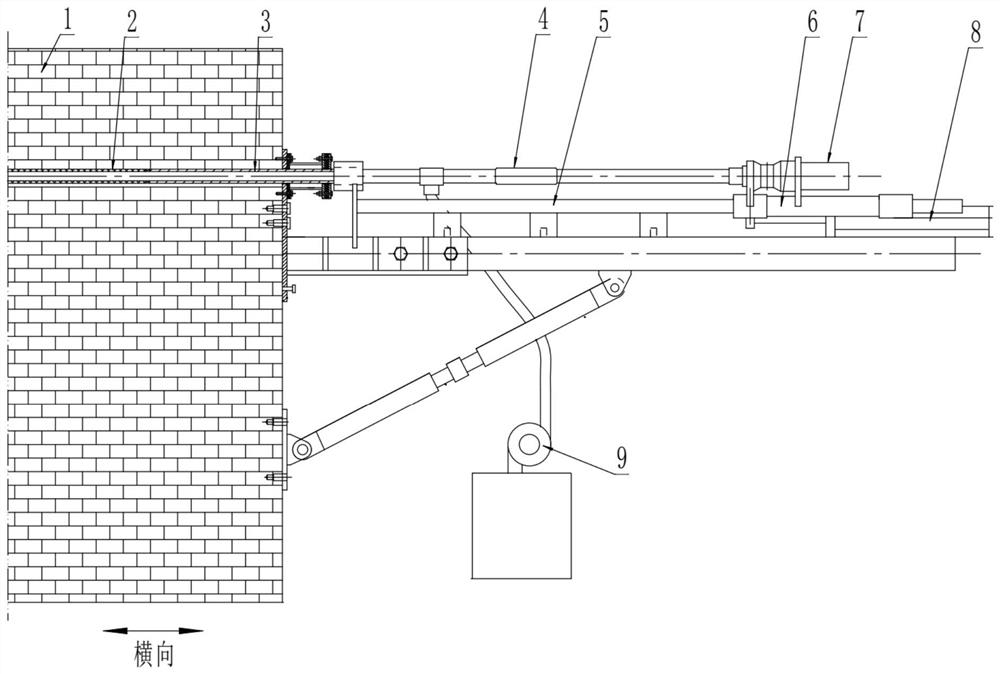

A kind of horizontal repair hole wall protection method of house wall

ActiveCN112031453BAvoid defacementIncrease viscosityBuilding repairsArchitectural engineeringBrick masonry

A wall protection method for a horizontal repair hole in a wall of a house, comprising the following steps: a. sending a drill pipe into the repair hole where the wall has been drilled; b. injecting wall protection slurry into the horizontal hole; c. coating the hole wall with the wall protection slurry; d. The retaining rods are left in the transverse holes, and the retaining wall layer is composed of the retaining wall slurry layer and the retaining rods. On the one hand, the method of the invention can effectively prevent grout from seeping out and contaminating the wall during the grouting and anchoring process, and on the other hand, can greatly improve the strength of the repair hole, thereby effectively improving the overall repair strength of the brick masonry wall. The wall protection slurry provided by the invention has the characteristics of high viscosity, good anti-seepage performance, good cohesiveness, easy curing, high consolidation strength, etc., and solves the problem of easy leakage of conventional grouting.

