Self-adaptive portable microwave heating repair bag, manufacturing process and using method

A microwave heating and portable technology is applied in the field of microwave curing and repairing of the airframe structure of aviation equipment, which can solve the problems of poor mechanical properties of the body, slow curing speed, low wave absorption efficiency, etc., and achieve the effects of improving repair strength, reducing restrictions and uniform temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

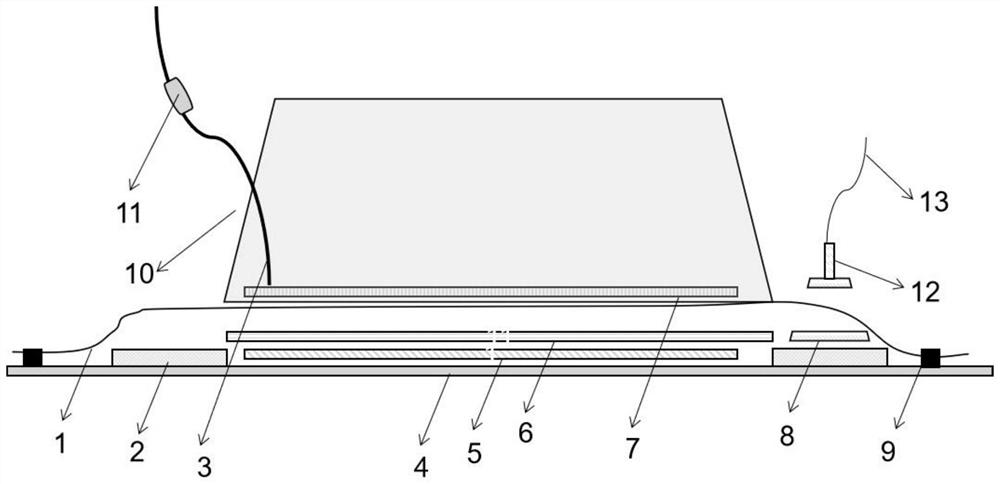

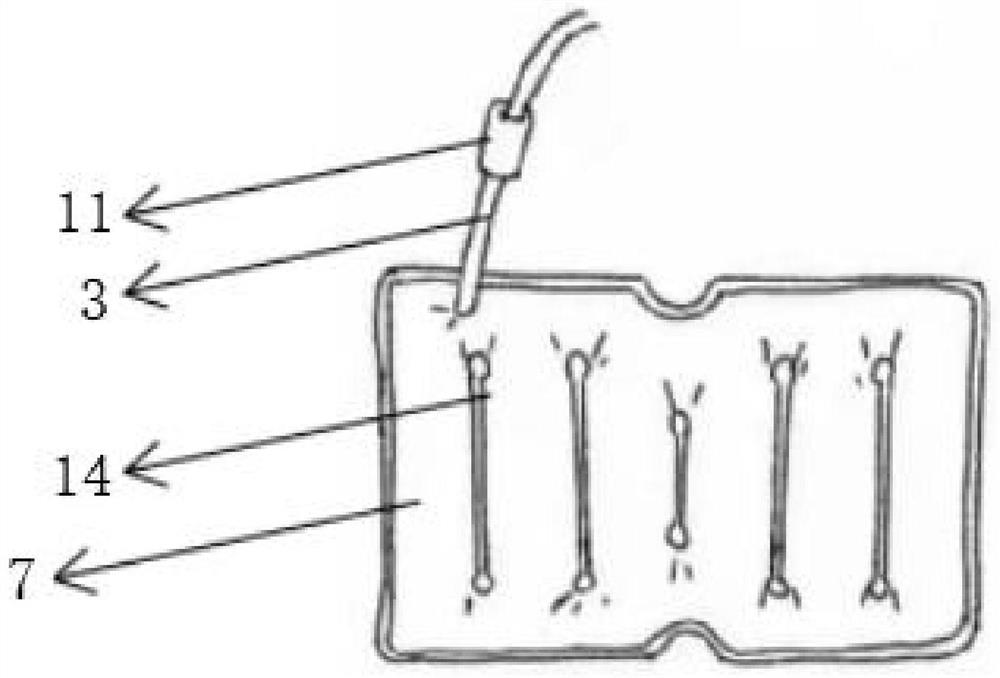

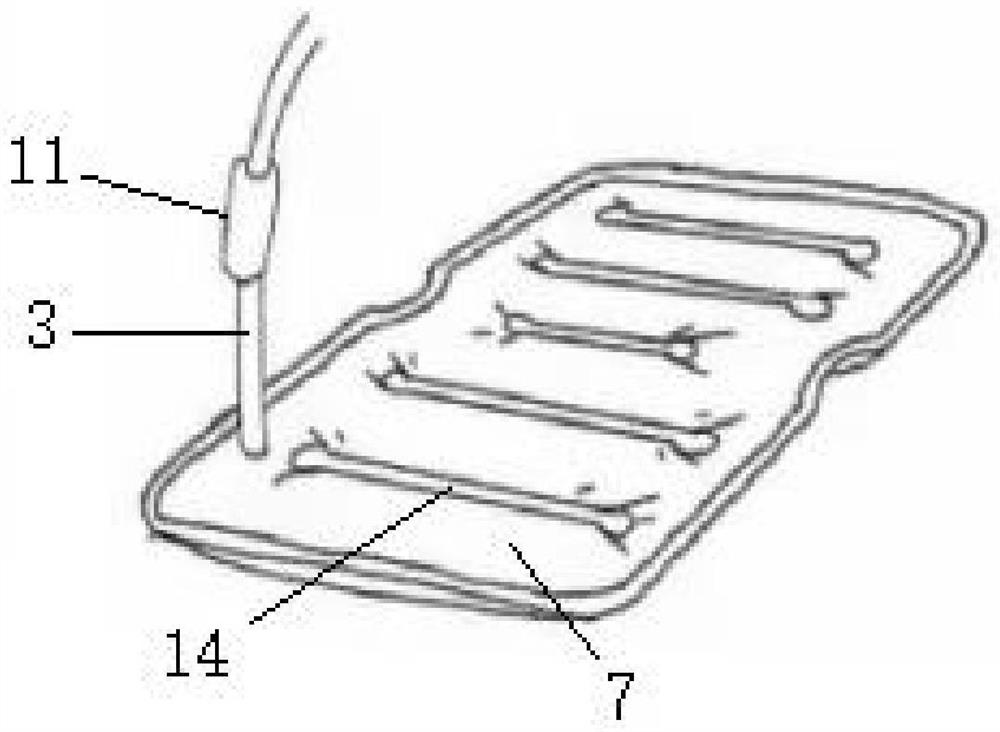

[0068] The self-adaptive portable microwave heating repair bag applying the second packaging process in the above-mentioned manufacturing process includes the part to be repaired 4 and the vacuum bag film 1 arranged on the part to be repaired 4, and the vacuum bag film 1 is laid by the sealing tape 9 Connected to the part to be repaired 4, the release cloth 5 and the isolation film 6 in the vacuum bag film 1 and above the repair area of the part to be repaired 4, the air felt 2 is laid around the repair area of the part to be repaired, and the air felt 2 is placed There is a vacuum seat 8, and the vacuum seat 8 is connected with a vacuum nozzle 12 and a high-pressure vacuum tube 13. The vacuum