Self-crack-repairing type low-failure-rate optical cable for network engineering construction

A technology of engineering construction and low failure rate, applied in the field of network engineering, can solve problems such as self-strength reduction, optical cable erosion damage, cracking, etc., and achieve the effects of improving repair strength, preventing secondary cracking, and improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

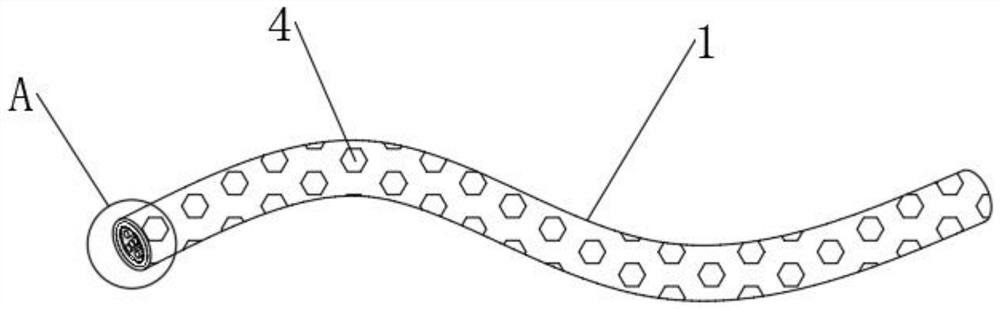

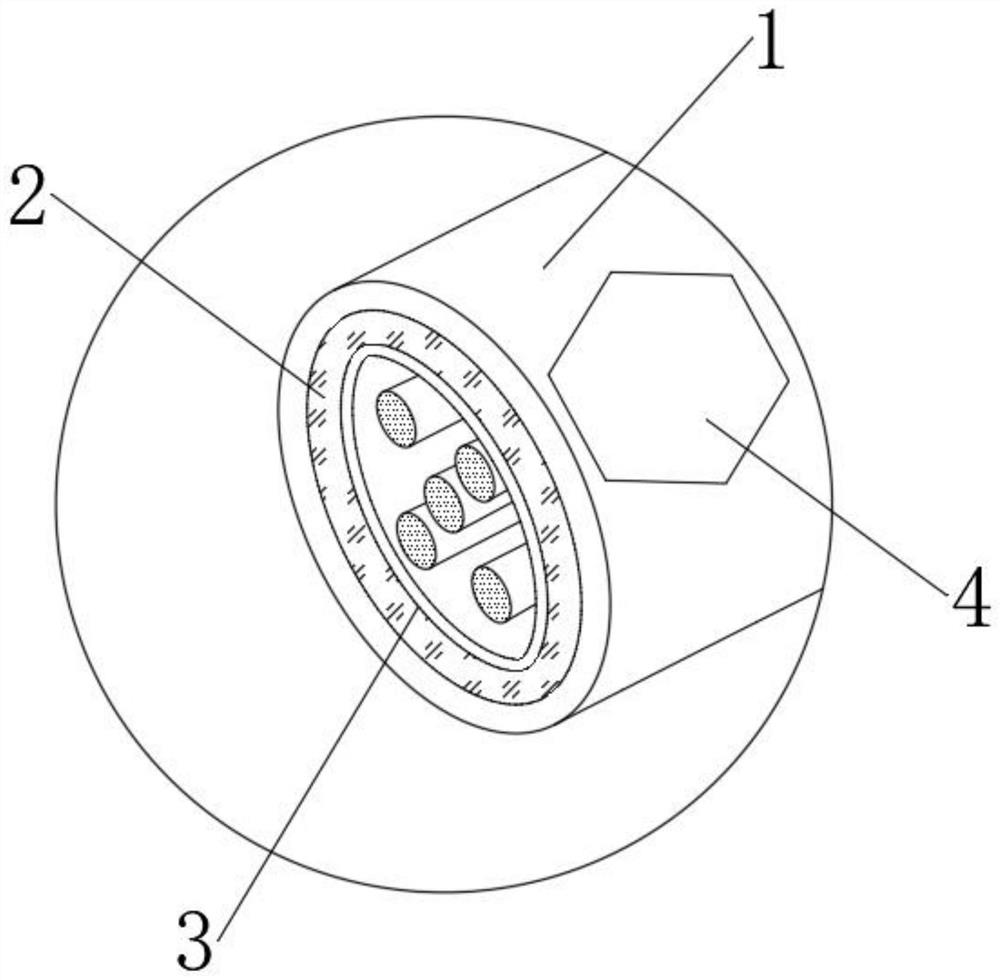

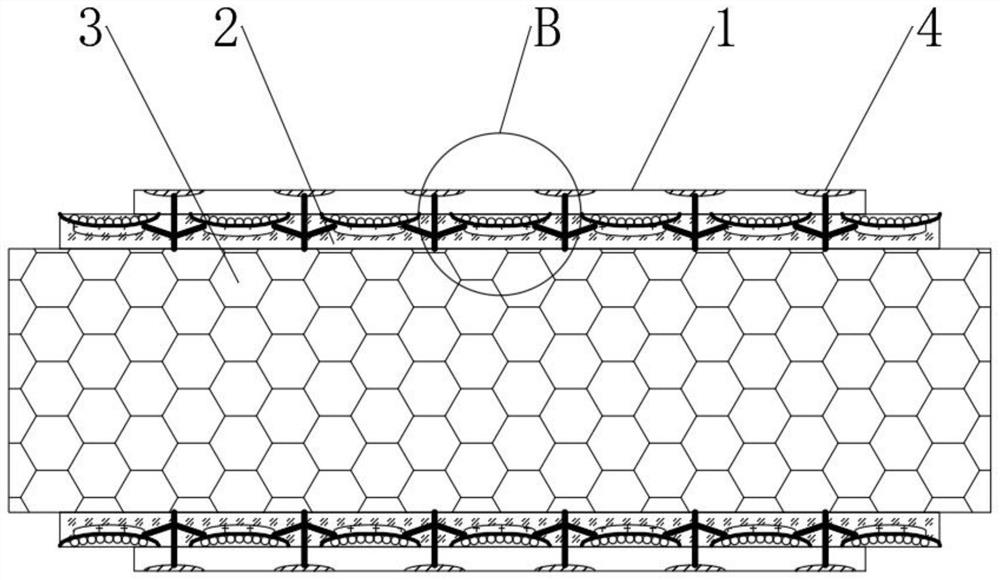

[0045] see Figure 1-4 , a self-sealing type low failure rate optical cable for network engineering construction, comprising a protective coat 1 and an optical cable body 3 embedded in the protective coat 1, a seam-filling layer 2 is filled between the protective coat 1 and the optical cable body 3, and the optical cable body 3 is inlaid and connected with a plurality of evenly distributed heat conduction wires 7 , and a plurality of heat dissipation ceramic sheets 4 corresponding to the heat conduction wires 7 are inlaid and connected on the outer surface of the protective coat 1 , and the heat conduction wires 7 penetrate the seam filling layer 2 and extend to the protective clothing. The inside of the coat 1 is connected with the heat dissipation ceramic sheet 4, and the outer surface of the seam repair layer 2 is provided with a plurality of evenly distributed seam repair grooves, and the seam repair grooves and the heat dissipation ceramic sheet 4 are alternately distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com