Owner:阮爱兵

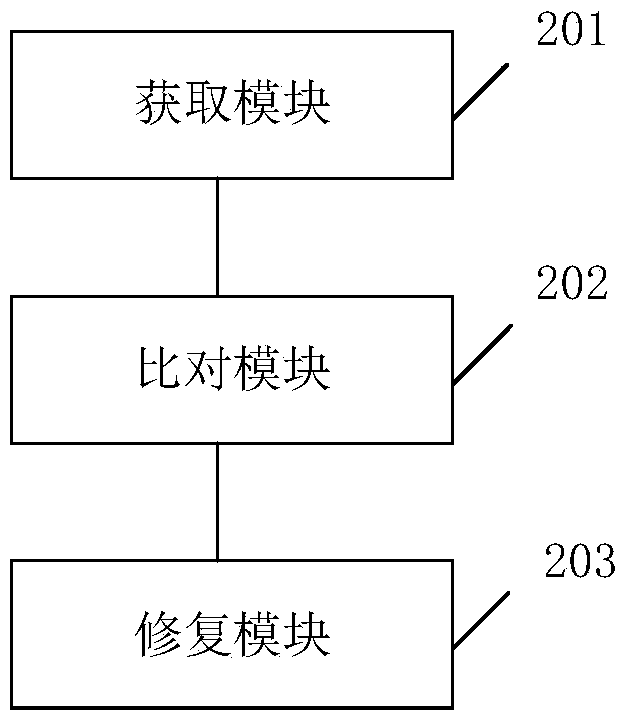

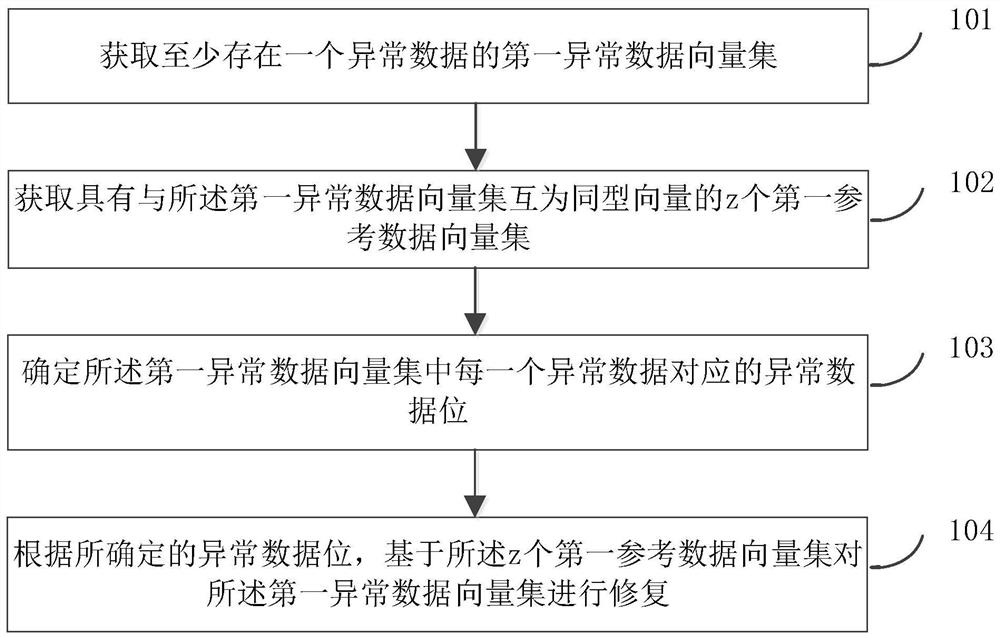

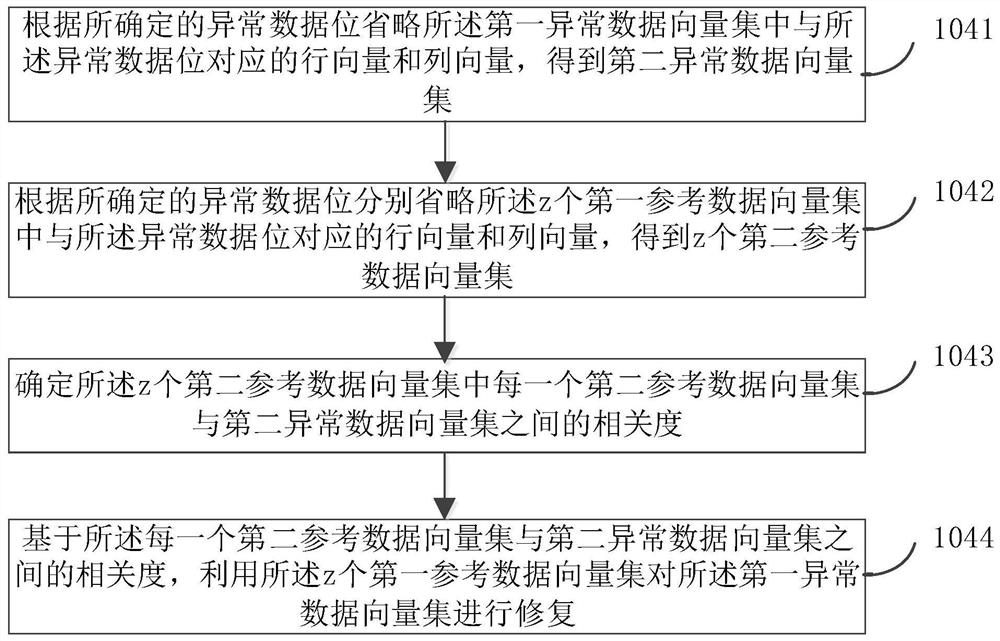

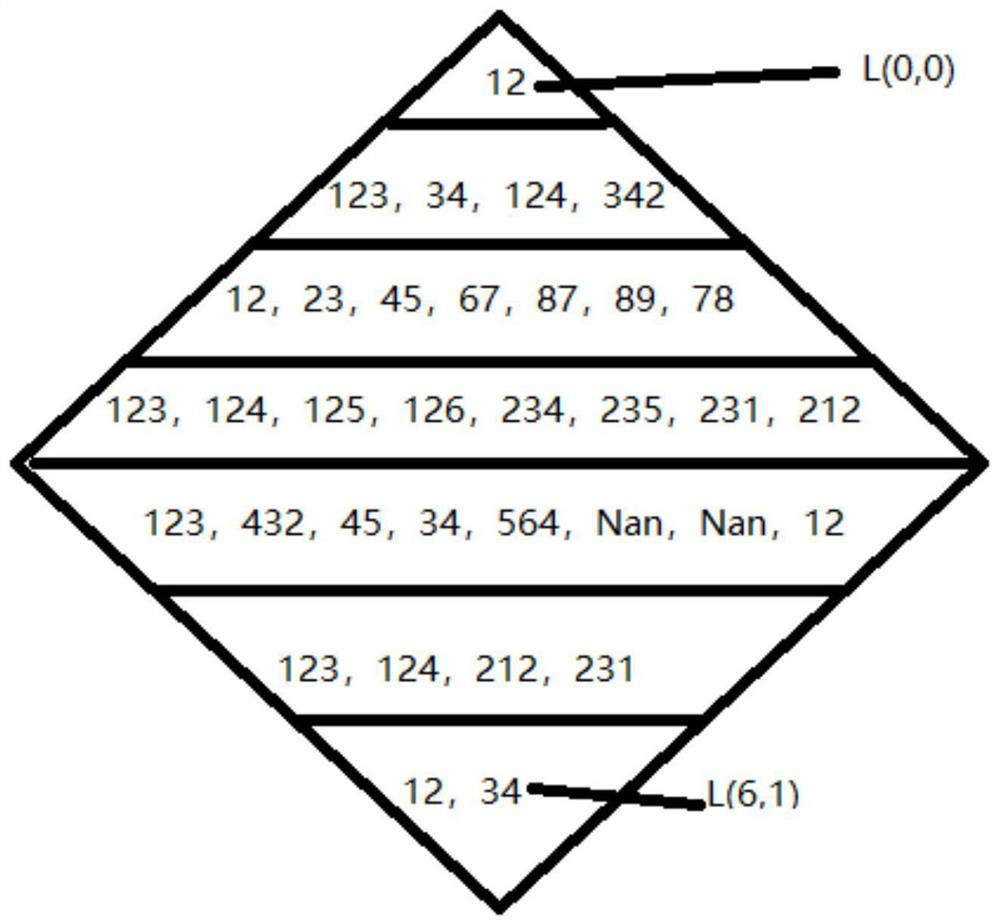

A data recovery method and device

InactiveCN109189773BEasy to find your own characteristicsImprove repair strengthDigital data information retrievalSpecial data processing applicationsEngineeringData mining

The embodiment of the invention discloses a data repairing method and adevice. The method comprises the following steps: firstly, acquiring a first abnormal data vector set with at least one abnormaldata; further acquiring a set of z first reference data vectors having vectors of the same type as the set of first abnormal data vectors; then determining an abnormal data bit corresponding to each abnormal data in the first abnormal data vector set; repairing the first set of abnormal data vectors based on the z sets of first reference data vectors according to the determined abnormal data bits.

Owner:北京睦合达信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com