nozzle 12 and the high-pressure vacuum tube 13 are located outside the vacuum bag film 1. When the vacuum nozzle 12 and the high-pressure vacuum tube 13 are in use, the vacuum bag The vacuum bag formed between the film 1 and the piece to be repaired 4 is vacuumed and pressurized.

[...

Embodiment 2

[0077] The self-adaptive portable microwave heating repair bag using the third packaging process in the above-mentioned manufacturing process includes the part to be repaired 4 and the vacuum bag film 1 arranged on the part to be repaired 4, and the vacuum bag film 1 is laid by the sealing tape 9 Connected to the part to be repaired 4, the release cloth 5 and the isolation film 6 in the vacuum bag film 1 and above the repair area of the part to be repaired 4, the air felt 2 is laid around the repair area of the part to be repaired, and the air felt 2 is placed There is a vacuum seat 8, and the vacuum seat 8 is connected with a vacuum nozzle 12 and a high-pressure vacuum tube 13. The vacuum nozzle 12 and the high-pressure vacuum tube 13 are located outside the vacuum bag film 1. When the vacuum nozzle 12 and the high-pressure vacuum tube 13 are in use, the vacuum bag The vacuum bag formed between the film 1 and the piece to be repaired 4 is vacuumed and pressurized.

[0078...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com